Journal list menu

Export Citations

Download PDFs

Cover Picture

Cover Picture: Chem. Eng. Technol. 8/2019

- Page: 1539

- First Published: 22 July 2019

Novel pilot plant for the screening of shaped catalysts located at IFPEN Lyon, with components designed by Computational Fluids Dynamics tools. Copyright: @IFPEN

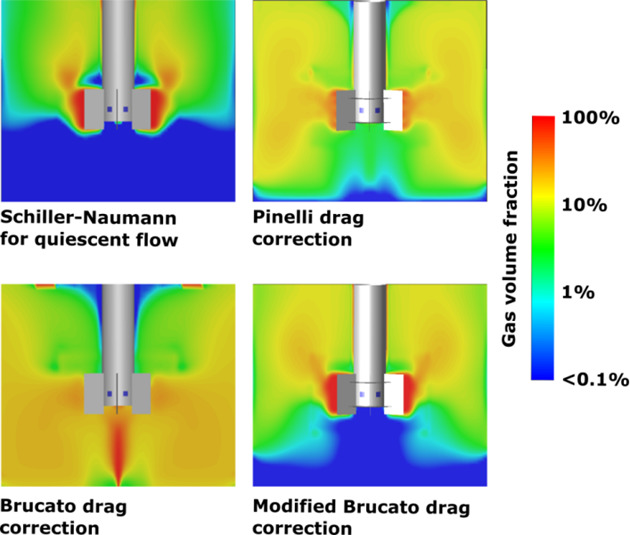

Advanced computational tools, such as computational fluid dynamics (CFD) codes, are being increasingly adopted by engineers for the design, scale-up, and intensification of industrial equipment. Nonetheless, the characterization of interphase gas-liquid mass transfer in stirred equipment can still be a challenging task, this being particularly true for small-scale equipment. In the presented work, a multiphase CFD methodology has been developed and proposed for the estimation mass transfer rates in a bench-scale reactor equipped with a self-inducing impeller. The importance of estimating an apparent drag coefficient that considers the effect of mechanically generated free-stream turbulence on the gas bubbles rising velocity is also shown in this work. The spatial distribution of values in the agitated vessel has been obtained from the CFD results using Danckwert's surface renewal model. The proposed model shows good agreement with experimental data.

Editorial Board

Editorial Board: Chem. Eng. Technol. 8/2019

- Page: 1540

- First Published: 22 July 2019

Overview

Overview Contents: Chem. Eng. Technol. 8/2019

- Page: 1541

- First Published: 22 July 2019

Highlights

Editorial

Advances in Mixing Research: 16th European Conference on Mixing

- Page: 1544

- First Published: 22 July 2019

Research Articles

Estimation of kLa Values in Bench-Scale Stirred Tank Reactors with Self-Inducing Impeller by Multiphase CFD Simulations

- Pages: 1545-1554

- First Published: 12 March 2019

A multiphase computational fluid dynamics simulation methodology has been developed for estimation of the spatial distribution of values like gas-liquid mass transfer in a bench-scale reactor equipped with a self-inducing impeller. Efforts were made to propose a computationally inexpensive modeling methodology as an attractive optimization tool for multiphase lab-scale reactors.

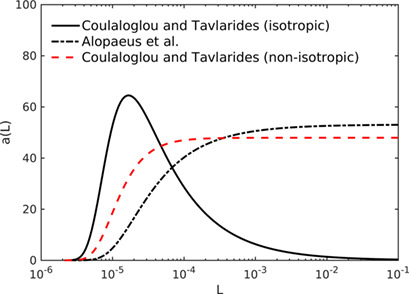

Simulation of Turbulent Emulsification in a Sonolator Mixer: Interpretation of Drop Breakage Time

- Pages: 1555-1565

- First Published: 20 March 2019

A unified framework for interpreting the time scale term of droplet breakage kernels based on the underlying turbulence structure is considered. Time scale terms that correspond to non-isotropic turbulence conditions typically encountered in high-shear mixers are able to better capture the droplet breakup in such devices and yield closer agreement with experiments.

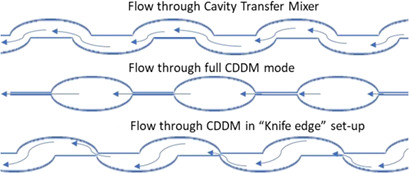

Plant Fiber Processing Using the Controlled Deformation Dynamic Mixer

- Pages: 1566-1573

- First Published: 28 March 2019

A novel mixing technology, the controlled deformation dynamic mixer, is shown to have lower specific energy requirements than other commercial mixers when processing plant fibers. Combining high-pressure homogenization and high-shear rotor-stator mixing, this mixer is able to generate products of equal viscosity compared to current mixing technologies but with less energy consumption and pressure.

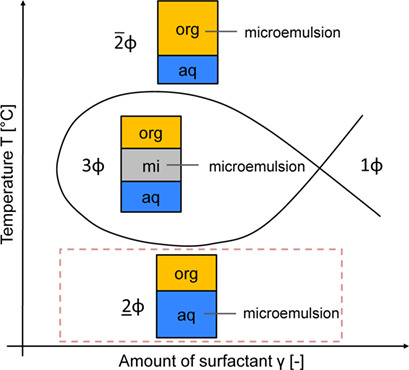

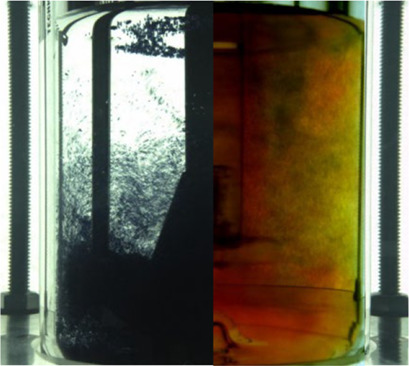

Dispersion and Phase Separation of Water-Oil-Amphiphile Systems in Stirred Tanks

- Pages: 1574-1586

- First Published: 28 March 2019

Steady-state drop sizes do not always indicate the correct trend for the phase separation process, which is attributed to intense coalescence in the decaying turbulence field. This was monitored with an endoscope measurement technique. The resulting distributions differed in shape and no self-similarity was observed while comparing steady-state and transient conditions.

Suspension and Mixing Characterization of Intermittent Agitation Modes in DASGIP Bioreactors

- Pages: 1587-1593

- First Published: 02 April 2019

Intermittent agitation although commonly used in a range of applications is yet to undergo any engineering characterization in the literature. This study introduces the characterization of both continuous and intermittent agitation modes within bioreactor configuration, focusing on the impact of microcarrier suspension dynamics and culture mixing efficiency.

Blend Time Measurement in the Confined Impeller Stirred Tank

- Pages: 1594-1601

- First Published: 15 April 2019

The blend time and macromixing performance were characterized for the confined impeller stirred tank in both turbulent and low transitional flow regimes. Six different impeller configurations were investigated and a formerly developed decolorization and image analysis technique was applied for the experiments. For tracking successful mixing, an acid-base reaction was employed.

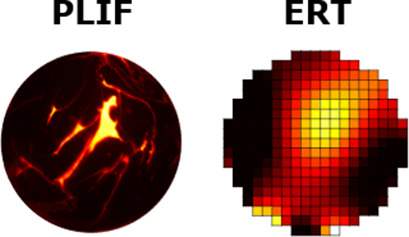

Assessing Blending of Non-Newtonian Fluids in Static Mixers by Planar Laser-Induced Fluorescence and Electrical Resistance Tomography

- Pages: 1602-1610

- First Published: 15 April 2019

Electrical resistance tomography was selected to assess the mixing performance for blending of non-Newtonian fluids in a static mixer. The areal fraction method allowed for comparing such measurements with planar laser-induced fluorescence, which served as a validation technique. Advantages and limitations of the proposed technique for in-line applications are described and evaluated.

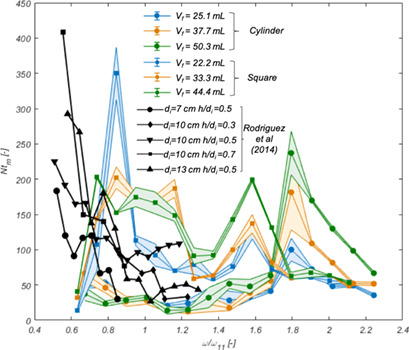

Mixing Time in Intermediate-Sized Orbitally Shaken Reactors with Small Orbital Diameters

- Pages: 1611-1617

- First Published: 15 April 2019

The mixing times in two intermediate-sized shaken reactors were quantified by the dual indicator system for mixing time technique for small-orbital diameter shakers. The natural frequency of a filled container, which only depends on the reactor size, fill volume, and geometry, was found to be an effective mixing time scaling parameter for shaken systems of different reactor sizes and orbital diameters.

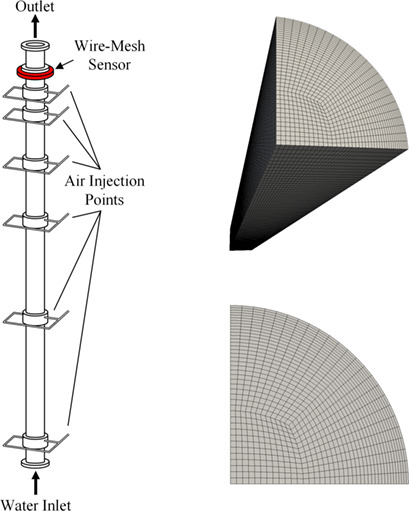

Evaluation of Hydrodynamic Closures for Bubbly Regime CFD Simulations in Developing Pipe Flow

- Pages: 1618-1626

- First Published: 15 April 2019

Predictions of Eulerian-Eulerian multiphase computational fluid dynamics simulations of bubbly flows depend strongly on the choice of closures for interfacial forces, i.e., drag, turbulent dispersion, lift, and wall lubrication. This work studies the effect of interfacial forces, particularly the lift and wall lubrication forces, by simulating a developing turbulent bubbly pipe flow.

Solid Dissolution and Liquid Mixing in Turbulent Stirred Tanks

- Pages: 1627-1634

- First Published: 24 April 2019

A novel method for the simultaneous identification of the liquid mixing time and the dissolution time of salt particles in stirred vessels is presented. During the dissolution, the time required for the liquid blending is found to be either uninfluential or significant on the total time required for the operation accomplishment, depending on the salt particle diameter and the vessel size.

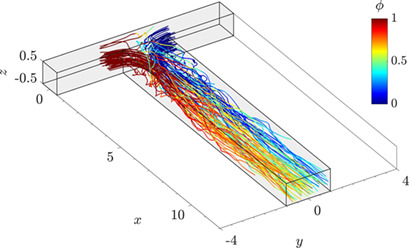

Influence of Mixing on the Precipitation of Organic Nanoparticles: A Lagrangian Perspective on Scale-up Based on Self-Similar Distributions

- Pages: 1635-1642

- First Published: 24 April 2019

The influence of mixing on the precipitation of organic nanoparticles is experimentally demonstrated. Using parameter-free direct numerical simulations, the origin of this mixing impact is deducted by analysis of the fluids phase composition along Lagrangian trajectories. Based on these insights, a scale-up method is proposed, aiming to save computational costs for direct numerical simulations.

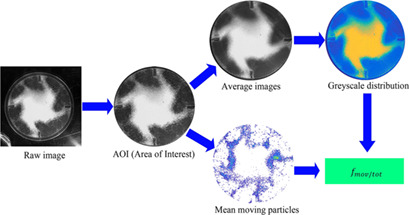

Quantitative Measurements of the Critical Impeller Speed for Solid-Liquid Suspensions

- Pages: 1643-1653

- First Published: 24 April 2019

An innovative quantitative methodology introducing a novel parameter is presented for measuring particle suspension characteristics which is more objective than the usual method relying on visual observation. A comparison of the effect of impeller clearance on minimum impeller speed with this quantitative method to predictions from previous studies and visual observation proves good agreement.

Simulation of Mixing in Structured Fluids with Dissipative Particle Dynamics and Validation with Experimental Data

- Pages: 1654-1662

- First Published: 24 April 2019

The capability of dissipative particle dynamics models to simulate structured fluids consisting of mixtures of the triblock copolymer Pluronic with water was assessed. The predictions were validated by experimental data. The main novelty lies in the demonstration of the portability of the dissipative dynamics model simulation parameters which were easily carried over from a previous work.

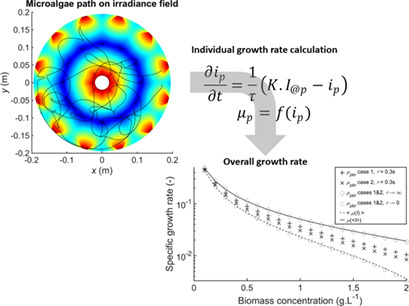

How Mixing and Light Heterogeneity Impact the Overall Growth Rate in Photobioreactors

- Pages: 1663-1669

- First Published: 25 April 2019

A general methodology is developed and applied for the calculation of the overall growth rate in a heterogeneous photobioreactor. The light exposition experienced by the cells obtained from their Lagrangian tracking on two-phase non-stationary computational fluid dynamics simulations is coupled to a biological growth model based on an experimental characteristic relaxation time.

Flow Compartments in Viscoelastic Fluids Using Radial Impellers in Stirred Tanks

- Pages: 1670-1679

- First Published: 25 April 2019

Sizes and shapes of cavern-like flow compartments are analyzed as a function of agitator size, rotational frequency, and viscoelastic rheology. By balancing centrifugal forces to normal stress differences, a simple model is derived predicting compartment sizes for all analyzed fluids, agitators, and stirring rates. The elasticity number is suitable as a scale-up criterion for stirring viscoelastic fluids.

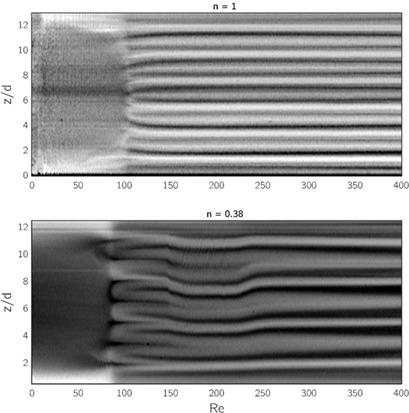

Influence of Shear-Thinning Rheology on the Mixing Dynamics in Taylor-Couette Flow

- Pages: 1680-1690

- First Published: 26 April 2019

The effect of shear-thinning rheology for non-Newtonian fluids in a Taylor-Couette reactor is studied by particle image velocimetry and flow visualization. Shear-thinning alters the critical Reynolds numbers for the formation of Taylor vortices and the higher-order wavy instability. Strong shear-thinning and weak viscoelasticity can lead to sudden wavelength transitions with varying Reynolds number.

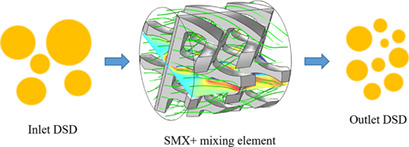

Modeling Emulsification in Static Mixers: Equilibrium Correlations versus Population Balance Equations

- Pages: 1691-1701

- First Published: 29 April 2019

A correlation and a population balance model are investigated for the prediction of droplet breakage during a continuous emulsification process using SMX+ static mixers. The transient correlation allows the prediction of the droplet mean diameter while the population balance model tracks the time evolution of the droplet size distribution between the inlet and the outlet of the mixing elements.

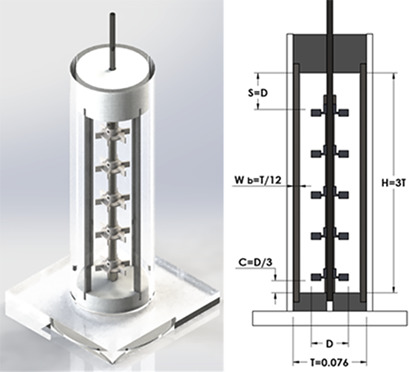

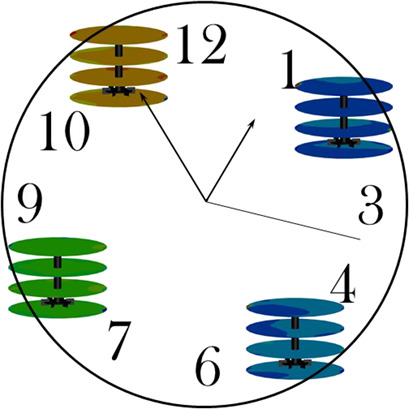

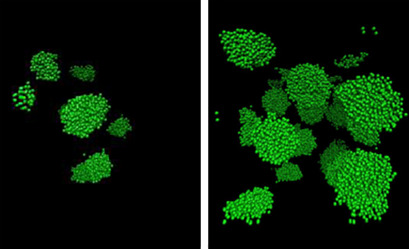

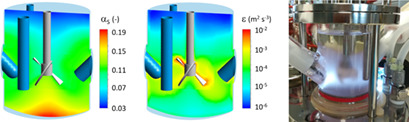

Optimization of the Impeller Design for Mesenchymal Stem Cell Culture on Microcarriers in Bioreactors

- Pages: 1702-1708

- First Published: 07 May 2019

A computational fluid dynamics-based optimization strategy was developed to improve the design of an impeller for stem cell culture on microcarriers. Based on local integration of the turbulent energy dissipation rate within the bioreactor, two criteria were defined to minimize the hydromechanical stress encountered by the particles.

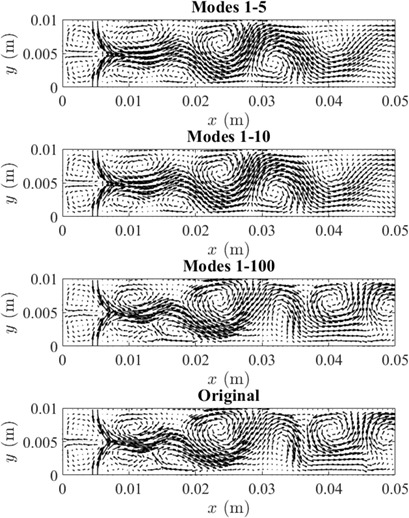

Proper Orthogonal Decomposition and Statistical Analysis of 2D Confined Impinging Jets Chaotic Flow

- Pages: 1709-1716

- First Published: 07 May 2019

The flow structures in confined impinging jets mixers are determined by proper orthogonal decomposition, which identifies the main characteristics of the chaotic flows and separates them into a few modes. The decomposition of the flow field into orthogonal modes related to coherent structures reveals mixing dynamics and scales that are not accessible from flow dynamics statistic quantities.

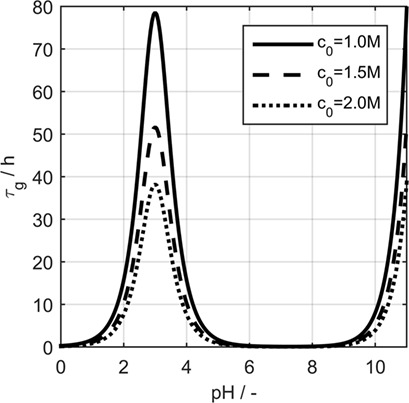

Aggregation Efficiency of Amorphous Silica Nanoparticles

- Pages: 1717-1724

- First Published: 17 June 2019

Colloidal systems are widely applied in industrial practice to manufacture fine particulate products. In reaction rate-limited cases, the Derjaguin-Landau-Verwey-Overbeek theory is not sufficient to explain the stability-coagulation behavior of such systems. A mathematical description of the reaction rate-limited aggregation based on analysis of characteristic time scales of the process is provided.

Overview

Overview Contents: Chemie Ingenieur Technik 8/2019

- Page: 1725

- First Published: 22 July 2019

Corrigendum

Simple Apparatus for the Measurement of Total Pressure of Polymer-Solvent Mixtures

- Page: 1726

- First Published: 22 July 2019