Editors' Choice

Every month, the Editors select two papers referring to current discussions in the scientific, public and economic communities and in view of the potential for further developments. The papers are freely accessible for one month.

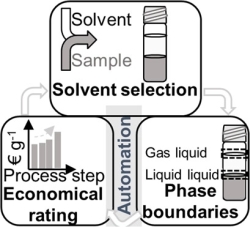

Robotic Platform Selects Solvent for Extraction Autonomously

September 14, 2021

Fast and reliable process design requires automation of process steps and overall optimization. Thereby, not only the automation of already established production processes but also of completely new processes is important. Since only limited data is available in the early process design stages, experiments are indispensable. But limited human and material resources and the crucial time to market make an automated process design approach desirable with which the overall production process can be improved. The work by M. Schreiber et al. addresses steps necessary for the intelligent and automatic design of a liquid-liquid extraction process on a robotic platform. The extraction is designed and executed by the robotic platform itself. Automatic solvent suggestion, autonomous detection of liquid phase boundaries, and economic rating by key performance indicators are combined to a powerful tool for downstream process design. The tool was tested for the separation of progesterone from a fermentation broth. Two suitable solvents, methanol and acetonitrile, were identified. Further experiments can be executed on the same robotic platform to identify optimal operating conditions concerning temperature and solvent-to-feed ratio.

Mareike Schreiber, Manuel Brunert, Gerhard Schembecker

Extraction on a Robotic Platform – Autonomous Solvent Selection under Economic Evaluation Criteria

Chem. Eng. Technol. 2021, 44 (9), 1578–1584.

DOI: 10.1002/ceat.202100171

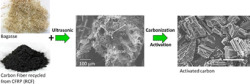

Recycling of Waste Bagasse to Activated Carbon

September 14, 2021

After sugar extraction from sugarcane, a large amount of bagasse remains as waste material. Bagasse is a lignocellulosic biomass composed of cellulose, hemicellulose, and lignin. T. Yamamoto et al. presented an effective recycling method for bagasse and carbon fiber reinforced polymer (CFRP), which is expected to become a major waste material in the near future. They prepared activated carbon using bagasse and carbon fibers recycled from CFRP (RCF), which are shorter than the critical fiber length. The authors used the residue generated during acid saccharification of cellulose as precursor for the production of activated carbon. Hydrolyzation of cellulose using sulfuric acid is essential to develop micropores and, therefore, high specific surface area, when activated carbon is produced from bagasse. Sulfuric acid impregnates the cellulose pores and when bagasse is subjected to high temperatures, the impregnated pores decompose, which results in micropores. By adding RCF, the maximum specific surface area of the prepared activated carbon could be increased by 20 % since RCF have a sufficient amount of functional groups to act as a catalyst for cellulose hydrolysis. This method could also be applied for the production of activated carbon from lignocellulose.

Tetsuya Yamamoto, Yuta Makino, Toshihira Irisawa

Synthesis of Activated Carbon Using Bagasse and Recycled Carbon Fibers

Chem. Eng. Technol. 2021, 44 (9), 1618–1622.

DOI: 10.1002/ceat.202100235