Journal list menu

Export Citations

Download PDFs

Cover Picture

Advances in Battery Cell Production

- First Published: 05 February 2020

The production of battery cells requires a long chain of processes which traditionally belong to different disciplines such as chemical engineering, production engineering, and electrical engineering. Thus, a deep understanding of the entire process chain and the process interactions is mandatory, but also very challenging and requires intensive research. The processes considered in this special issue include coating and calendering as part of electrode production, as well as electrode stacking for cell production and formation as important cell conditioning steps. An overview of the articles discussed in “Advances in Battery Cell Production” can be found in the Editorial, article number 1900751, by Arno Kwade.

Back Cover

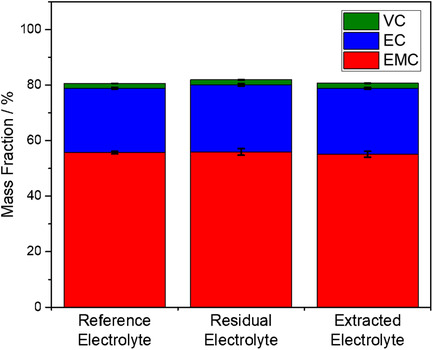

Concept for the Analysis of the Electrolyte Composition within the Cell Manufacturing Process: From Sealing to Sample Preparation

- First Published: 05 February 2020

An 18650 cell filled with electrolyte by applying cycles of over- and reduced-pressure is demonstrated. The pristine and the extracted electrolyte do not differ with respect to their carbonate content, however, sodium is found to be introduced by the sodium-carboxymethyl cellulose (Na-CMC) binder. More details can be found in article number 1801081 by Sascha Nowak and co-workers.

Masthead

Editorials

Communications

Concept for the Analysis of the Electrolyte Composition within the Cell Manufacturing Process: From Sealing to Sample Preparation

- First Published: 28 January 2019

18650 lithium-ion battery cells are built in-house with different amounts of an electrolyte. After wetting, the cells are opened, and the electrolyte is regained by centrifuging the entire jelly roll and quantified by a gas chromatography-flame ionization detector and inductively coupled plasma-optical emission spectroscopy. There is no influence of the filling protocol applying cycles with over- and reduced pressure on the electrolyte composition.

Full Papers

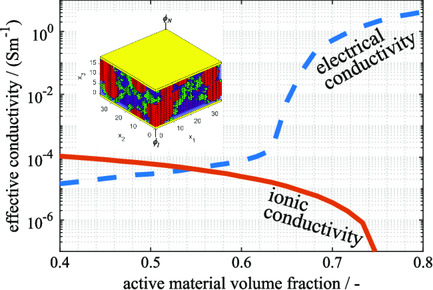

Modeling the Influence of Mixing Strategies on Microstructural Properties of All-Solid-State Electrodes

- First Published: 29 January 2019

Artificial microstructures are generated, and their effective properties are determined to develop enhanced production processes for the electrode production of all-solid-state electrodes. Simulation results reveal the optimal trade-off between electric and ionic conductivities. The simulated enhanced premixing routines for the active material, carbon black, and solid electrolyte allow further improvement of the cell performance.

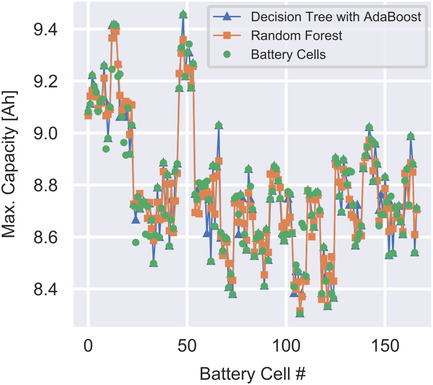

Enhanced Processing and Testing Concepts for New Active Materials for Lithium-Ion Batteries

- First Published: 29 March 2019

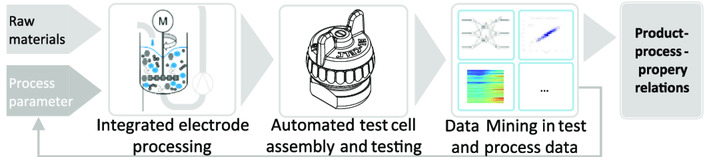

To reveal the effects of parameter variations in electrode production for lithium-ion batteries, the prevention of undefined errors in the process chain is crucial. For targeted development, new concepts for suspension production and reproducible sample preparation, supported by methods of data mining, are proposed.

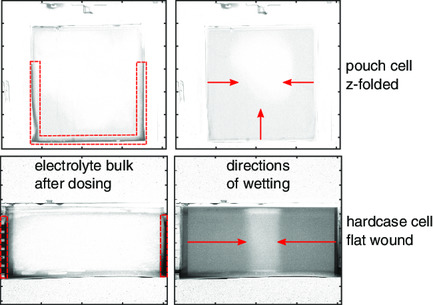

Influence of the Cell Format on the Electrolyte Filling Process of Lithium-Ion Cells

- First Published: 22 February 2019

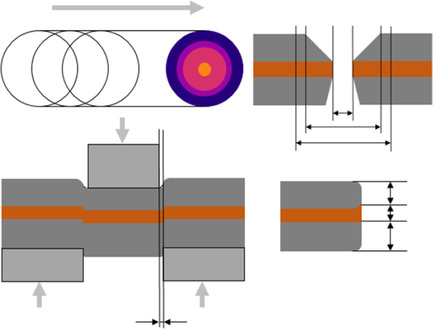

Heated Calendering of Cathodes for Lithium-Ion Batteries with Varied Carbon Black and Binder Contents

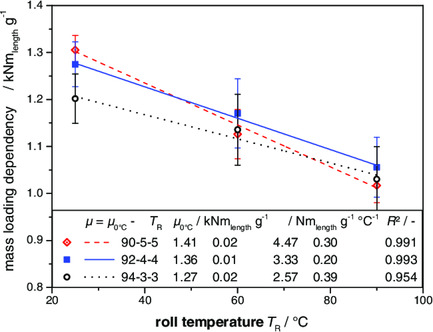

- First Published: 02 April 2019

The impact of the roll temperature TR is implemented in an exponential compaction model for electrode calendering. Increasing TR linearly decreases the line load effort represented by the mass loading dependency µ. Furthermore, reduced contents of simultaneously less-distributed additives lower the line load effort. Moreover, the adhesion strength of the coating improves with increasing TR and binder content.

Mechanical, Electrical, and Ionic Behavior of Lithium-Ion Battery Electrodes via Discrete Element Method Simulations

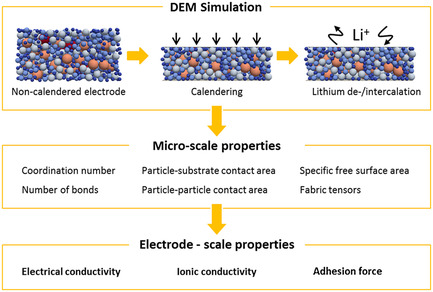

- First Published: 28 March 2019

Correlations between the microstructure and electrode macroscopic properties are established using discrete element method (DEM) simulations. The goal is to assess the impact of the calendering production step and the mechanism of intercalation on the electrode structure, mechanics, and connectivity.

Model-Based Uncertainty Quantification for the Product Properties of Lithium-Ion Batteries

- First Published: 29 March 2019

Investigation of the Adhesion Strength along the Electrode Manufacturing Process for Improved Lithium-Ion Anodes

- First Published: 29 March 2019

Mechanical properties of lithium-ion electrodes, such as the adhesion strength, play an active role for the life span of lithium-ion batteries. Parameter- and process-oriented investigations are conducted within electrode manufacturing to identify the main levers for the improvement of the adhesion strength of electrodes.

Influence of Separator Material on Infiltration Rate and Wetting Behavior of Lithium-Ion Batteries

- First Published: 08 April 2019

The production of lithium-ion-battery cells is very crucial for actual and prospective electric vehicles. Very time-consuming steps are the electrolyte filling and wetting of the cells. Herein, the comparison of a polymer and a ceramic separator by a classical wetting balance test and a newly developed thermography method is presented.

The Effects of Mechanical and Thermal Loads during Lithium-Ion Pouch Cell Formation and Their Impacts on Process Time

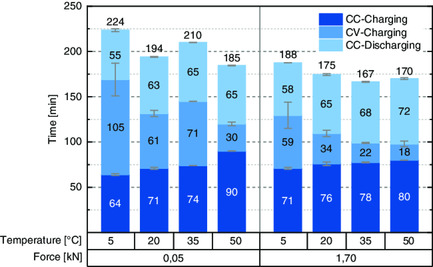

- First Published: 05 April 2019

Cost drivers in lithium-ion battery cell production are essential to enable potentials for cost reduction. In particular, the formation and aging processes represent a high potential for cost reduction because of the enormous time expenditure. Environmental conditions such as mechanical load and temperature as well as the electrical and chemical conditions during formation and aging are investigated.

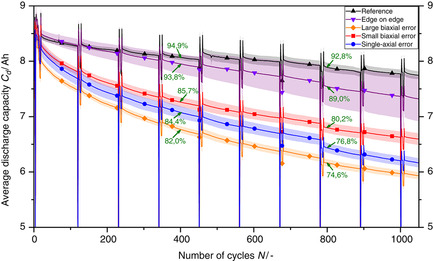

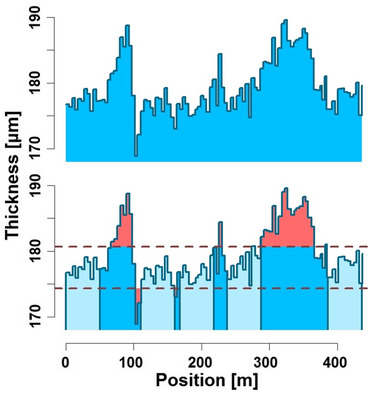

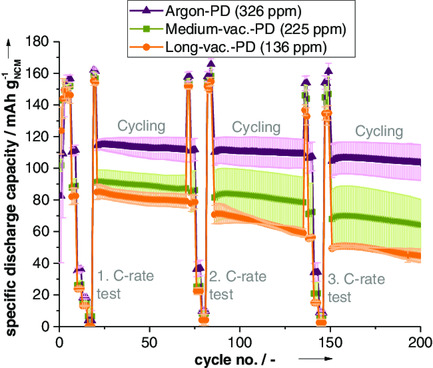

Investigation of the Influence of Deposition Accuracy of Electrodes on the Electrochemical Properties of Lithium-Ion Batteries

- First Published: 25 March 2019

Interactions between product properties and process parameters in lithium-ion battery production are limited to best-practice-experience rather than based on actual quantitative correlations. This work quantifies the influence of electrode deposition accuracy in cell assembly on the electrochemical performance of large battery cells. Electrochemical results show a linear decrease in the discharge capacity with a linear increase in the deposition error.

Toward Data-Driven Applications in Lithium-Ion Battery Cell Manufacturing

- First Published: 16 April 2019

Production chain of lithium-ion battery cells is a highly complicated system, which makes it difficult to control and regulate economic and environmental target criteria (e.g., product quality, cost, and energy demand). This study presents a data-driven concept for data acquisition, data management, and analysis, to enable the control and regulation of these criteria.

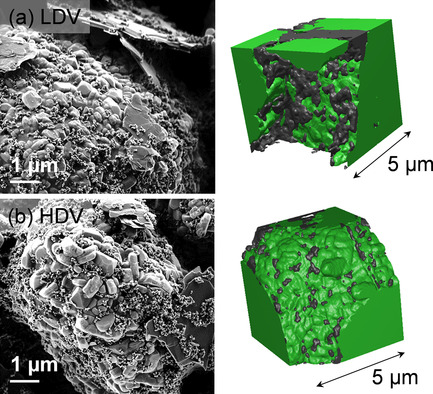

Influence of the Carbon Black Dispersing Process on the Microstructure and Performance of Li-Ion Battery Cathodes

- First Published: 29 April 2019

The microstructure of lithium-ion battery electrodes is determined by (dispersion) process and formulation parameters, which can be directly correlated with mechanical, electrical, and electrochemical properties. Accordingly, to optimize the properties of the electrode and, hence, the battery, the microstructure of the electrode must be improved. Therefore, carbon black is an important structuring component.

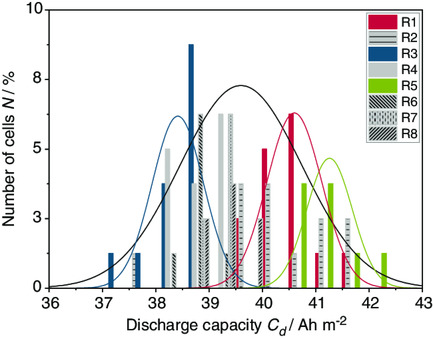

Capacity Distribution of Large Lithium-Ion Battery Pouch Cells in Context with Pilot Production Processes

- First Published: 05 April 2019

A large number of battery cells are produced and extensively electrochemically investigated. Thus, a deep understanding of each process step within the production chain, and their resulting cell properties, is required. In contrast to other studies, the scope of this study is to investigate a large sample size of industrial-scale battery pouch cells to ensure statistical relevance and generate distributed data of cell properties.

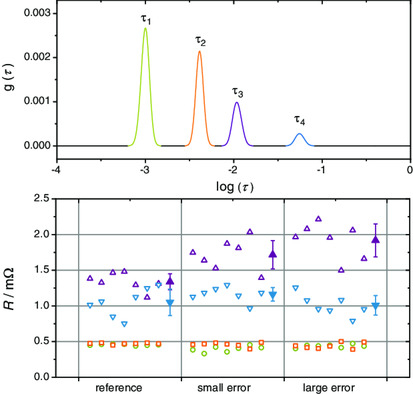

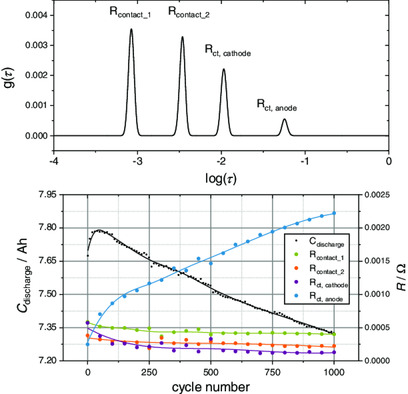

On the Interpretation of Impedance Spectra of Large-Format Lithium-Ion Batteries and Its Application in Aging Studies

- First Published: 03 May 2019

Based on the method of the distribution of relaxation times, the impedance spectra of large-format lithium-ion batteries are evaluated. Thereby, a profound assignment of time constants to the respective underlying loss process is derived and applied to an aging study to gain electrode-resoluted data.

Impedance Spectroscopic Investigation of the Impact of Erroneous Cell Assembly on the Aging of Lithium-Ion Batteries

- First Published: 03 May 2019

Development and Implementation of Statistical Methods for Quality Optimization in the Large-Format Lithium-Ion Cells Production

- First Published: 16 April 2019

This work introduces two techniques to optimize the production process of large-format lithium-ion cells using data-driven methods. The first uses standard settings of the quality influencing factors to optimize the number and quality of produced electrode sheets. The second method determines the levels of the quality influencing factors, which optimize all quality parameters of the corresponding product jointly.

Moisture Adsorption Behavior in Anodes for Li-Ion Batteries

- First Published: 17 May 2019

Sorption equilibria of moisture in components of lithium-ion batteries are an important fundament for an improved understanding of the post-drying process, which has hardly been scientifically investigated. Therefore, adsorption equilibria of moisture in anodes with different material compositions and structures are presented. Furthermore, the contribution of the equilibria of the individual materials to the equilibrium of the anode is investigated.

Classification of Calendering-Induced Electrode Defects and Their Influence on Subsequent Processes of Lithium-Ion Battery Production

- First Published: 25 March 2019

Defects in lithium-ion electrodes can impair processability in subsequent processes. As the final process of electrode manufacturing, calendering finalizes their properties. Calendering-induced electrode defects are, therefore, described and classified on the basis of a literature review, an expert survey, and operating experience. Moreover, their influence on subsequent processes of lithium-ion battery production is shown.

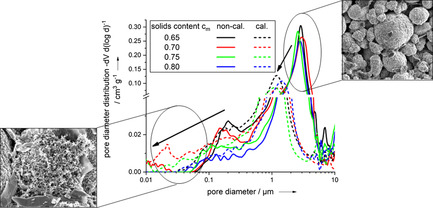

Extrusion-Based Processing of Cathodes: Influence of Solid Content on Suspension and Electrode Properties

- First Published: 16 May 2019

The high cost of lithium-ion-batteries (LiB) is attributed 25% to their production processes. One possibility for cost reduction and also for performance enhancement is increasing the solids content during electrode production using a novel twin screw extrusion process. This study mainly focuses on changes in physical and electrochemical properties and cost reduction appraisals due to increasing solids contents.

Edge Formation in High-Speed Intermittent Slot-Die Coating of Disruptively Stacked Thick Battery Electrodes

- First Published: 30 May 2019

There is scope for process improvements in lithium-ion-battery production due to intermittent coatings. New, improved cell stacking methods require a high coating quality. Herein, the influence of coating speed up to 50 m min−1 and wet-film thickness up to 400 μm on the length of the intermittent coating edges is shown.

Manufacturing Process for Improved Ultra-Thick Cathodes in High-Energy Lithium-Ion Batteries

- First Published: 17 April 2019

Ultra-thick electrodes promise a higher energy density and a better ratio of active to inactive cell components than state-of-the-art electrodes. By application of an improved manufacturing process, ultra-thick cathodes (50 mg cm−2) with an enhanced rate capability were yielded, that provide an 18% higher specific energy at a current density of 1 mA cm−2 compared with a state-of-the-art cathode (20 mg cm−2).

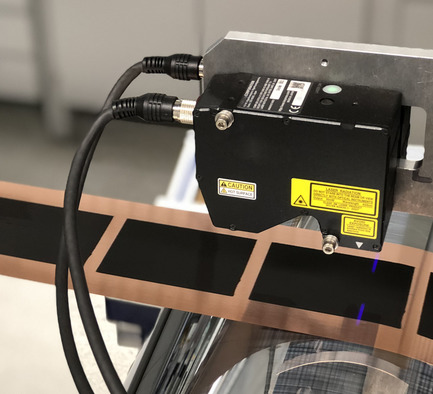

Evaluation of the Separation Process for the Production of Electrode Sheets

- First Published: 23 May 2019

Previous investigations have never compared the separation process of the electrodes with regard to their influence on electrochemical performance. This knowledge gap can be closed with this study, which shows that laser cutting offers the potential to replace the die-cutting process in a battery production line.

The Influence of Different Post-Drying Procedures on Remaining Water Content and Physical and Electrochemical Properties of Lithium-Ion Batteries

- First Published: 17 May 2019

For lithium-ion-batteries, water constitutes a substantial contamination, which makes a second drying step of electrodes and separators, just before the cell-assembly, necessary. This work examines the effect of different post-drying procedures as well as the properties of non-post-dried electrodes. Results show that not only low water content but also gentle post-drying in particular guarantees a good electrochemical performance.

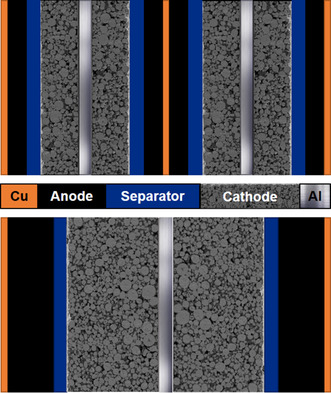

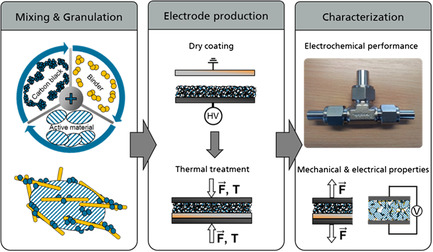

Solvent-Free Manufacturing of Electrodes for Lithium-Ion Batteries via Electrostatic Coating

- First Published: 17 June 2019

The feasibility of an ecological and economic solvent-free coating process of graphite-based anodes for lithium-ion batteries is demonstrated. The powder mixtures prepared in a two-step mixing process are transferred to the current collector via an electrostatic process and permanently fixed by hot pressing. The dry-coated anodes show comparable electrochemical performances to conventionally produced ones.