Journal list menu

Export Citations

Download PDFs

Cover Picture

Towards Sustainable, Competitive Production of Large-Format Battery Cells

- First Published: 11 May 2023

The cost- and energy-efficient production of high-performance lithium-ion battery cells on a giga-scale, with minimal waste, is essential for further energy transition. The articles in this Special Issue present new and in-depth process knowledge, process innovations and digital solutions along the process chain from dry powder mixing to electrode production, cell assembly and formation. The results, achieved within the German ProZell cluster and the DaLion4.0 research project, provide a scientific backbone for establishing a sustainable and competitive battery cell manufacturing industry. More details can be found in the Guest Editorial 2300265, Arno Kwade, Laura Jess, and Fabienne Huttner. Cover design by Marén Gröschel.

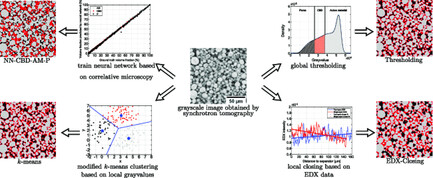

Inside Front Cover

Quantitative Comparison of Different Approaches for Reconstructing the Carbon-Binder Domain from Tomographic Image Data of Cathodes in Lithium-Ion Batteries and Its Influence on Electrochemical Properties

- First Published: 11 May 2023

The cover shows the 3D microstructure of a cathode in a lithium-ion battery, which is crucial for the resulting electrochemical performance. In particular, the lateral faces show two different three-phase reconstructions obtained by a closing approach based on EDX data and by a neural network trained with correlative microscopy. The background shows the fluorine mapping of an EDX image, which provides insight into the spatial distribution of the binder. More details can be found in article number 2200784, Benedikt Prifling and co-workers.

Back Cover

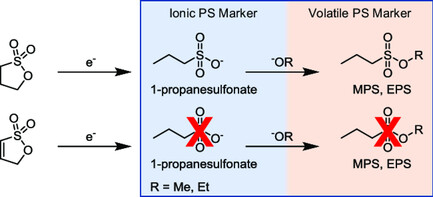

Defining Aging Marker Molecules of 1,3-Propane Sultone for Targeted Identification in Spent LiNi0.6Co0.2Mn0.2O2||AG Cells

- First Published: 11 May 2023

This cover image visualizes the “targeted fishing” of aging marker molecules in the complex matrix of spent lithium-ion battery electrolytes. Chromatographic techniques with high-resolution accurate mass spectrometric detection enable sensitive and selective identification, applicable for reverse engineering or risk assessment approaches. More details can be found in article number 2200189, Sascha Nowak and co-workers.

Masthead

Guest Editorial

Towards Sustainable, Competitive Production of Large-Format Battery Cells

- First Published: 11 May 2023

Research Articles

Quantitative Comparison of Different Approaches for Reconstructing the Carbon-Binder Domain from Tomographic Image Data of Cathodes in Lithium-Ion Batteries and Its Influence on Electrochemical Properties

- First Published: 27 August 2022

Four different methods for reconstructing the carbo-binder domain from 3D image data of lithium-ion battery electrodes obtained by synchrotron tomography are presented and quantitatively compared with regard to their morphological, as well as electrochemical properties. The results from the spatially resolved numerical simulations are validated by means of experimental data and show a high degree of accordance.

Defining Aging Marker Molecules of 1,3-Propane Sultone for Targeted Identification in Spent LiNi0.6Co0.2Mn0.2O2||AG Cells

- First Published: 28 April 2022

Decomposition of the lithium ion battery electrolyte additive 1,3-propane sultone (PS) is reevaluated by means of gas and ion chromatography coupled to high-resolution accurate mass spectrometry. Proposed decomposition products are evaluated based on speciation analysis and characteristic ionic and volatile aging markers defined. Thus, a method for targeted and reliable reidentification of hazardous PS in spent battery material is presented.

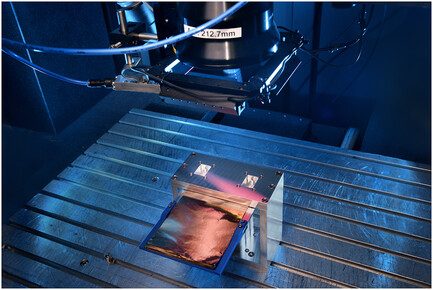

Laser-Based Joining of Electrode Stacks for Automated Large-Scale Production of Li-Ion Battery Cells

- First Published: 05 November 2022

The shift to battery-electric forms of transport is increasing the demand for the efficient large-scale production of battery cells. Laser beam welding is a noncontact joining process that enables a high degree of automation and high process speeds. This article presents high-speed laser welding of electrode sheets with “blue,” “green,” and near-infrared laser radiation.

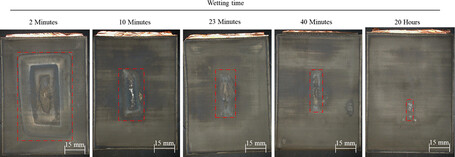

Lean Cell Finalization in Lithium-Ion Battery Production: Determining the Required Electrolyte Wetting Degree to Begin the Formation

- First Published: 09 August 2022

Within this work, lithium-ion pouch and hardcase cells are filled with electrolyte and the formation is started at varying wetting degrees. The effect of beginning the formation with a partial wetting degree is studied based on cell testing data and postmortem analysis, which shows pronounced lithium plating in cells with insufficient wetting.

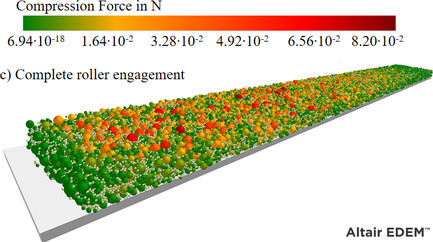

Simulation of the Calendering Process of NMC-622 Cathodes for Lithium-Ion Batteries

- First Published: 30 August 2022

Herein, a discrete element method modeling approach is proposed to predict the roll gap width required for a given target porosity of the calendering process. For this purpose, a particle bed of 9 mm in length is compacted using a roll section enabling a deeper look into the compaction behavior of the microstructure.

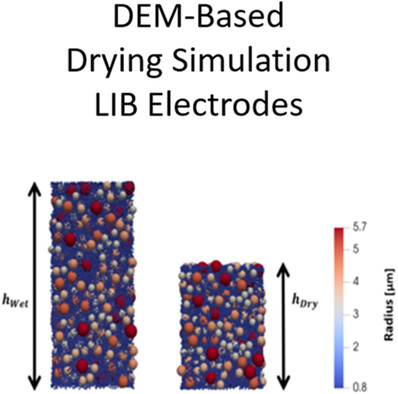

Simulation of Structure Formation during Drying of Lithium-Ion Battery Electrodes using Discrete Element Method

- First Published: 10 September 2022

Herein, a numerical approach based on the discrete element method (DEM) to describe the formation of the electrode structure during drying is presented. All relevant fluid effects are depicted using surrogate models. The relevant interparticulate effects are evaluated and implemented in the DEM model. A high agreement with experimental densities is achieved.

Experimental Investigation of the Temperature, Pressure, and Binder System Influence on Vacuum Postdrying Processes and Moisture Management of Li-Ion Battery Electrodes

- First Published: 13 September 2022

This experimental study shows the influence of sorption mechanisms and mass transport in the anode for Li-ion batteries on postdrying and moisture management during electrode production. Desorption experiments of a sample with a 1D diffusion path (resembling an electrode coil) and two common binder systems allow a conclusion about temperature and pressure influence.

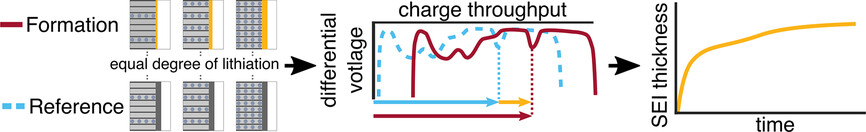

Characterization of the Solid–Electrolyte Interphase Growth During Cell Formation Based on Differential Voltage Analysis

- First Published: 06 September 2022

A novel method to investigate the solid–electrolyte interphase growth during the first formation cycle with low experimental effort is introduced. Differential voltage analysis and electrochemical models are used to determine the capacity loss as a function of the formation time. The capability of this method is demonstrated by investigating cells with two different electrolytes.

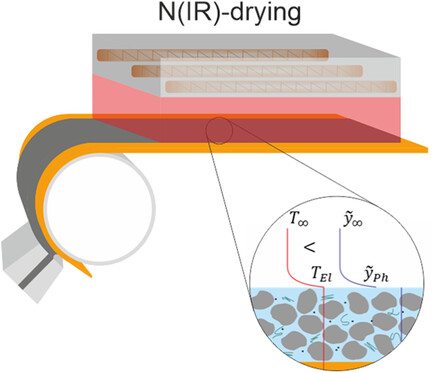

(Near-) Infrared Drying of Lithium-Ion Battery Electrodes: Influence of Energy Input on Process Speed and Electrode Adhesion

- First Published: 16 September 2022

The suitability of the application of infrared radiation in the drying process of battery electrodes with regard to high drying rates and proper quality in terms of electrode adhesion is demonstrated. Therefore, an experimental approach is used to investigate the influence of infrared power and convection on the drying of aqueous-processed graphite anodes in different process variants.

Influence of the Mixing and Dispersing Process on the Slurry Properties and the Microstructure and Performance of Ultrathick Cathodes for Lithium-Ion Batteries

- First Published: 20 September 2022

The influence of industrial-suited mixing and dispersing processes on the processability, structure, and properties of suspensions and electrodes for lithium-ion batteries is investigated for the case of ultrathick NCM 622 cathodes. By a beneficial process, a strongly enhanced elasticity of ultrathick electrodes making them suitable for roll-to-roll processing and a drastic increase of their rate capability are reached.

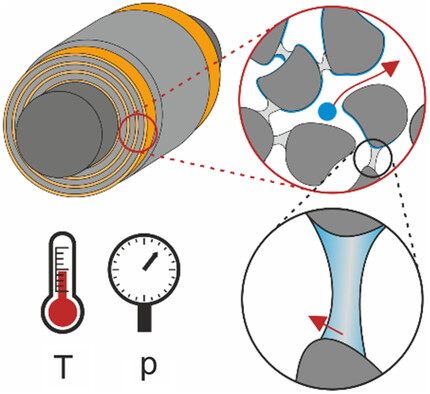

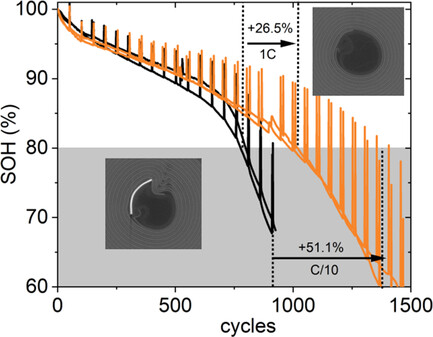

Effects of Tab Design in 21700 Li-Ion Cells: Improvements of Cell Impedance, Rate Capability, and Cycling Aging

- First Published: 20 September 2022

Tab designs in pilot-line built 21700 cells are investigated systematically. It turns out that the number of tabs and tabs made from the current collecting foils instead of conventionally welded tabs show significant improvements in cell impedance and fast-charging capability. The long-term cycling stability is enhanced by hindering deformations of the jellyroll as shown by X-ray computed tomography measurements.

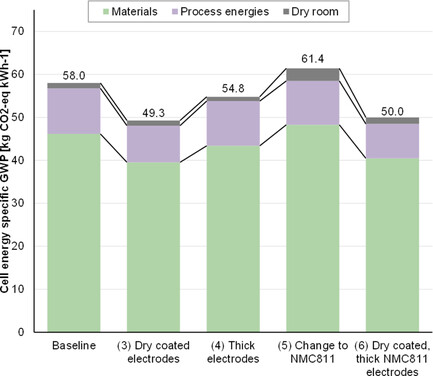

Life Cycle Assessment of the Battery Cell Production: Using a Modular Material and Energy Flow Model to Assess Product and Process Innovations

- First Published: 14 September 2022

The growing number of innovations in battery cell production requires regular environmental assessment. Hence, a life cycle assessment is performed for six innovations in battery cell production using a novel methodology to develop modular material and energy flow models. The results underline the advantageousness of innovations that reduce energy consumption and increase the specific energy of cells.

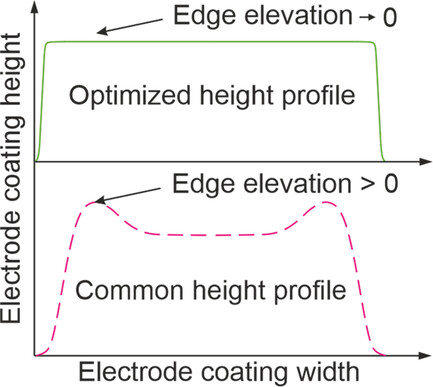

Optimization of Edge Quality in the Slot-Die Coating Process of High-Capacity Lithium-Ion Battery Electrodes

- First Published: 20 September 2022

Herein, the influence of different process parameters on edge formation during slot-die coating of lithium-ion battery electrodes is investigated. Using an optimized coating setup with combined advantages of investigated process parameters, edge elevations for state-of-the-art electrode coatings are eliminated. With this setup even for ultrathick high-capacity electrode coatings, a strong reduction of edge elevations is possible.

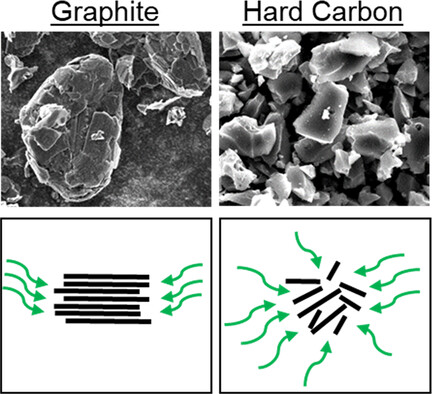

The Influence of Calendering on the Fast Charging Performance and Lithium Plating of Hard Carbon Blend Anodes

- First Published: 06 October 2022

Herein, graphite and hard carbon blend anodes at different electrode densities are investigated in terms of their structural features as well as their electrochemical performance. While a reduction in tortuosity and lithium plating can be observed due to the interporous hard carbon, the performance improvement of the blend anodes is shown to be highly dependent on the electrode density.

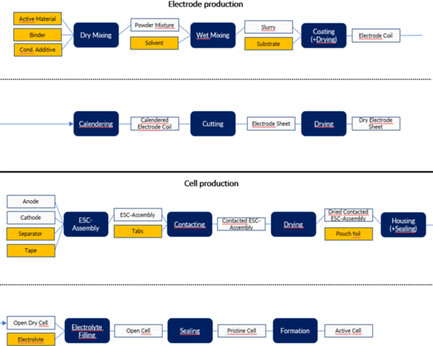

Toward a Li-Ion Battery Ontology Covering Production and Material Structure

- First Published: 21 September 2022

An ontology for the structured storage, retrieval, and analysis of data on lithium-ion battery materials is presented. Materials and processes are specified using consensual terminology and a chain of unit processes (“steps”) that connects the intermediate products (“items”) of battery cell production.

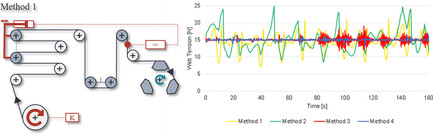

Model-Based Optimization of Web Tension Control for the Flexible Cell Stack Assembly of Lithium-Ion Battery Cells

- First Published: 14 September 2022

This article deals with the model-based determination of an optimal web tension control method for cell stacking processes. Using a digital twin, different control methods are checked in virtual space and then tested on the real system. This is intended above all to reduce the commissioning effort and material scrap.

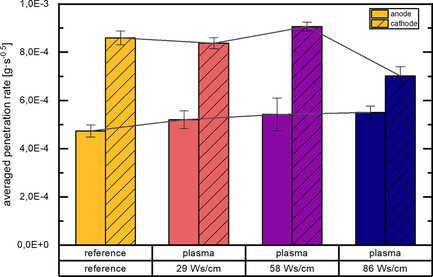

Improving Wetting Behavior and C-Rate Capability of Lithium-Ion Batteries by Plasma Activation

- First Published: 02 October 2022

Electrodes for Lithium-Ion-Batteries are modified as-coated by atmospheric corona plasma activation, resulting in significant improvement of electrolyte uptake characteristics and C-rate capability. Insights into underlying interaction mechanisms are highlighted by scanning electron microscopy, X-ray diffraction, and electrochemical impedance spectroscopy studies.

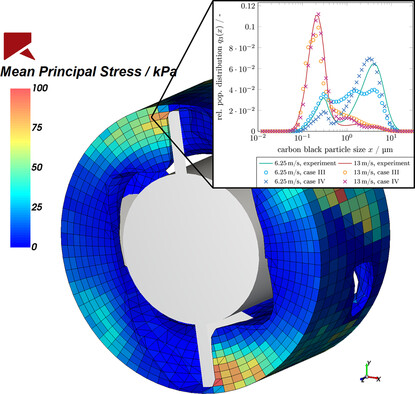

Modeling of Carbon Black Fragmentation During High-Intensity Dry Mixing Using the Population Balance Equation and the Discrete Element Method

- First Published: 30 September 2022

The process design of the dry mixing of the cathode material influences the microstructure and thus the performance of the Li-ion battery. The discrete element method provides information about the intensity of stress. The change of the carbon black size distribution is done by the population balance equation. The models provide good agreement with the experimental data.

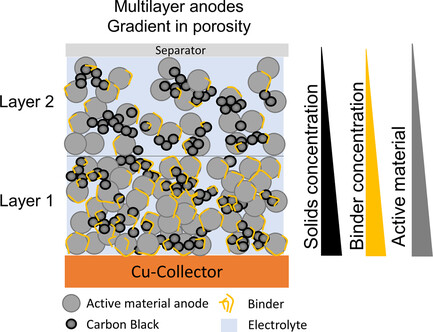

Improving the Performance of Lithium-Ion Batteries Using a Two-Layer, Hard Carbon-Containing Silicon Anode for Use in High-Energy Electrodes

- First Published: 08 October 2022

In this investigation, the focus is on two-layered anodes containing three different active materials (graphite, silicon, and hard carbon (HC)) to create a defined pore network within the anode. It could be demonstrated that the interporous HC leads to a capacity retention increase up to 20% with no loss of capacity at moderate C-rates and a low electrode density.

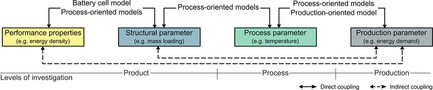

Digitalization Platform for Sustainable Battery Cell Production: Coupling of Process, Production, and Product Models

- First Published: 08 October 2022

The digitalization platform represents a valuable tool for comprehensive decision-making under consideration of cause–effect relations. The complexity of the results highlights the importance of multilevel analysis to deeply understand the mechanisms behind the parameter variations. This is critical for planning and improving battery cell production, as it helps to increase battery cell performance and support more environmentally sustainable production.

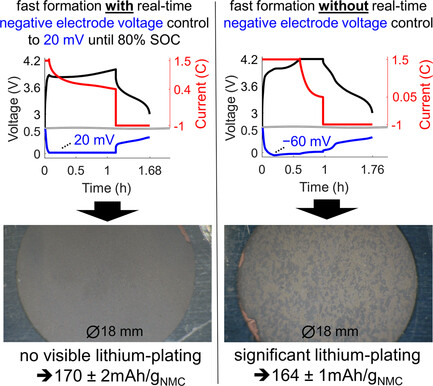

Fast Charging Formation of Lithium-Ion Batteries Based on Real-Time Negative Electrode Voltage Control

- First Published: 20 October 2022

The formation process of lithium-ion battery cells is the last process step during the manufacturing and consists of current cycles which are time-consuming (many hours to days). Herein, a fast charging formation approach based on a real-time electrode voltage control is presented. The results show that this approach reduces the formation time while also ensuring durable battery cell properties.

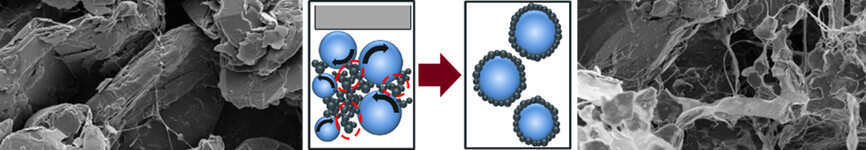

Modifying the Network Structures of High Energy Anodes for Lithium-Ion Batteries through Intensive Dry Mixing

- First Published: 13 October 2022

The effect of an intensive dry mixing process on the slurry, electrode, and cell properties is investigated. The tangential velocity and the amount of carbon black in the dry mixing process are varied. The results reveal new insights into material interactions between the binder, carbon black, and the active material that can be purposefully modified.

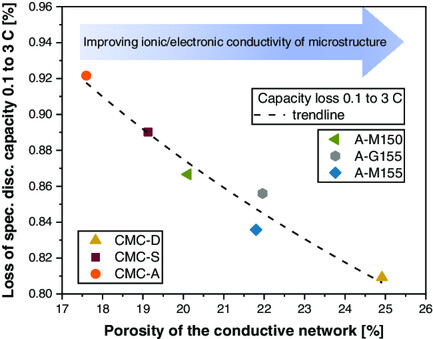

Influence of Different Alginate and Carboxymethyl Cellulose Binders on Moisture Content, Electrode Structure, and Electrochemical Properties of Graphite-Based Anodes for Lithium-Ion Batteries

- First Published: 22 October 2022

Binder are one of the most important components of lithium-ion batteries. They are necessary to control the slurry behavior, mechanical stability, structure of the electrodes, and electrochemical performance. Herein, a knowledge-based material–structure–performance relationship along the anode manufacturing process of different carboxymethyl cellulose and alginate types with varying molecular mass and polymer structure is demonstrated.

Model-Based Design and Experimental Evaluation of a High-Throughput Electrode Feeding and Stacking Process

- First Published: 21 October 2022

Calibration of Li-Ion Cathode Materials for Discrete Element Method Simulations

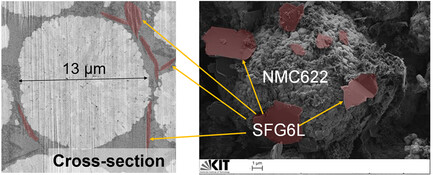

- First Published: 25 October 2022

The flow behavior of cohesive NMC-622 cathode active material is studied in a Schulze RST-01 ring shear cell and a rotating drum. For both devices, experiments and simulations are done to characterize the dynamic behavior of the material and to calibrate all relevant parameters for a robust coarse-grained simulation model based on the discrete element method.

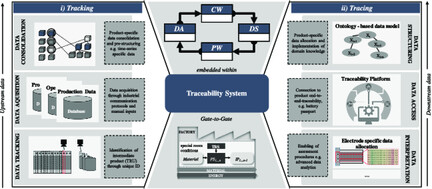

Traceability in Battery Cell Production

- First Published: 16 November 2022

Effective quality management strategies (QMS) in battery cell manufacturing are essential. Herein, data-driven technologies foster an improved understanding; however, there are still often limited due to a lack of data. This work presents the implementation of a traceability system as part of QMS consisting of a set of technologies enabling traceability on electrode-sheet level through continuous and feature-based approaches.

Optimizing the Microstructure and Processing Parameters for Lithium-Ion Battery Cathodes: A Use Case Scenario with a Digital Manufacturing Platform

- First Published: 21 November 2022

The escalation in lithium-ion battery applications necessitates optimization of manufacturing to produce premium batteries at minimal emissions and cost. Using a digital modeling framework, a numerical optimization routine is set up, which optimizes the cathode microstructure parameters for maximum discharge energy density, while minimizing the processing energy expenditure. The model framework and methodology are adaptable for other battery types and manufacturing lines.

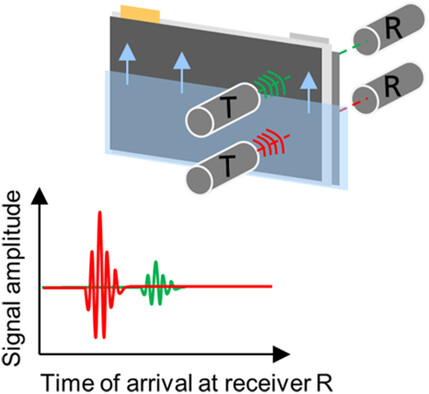

Ultrasound Propagation in Lithium-Ion Battery Cell Materials: Basis for Developing Monitoring and Imaging Methods

- First Published: 26 November 2022

Herein, it is demonstrated that ultrasound propagates at different sound velocities (up to 100%) in dry and electrolyte-filled porous lithium-ion battery materials. Therefore, implementing an ultrasound-based imaging method for the degree of wetting during cell production is feasible. In addition, acoustic impedance and wavelength are determined, enabling the design of ultrasonic setups for a variety of future applications.

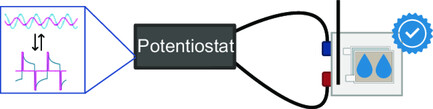

Simplified Electrochemical Approaches for Quality Determination of the Wetting Process in Lithium-Ion Cell Production

- First Published: 21 December 2022

Herein, two electrochemical approaches for monitoring the electrolyte wetting in lithium-ion cell production are presented. First, a simplified impedance approach is shown, which is used to determine optimal electrolyte amounts in the filling process. Furthermore, a direct current-based method is introduced that does not require impedance equipment, and can thus be performed with standard battery cyclers.

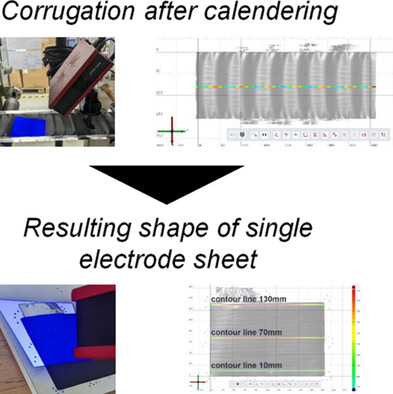

Influence of Electrode Corrugation after Calendering on the Geometry of Single Electrode Sheets in Battery Cell Production

- First Published: 02 December 2022

Calendering is an essential process step in battery cell production. During processing, corrugations can occur in the machine direction, which are characterized in this article in relation to the material systems LiNi0.8Mn0.1Co0.1O2 and LiNi0.6Mn0.2Co0.2O2 as well as the rate of compaction and the web tension. Subsequently, single electrode sheets are cut from the coils, and their shape is investigated.

Toward Calenderability of High-Energy Cathode based on NMC622 during the Roll-to-Roll Process

- First Published: 13 January 2023

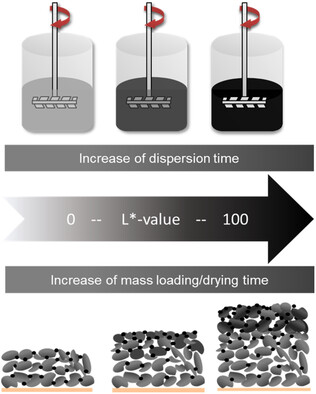

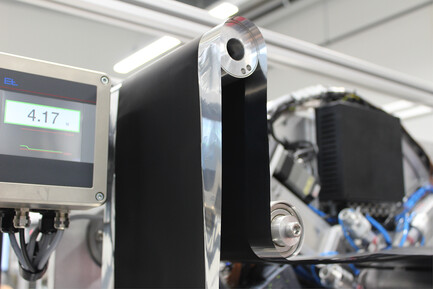

Introducing Spectrophotometry for Quality Control in Lithium-Ion-Battery Electrode Manufacturing

- First Published: 08 December 2022

Spectrophotometry is introduced as a characterization method in electrode production for lithium-ion batteries. Correlations between intermediate product properties and the color value are investigated in process studies for individual process steps. Based on the experiments, the suitability of the spectrophotometry as an indirect measurement method of intermediate product properties is demonstrated.

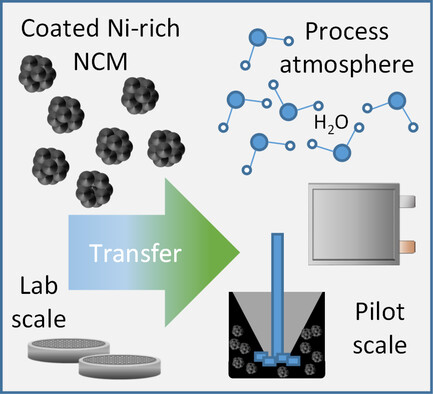

Production of Nickel-Rich Cathodes for Lithium-Ion Batteries from Lab to Pilot Scale under Investigation of the Process Atmosphere

- First Published: 31 January 2023

Cathodes with coated nickel-rich LiNixCoyMnzO2 (NCM, x+y+z=1) active material are processed in dry-room, as well as in ambient atmosphere at lab scale including slurry production and coating, revealing the impact of process atmosphere. Moreover, processing is transferred to pilot scale by continuous coating and drying at ambient atmosphere under detailed investigation of electrode properties and cell performance.

Quality Assurance for Flexible Stack Assembly of Lithium-Ion Cells

- First Published: 06 January 2023

When integrating new machinery into a production line, the procedures for assuring product quality have to be defined to conform with the applying standards of certification. A new quality assurance concept for an innovative flexible stacking process for lithium-ion battery cells is presented and implemented, in which a digital twin is employed to surveil the process and product properties.

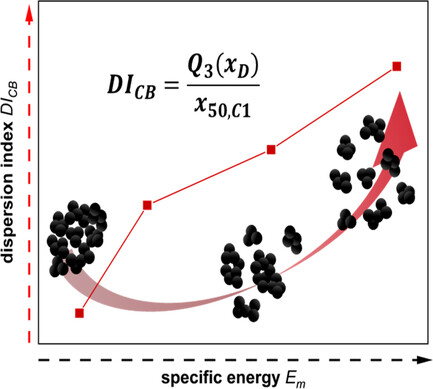

The Carbon Black Dispersion Index DICB: A Novel Approach Describing the Dispersion Progress of Carbon Black Containing Battery Slurries

- First Published: 31 January 2023

The Carbon Black Dispersion Index DICB is introduced as a novel approach describing the dispersion progress of CB containing battery slurries. This method is used to evaluate the morphological changes of CB based on the particle size distribution utilizing fragmentation behavior of CB under mechanical stress. It offers major benefits with regard to product monitoring and quality control.

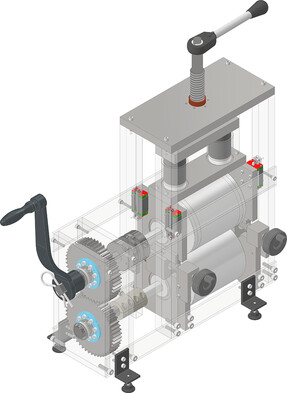

Mechanical Structuring of Lithium-Ion Battery Electrodes Using an Embossing Roller

- First Published: 06 March 2023

Within this work, an alternative concept for structuring lithium-ion battery electrodes through mechanical embossing in a high-throughput roll-to-roll process is elaborated. Different integration options are described and discussed. To provide a proof of concept, a hand-operated embossing device is built and used to structure graphite anodes. The structured anodes are optically and electrochemically analyzed.