Journal list menu

Export Citations

Download PDFs

Cover Image

Cover Image, Volume 137, Issue 12

- First Published: 17 December 2019

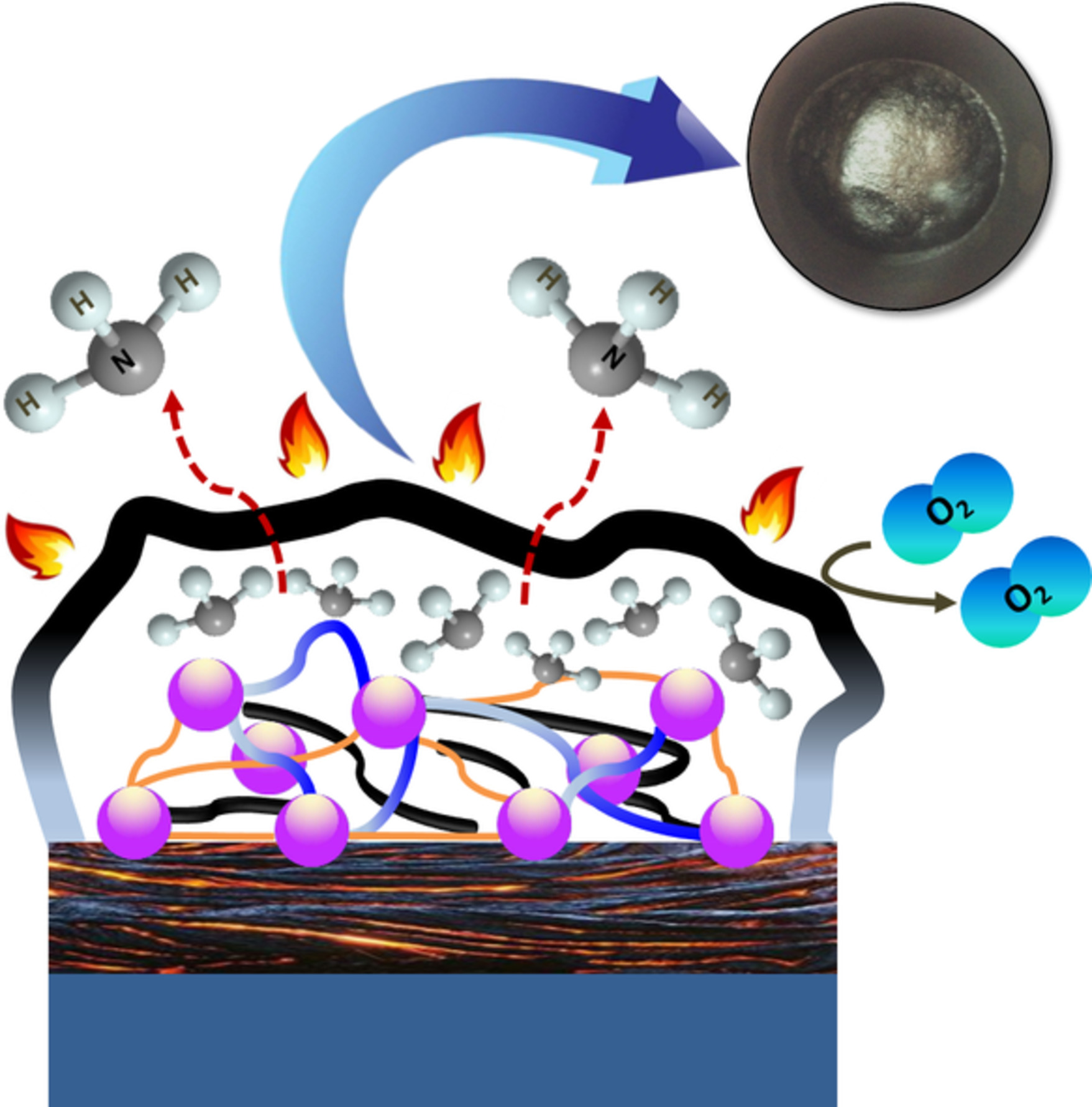

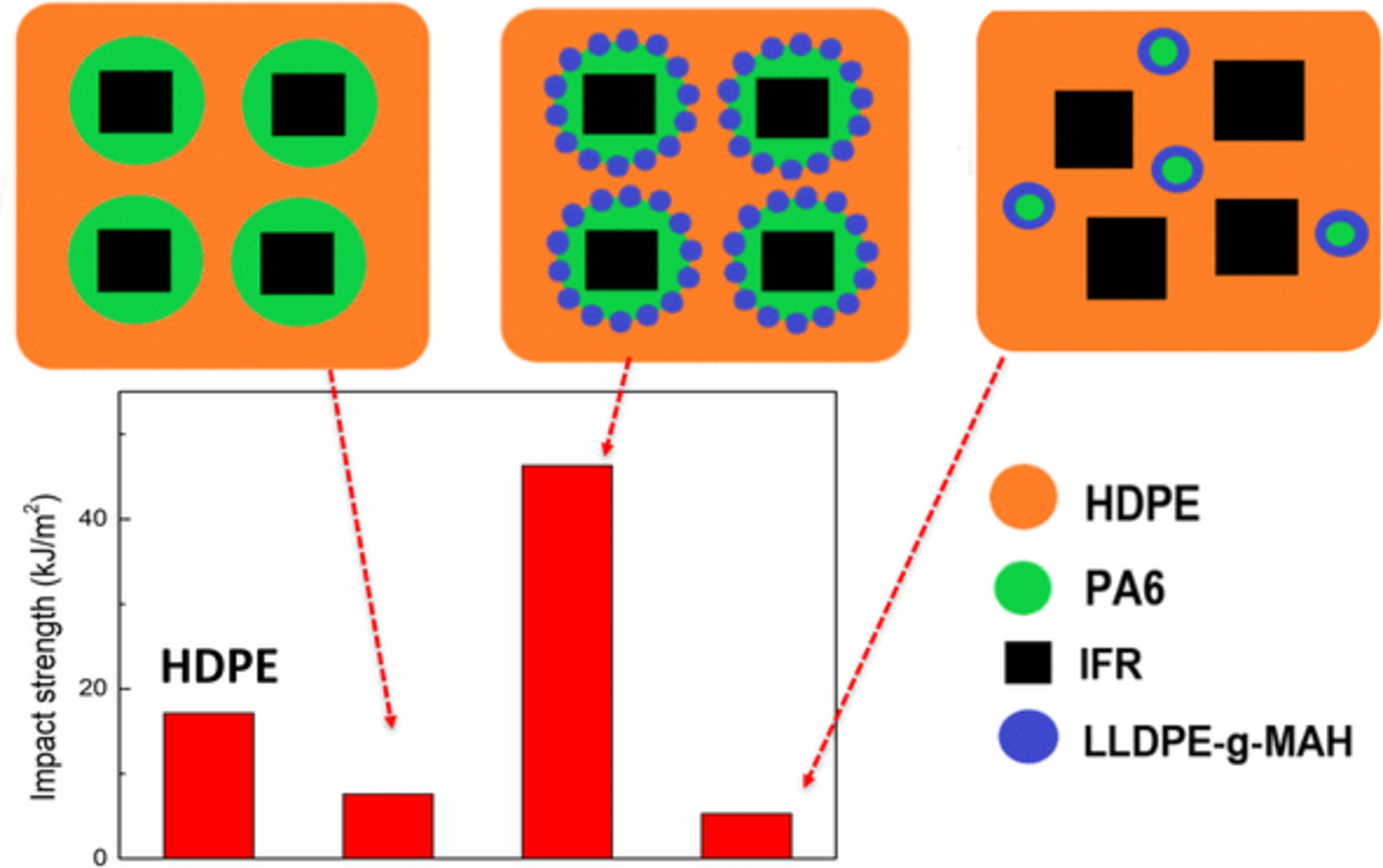

Elastomer always exhibited poor efficiency for toughening flame-retardant polymer. In intumescent flame-retardant HDPE, a novel multi-steps processing method was employed by Chang Lu and colleagues, to fabricate a partial wetting structure in which LLDPE-g-MAH phase with the sphere was dispersed at the interface. The partial wetting structure caused a remarkable improvement of the toughness of flame-retardant HDPE with 2 wt% LLDPE-g-MAH. Its elongation at break and notched impact strength were 43% and 270% higher, respectively, than that of neat HDPE. The unique interface failure mode should be responsible for the high impact strength. DOI: 10.1002/app.48735

Issue Information

Review

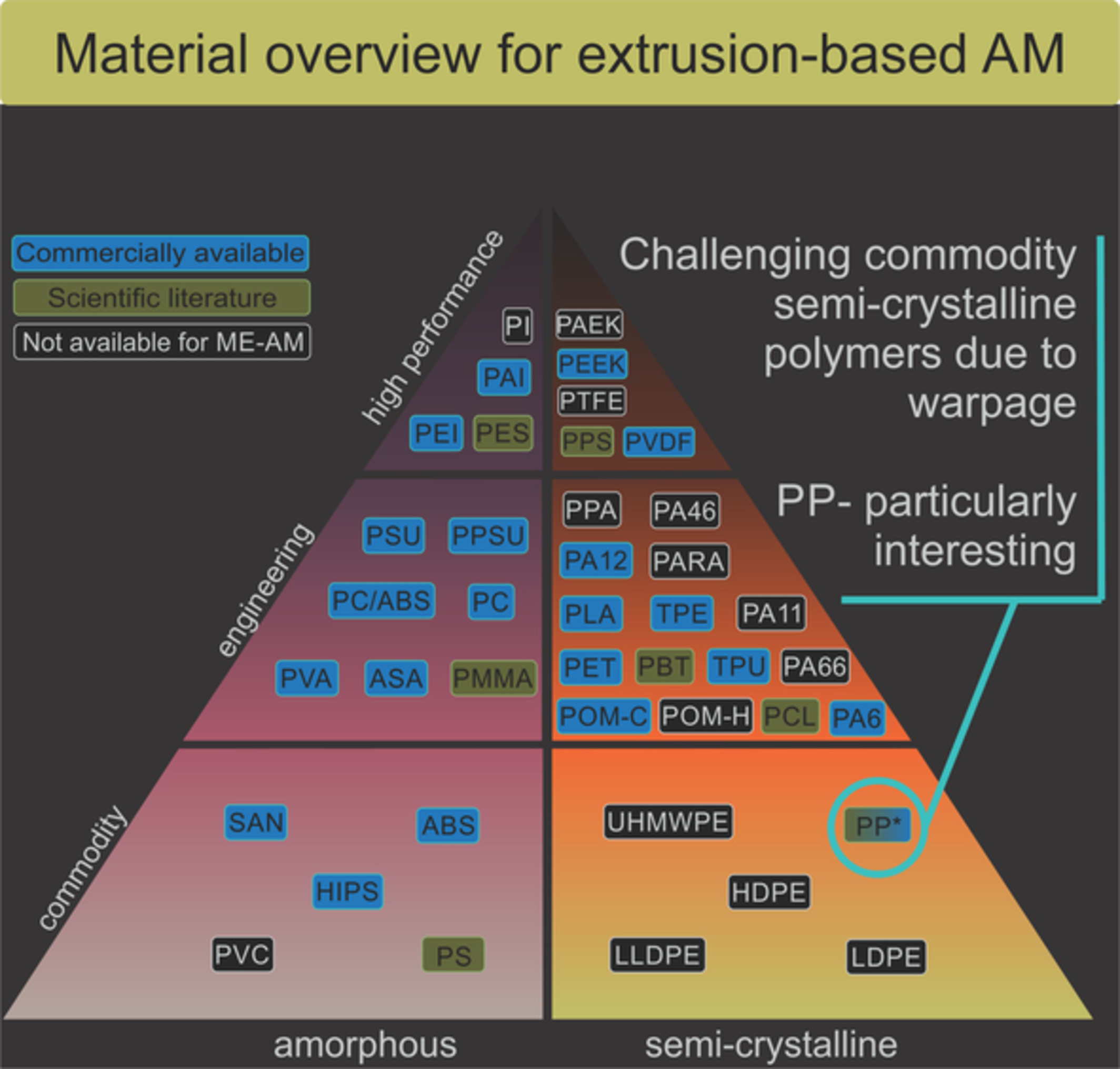

Material extrusion-based additive manufacturing of polypropylene: A review on how to improve dimensional inaccuracy and warpage

- First Published: 15 October 2019

Articles

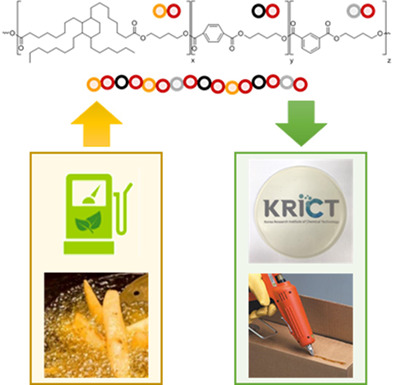

Polybutylene terephthalate modified with dimer acid methyl ester derived from fatty acid methyl esters and its use as a hot-melt adhesive

- First Published: 05 September 2019

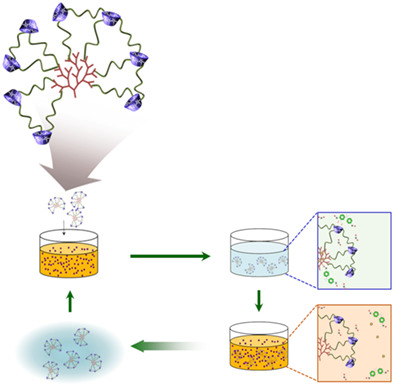

Branched polyethylenimine-polyethylene glycol-β-cyclodextrin polymers for efficient removal of bisphenol A and copper from wastewater

- First Published: 11 September 2019

Composite mixed matrix membranes incorporating microporous carbon molecular sieve as filler in polyethersulfone for CO2/CH4 separation

- First Published: 11 September 2019

Immobilization of polyvinyl alcohol-siloxane on the oxygen plasma-modified polyurethane-carbon nanotube composite matrix

- First Published: 10 September 2019

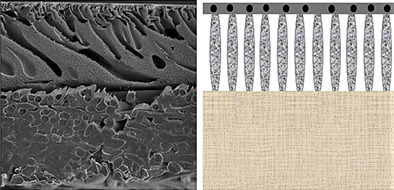

Electrospun polyurethane-carbon nanotube composite scaffolds were modified using oxygen plasma generator. Then, polyvinyl alcohol and polyvinyl alcohol-siloxan were immobilized on the modified surface of fibers in order to improvement of water-fiber interactions, biomineralization potential, cellular adhesion and proliferation, and osteogenic expression for efficient bone reconstruction.

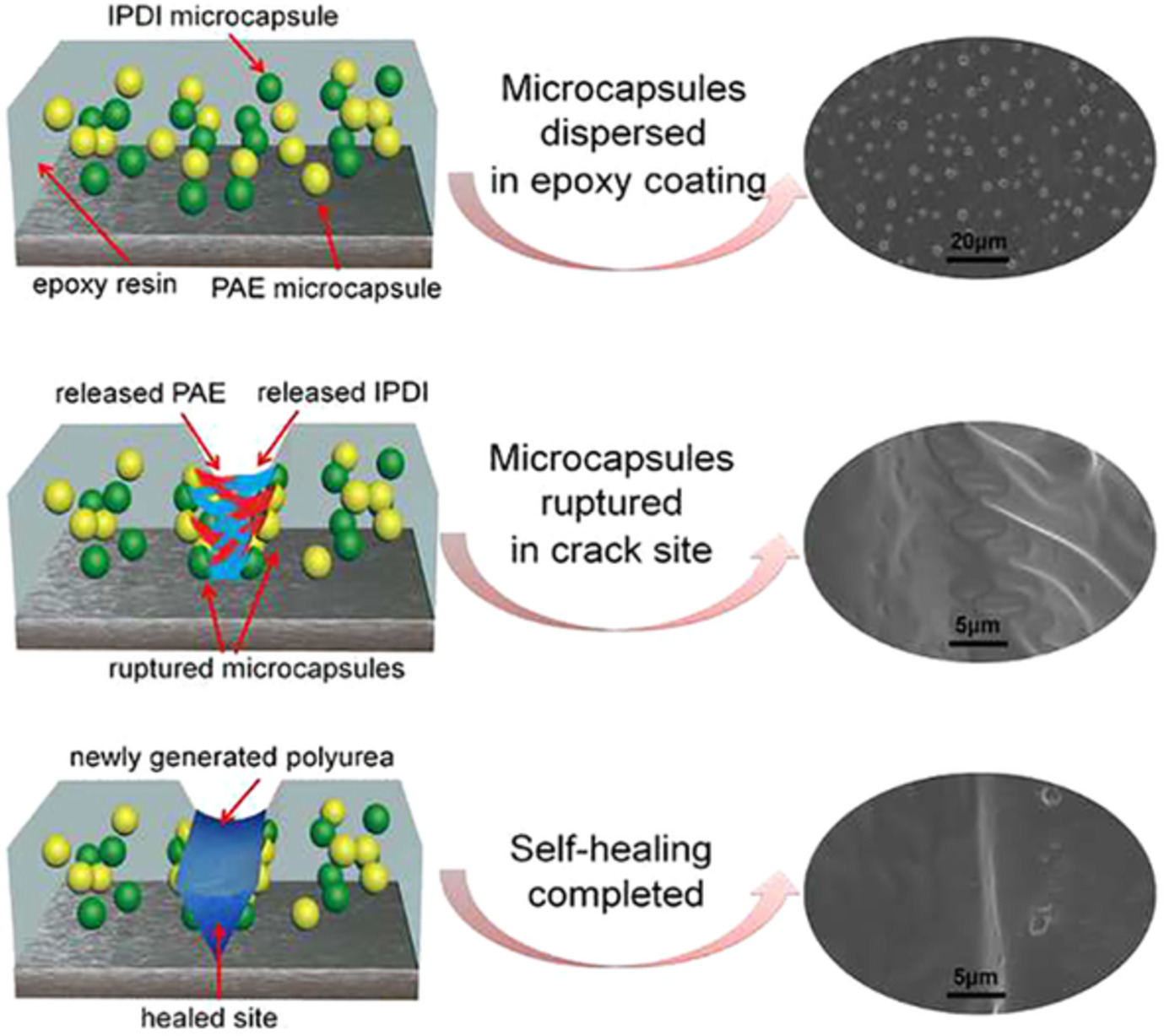

Microencapsulation of oil soluble polyaspartic acid ester and isophorone diisocyanate and their application in self-healing anticorrosive epoxy resin

- First Published: 10 September 2019

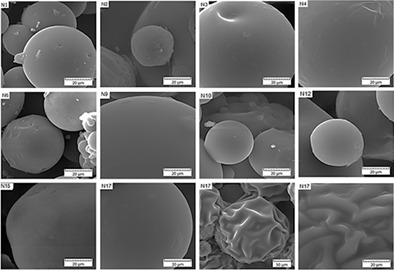

In this study, IPDI and PAE are microencapsulated, respectively, to realize self-healing in epoxy matrix. First, IPDI microcapsules with different core/shell ratios, emulsifier dosages, and emulsification rates are prepared. Besides, during the microencapsulation of PAE, urea, tung oil, as well as aqueous isocyanate are proposed to improve the emulsion stability. Further, IPDI-PAE dual microcapsules are incorporated into epoxy coatings, and the self-healing and anti-corrosion performance are investigated systematically.

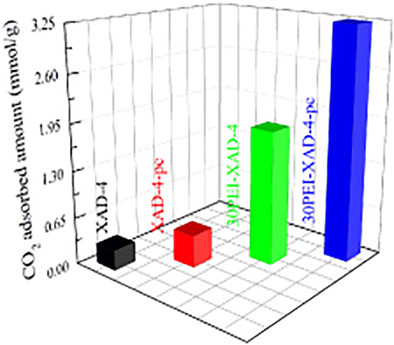

Adsorption behavior and kinetics of CO2 on amine-functionalized hyper-crosslinked polymer

- First Published: 11 September 2019

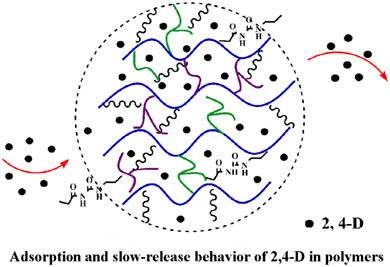

Amphoteric superabsorbent polymer based on waste collagen as loading media and safer release systems for herbicide 2, 4-D

- First Published: 30 September 2019

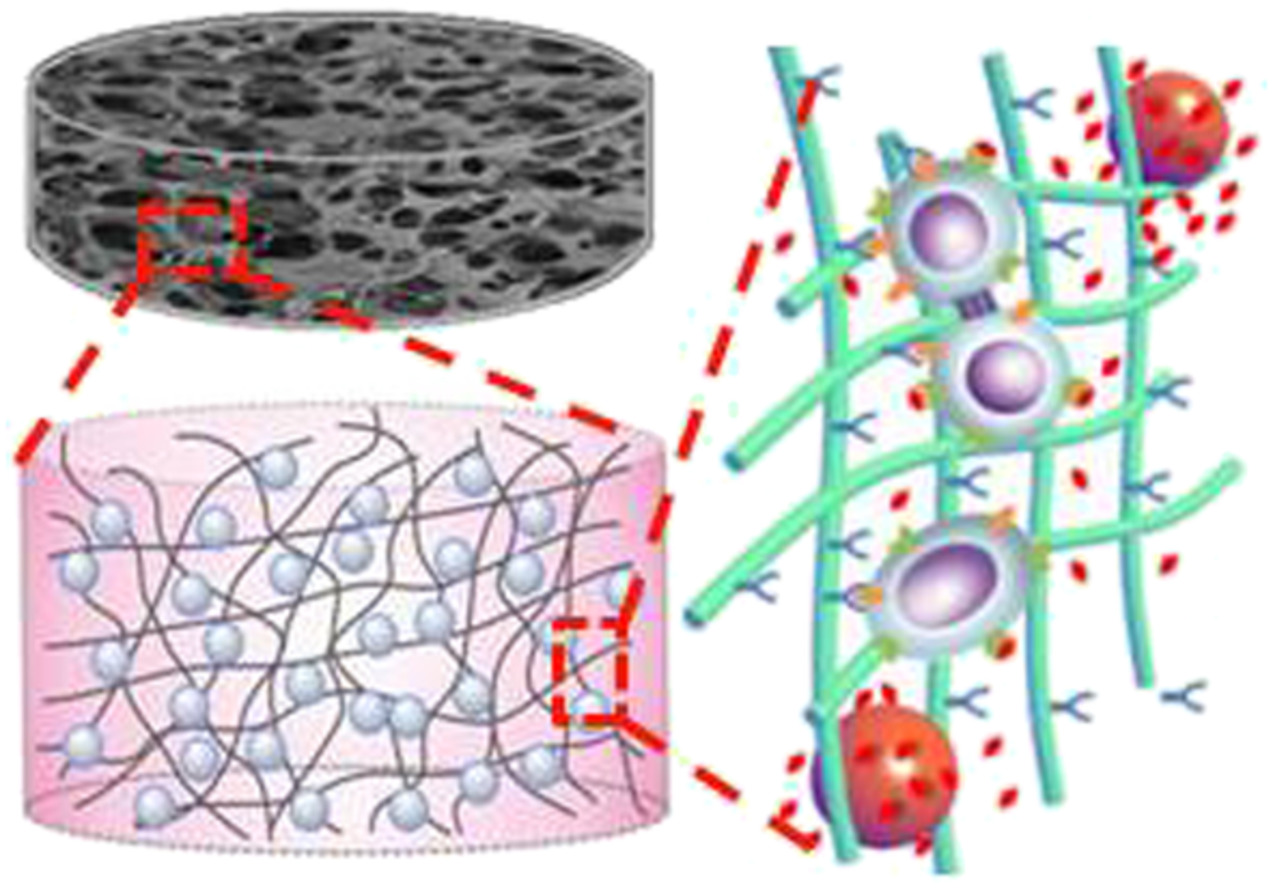

Synthesis and characterization of cellulose nanowhisker-reinforced-poly(ε-caprolactone) scaffold for tissue-engineering applications

- First Published: 12 September 2019

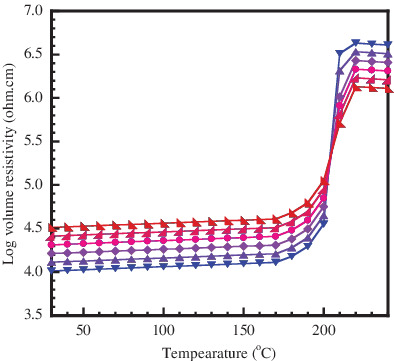

Improvement of polyimide/polysulfone composites filled with conductive carbon black as positive temperature coefficient materials

- First Published: 12 September 2019

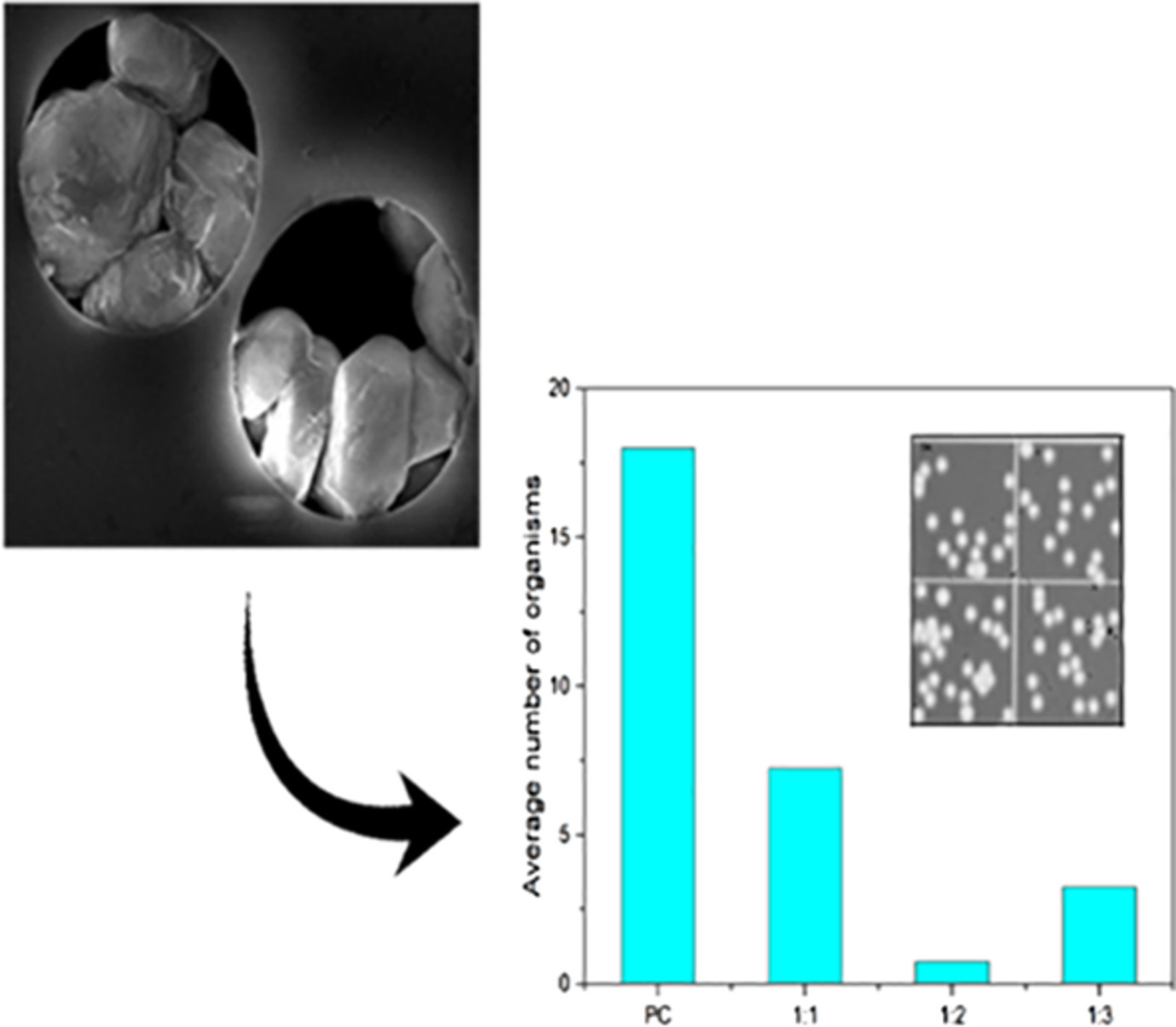

Saccharomyces cerevisae microfiltration performance of polycarbonate membranes containing chitosan-based polyelectrolyte complexes

- First Published: 30 September 2019

Green facile fabrication of polyimide by microwave-assisted hydrothermal method and its decomposition dynamics

- First Published: 30 September 2019

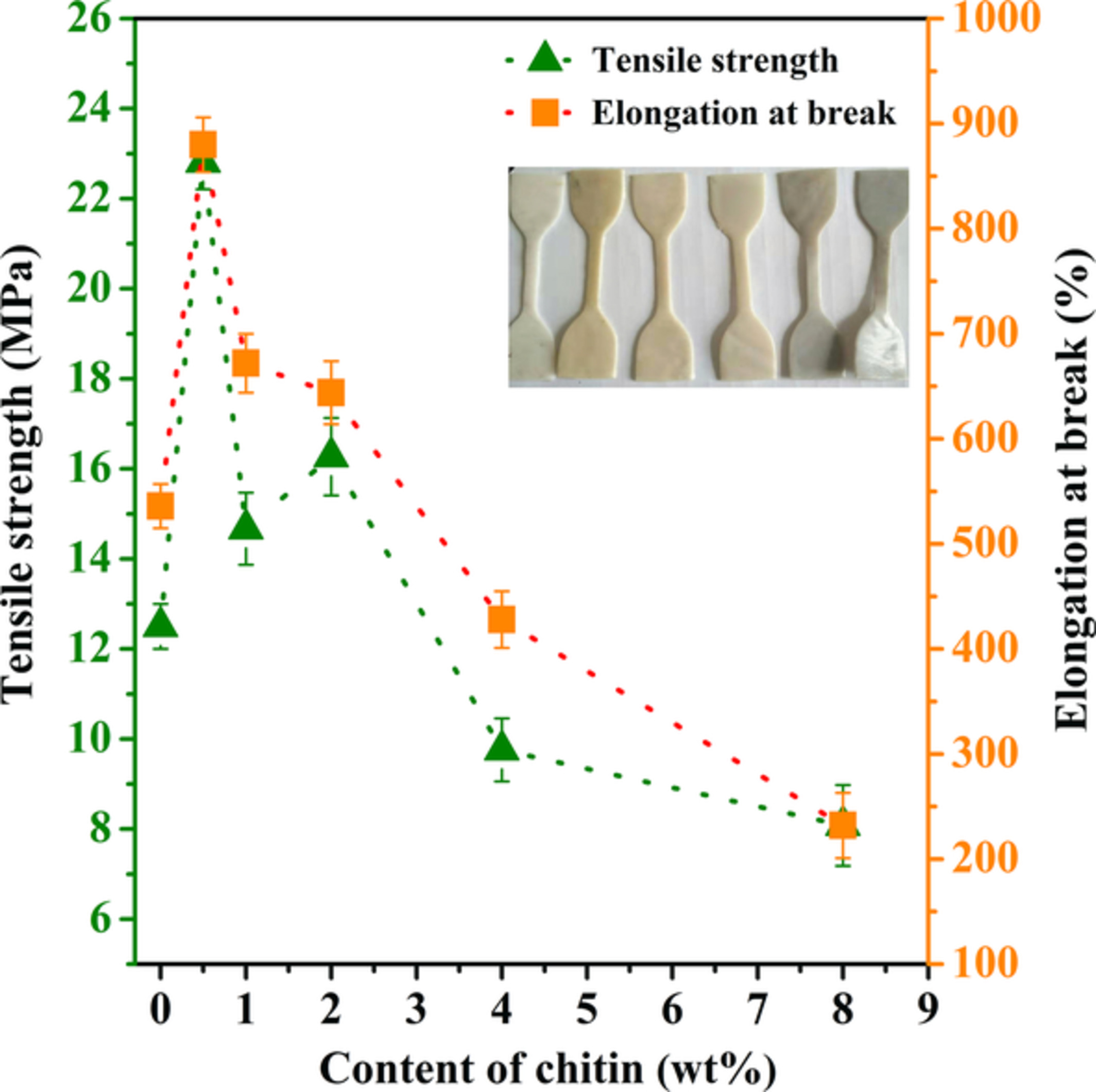

Biodegradable Poly(butylene adipate-co-terephthalate) composites reinforced with bio-based nanochitin: Preparation, enhanced mechanical and thermal properties

- First Published: 30 September 2019

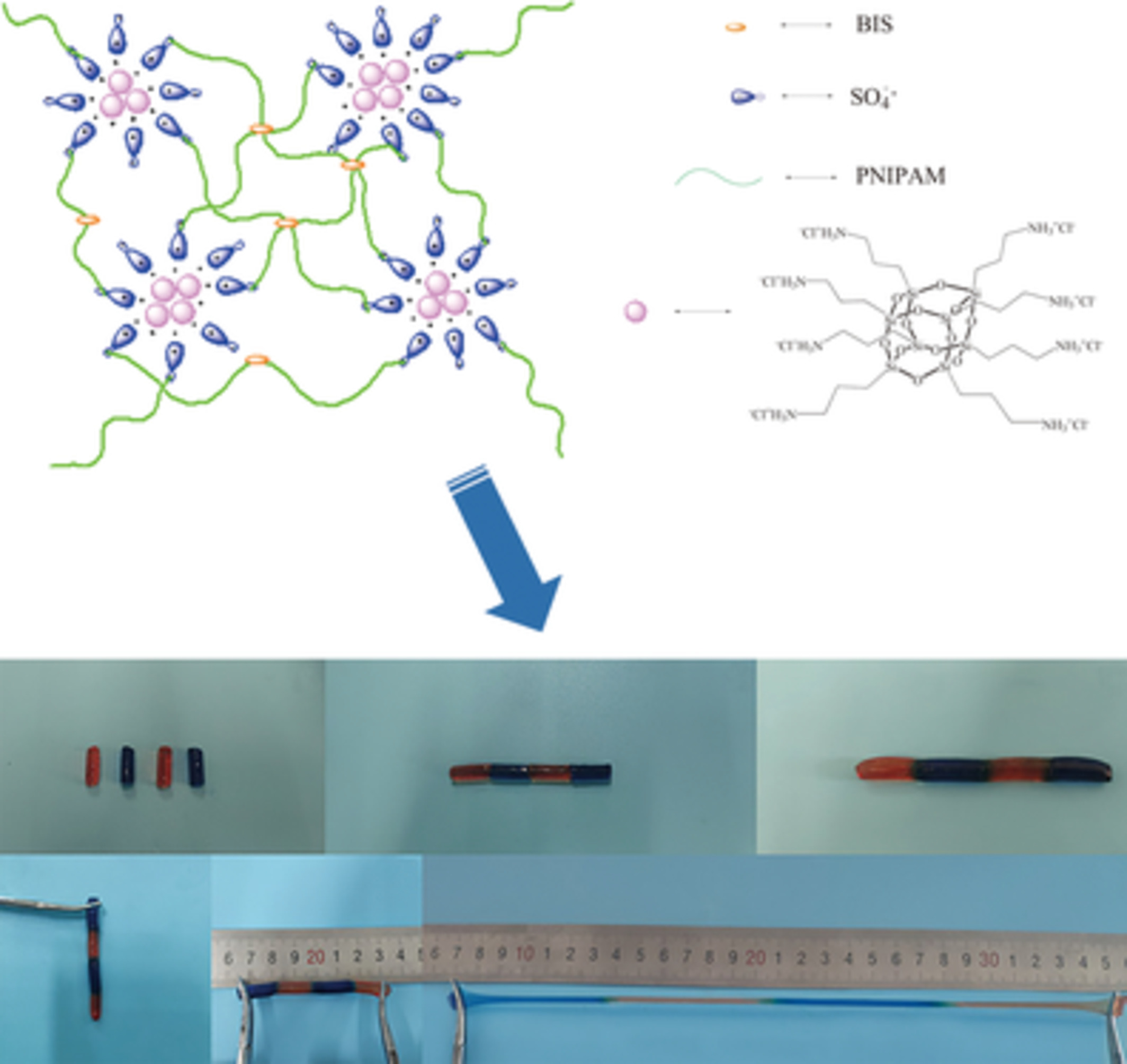

Enhanced mechanical properties and self-healing behavior of PNIPAM nanocomposite hydrogel by using POSS as a physical crosslinker

- First Published: 12 September 2019

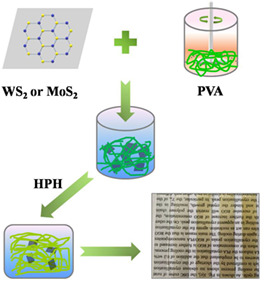

Preparation of polyvinyl alcohol/two-dimensional transition metal dichalcogenides composites by high-pressure homogenization

- First Published: 10 September 2019

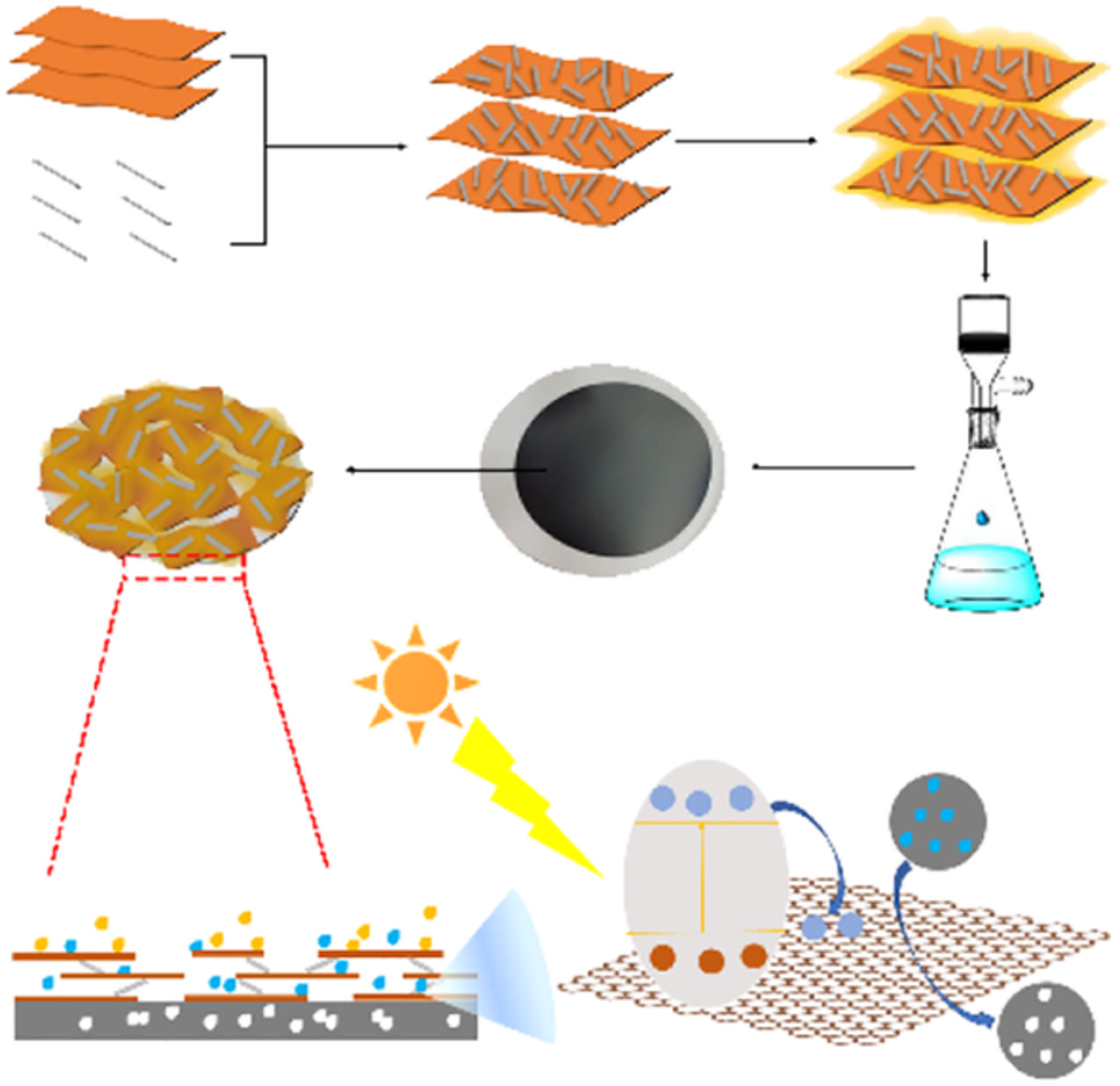

High-performance composite photocatalytic membrane based on titanium dioxide nanowire/graphene oxide for water treatment

- First Published: 30 September 2019

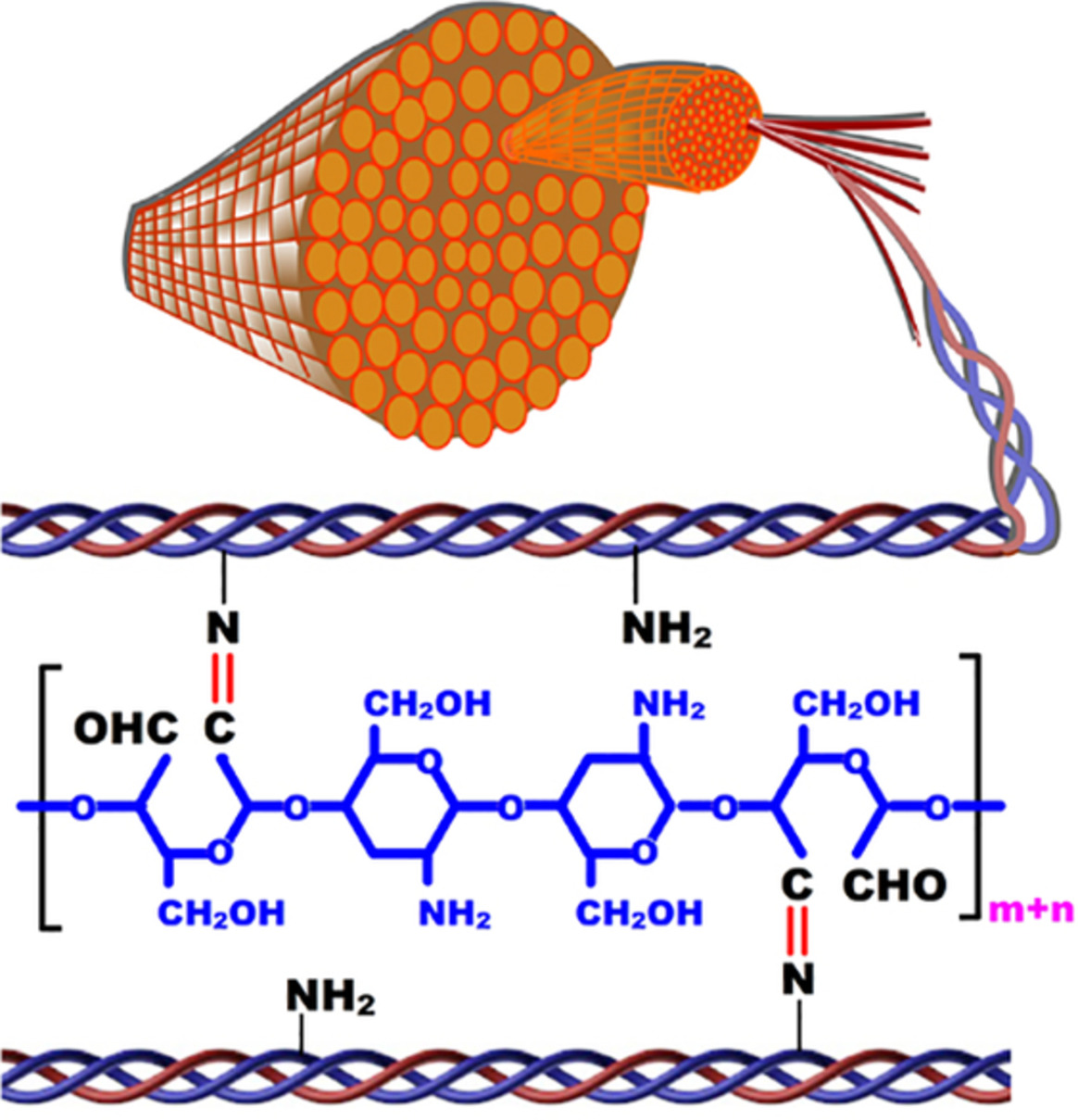

Insights into the interactions between collagen and a naturally derived crosslinker, oxidized chitosan oligosaccharide

- First Published: 13 September 2019

Influence of modified fiber–MHSH hybrids on fire hazards, combustion dynamics, and mechanical properties of flame-retarded poly(butylene succinate) composites

- First Published: 30 September 2019

Synthesis and characterization of pH-sensitive poly(acrylamide-co-methylenebisacrylamide-co-acrylic acid) hydrogel microspheres containing silica nanoparticles: Application in enhanced oil recovery processes

- First Published: 30 September 2019

Fabricating a partial wetting structure for improving the toughness of intumescent flame-retardant HDPE

- First Published: 21 November 2019