Model-Based Optimization of Web Tension Control for the Flexible Cell Stack Assembly of Lithium-Ion Battery Cells

Abstract

The transformation toward electromobility presents a significant challenge to the battery cell production processes. It is, therefore, necessary to establish efficient and robust operations and machines to meet the forecasted demand for manufactured cell capacity. Currently, the development and ramp-up phases of production machines, especially for cell stack assembly, are characterized by high material scrap rates and large personnel expenses. Aspects such as the web tension of electrodes or separator materials during separation and stack assembly have a significant influence on the subsequent intermediate product properties, and therefore present a key challenge. Herein, the optimal methodology for the web tension control of electrode materials is determined via a model-based approach by the means of a digital twin. The focus is hereby set on a production machine for the flexible cell stack assembly. Appropriate control methods are implemented and validated on the real system, thus reducing material scrap rates and overall costs. The control of the web tension by means of an unwinder and material storage was found to be optimal on the basis of the model and confirmed experimentally.

1 Introduction

The transformation toward electromobility presents a significant challenge to the battery cell production processes. To meet the forecasted cell capacity demands, processes must be operated efficiently and the scaling up from laboratory to industrial readiness must be accelerated.[1-3] In addition to the general significant increase in demand for batteries, other trends such as the increasing diversity of materials can be observed. These pose enormous challenges for the commissioning and operation of the production machines.[4] Therefore, the production of lithium-ion batteries is currently impacted by material scrap rates of up to 40%.[5] Furthermore, according to,[6] material costs make up the highest proportion of battery production at 75%. Waste of material is extremely critical in this context.

Many cause–effect relationships of the production processes are not yet, or only partially understood.[7, 8] For efficient operation, it is essential to know both the behavior of the production machine and the resulting material behavior. Against this background, the use of digital twins is a suitable way to quantify corresponding cause–effect relationships.[9] Digital twins represent real applications in virtual space. In the context of production technology, processes, machines, or entire production lines can be represented in virtual space and tested without risk. Changes to the real system over time can also be implemented within the digital twin. This way optimization approaches can be virtually tested in an early stage of the development process, before they are subsequently incorporated into the physical machine.[10] Currently, no uniform definition of the term “digital twin” exists within literary works. Therefore, the term digital twin is understood as a digital machine model within this article. A more detailed description is provided in chapter 3.2.

Web guiding applications can be found in electrode manufacturing as well as in the assembly process of battery cells. Understanding the interaction of web guiding applications on the material behavior of electrode and separator webs is essential for efficient production, since there is a direct correlation between the web tension and the dimensional accuracy of separated electrode sheets in the production of stacked pouch cells.[11, 12] The applied web tension also has a major influence on separator damage.[13] Furthermore, the Z-folding-stack assembly process includes a complex kinematic motion profile of the individual machine components. This further increases the need for an appropriate control mechanism for the web tension of the processed material. In the Z-folding assembly process, the cell stack is produced by alternately stacking the singulated electrode sheets and overfolding a separator web.[14] Precise web tension control is, therefore, indispensable for stack assembly, especially when separating sheets from the electrode web and handling separator webs without damage.[15] Web tension describes the tensile force that is applied to the web material to be processed and in practice, various systems and web tension control methods have become established.[16] Especially during the development and commissioning of new processes and production machines, it is often not clear, which web tension control method is the ideal one. This article, therefore, seeks to answer the research question, whether model-based optimizations are suitable for determining the best possible web tension control setup for a given machine. If this is the case, the iterative determination of optimal possibilities and parameters, which is currently characterized by large time demands and extensive material scrap could be avoided. To answer this question, a method for the model-based optimization of a web tension control system for a cell stack forming machine is presented in the following. With the help of a digital twin of the machine and the process, an optimal web tension control method is derived and implemented on the real system. A cost-saving through the reduction of material scrap and commissioning time is thereby enabled.

2 Approved Web Tension Control Concepts

Controlling the web tension is an inert challenge of any process which includes coiled goods. These can be, for example, the textile or paper industry. On the one hand, the tension needs to be high enough to enable the required process accuracy. This is especially true when handling and transporting material throughout the machine. Slipping on rollers or similar effects need to be avoided. At the same time, the material needs to be able to handle the exerted tensions, without entering a stage of plastic deformation. This will have a negative influence on the final product.[17] In addition, even elastic deformations may introduce uncertainties into the process, especially when tracking specific sections of the material throughout the process.[18] As a final challenge, the web tension within a machine or process needs to be adjusted continuously, since coil dimensions vary due to the nature of the process, and therefore introduce changes in the moments of inertia for both the un- and the rewinder.[19]

To influence the tension of the handled materials, several possibilities exist. The rewinder is normally equipped with a motor pulling the material throughout the machine. At the start of the process, the unwinder can equally be equipped with a motor or a break to introduce the desired tension. Furthermore, various dancer systems, such as linear or rotational systems, may be included to exert additional forces onto the processed materials. These forces can either be set to static values, or varied by a control system.[20]

When processing materials with high tensile strength, such as paper, it is often possible to use open-loop control systems. These do not involve a direct measurement of the actual web tension.[18] They compensate for the changing moments of inertia of the used coils by measuring their diameter and then adjusting the tension through appropriate measures, such as varying the forces of the dancer system or by adjusting the breaking torque on the unwinder. When operating with more sensitive materials, a closed-loop control system becomes necessary. They require a measurement of the actual web tension as an input, which can be retrieved by including load cells into the roller systems, as done within a measuring roller for example. Alternatively, it is also possible to use the position of the dancer system as a proxy value for the existing web tension.[16]

It can be concluded that several opportunities for controlling the web tension within a machine exist. However, there is only limited knowledge about the preferable technique for a given application scenario. This is especially true for new machine concepts, where long-time experience with previous machines and techniques for adjusting the web tension is not available. This is where this work connects to the current state of the art, by presenting an opportunity to use the concept of digital twins for aiding in the decision for an appropriate web tension control setup.

3 State of the Art: Coil2Stack and its Digital Twin

The following considerations refer to the stack assembly machine “Coil2Stack” developed at the wbk Institute of Production Science (KIT). This system is used for the investigations in this paper. The design and functionality of this production machine are explained in detail in ref. 21.

3.1 Machine Concept––Coil2Stack

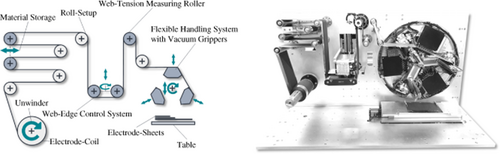

The concept of the machine and its realization are shown in Figure 1. The electrode material is supplied to the process as a coil. Via an unwinder, the electrode web is guided through a roller setup to a material storage, a web edge control system, and a web tension measuring roller to the flexible handling system. In the handling system, the web is wound up by vacuum grippers and then electrode sheets are continuously cut off by a lateral cut. Afterward, the sheets are placed on a table. The position of the grippers can be adjusted perpendicular to the rotational axis of the handling system to automatically separate sheets of different lengths.

The web tension of the electrode material can be controlled with both the material storage and the unwinder. The material storage consists of 2 movable rollers which are controlled by a pneumatic cylinder, thus creating a traditional linear dancer system. By adjusting the force applied to the rollers, the web tension in the system can be increased or decreased. Control of the web tension by use of the unwinder is achieved by adjusting the unwinder speed.

3.2 Digital Model of the Coil2Stack Machine

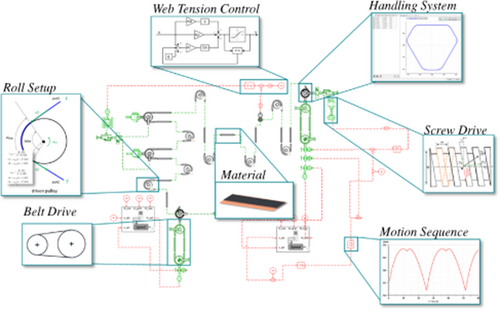

For the model-based optimization of the web tension control, the digital twin described in ref. 22 is used. It consists of a system simulation using the software Simcenter Amesim. Mechatronic components of the system and material properties are represented by physical relationships. For example, the moments of inertia for the individual rollers, as well as the frictional effects that occur within the bearings and between the material and the rollers are considered. The virtual exploration of different machine parameters and control systems can thus be conducted in the virtual space. Figure 2 illustrates the Amesim model of the Coil2Stack machine.

In the following, the digital twin is used to validate different web tension control methods within the virtual space before they are implemented in the real system.

4 Approach for Web Tension Control of the Coil2Stack Machine

In the first step, different methods for the web tension control of the electrode material within the Coil2Stack machine are investigated with the presented digital twin. Due to the nature of the virtual space, this occurs without risk and with minimal cost. Subsequently, an optimal method for web tension control is derived and implemented on the real system. Table 1 illustrates the considered setups for web tension control. These are drawn from the presented literature research by creating a closed loop control system that combines fixed with dynamically regulated inputs for the existing winders of the machine.

| No. | Input material storage | Input unwinder |

|---|---|---|

| 1 | PID-signal of measured web tension | Constant speed |

| 2 | PID-signal of measured web tension | Web speed at the handling system |

| 3 | Fixed position | PID-signal of measured web tension |

| 4 | Constant pressure | PID-signal of measured web tension |

Figure 3 shows a simplified illustration of the web tension control concepts under consideration. The web tension is measured at the measuring roller and carried back to the unwinder, respectively, the material storage.

Using Method 1, the web tension is controlled only via the material storage device and the resulting linear movement of the rollers. The web tension is measured, compared with the target web tension, and a pressure control element is used to control a pneumatic cylinder by means of a PID controller. With this method, the unwinder rotates at a constant speed and is not controlled further. With Method 2, the web tension is also actively controlled via the material storage. Compared to the first method, the speed of the unwinder is set so that its tangential speed is equal to the tangential speed of the electrode web on the handling element. This is to ensure an adjusted material feed. In Method 3, the material storage is not used and is fixed at one position. The web tension is controlled only by adjusting the speed of the unwinder. In Method 4, the web tension is also controlled by the unwinder. Furthermore, a constant pressure is applied to the material accumulator. Damping effects to the web tension are enabled.

5 Implementation and Validation

5.1 Boundary Conditions

A constant machine and material setup are selected for the considerations. Adjustable parameters on the machine are the electrode sheet length to be produced, the target web tension at the handling system, and the web speed of the electrode material. According to these settings, a cam profile is calculated in the control system of the machine. The corresponding motion profile essentially refers to the speed of the handling system and a vertical movement of it. For the investigations, an anode material is processed. Table 2 shows the considered machine and material parameters. Double-sided coated anode material was used. The Young's modulus was previously determined by means of tensile tests. Samples of the coated part of the material were used here.

| Parameter | Unit | Value | |

|---|---|---|---|

| Machine | Web speed of electrode material | mm s−1 | 16 |

| Web tension | N | 15 | |

| Electrode sheet length | mm | 240 | |

| Material | Young's modulus | GPa | 54.6 |

| Foil thickness | μm | 10 | |

| Coating thickness | μm | 73.5 | |

| Total width | mm | 200 | |

| Coating width | Mm | 148 | |

| Foil grammage | mg mm−2 | 24 | |

| Coating grammage | mg mm−2 | 0.07 |

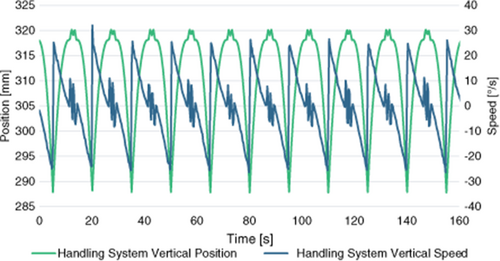

The main influence of web tension fluctuation is caused by the movement profile of the handling system. This involves both a vertical up and down movement of the entire handling element and an adjustment of the turning speed. The motion profile is used to achieve a constant deposition point of the electrode sheets and a constant tangential velocity at this point. Figure 4 shows an exemplary movement profile of the handling system for the selected machine setup. This compensates for the noncircular profile of the gripper contour.

A repeating profile in the vertical position and the rotational speed of the handling system can be seen. The corresponding web tension control must be able to compensate for the web tension fluctuations caused by the motion profile.

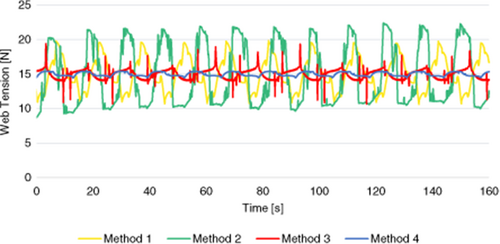

5.2 Modeled and Measured Web Tension

Figure 5 shows the results of the modeled web tension curves for the four illustrated control methods. Overall, it can be seen that there are deviations from the target web tension of 15 N for all methods. Furthermore, a periodic trend of web tension fluctuations can be seen for all control methods.

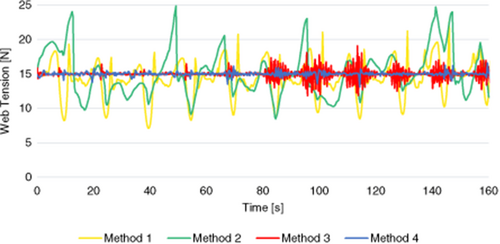

It can be seen that controlling the web tension of the electrode material using Methods 1 and 2 leads to significantly higher fluctuations than using Methods 3 and 4. The control by using the unwinder shows a more stable course of the web tension. The investigations with the digital twin show that controlling the web tension using Method 4 leads to the smallest fluctuations. Figure 6 shows the results of the measured web tension, when applying the different control methods to the physical machine. Here, it can also be seen that the target web tension is not perfectly controlled with any method. The modeled fluctuations can also be seen in the real measured data. The measured data also shows that the control of the web tension with Methods 1 and 2 leads to significantly higher fluctuations than with Methods 3 and 4. Furthermore, noticeable disturbance effects can be seen for Method 3 from ≈80 s of system operation. The reasons, therefore, can be found in an oscillation of the control loop due to disturbance variables that have occurred. These can be, for example, friction peaks in the mechanical components of the machine. Overall, Method 4 also performs best, analogous to the modeled results.

The simulated data sets show a more consistent fluctuation of the web tension compared to the measured values. The main effect of the web tension fluctuations in the simulation model is essentially caused by the motion sequences of the handling element and the web tension control elements. In the measured data sets, additional effects such as the above-mentioned disturbances also come into play, which are not considered in the model at the current time. However, the rough deviations from the required nominal web tension can be represented on the basis of the model.

5.3 Interpretation of the Results

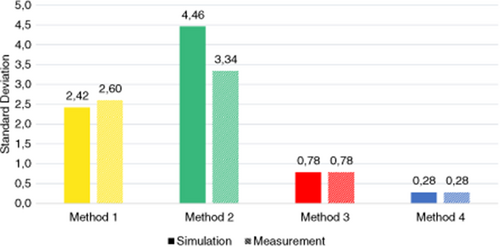

Figure 7 shows a summary of the standard deviations of the modeled and measured data sets of the web tension. It can be assumed that a higher fluctuation of the web tension leads to a higher fluctuation of the dimensional accuracy of the individual electrode sheets as well.

At first, it can be noted that the results regarding the standard deviation of the digital model reflect the reality closely, so that sufficient conclusions can be drawn. The exact course of the web tension is not represented by the simulation model. Further aspects would have to be added, for example, a more detailed simulation of the cylinder for the material storage. Statements about the suitability of different control methods of the web tension of the electrode material can be made by analyzing the material's behavior in the virtual space before performing physical tests. The measured data underlines the model-based statement that Method 4 is the most appropriate. Both the simulated data and the measured data sets show on average the smallest deviations from the target web tension for Method 4.

In the following, an interpretation of the results will be given. Primarily, the results show that active control of the web tension via the unwinder enables a more stable web tension course compared to the control by using the material storage system as a linear dancer. The results also show that contrary to expectations, the control according to Method 2 is worse than the control according to Method 1. The reason for this is primarily the increased “stick-slip effect” in the controlled cylinder.[23] The fact that a constant unwinder speed was selected for Method 1 causes the material storage cylinder to move in one direction continuously, thus decreasing the amount of material stored within the system. This is necessary to compensate for the speed of the unwinder, which is ever so slightly below the material speed at the handling system. As a result, there are no changes in the directional movement of the cylinder. The static friction in the cylinder, therefore, has to be overcome only once. With this method, however, the material storage unit will move to the limit stop after a certain period of time and is, therefore, not very well suited for practical implementation. In the second method, the speed is controlled in such a way that an adapted material flow over the unwinder is ensured in accordance with the movement profile of the handling system. This has the consequence that the material accumulator experiences more frequent reversals of direction. With each reversal of direction, the corresponding static friction in the cylinder must be overcome again. The corresponding “stick-slip-effects” finally result in the web tension fluctuations shown for the second method. The control of the web tension according to Method 3 leads to the system being considerably more unstable than that of Method 4. In Method 3, the material storage is fixed. It can, therefore, be seen that the unwinder is much more sensitive to disturbances. In Method 4, this is counteracted by the material storage, which acts as a spring-damper element.

Overall, it was determined that Method 4 is the appropriate strategy to control the web tension of the electrode material, by using a digital model. Major fluctuations are avoided and the statements of the model were confirmed via corresponding experiments and measurements. No material scrap is generated by the virtual determination of the optimum control method. An iterative procedure on the real system is avoided. Costs are therefore reduced.

6 Summary and Outlook

Web guiding processes are used in the processing of electrode and separator materials in cell stack assembly. A quality-critical parameter here is the web tension. The production machines must therefore be able to control the required web tension. Various methods of web tension control have become established. For example, dancer systems and unwinder controls are used. When commissioning new machines and systems, it is initially not obvious which the optimal control method is. Iterative methods for determining the optimal method result in high personnel expenses and material waste. In this work, a procedure to determine the optimal control method of the quality-critical web tension of the electrode material for a machine was described. This was done for the flexible cell stack formation on the basis of a model using a digital twin. This makes it possible to virtually represent the machine and the resulting material behavior and changes to the system. Four different methods were investigated using the digital twin and later validated using experiments. A control of the web tension by means of an unwinder with a constant force applied to the material storage system proved to be the optimum model-based method and was also approved experimentally. The use of digital machine models for the identification of optimization approaches is to be motivated by this work. Especially due to the scrap rates and high material costs, there is potential for battery production. Furthermore, the digital twin offers the possibility to examine a scale-up of the system concept in digital space. In this way, it is also possible to consider significantly higher web speeds than 16 mm s−1, even if they cannot be implemented on the real system. The methodology is not limited to this process, it can be extended to other web guiding machines and equipment. This is true especially true for other innovative processes, such as the assembly of fuel cells for example. However, also established assembly systems can benefit from this approach, since different setups can be tested without having to risk any downtime of the physical machine. The current limitations of the digital twin are mainly in its high demand for computation time and that it therefore cannot be used in sync with the physical machine. For this reason, the near-real-time use of the digital twin is in the outlook. Here, the digital twin of the machine is to process drive data from the real control system during the running process. This will make it possible to detect non-measurable or non-sensor-based parameters in the context of virtual sensing. For example, the web tension of the material can be determined at any position in the system, or a load profile can be created for each electrode sheet. Approaches for controlling the machine based on real-time modeled data are thus conceivable.

Acknowledgements

The presented research is funded by the German Federal Ministry of Education and Research under the funding code 03XP0252B (Project: E-Qual). This work was done at the KIT Battery Technology Center (KIT-BATEC) and contributes to the research performed at CELEST (Center for Electrochemical Energy Storage Ulm-Karlsruhe).

Open Access funding enabled and organized by Projekt DEAL.

Conflict of Interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.