Material extrusion-based additive manufacturing of polypropylene: A review on how to improve dimensional inaccuracy and warpage

ABSTRACT

Material extrusion-based additive manufacturing (ME-AM) is an emerging processing technique that is characterized by the selective deposition of thermoplastic filaments in a layer-by-layer manner based on digital part models. Recently, it has attracted considerable attention, as this technique offers manifold benefits over conventional manufacturing technologies. However, to meet the challenges of complex industrial applications, certain shortcomings of ME-AM still need to be overcome. A case in point is the limited amount of semicrystalline thermoplastics, which are still not established as reliable, commercial filament materials. Particularly, polypropylene (PP) offers attractive properties that are unique among the ME-AM material portfolio. This review describes the current approaches of fabricating PP components by ME-AM. Both commercial and scientific strategies to make PP 3D-printable are elaborated and compared. As dimensional issues are especially problematic for PP, a comprehensive section of this review focuses on the strategies developed for mitigating warpage for PP parts fabricated by ME-AM. © 2019 The Authors. Journal of Applied Polymer Science published by Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2020, 137, 48545.

INTRODUCTION

Polypropylene (PP) is a thermoplastic derived from propene, which is a relatively inexpensive by-product of the oil refining process. Besides being inexpensive, PP is a very versatile thermoplastic with numerous applications due to its good mechanical and biological properties, chemical resistance, and inertness. These properties make PP a good candidate to fabricate products by additive manufacturing (AM) techniques, such as material extrusion-based AM (ME-AM) and powder bed fusion.1 However, due to the semicrystalline nature of PP, it is not so easy to obtain specimens with excellent geometrical accuracy, as the fabricated components tend to shrink and warp during the AM process. Many research teams throughout the world have been studying ways to improve the processability of PP for AM techniques, in particular for ME-AM. In this review article, the authors summarize the findings of these research groups on how to prevent warpage of PP specimens by adapting the ME-AM processing parameters, copolymerizing, blending, and adding fillers to PP polymers.

- A description of the ME-AM process is given including the requirements for materials and the materials currently available.

- The properties and advantages of using PP in ME-AM are discussed.

- A summary of the properties of filaments sold as PP is given.

- The problems of processing neat PP via ME-AM are described.

- The strategies different research groups have used to prevent warpage of PP during ME-AM are discussed.

- A summary of the actual printing conditions used to process PP in the literature is given.

- The possible applications for parts made out of PP via ME-AM are outlined.

- The conclusions are drawn and an outlook for the future is provided.

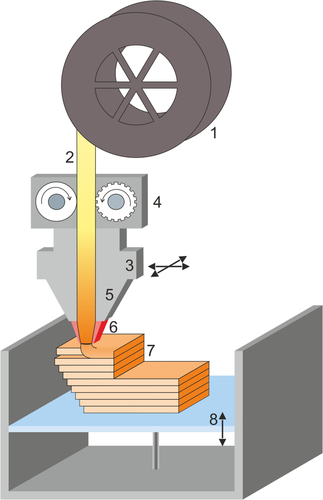

Material Extrusion

Material extrusion, also known as ME-AM, fused filament fabrication, or fused layer modeling is an extrusion-based AM technique that was developed in the late 1980s by Stratasys Inc. under the name fused deposition modeling (FDM™).2, 3 In the course of a state-of-the-art ME-AM process, a solid thermoplastic filament is hauled off into a hot die by two counter-rotating driving wheels (Figure 1). The spooled filaments, typically prepared by extrusion of any thermoplastic polymer, are transported through a moving deposition unit onto a heated build platform, resulting in a layer-by-layer fabrication of the structural element according to CAD-defined layer contours. In order to be extruded through the nozzle, the filament is heated in the liquefier and the nozzle up to a temperature, at which it can easily flow, which is mostly above the melting temperature of semicrystalline thermoplastic filaments. After leaving the nozzle, the extruded material is deposited onto a build platform or a previous layer in the horizontal plane; the deposited melt cools down and resolidifies. Once the selective deposition of one layer is completed, the build platform is lowered by the amount of one layer height in order to print subsequent layers.2-5

Filament Material Requirements

The filament materials used in ME-AM need to fulfill certain requirements in order to be flawlessly processable. The filament needs to be a thermoplastic that can be extruded within a certain diameter and ovality tolerance in order to be three-dimensional (3D) printable at a constant flow rate over time.6, 7 Moreover, the filament needs to be stiff yet flexible enough so that the filament can be spooled during filament production and despooled during printing.8, 9 It has been suggested that the filament should reveal a minimum strain at yield of roughly 5% so that the filament can be continuously spooled and despooled.8 This can be a challenging factor for composites that contain high percentages of fillers. The addition of small amounts of amorphous polymers such as poly(vinyl chloride),10 polycarbonate (PC),11 or amorphous polyolefins8, 12, 13 to PP-based composites can provide a remedy as it increases the yield strain.

For a reliable transport through the drive wheels, the filament needs to retain its shape, withstand frictional forces from the drive wheels, and withstand buckling between the drive wheels and the liquefier. This can only be guaranteed as long as a sufficient strength and stiffness of the filament is given.8, 14 In turn, for multicomponent materials, a strong filler–matrix adhesion is a prerequisite for high filament strength and stiffness. In order for the material to deposit in a controlled manner without dripping, the viscosity of the filament material cannot be too low. Concurrently, if the viscosity is high, the filament needs to reveal an improved strength and stiffness to be able to pass through the nozzle.8 However, high viscosities can be counteracted by increased nozzle temperatures15-17 or by implementing additional hardware like an ultrasonic transducer at the nozzle,18 resulting in an easier dispensability of the melt.14 For composites, although, highly viscous materials tend to agglomerate, which can result in clogged printing nozzles.19 Consequently, a homogeneous filler distribution within the filament is a must for a reliable processability.8

For semicrystalline thermoplastics, filaments with a low degree of crystallinity and a slow crystallization rate are preferred, as the material's tendency to shrink and warp is therefore extensively reduced.20 Simultaneously, the thermal expansion is diminished, resulting in a dimensionally more accurate 3D-printed part.14

Parts produced by ME-AM are built onto a build platform. The adhesion between the first deposited layer and the platform determines the success of the print.21 Therefore, each filament material needs an appropriate build platform. If the adhesion is too weak, the deposited material detaches from the platform.22 As a result, the production of the final part cannot be continued flawlessly. If the adhesion is too good, especially at room temperature, the final product cannot be removed from the platform without damaging the part, the platform, or both.23 In an ideal process, the part is processed at high adhesion between the first layer and the platform, controllable, for example, through the temperature of the build platform, whereas the part removal is conducted at a state of low adhesion.24 The type of platform material and the corresponding process parameters heavily depend on the filament material used.

Materials Used in ME-AM

In contrast to photopolymerization- and powder-based AM techniques, ME-AM allows to use a wide range of thermoplastics that are commercially available in spools, satisfy nearly all the material requirements discussed above, and are moderately priced compared with other AM techniques.4, 25 Until the year 2012, the materials for ME-AM, especially those for low cost 3D printers, were mainly limited to poly(lactic acid) (PLA) and acrylonitrile butadiene styrene (ABS),5 due to their facile processability both in terms of filament extrusion and ME-AM. Up to now, these two materials are still the top sellers among the ME-AM material portfolio5 and are two of the few materials that can be processed nearly without distortions. Recently, the material alternatives have increased considerably,5 leading to a variety of commercially available thermoplastics. Figure 2 summarizes the current availability of the most important polymer types as filaments for ME-AM, in which the information about the commercial availability is based on Refs. 5, 26-30. Many polymer types (displayed in orange in Figure 2) have already been commercialized, as both the industry and researchers have emphasized in widening the material portfolio for ME-AM.31 Apart from PLA and ABS, particularly poly(ethylene terephthalate) and PC can nowadays be already declared as standard ME-AM materials.5 Most of the other materials, even those that are commercially available, though, cannot always be used trouble free, need plenty of hands-on experience and, thus, still need improvements in terms of part processability, stability and accuracy, as has been shown for various investigated filament types.22, 32-36

The evolving growth of scientific studies (displayed in purple in Figure 2) on polystyrene (PS),38 poly(ether sulfone),39 poly(butylene terephthalate),40, 41 and other polyesters,42 as well as poly(ε-caprolactone)43-48 represent the expanding urge of widening the material portfolio. The fact that even niche materials, such as plant-based polymers,49 biopolymers,50 silicone elastomers,51 recycled polymers,52-54 or highly filled polymers for the production of metals/ceramics,55, 56 have been under investigation for the use in ME-AM confirms the desired rapid growth in the process's material variety. Nevertheless, the usability of such novel materials for ME-AM as an everyday usable and reliable material such as PLA or ABS will be determined in the future.

It is derivable from Figure 2 that in particular a large proportion of the amorphous polymers are widely commercialized. Their main success factor in terms of ME-AM is their low coefficient of thermal expansion, which facilitates their processability, especially in terms of shrinkage, warpage, and distortion. However, most of the amorphous filaments reveal low toughness, a small range of service temperature, and a very weak chemical resistance.57 Conversely, Figure 2 presents that only a limited amount of semicrystalline thermoplastics are available for sale or are under scientific investigation. Especially polymers with a high degree of crystallinity (>40%), such as the commodity semicrystalline plastics, namely low-density polyethylene (LDPE), linear LDPE, high-density polyethylene (HDPE), ultrahigh molecular weight polyethylene (UHMWPE), and PP, polyoxymethylene homopolymers, polytetrafluoroethylene (PTFE), or certain polyamide types, appear to be particularly challenging to be processed by means of ME-AM. Although these materials possess outstanding and unique properties,58 their application in ME-AM has not yet been thoroughly studied in the literature.

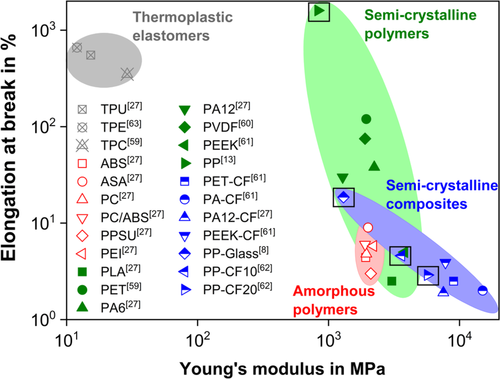

To exemplarily visualize the tremendous potential of the semicrystalline materials, Figure 3 represents the toughness/stiffness balance of different commercially available filament types as well as PP-based 3D-printing materials from literature. Amorphous polymers may be easy to process, but their mechanical properties are restricted to a small toughness (elongation at break between 3 and 9%) and stiffness (Young's modulus between 1900 and 2400 MPa) area. Semicrystalline thermoplastics, though, reveal a much wider toughness and stiffness range. Their Young's modulus can stretch between 800 and 4000 MPa and their elongation at break between 2.5 and 1600%, for example for polyolefins,8, 13 outperforming even the very flexible thermoplastic elastomers that have currently been commercialized for ME-AM. If fillers are introduced into semicrystalline polymers (referred as semicrystalline composites in Figure 3), their stiffness can be enhanced drastically (e.g., up to 15,000 MPa for PA filled with carbon fibers [CF]), surpassing that of the amorphous polymers, whereas their toughness stays in a range comparable to that of the amorphous polymers. Hence, semicrystalline polymers, especially when filled, possess great potential in terms of mechanical properties for the use as filaments in extrusion-based AM. In particular, PP reveals outstanding and incommensurable elasticity compared with all other semicrystalline thermoplastics. Therefore, PP-based composites exhibit potential for a very broad range of applications in terms of mechanical performance. If the price of the raw material is taken into consideration, the PP-based composites clearly reveal the most promising properties. Therefore, this material class might be in the focus of future commercializations.

UNIQUE PROPERTIES OF PP FOR ME-AM

PP exhibits a wide range of customizable properties, and it has been studied thoroughly over the last 70 years. During the last decades, it has undergone great growth both in scientific studies, in which PP often has served as the standard thermoplastic to explain novel phenomena, and production and use, as it has the potential to substitute engineering polymers and metals. For the low price of PP (roughly 1.2€/kg64), it provides satisfying mechanical properties, such as a decent tensile strength (25–40 MPa64) and Young's modulus (1300–1800 MPa64), high toughness (elongation at break of >50%64), impact and abrasion resistance, in combination with a low density of approximately 0.9 g·cm−3,64 which makes PP particularly attractive for ME-AM.

As PP is an easily customizable polymer, different approaches exist to improve/alter its mechanical properties. A variation of its chain regularity content and distribution, its tacticity, its orientations, or its average chain length leads to a very broad property portfolio that can be adjusted depending on the prevalent needs. Furthermore, PP is known to be easily modified by the addition of comonomers such as ethylene or octane into the polymer chains or by incorporating additives such as fillers, impact modifiers, fibers, or other polymers.65, 66

Additionally, its nontoxicity, applicability as a biologically inert material and its excellent chemical resistance against various reactants make PP an outstanding material for the ME-AM market, which can only be outreached by far more expensive polymers such as poly(ether ether ketone). Particularly, the outstanding chemical resistance of PP to polar solvents, nonoxidizing acids, aqueous alkalis, and aqueous salt solutions creates novel possibilities for ME-AM, as other commercially available filament types are considerably less resistant to chemicals, which has limited the applicability of parts produced by ME-AM.57, 67

All polyolefins including PP inherently reveal a very low water and moisture absorption. Compared with the standard ME-AM materials PLA and ABS, the water absorption of PP is more than one order of magnitude lower.57 Consequently, vaporized water cannot complicate the printing process, resulting in less voids and a more appealing surface quality.68 Moreover, the low moisture absorption enables the longevity of components in demanding applications in humid surroundings, which would not be feasible for conventional ME-AM materials.69 Finally, the low water absorption of PP saves costs, as no additional drying steps prior to printing are required.57

Having a glass transition temperature of around −15 °C,70 PP provides good thermal stability between 0 and 150 °C. As it is a semicrystalline polymer, its melting point at 165 °C limits its upper service temperature, but it is high in comparison to many other commercially available ME-AM materials. Moreover, the constituent monomers of this nonpolar polymer are readily available, consolidating its position as a leading thermoplastic material also in the future.66, 71, 72

COMMERCIALLY AVAILABLE PP FILAMENTS

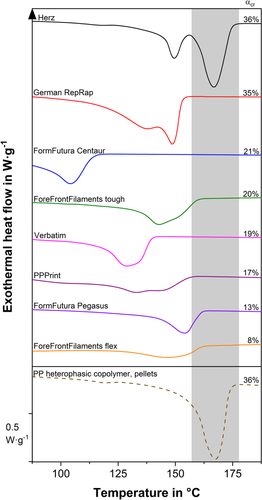

Due to the aforementioned unique properties of PP among the commercially available materials for ME-AM, the ever increasing interest for PP filaments from the industry has been satisfied by many different PP filament producers. As the term PP can be quite variable, Figure 4 compares the differential scanning calorimetry thermographs of all commercially available PP filaments found by the authors. Interestingly, none of the commercially available PP filaments corresponds to pure isotactic PP, which has a characteristic melting peak of the monoclinic α-crystals at ~165 °C (highlighted by the gray area and the example in Figure 4),73 although mainly PP containing largely α-crystals reveal the aforementioned outstanding properties.58 Most of the investigated filaments reveal either small quantities of β-crystal structures or are random PP copolymers. Some available filaments are just sold as PP, although the material does not even contain small quantities of PP (Figure 4).

As can be derived from the PP atypical thermograms, the filament producers obviously make use of the facile modifiability of PP. Accordingly, the degrees of crystallinity (αcr) of most of the investigated PP filaments (Figure 4) are untypically low for industrial grade PP. On the one hand, such low αcr results in rather weak mechanical properties, as only isotactic PP with αcr up to 70% enables the aforementioned exceptional mechanical properties.64 On the other hand, such low αcr can mitigate the main disadvantage of PP: PP is known to be vulnerable to dimensional inaccuracies, especially in the form of warpage due to its high shrinkage coefficient. Therefore, the available materials make a compromise between dimensional accuracy and mechanical performance.

PROCESSING OF NEAT PP BY ME-AM

Apart from studies dealing with PP as a base compound for highly filled systems, in which the polymeric part is burnt away before the sintering step,56, 74-77 only a handful of studies on neat PP have so far been conducted for the use in ME-AM. Next, to PP-based blends used for ME-AM10, 11 and PP blends based on polymeric waste,78-80 Volpato et al.81 used neat PP for one of the first times in an extrusion-based AM approach by feeding the material in the shape of pellets into their self-designed piston-driven 3D printer. As the focus on their research lay on the optimization of the feeding system, the novel material's behavior in the 3D-printing process was not analyzed. One of the first that recognized the significance of PP as a material for ME-AM was Jagenteufel et al.82 The authors compared the standard printing material ABS with PP by means of rheological measurements and die swell experiments on 3D-printer nozzles. It was found that PP could be a promising material for ME-AM, as compared with ABS, PP was more stable over time at elevated temperatures, less prone to oozing and revealed a higher melt stiffness. However, tests on parts produced by ME-AM have not been conducted.

Several individual research groups discovered that the first layer adhesion to the build platform is one of the main process limitations of PP.21, 23 It was found that PP does not adhere to standard ME-AM build platform substrates,83 such as glass mirrors or polyimide tapes,24 mainly due to the material's lack of surface functional groups, low surface energy, and low polarity.84 In order to counteract a possible delamination of the first deposited layer, most researchers recommend to deposit PP-based filaments onto PP substrates.23 However, special care needs to be taken in order not to weld the first deposited layer onto the PP build platform, which can lead to a complete damage of the 3D-printed component during part removal. Strategies to counteract this issue address the choice of build platforms with a slightly different surface energy as well as polarity but similar chemical composition. Recommended platform materials for successful 3D-printing PP include random PP copolymers or UHMWPE.13, 23

In the seminal work of Hertle et al.,85 actual 3D-printed specimens of PP that were produced by means of a special ME-AM technique, in which pellets are used instead of a filament, were investigated. The authors elaborated the influence of different processing conditions (varying extrusion, build platform, and cooling temperatures) on the temperature evolution, the shear stress, and the strand interface morphology and suggested a process window for neat PP. They found that for semicrystalline polymers such as PP, the build platform temperature is limited by the material's crystallization onset temperature, in order to provide dimensional stability of the printed part. To achieve a high interfacial bonding between adjacent strands, the interface between the freshly deposited as well as the previously deposited material, which was controlled by the build platform temperature, should reveal a contact temperature higher than the crystallization onset temperature of PP. If the strands exhibit such high temperatures for a longer period of time, an improved autoadhesion and interdiffusion depths, and therefore a better bonding is realized. For best possible interlayer strengths, the contact temperature should succeed the crystallization temperature up to the melting temperature of PP, in order to enable a short-term melting of the crystalline areas of the adjacent strands. Additionally, low cooling rates were found to be essential for a homogeneous strand morphology, in which weld lines were hardly detectable. The authors additionally expected a lower shrinkage for higher cooling rates. This higher specific volume may lead to a lower stress development at the strand interface, but also to an increased shrinkage after the production of the part, as the polymer chains tend to reach their thermodynamical equilibrium after a certain time.86 However, these hypotheses have not been verified.

Recently, Wang et al.87, 88 adapted the idea of using high build platform temperatures for best mechanical properties from Hertle et al.85 The authors studied the influence of the extrusion temperature and the layer thicknesses on the impact strength of neat PP produced by ME-AM at a platform temperature of 130 °C and compared the results to homogeneous specimens produced by injection molding, similarly to Ref. 57. Elevated extrusion temperatures and small layer thicknesses resulted in smaller air gaps between adjacent strands and a higher part density due to a higher degree of diffusion and a bigger cross flow. Additionally, the authors discovered that the lower extrusion temperature of 200 °C in combination with the rather high platform temperature resulted in a mixture of α- and β-PP, whereas the settings for extrusion temperatures of 250 °C and injection-molded specimens only revealed the crystalline modification of α-PP. Due to the existence of β-PP and more air gaps, the specimens produced at the extrusion temperature of 200 °C led to significantly higher impact strengths than those produced at 250 °C, so that the specimens processed at 200 °C were comparable to those of injection-molded specimens.

Spoerk et al.13 also found small fractions of β-crystal structures among the dominant α-PP when fabricating PP by means of ME-AM in an encapsulated insulated chamber with a chamber temperature (TCh) of 55 °C. Due to the increased TCh, the strand temperatures repeatedly surpassed 100 °C, which triggered the formation of β-PP. Specimens printed at a TCh of 25 °C, however, did not form β-crystals due to the considerably lower strand temperatures. The increase of the TCh of only 30 °C additionally resulted in significant crystallographic changes in terms of spherulite size. The parts printed at the elevated TCh revealed twice as large spherulites as those processed at the lower TCh, as the mean strand temperature during printing is for the high TCh close to the temperature of the maximum crystal growth rate, whereas the nucleation rate is low. Consequently, few nuclei grow to a larger size at the high TCh. Accordingly, such drastic changes in the morphology and crystallography altered the impact properties of 3D-printed PP, increased the yield stress,57 but did not influence the interlayer strength.13

Based on these investigations, the temperature of the strands obviously not only determines the interdiffusion depth and therefore the mechanical performance of printed PP parts but also the growth and nucleation of different crystalline modifications. The studies revealed a fundamental understanding of how complex the behavior of PP in AM technologies can be. Moreover, the studies highlight that only minor changes in the processing settings, for example, an increase in the TCh, can critically alter the morphology of 3D-printed PP, as annealing steps or postcrystallization for PP takes place in the typical temperature range for ME-AM.

THE BIG ISSUE OF WARPAGE FOR 3D-PRINTED PP

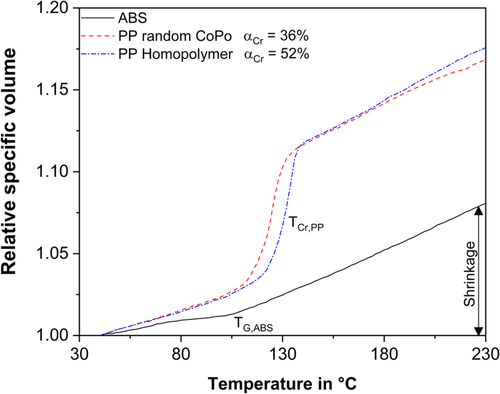

The main disadvantage of using PP in ME-AM is the strong susceptibility of the polymer to shrink and warp extensively. As a polymer melt cools down, the volume of the polymer, both the free volume between the macromolecular chains and their vibrational volume, decreases, as long as the temperature is above the glass transition temperature. This results in material shrinkage. Amorphous polymers such as ABS exhibit a linear weakly developed decrease of specific volume until its glass transition temperature during cooling (Figure 5). Semicrystalline polymers such as PP, however, reveal a drastic change in specific volume in the crystallization region of the polymer chains, as the formed crystal structures are considerably denser than the amorphous structures in the melt state.89 Due to the considerably higher change of specific volume over a certain temperature range compared with the amorphous materials, PP tends to shrink far more than ABS, especially if the αCr is high (Figure 5), for example, for PP homopolymers. When polymeric parts shrink differently or in an anisotropic manner at various positions, for example, due to an inhomogeneous or nonuniform cooling, or due to a different amount of shrinkage in flow and transverse flow direction, which is nearly omnipresent for 3D-printed semicrystalline polymers, the fabricated part is prone to warpage. Thermoplastics that reveal extensive volumetric shrinkage and high degrees of crystallinity are particularly susceptible to warp.86, 90 Especially in the ME-AM process, the combination of the material-dependent shrinkage upon cooling, the anisotropic deposition of the strands,91 the associated introduced polymeric chain orientations,92 and the complex temperature distribution in the AM machine93-97 causes contractile forces within the deposited strands, which result in residual stresses and finally in excessive warpage.57 As the forces induced by warpage counteract the adhesion forces of the first layer to the build platform,24 3D-printed PP components easily detach from such platforms.23 If sufficient first layer adhesion is guaranteed, PP components can nonetheless suffer heavily from warpage occurring after processing due to the tremendous residual stress build up during ME-AM.57

Carneiro et al.21 were the first researchers to address warpage issues during the fabrication of PP parts produced by ME-AM. Apart from an evaluation of the entire production chain starting from the filament and investigations on the effect of printing orientation, infill degree, and layer thickness on tensile properties, the authors argued that changes in the processing conditions can improve the dimensional control in terms of warpage. They found that an improved compatibility between the build platform and the printed part and an optimal printing direction are advantageous for the warpage control of printed parts. Moreover, they incorporated glass fibers to PP and fabricated parts of this compound by means of ME-AM for the first time. Although no influence on the warpage behavior was investigated for the fiber-reinforced PP, it can be expected that due to the fillers' low tendency to shrink, the warpage of the composite was improved compared to the part produced of neat PP as it was later demonstrated by Spoerk et al. with carbon fibers.62 In a nutshell, Carneiro et al.21 laid the cornerstone for further studies on the warpage improvement of PP and displayed two strategies for improving the dimensional inaccuracies of 3D-printed specimens that are analyzed in more detail in the following paragraphs.

Process-Induced Warpage Optimization for 3D-Printed PP

Apart from material alterations, for example, by decreasing the degree of crystallinity by incorporating ethylene monomer segments to PP90, 98 or by blending PP with other thermoplastics,99 changes in the processing can significantly improve the warpage behavior of 3D-printed PP components. Hämäläinen,57 for example, found that the degree of warpage of 3D-printed PP is highly dependent on the geometry of the component that is processed. Dense cylindrical specimens revealed a well-controllable warpage, whereas cubic parts exhibited part distortion especially on the corners. This finding was caused by strong contractile forces originating from the corners of the cubes toward the center of the cube, the lengthwise shrinkage of the ±45° infill, and a higher stress build up. A similar trend for decreased warpage for cylindrical parts was found for hollow specimens. However, both thin-walled parts exhibited considerably poorer dimensional stability than the dense parts. This finding was related to the fast cooling rate of the freshly deposited material in thin walled specimens, which resulted in higher residual stresses and therefore increased warpage compared with the dense specimens.

Watanabe et al.100 recently published a study, in which the warpage of neat PP was investigated both by modeling/simulation of the first two layers of 3D-printed strands and by an experimental parametric study. The authors found that certain changes in processing conditions can have detrimental effects on dimensional distortions. A minimal amount of warpage was achieved by short stacking lengths, lower nozzle temperatures, higher deposition speeds, and increased layer thicknesses, which is also in agreement with warpage studies on PLA.101 All these factors change the temperature distribution within the printed strands. Therefore, factors that induce a small temperature gradient in the produced part result in an improved dimensional control. Fitzharris et al.33 extended these findings by comparing the modeled warpage of PP to that of PPS and by additionally simulating the temperature and residual stress distribution in the strands. According to the authors, the inferiority in terms of warpage of PP over PPS can be explained by the material's higher coefficient of thermal expansion and by the poor adhesion to the investigated build platform, which was also confirmed in the form of the distortion ratio by Duty et al.102 In addition, Watanabe et al.100 simulated the effect of the addition of fillers on the part warpage of the first two layers of 3D-printed parts. The incorporation of the filler resulted in an increase in thermal conductivity and Young's modulus and a decrease in the coefficient of thermal expansion. All these consequences had in turn a positive effect on the simulated part deformation, leading to an improved warpage compared with neat PP.

Apart from studies on PP-based materials, plenty of other processing strategies on improving the warpage of standard ME-AM polymers have been conducted.103 Many other independent researchers agree on the positive effect of a short stacking length and a high amount of layers on the warpage of 3D-printed parts.104-106 However, recently the consequences of the amount of layers on the distortion of parts have been debated. At a first glance, it was expected that lower layer numbers lead to more warpage due to a lower bending stiffness of the component. Armillotta et al.,107 however, revealed in their experimental results that very thin parts distort less than slightly thicker parts due to the thermal conductivity of the deposited material and the permanent deformation of the material under bending stresses. Moreover, another contradicting trend was discovered for the effect of stacking length on the warpage. Kantaros et al.108 experimentally found that residual strains in parts produced by ME-AM are lower for longer stacking lengths than for shorter ones, although it is known that a reduction in residual stresses and strains is essential to decrease warpage in 3D-printed parts.109 Irreversible thermal strain that is formed during the solidification of a strand110 and causes residual stresses was determined to be critically dependent on the printing orientation and the layer thickness.111 Low layer thicknesses result in elevated thermal strains and therefore high residual stresses and warpage,111-113 which is in agreement with simulation results.104-106

Other more elaborated strategies that could be applied to PP components to mitigate warpage deal with geometrical or external processing parameters. A case in point is a change in the slicing strategy, in which the warpage is decreased by reducing the stacking section length by slicing smaller brick structures instead of the whole geometrical feature.114 This strategy, although, can have detrimental effects on the mechanical properties of the printed parts. Another possible solution is to slightly modify the CAD data. One way is to predeform the CAD data, contrary to the expected warpage deviations.115 Another possibility is to adapt the interior design of 3D-printed parts in a way that the interior design shrinks so that the essential outer periphery does not shrink.116

One elegant and practical solution that has been elaborated for amorphous polymers in a mathematical model is to diminish the warpage of 3D-printed parts by rising the surrounding temperature of the deposited strands in the printing chamber (TCh).104 For ABS, the estimated warpage turns almost to zero, as soon as the temperature in the printing chamber equals the glass transition temperature of the filament. Although this theory is not fully applicable to semicrystalline polymers due to their low glass transition temperatures and complex crystallization kinetics, an increased TCh was shown to be beneficial in terms of part distortion for PP produced by ME-AM.13 As the surrounding printing temperature exhibited less temperature fluctuations for higher TCh, the strand temperatures were found to be more homogeneous. Additionally, it was found that the strands at the higher TCh cooled down more slowly compared with the low TCh, resulting in less residual stresses and a lower degree of volumetric shrinkage. The exposure of the components to the high TCh for longer printing times also led to typical annealing consequences, such as promoted stress relaxations and crystallizations. Moreover, the first layer adhesion to the build platform was improved for high TCh,57 leading to less warpage during processing. As a consequence of all these findings, 3D-printed PP fabricated at a TCh of already 55 °C revealed a far better dimensional stability in terms of warpage than specimens processed at room temperature, if sufficient first-layer adhesion was provided.

To sum up, changes in processing conditions clearly have the potential to improve the dimensional stability of parts produced by ME-AM. However, parameters that traditionally have been elaborated and declared as effective can be used as guidelines for a warpage reduction but cannot be universally suggested for all geometries and parts. For instance, if the geometry of the desired part is fixed, which is the case in most of the industrial parts such as spare parts, a change in stacking lengths or part thickness is not an option. Furthermore, high layer thicknesses may decrease the warpage effectively but also completely deteriorate the mechanical and surface properties of the produced specimen.16 Hence, recent strategies that diminish the residual stresses or homogenize the temperatures within the part, for example, an increase in the TCh, appear more appealing. All in all, the most effective warpage control is expected to be achieved by such processing adaptions in combination with a modified build material that is optimized for a minimal degree of warpage, such as by the inclusion of fillers.

Fillers Preventing Warpage for 3D-Printed PP

Within the last years, a myriad of studies on the incorporation of various fillers into thermoplastics for extrusion-based AM have been conducted.117-119 Various fillers, such as cellulose nanofibrils,98, 120, 121 thermotropic liquid crystalline fibrils,122, 123 bamboo fibers,124 hemp and harakeke fibers,125 short glass fibers,126 ash,87 and mineral fibers127 have been incorporated into 3D-printed PP to improve the material's mechanical, rheological, or thermal properties. However, only a handful of studies have focused on the warpage prevention by incorporating fillers into PP filaments.

Wang et al.20 did a prestudy on the warpage behavior of PP compounds, in which the complex crystallization behavior of PP was assumed to be responsible for the warpage susceptibility. The authors claimed that mainly the crystallization rate determines the degree of shrinkage and warpage of 3D-printed PP. According to the authors, PLA is much less prone to warpage and therefore easier to 3D print, as the crystallization rate is nine times lower than that of PP. By adding 10 wt % spray-dried cellulose nanofibrils and a compatibilizer to PP, a slightly lower crystallization rate compared with PP was realized. Simultaneously, the coefficient of expansion was decreased by 11.7%, which in turn reduced the shrinkage tendency. Although the real warpage of 3D-printed specimens was not analyzed by the authors and it is influenced by far more factors than discussed by Wang et al.,20 a trend toward a reduced part warpage due to the decreased crystallization rate and coefficient of expansion can be expected.

Stoof et al.128 and Pickering et al.129 showed for the three fillers harakeke, hemp fibers, and recycled gypsum that were incorporated into preconsumer recycled PP a clear warpage improvement on specially designed 3D-printed specimens. A trend toward decreasing warpage was found for increasing filler contents. The filler harakeke exhibited the most effective warpage reduction. As soon as the fillers were agglomerating (e.g., gypsum), the warpage reduction as well as the mechanical property improvement were not as effective as for the evenly distributed fillers harakeke and hemp. A similar trend was also found for PP filled with glass spheres and cellulose, respectively.8, 130 The filaments of both materials were only processable by ME-AM and only revealed an effective warpage reduction, when a compatibilizer and filler coating were applied to guarantee a homogeneous filler distribution and a strong filler–matrix interface.

Spoerk et al.12 analyzed the shrinkage and warpage behavior of 3D-printed PP parts filled with expanded perlite spheres as a function of the mean filler diameter and the filler load. As the inorganic fillers hinder the volumetric change of the polymer chains, the volumetric shrinkage decreased with increasing filler load. The compounds filled with smaller fillers showed a reduced shrinkage compared with those filled with larger fillers due to the larger interfacial surface area between the fillers and the matrix. As the particles were evenly distributed in the matrix and exhibited a good filler–matrix interface, both filled materials were flawlessly printable, despite the high filler load of 30 vol. %. The dimensional accuracy of 3D-printed components was tested by means of optical analysis on specially designed specimens that were particularly prone to warpage. As expected from the distinct difference in volumetric shrinkage, both filled materials revealed an improved warpage behavior. However, the composite filled with the smaller particles was shown to be considerably more dimensionally stable compared with the composite filled with the larger spheres. The same finding was also later confirmed for 3D-printed PP filled with glass spheres with different sizes.13

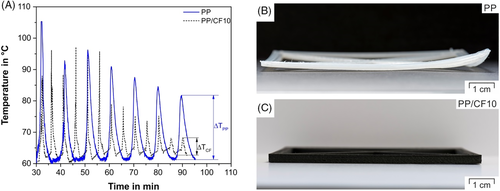

Although an anisotropic behavior in shrinkage and warpage can be expected for fiber-reinforced thermoplastics,131 various studies, both on ABS reinforced with carbon fibers132 and PP filled with high amounts of hemp fibers,128 glass fibers,21 or carbon fibers,62 showed that also high aspect ratio fillers can reduce warp deformations effectively. Especially the most recent study on PP filled with short carbon fibers62 demonstrated an outstanding dimensional accuracy particularly in terms of isotropic warpage on highly complex and large engineering parts despite the highly anisotropic filler. The reason for this rather unexpected finding is twofold. First, the stiff fibers can decrease warp deformations especially in corners of printed specimens, as the fibers can hinder the entropically driven contraction movement of the polymer chains as long as the fibers are stiff enough and are aligned in the printing direction. Second, it can be explained by the high thermal conductivity of the carbon fibers, which in turn augment the overall thermal conductivity of the composite. As a consequence, the rapid temperature fluctuations during printing94 are compensated by the highly conductive filler. This leads to a more homogeneous temperature distribution and therefore in less internal/residual stresses and a decreased warpage. This trend is verified by thermography measurements shown in Figure 6, in which the temperature evolution of one contour strand of a Charpy specimen is recorded for neat PP and a carbon fiber reinforced PP (PP/CF1062) during the fabrication of five Charpy specimens. The printing sequence for PP/CF10 had to be altered compared with that of neat PP (displayed in Ref. 13) in order to guarantee the most promising repeatability and printability. As a result, the temperature evolution of PP/CF10 shows double the amount of temperature peaks that occur when the measurement position is close to the printer nozzle, compared with that of neat PP. Nevertheless, the peak temperatures of the two materials are still comparable.

In spite of some fluctuations at the beginning of the measurement [Figure 6(a)], both materials exhibit a reduction of the maximum of the temperature peaks with increasing printing time due to the insulation of subsequently printed layers between the measurement position and the nozzle. A clear difference between the two materials can be discerned, although. As neat PP behaves like a thermal insulator62 (λaxial, 90° = 0.30 ± 0.01 W m−1 K−1), the amplitude of the peaks reduces slowly over time, which means that the thermal equilibrium is reached very late.133 Hence, after a printing time of more than 90 min, a rather inhomogeneous temperature distribution of the printed part prevails, as still a temperature amplitude ΔTPP of 20 °C is present. On the contrary, the temperature amplitude of the considerably more conductive PP/CF1062 (λaxial, 90° = 0.87 ± 0.02 W m−1 K−1) converges much faster toward a thermal equilibrium than that of neat PP.133 After 90 min of printing, the observed strand in the PP/CF10 Charpy specimen shows a roughly four times lower temperature amplitude (ΔTCF = 5.5 °C) than that of PP. Thus, the higher thermal conductivity induced by the incorporation of carbon fibers leads to a more homogeneous temperature distribution within the fabricated specimens during printing. Consequently, the internal/residual stresses of the material are expected to be reduced, too, which explains the promising dimensional accuracy [Figure 6(c)] compared with neat PP [Figure 6(b)], despite the high aspect ratio of the fillers.

SUMMARY OF THE PROCESS SETTINGS FOR 3D-PRINTING PP

In the previous sections of this review, the general trends observed when different printing parameters are changed have been described and linked to warpage of parts produced by ME-AM. This section is a practical summary of the actual values used during production of parts by ME-AM when using PP-based filaments. The aim of this section is to provide guidelines for printing PP filaments. The values of the processing parameters that have been found in the literature are summarized in Table 1.

| Material | Softening/melting temperature (°C) | Extrusion temperature (°C) | Build platform temperature (°C) | Flow rate (%) | Printing speed (mm/s) | Layer thickness (mm) | Build platform material | ME-AM machine | Fabricated specimens | Reference |

|---|---|---|---|---|---|---|---|---|---|---|

| PP homopolymer | Vicat: 153 (10 N) | 165 | Room | N/A | 8 (first layer), 60 (next layers) | 0.2 and 0.35 | PP scrubbed plate | Prusa i3, Prusa Research s.r.o, Prague, Czech Republic | Single-filament-thick wall box and tensile specimens (DIN 53504-S3a) | 21 |

| PP reinforced with glass fibers | Vicat: 135 (10 N) | 185 | Room on PP plate, 80 on blue tape | N/A | 8 (first layer), 60 (next layers) | 0.2 and 0.35 | PP scrubbed plate or blue tape | Prusa i3, Prusa Research s.r.o., Czech Republic | Single-filament-thick wall box and tensile specimens (DIN 53504-S3a) | 21 |

| PP reinforced with glass spheres | Melting temp.: 166 | 230 | 80 | 60 | 64 | 0.25 | PP plate | Wanhao Duplicator i3 v2, Wanhao | Impact specimens 100% infill (ISO 179-1) | 8 |

| PP reinforced with short carbon fibers | Melting temp.: 166 | 230 | 70 | 150 | 28.3 (first layer), 56.6 (next layers) | 0.25 | PP plate | Wanhao Duplicator i3 v2, Wanhao | Bending/Charpy specimens 100% infill (ISO 178 and ISO 179-1) and different technical parts | 62 |

| PP reinforced with glass spheres of different size | Melting temp.: 166 | 230 | 20 and 70 | 150 | 28.3 (first layer), 56.6 (next layers) | 0.25 | PP plate | Wanhao Duplicator i3 v2, Wanhao | Specimens prone to warpage and impact specimens 100% infill (ISO 179-1) | 13 |

| PP copolymer | Melting temp.: 151 | 200–240 | N/A | N/A | 10, 20, and 30 | 0.1–0.3 | N/A | HYREL System 30, Hyrel 3D | Five-layer specimens 20 mm in length | 100 |

| Isotactic PP with POE-g-MAH | Melting temp.: 165 | 220 | 110 | N/A | 30 | 0.1 | N/A | A8 Quasi-Industrial grade, Shenzhen JG Aurora Technology Co., Ltd., China | Sheet specimens | 99 |

| Isotactic PP with PA6 | Melting temp.: 165 and 220 | 250 | 110 | N/A | 30 | 0.1 | N/A | A8 Quasi-Industrial grade, Shenzhen JG Aurora Technology Co., Ltd., China | Dragon fly with shape memory effects | 99 |

| PP block copolymer reinforced with cellulose nanofibrils | Melting temp.: 159 to 162 | 200 | 120 | 100 | 45 | 0.3 | PP-based packing tape | LulzBot TAZ 6, Aleph Objects Inc. | Specimens for DMA (ASTM D 648) | 98 |

| PP filament Reprap Germany; PP filament from Popbit, China; PP-ethylene random copolymer | N/A | 250 | 120 | N/A | 15 | 0.25 | Epoxide resin plate | A4, 3ntr, Italy | Free-standing square tube (5 cm × 5 cm) with single-filament-thick walls | 90 |

| Isotactic PP | N/A | 240 | 120 | N/A | 15 | 0.25 | Epoxide resin plate | A4, 3ntr, Italy | Free-standing square tube (5 cm × 5 cm) with single-filament-thick walls | 90 |

| PP random copolymer; PP reinforced with perlite, compatibilizer and amorphous polyolefin | N/A | 200 | 25 to 100 | N/A | 50 | 0.1 to 0.3 | UHMWPE | Hage 3DpA2, Hage Sondermaschinenbau GmbH, Austria | Single strands, cylindrical labyrinth; screws and nut; specimen with pyramid and thin walls; and hexagonal cup | 23 |

| PP/PC blend | N/A | 215 | 90 | N/A | 10 to 37 | 0.1 | N/A | N/A | Tensile specimens 100% infill with different strand orientations (ASTM-D638) | 11 |

| PP/PET blend | Melting temp.: 164 and 250 | 260 | 100 | N/A | 20 and 50 | 0.2 | PET tape | LulzBot TAZ 6, Aleph Objects Inc. | Type V tensile bars (ASTM D638) | 80 |

| PP/PS blend | Melting temp.: 161 to 166 | 260 | 100 | N/A | 20 and 50 | 0.2 | Polyetherimide surface | LulzBot TAZ 6, Aleph Objects Inc. | Type V tensile bars (ASTM D638) | 80 |

| PP homopolymer | Melting temp.: 159 | 180, 210 and 230 | 25, 85, and 105 | N/A | 36 | N/A | PP specimen | Screw extruder on a gantry | Test specimen based on DIN EN ISO 3167 | 85 |

| Nucleated PP homopolymer | Melting temp.: 165 | 200 and 250 | 130 | N/A | 45 and 90 | 0.4 | Office packing tape | Makerbot Replicator 2X, Maker-Bot Industries, LLC | Tensile specimens Type I (ASTM D790-10) | 87 |

As can be derived from Table 1, PP-based filaments have been processed in a variety of commercially available ME-AM machines. ME-AM processing parameters for PP-based materials vary significantly, mainly depending on the machine used, material used, and user preferences. For example, the extrusion temperature could be set between 165 and 250 °C; the build platform temperature varies between 25 (room) and 130 °C; the flow rate multiplier could be between 60 and 150%, where higher flow rates can result in parts without air gaps16; the printing speeds reported were set from 8 to 64 mm s−1, where low printing speeds are usually recommended for first layers in order to increase the adhesion between layers and later the printing speed is increased as high as for standard filaments in order to increase productivity; and the layer thickness reported in the literature vary between 0.1 and 0.35 mm, but this depends on the geometry to be produced and the accuracy needed. The printing surfaces used to print PP-based filaments include PP plates or PP tapes, blue tape (tesa 56 250), packing tape (OfficeMax # 24767995), UHMWPE, and epoxide resins, as the use of glass results in poor adhesion.23

POTENTIAL APPLICATIONS FOR 3D-PRINTED PP

Although PP has been reported as difficult to use thermoplastic for ME-AM134 due to the aforementioned warpage issues, 3D-printed PP has been widely used in specific applications such as in applied chemistry. For instance, Gordeev et al.135 investigated the wall permeability of 3D-printed objects with different geometries for chemical reaction vessels. PP tubes processed by ME-AM were found to yield comparable chemical transformation to the traditional glass tubes, even for complex chemical reactions such as the Suzuki–Miyaura or the Heck reaction. Other studies that revealed PP's potential as an engineering material with excellent stability against chemicals include the production of chemical process laboratories136 or chemical reaction vessels, for example, for the synthesis of bicyclic and tetracyclic heterocycles,137 the anti-inflammatory drug ibuprofen,138 or multistep organic syntheses,139 the production of microfluidic devices for the medical and chemical industry,140-142 the fabrication of tailored reactor devices for mass spectrometry,143, 144 or reactionware devices for continuous-flow organic reactions.145 Additionally, various researchers recommended the use of 3D-printed PP for various promising applications, such as for a chemically resistant laboratory equipment for the processing of semiconductors,146, 147 for terahertz devices,134 or for a cheap and light weight alternative for the electrolysis of water.148

Moreover, 3D-printed PP was shown to exhibit the ideal properties for ankle foot orthoses149 or for a cranial bone substitution,150 as it reveals similar strength to bone, is inert, nondegradable, nonmagnetic, and inexpensive. In addition, 3D-printed PP was found to reveal tremendous potential in terms of thermal stability in the course of manifold consecutive extrusions.127 PP-based filaments were the only commercially available filaments that did not suffer from aging mechanisms such as chain scission or crosslinking, but revealed outstanding stability over time. Consequently, both stabilized and unstabilized PP-based composites could be used for up to 15 consecutive filament extrusions and still remained unaltered mechanical properties. The proposed strategy of remanufacturing unsatisfying 3D-printed components could lead the ME-AM technique toward a cleaner production, particularly when using PP as the raw material. All these studies prove the potential of PP as a promising material for ME-AM.

SUMMARY AND OUTLOOK

The ME-AM technology of thermoplastic polymers has received considerable attention over the last decade due to its simple use, low cost, and possibility of generating large parts with rather high throughput. From the many thermoplastic polymers, PP has many attractive properties and low cost, which makes it a very desirable material for the fabrication of unique products with complex geometries via AM, particularly ME-AM. However, processing PP via ME-AM is not so simple due to the semicrystalline nature of PP. Currently, several PP filaments are available on the market that have been chemically modified in order to improve the quality of the products fabricated by ME-AM. In this review, it was observed that none of the commercially available filaments are isotactic PP homopolymers, as such homopolymers have a great tendency to warp during the ME-AM process, leading to specimens with poor geometrical accuracy. Besides the chemical modification of PP by blending with other polymers or by copolymerizing, other strategies to improve the geometrical accuracy of PP specimens include: (1) use of different build platform materials to guarantee ideal adhesion during the printing process; (2) insulate the printing chamber and maintain the chamber temperature relatively high to reduce thermal stresses through a process similar to annealing; and finally (3) the addition of fillers, specially thermally conductive ones in order to prevent shrinkage during the fabrication process and to decrease the time to reach thermal equilibrium in the deposited layers.

- One case in point is investigating the addition of nucleating agents to change the crystallization kinetics during ME-AM of PP parts. The addition of nucleating agents to PP could decrease and homogenize the size of their spherulites. Therefore, the mechanical properties, especially the toughness of the parts, could be maximized.

- More engineering investigations should also be carried out to analyze different methods to locally heat the deposited strands and/or the printing chamber. Infrared or microwave sources and even low power lasers could lead to a maximization of mechanical properties of the weld lines,151, 152 but also can homogenize the temperature distribution within the printed parts to locally prevent part distortion. It would be especially important to understand the consequences of having additional heat sources on the thermal, crystallographic, mechanical, and dimensional properties of fabricated PP components. Independent of the heating method used, an investigation on further increasing the chamber temperature, so that the mean strand temperatures are slightly below the crystallization temperature of PP, could lead to particularly fascinating results, as no distinct fusion zone between the strands is expected to be discerned.85 Consequently, a comparable spherulite size is predicted for both the bulk of the deposited strands and their interfaces, which could reduce the heterogeneousness of the mechanical properties of the produced components.

- Moreover, studies to analyze whether higher amounts of β-PP can be formed by increasing the chamber temperature could additionally maximize the impact toughness while simultaneously mitigating the warpage.

- Finally, in an effort to establish a circular economy, the use of recycled and upcycled PP as a feedstock material for ME-AM should be further investigated, as well as the recycling process of parts produced by ME-AM should continue in order to mitigate the environmental impact of the production of PP components for numerous applications.80

ACKNOWLEDGMENTS

This work was supported by the European Union's Horizon 2020 research and innovation program as part of the INEX-ADAM project (grant agreement 810708) and by the Austrian Research Promotion Agency (FFG) as part of the COMET K-project CAMed (Clinical additive manufacturing for medical applications, grant agreement 871132). Special thanks go to Gerhard Traxler for help with the thermography measurements.

Biographies

Martin Spoerk received his PhD at the Montanuniversitaet Leoben, Austria, and Ghent University, Belgium. His doctoral dissertation dealt with the investigation of how to improve the processability of polymeric materials for material extrusion-based additive manufacturing. He has coauthored 17 peer-reviewed journal papers and works currently as a senior scientist at the Research Center Pharmaceutical Engineering GmbH, Graz, Austria.

Clemens Holzer is a full university professor and head of the Institute of Polymer Processing at the Montanuniversitaet Leoben. He is an expert in polymer processing, rheology, and process and material simulations. His current interests include material development and applications of additive manufacturing with polymers. He is coauthor of 80 peer-reviewed journal papers and 2 book chapters.

Joamin Gonzalez-Gutierrez is a postdoctoral senior researcher at the Institute of Polymer Processing, Montanuniversitaet Leoben. He received his BSc at the University of Manitoba, Canada, his MSc at the Universite catholique de Louvain, Belgium, and his PhD at the University of Ljubljana, Slovenia. His current research interests include the development and characterization of polymer-based materials for extrusion-based additive manufacturing. He has coauthored 25 peer-reviewed journal papers and 5 book chapters.