Microencapsulation of oil soluble polyaspartic acid ester and isophorone diisocyanate and their application in self-healing anticorrosive epoxy resin

ABSTRACT

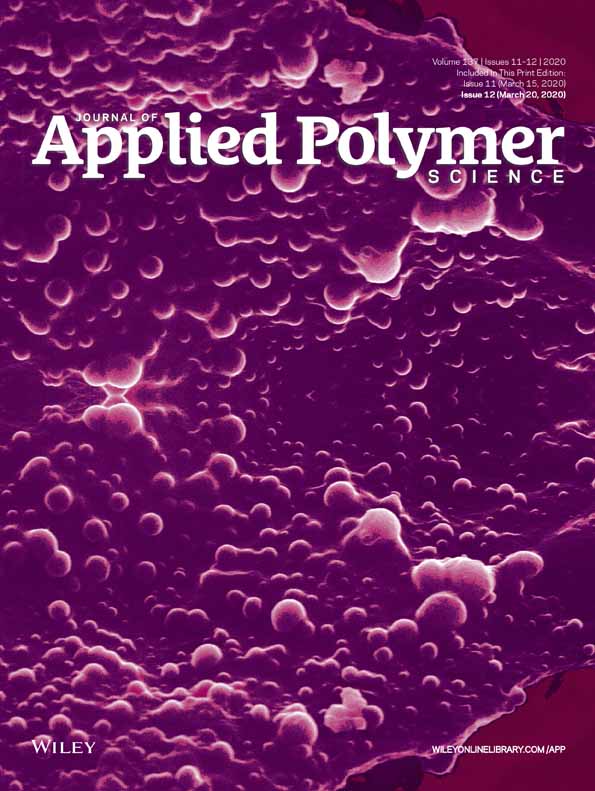

Isocyanate and amine solution are microencapsulated, respectively, via in situ polymerization to realize the self-healing function in epoxy matrix. First, the isophorone diisocyanate (IPDI) microcapsules prepared with different core/shell ratios, emulsifier dosages and emulsification rates are characterized by field emission scanning electron microscope (FE-SEM). They exhibit integral spherical shape when the core/shell ratio is 3:1 and emulsifier concentration is 2.52 wt %, and the diameter of IPDI microcapsules ranged from 2.66 μm to 11.25 μm is manufactured by adjusting emulsification rate over the range of 3000–9000 rpm. Besides, during the microencapsulation of polyaspartic acid ester (PAE), urea, tung oil, as well as aqueous isocyanate are proposed to improve the stability of PAE emulsion. SEM and FTIR results reveal that aqueous isocyanate can react with partial PAE and form polyurea (PU) layer to take protection effectively. Further, IPDI-PAE dual microcapsules are incorporated into epoxy coatings, the self-healing and anticorrosion performance of coatings with various amounts of microcapsules are investigated systematically. It was found that the degree of repair and anticorrosion are increased with increasing microcapsules loading, and the appropriate amount of microcapsules addition is 15 wt %, which corresponding to 93% repair efficiency. © 2019 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2020, 137, 48478.