Journal list menu

Export Citations

Download PDFs

Cover Picture

Factors of Kinetics Processes in Lithium–Sulfur Reactions

- First Published: 02 December 2019

The Lithium-Sulfur (Li-S) battery is the most promising next-generation secondary battery due to its high theoretical energy density but suffers from complex Li-S reaction kinetics. In article number 1900574, key factors and insights into the kinetics process in Li-S electrochemistry are reviewed. Additionally, insights are provided on the direction of future kinetic investigations of Li-S batteries. More details can be found in article number 1900574 by Xiaonan Tang and co-workers.

Back Cover

Sulfur-Based Composite Electrode with Interconnected Mesoporous Carbon for All-Solid-State Lithium–Sulfur Batteries

- First Published: 02 December 2019

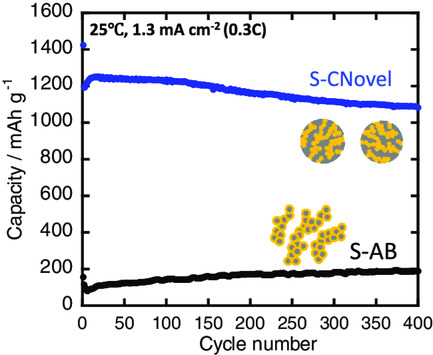

In article number 1900077, a composite electrode is fabricated for the high-rate operation of all-solid-state lithium–sulfur batteries. The composite electrode is made of sulfur and carbon with “interconnected mesopores” with a diameter of 5 nm. The all-solid-state lithium–sulfur battery shows a high capacity of 1100 mA h g−1 per sulfur after 400 cycles at 1.3 mA cm−2 at 25°C. More details can be found in article number 1900077 by Atsushi Sakuda and co-workers.

Masthead

Editorials

Reviews

Factors of Kinetics Processes in Lithium–Sulfur Reactions

- First Published: 05 September 2019

Lithium–sulfur (Li–S) batteries are the most promising next-generation secondary batteries due to a high theoretical energy density, but suffer from complex Li–S reaction kinetics. Herein, the key factors and insights into improvements of the kinetics process in Li–S electrochemistry are given. Finally, insights are provided for the direction of future kinetic investigations of Li–S batteries.

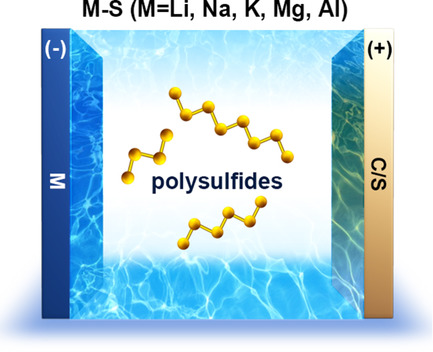

Electrolyte Evolution Propelling the Development of Nonlithium Metal–Sulfur Batteries

- First Published: 26 April 2019

In the development of room-temperature metal–sulfur batteries (Li–S, RT Na–S, K–S, Mg–S, and Al–S), the electrolyte plays a key role. To achieve a high-performance battery system, the electrolyte needs to combat the polysulfide diffusing and shuttling problem, transport ions, and be compatible with both the cathode and the anode.

Communications

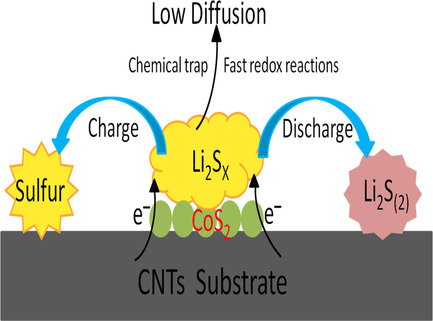

In Situ Synthesis of Sulfur Host with Chemisorption and Electrocatalytic Capability toward High-Performance Lithium–Sulfur Batteries

- First Published: 08 March 2019

CoS2/carbon nanotubes (CNTs) is obtained by an in situ synthesis method and used as an advanced sulfur host. The interconnected CNTs facilitate electron transport and mitigate volume expansion of the cathode. The CoS2 nanoparticles provide a chemical trap for soluble polysul-fides and enhance their redox reactions. Because of such synchronous advantages, the CoS2/CNTs-based sulfur cathode delivers enhanced electrochemical performances.

Sulfur-Based Composite Electrode with Interconnected Mesoporous Carbon for All-Solid-State Lithium–Sulfur Batteries

- First Published: 15 March 2019

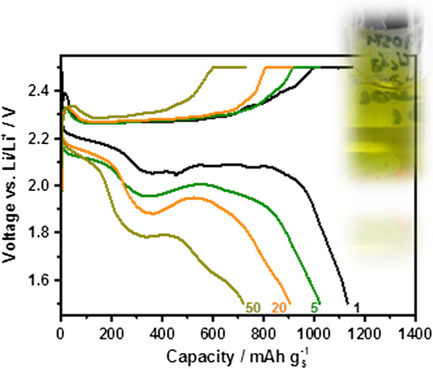

A sulfur-based composite electrode for the high-rate operation of all-solid-state Li/S batteries is prepared using carbon with interconnected mesopores. This structure drastically improves the rate capability of the composite electrode. The all-solid-state Li/S battery has a high capacity of 1100 mA h g−1 per sulfur after 400 cycles at a high current density of 1.3 mA cm−2 at 25 °C.

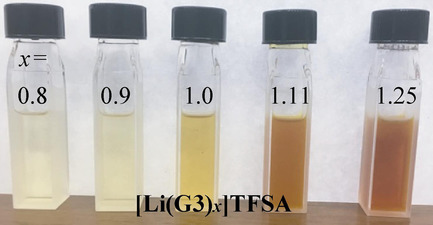

Effect of Electrolyte Composition on Performance and Stability of Lithium–Sulfur Batteries

- First Published: 06 May 2019

A Facile Strategy to Improve the Electrochemical Performance of Porous Organic Polymer-Based Lithium–Sulfur Batteries

- First Published: 17 July 2019

A porous organic architecture is developed as a dual-confinement host cathode in lithium–sulfur batteries via a simple temperature-regulating strategy. Increasing the sulfur infiltration temperature to a suitable value triggers covalent attachment of sulfur on pore walls. The synergetic chemical and physical confinement effect restrains the shuttling of polysulfides, thus leading to superior sulfur utilization, high-rate performances, and good cycle stability.

All-Solid-State Lithium-Sulfur Batteries Using Sulfurized Alcohol Composite Material with Improved Coulomb Efficiency

- First Published: 30 July 2019

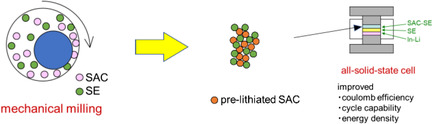

A new type of organosulfur material, sulfurized alcohol composite (SAC), is applied to an all-solid-state cell. The cell shows high specific capacity (600–800 mAh g−1) and improved initial coulomb efficiency by milling SAC and solid electrolyte. The improvement is attributed to the partial lithiation of the SAC sample and is advantageous for fabricating high-energy-density all-solid-state cells.

Full Papers

Amorphous Lithium Sulfide as Lithium-Sulfur Battery Cathode with Low Activation Barrier

- First Published: 02 January 2019

Embedding ethylenediamine molecules into Li2S particles decreases their crystallinity, leading to smaller activation barriers. This is specifically beneficial to solid-state cells, where the material is directly converted from Li2S to sulfur. The result is solid-state cells with high specific capacities and coulombic efficiency from the first cycle onward.

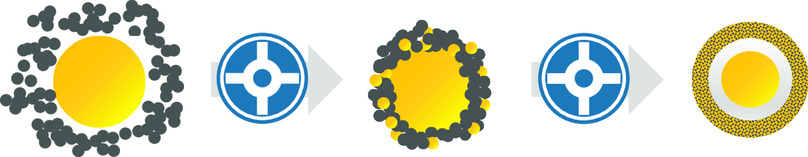

Evaluation of a High-Intensive Mixing Process in a Ring Shear Mixer and Its Impact on the Properties of Composite Particles for Lithium–Sulfur Battery Cathodes

- First Published: 25 April 2019

The capabilities of using a high-intensity mixing process to produce composite particles of carbon and sulfur for the use in cathodes for lithium–sulfur batteries are shown. The effects of the process parameters on the structure and properties of the composites are investigated. Furthermore, the effect of the composite particles on the performance properties of the sulfur cathodes are evaluated.

Nonuniform Redistribution of Sulfur and Lithium upon Cycling: Probing the Origin of Capacity Fading in Lithium–Sulfur Pouch Cells

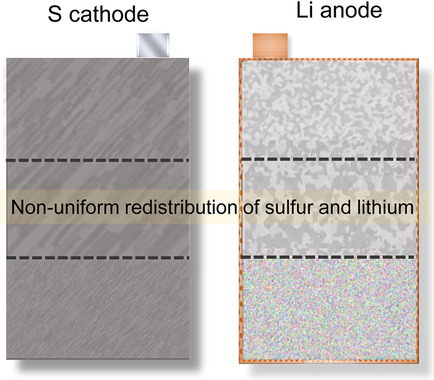

- First Published: 04 March 2019

Nonuniformity of sulfur and lithium distribution in a Li–S pouch cell is identified as a major reason for the rapid capacity fading. The mobile polysulfides lead to the agglomeration of bulk sulfur and reduction of lithium source in the central anode sheets, which thus induce the sluggish liquid–solid conversion low utilization of active sulfur cathode.

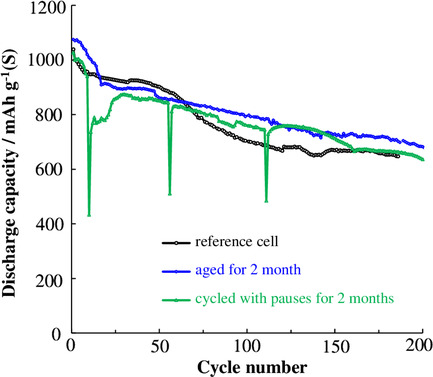

On the Factors Affecting Aging and Self-Discharge of Lithium–Sulfur Cells. Effect of Positive Electrode Composition

- First Published: 05 April 2019

Self-discharge (reversible capacity loss) and aging (irreversible capacity loss) are important problems in the development of lithium–sulfur batteries. This work summarizes the results of studying the effect of the sulfur/carbon ratio (Ketjenblack EC-600JD) in the positive electrode and the prehistory of the cells on their irreversible and reversible capacity loss.

Toward Improving the Areal Energy Density of Lithium–Sulfur Batteries with Ultramicroporous Carbon–Sulfur Composite Electrodes

- First Published: 09 April 2019

The challenges associated with sulfur cathodes in Li–S battery technology, such as the polysulphide shuttle and its detrimental effects, can be effectively addressed by the use of ultramicroporous carbon–sulfur (UMC-S). The quasi-solid-state lithiation/delithiation of the UMC-S cathode enables stable performance under lean electrolyte conditions and at increased sulfur loadings. This article holds potential for future applications of the UMC-S cathode in practical Li–S batteries.

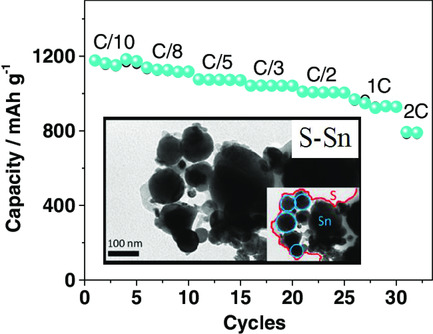

Sulfur Loaded by Nanometric Tin as a New Electrode for High-Performance Lithium/Sulfur Batteries

- First Published: 05 April 2019

In the Li/S battery, a composite electrode formed by sulfur surrounding a metallic core of nanometric tin shows a highly reversible electrochemical process evolving between 1.9 and 2.8 V with efficiency approaching 100%. The battery shows a maximum specific capacity of about 1200 mAh g−1, high rate capability, and suitable retention upon 100 charge/discharge cycles.

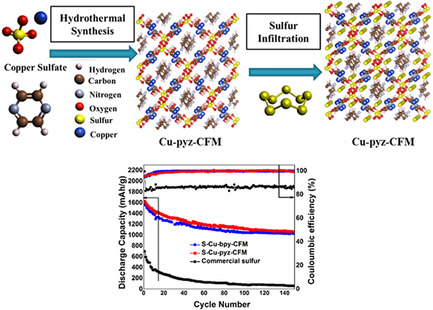

Effective Bipyridine and Pyrazine-Based Polysulfide Dissolution Resistant Complex Framework Material Systems for High Capacity Rechargeable Lithium–Sulfur Batteries

- First Published: 11 April 2019

New polysulfide dissolution resistant complex framework materials (CFMs) based sulfur cathodes are generated using the chemical interaction of carbon–nitrogen moieties with sulfur. The absence of carbonate moieties prevents unwanted sulfate formation. The resultant carbon–nitrogen containing CFMs exhibit complete polysulfides trapping combined with stable capacities (≈1000 mAh g−1) compared with commercial sulfur showing their potential for cathode use in rechargeable lithium–sulfur batteries.

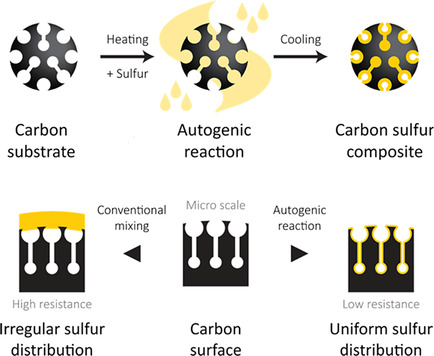

Effect of Synthesis Method Using Varying Types of Micropore Level Sulfur Infiltration on Electrochemical Performance in Lithium–Sulfur Batteries

- First Published: 23 April 2019

The role of physically restrained, noncrystalline sulfur species in rechargeable lithium–sulfur batteries is examined by electrochemical and high-resolution material characterizations. Composites are created by a melting and sublimation process for lithium–sulfur batteries. These noncrystalline sulfur cathodes demonstrate a high specific capacity of ≈1000 Ah kg−1 after 100 cycles with a gravimetric current of 557 A kg−1.

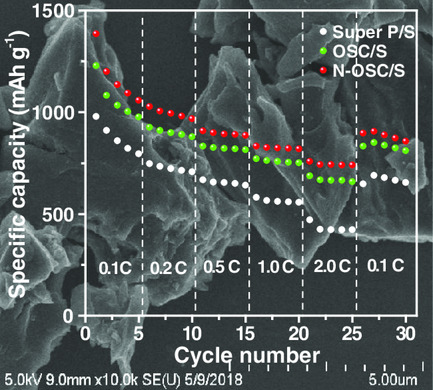

Natural Okra Shells Derived Nitrogen-Doped Porous Carbon to Regulate Polysulfides for High-Performance Lithium–Sulfur Batteries

- First Published: 26 April 2019

N-doped biomass-derived porous carbon (N-OSC), which is derived from common okra wastes, okra shells, is successfully fabricated. N-OSC exhibits a high specific surface area of 2702 m2 g−1, large pore volume (0.17 cm3 g−1), and high sulfur loading (69.71 wt%). The cell with N-OSC/sulfur composite as an electrode manifests excellent performance, where the capacity is up to 750 mA h g−1 even at 2 C rate.

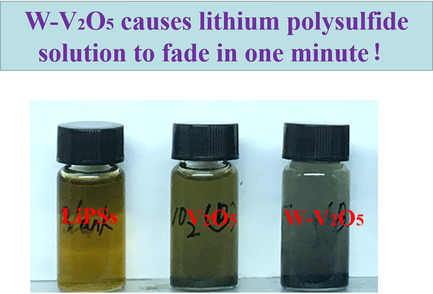

A New Finding on the Enhancement of the Ability of Polysulfide Adsorption of V2O5 by Doping Tungsten in Lithium–Sulfur Batteries

- First Published: 08 May 2019

W6+-doped V2O5 can greatly enhance the adsorption speed of V2O5 for lithium polysulfide (LiPS), which makes a red LiPS solution fade in 1 min. The metal oxide is mixed with the graphene/carbon nanotube composite to modify the separator, which can greatly improve the cycle performance of the lithium–sulfur battery.

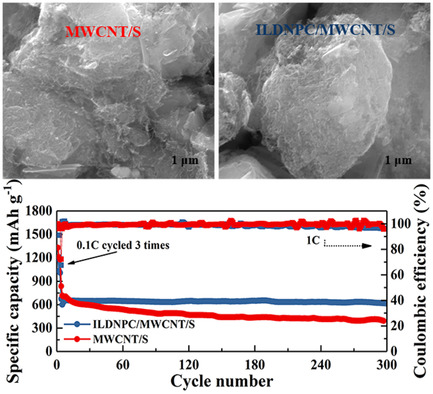

Polar and Nonpolar Matrix Consisting of Twined Multiwalled Carbon Nanotube and High Nitrogen-Doped Porous Carbon Derived from Ionic Liquid for Stable Li-S Battery

- First Published: 14 June 2019

Herein, a nonpolar and polar matrix is comprised of intertwined multiwalled carbon nanotubes (MWCNTs) and ionic-liquid-derived nitrogen-rich porous carbon. Benefiting from the nonpolar physical binding of microporous and mesoporous structure (diameter < 8 nm) and polar chemical anchoring of N-doped (7.42 At%) carbon, the cathode exhibits a very stable cycle stability of 0.021% attenuation for each cycle with 300 cycles at 1 C.

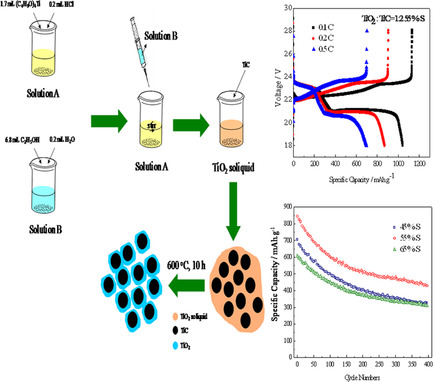

A Facile Synthesis of Stable TiO2/TiC Composite Material as Sulfur Immobilizers for Cathodes of Lithium–Sulfur Batteries with Excellent Electrochemical Performances

- First Published: 28 June 2019

The facile synthesis of stable TiO2/TiC composite materials as sulfur immobilizers for lithium–sulfur batteries is shown. The conductivity of TiC and the strong adsorption of the Ti—O bond on sulfur in TiO2 are combined together. After sulfur-loading, the achieved specific capacity is 1044.68 mAh g−1, and the capacity retention rate is still over 50% after 400 cycles.

Polysulfide Shuttle Suppression by Electrolytes with Low-Density for High-Energy Lithium–Sulfur Batteries

- First Published: 16 July 2019

A low-density electrolyte composition is introduced for lithium 1,3-dioxolane sulfur batteries. The choice of the solvent limits the dissolution of polysulfides, leading to successful polysulfide shuttle suppression. In contrast to concepts relying on hydrofluoro ether dilution, the presented electrolyte features a significantly reduced mass density possibly enabling significant weight reduction on the Li–S prototype cell level.

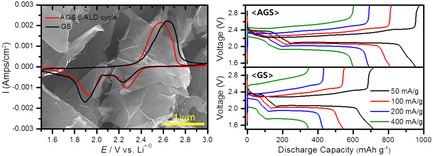

Blocking Polysulfides in Graphene–Sulfur Cathodes of Lithium–Sulfur Batteries through Atomic Layer Deposition of Alumina

- First Published: 01 August 2019

Low-temperature atomic layer deposition of Al2O3 is presented as a strategy to suppress performance degradation of 2D graphene–sulfur hybrid cathodes. Superior electrochemical performance is credited to the synergy between the high electronic conductivity of multilayered graphene platelets and low charge transfer resistance, resulting from effective polysulfide blocking by atomic scale Al2O3 coating.