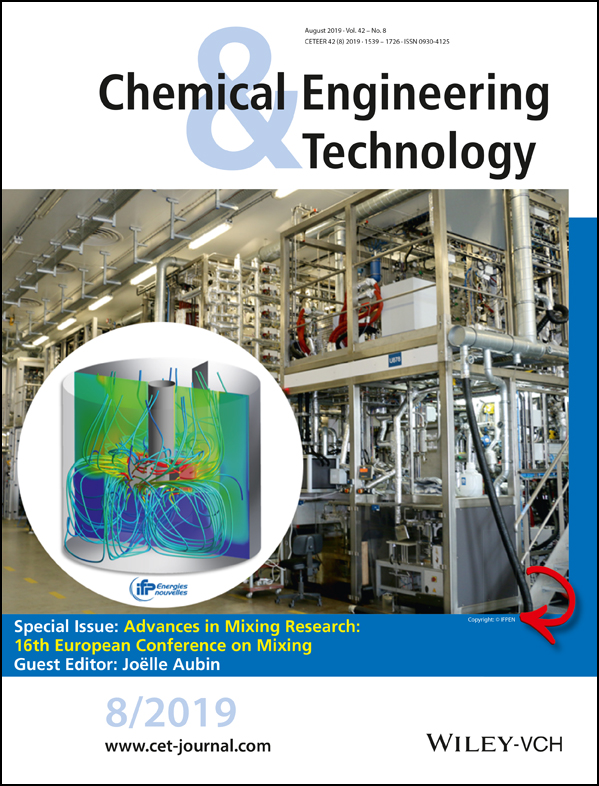

Cover Picture: Chem. Eng. Technol. 8/2019

Graphical Abstract

Novel pilot plant for the screening of shaped catalysts located at IFPEN Lyon, with components designed by Computational Fluids Dynamics tools. Copyright: @IFPEN

Advanced computational tools, such as computational fluid dynamics (CFD) codes, are being increasingly adopted by engineers for the design, scale-up, and intensification of industrial equipment. Nonetheless, the characterization of interphase gas-liquid mass transfer in stirred equipment can still be a challenging task, this being particularly true for small-scale equipment. In the presented work, a multiphase CFD methodology has been developed and proposed for the estimation mass transfer rates in a bench-scale reactor equipped with a self-inducing impeller. The importance of estimating an apparent drag coefficient that considers the effect of mechanically generated free-stream turbulence on the gas bubbles rising velocity is also shown in this work. The spatial distribution of values in the agitated vessel has been obtained from the CFD results using Danckwert's surface renewal model. The proposed model shows good agreement with experimental data.