Journal list menu

Export Citations

Download PDFs

Cover Picture

Macromol. React. Eng. 4/2016

- Page: 303

- First Published: 19 August 2016

Front Cover: The figure shows the flow patterns and conversion achieved in a Couette-Taylor reactor used for the continuous production by inverse microemulsion copoly-merization of high molecular weight polycations, which showed improved flocculation efficiency. Further details can be found in the article by José M. Asua on page 311.

Masthead

Contents

Contents: Macromol. React. Eng. 4/2016

- Pages: 305-307

- First Published: 19 August 2016

Essays

Batch to Conti Transfer of Polymer Production Processes

- Pages: 308-310

- First Published: 22 July 2016

Full Papers

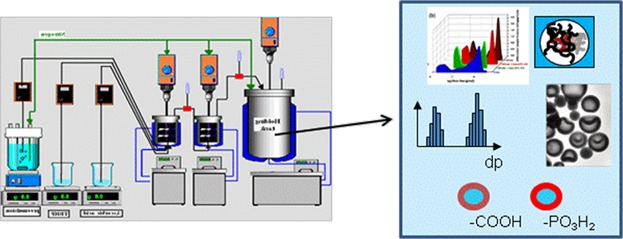

Challenges and Opportunities in Continuous Production of Emulsion Polymers: a Review

- Pages: 311-323

- First Published: 14 July 2015

Profit margin reduction and global competition are pushing emulsion polymer producers to consider process intensification that mainly relies on the replacement of semicontinuous reactors by continuous ones. In this work, the challenges in the continuous production of emulsion polymers are discussed and ways in which the challenges can be transformed in opportunities are reviewed.

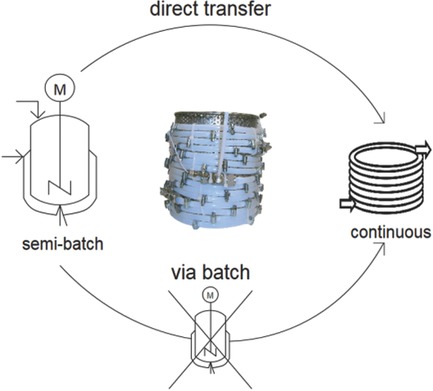

Transfer of Emulsion Polymerization of Styrene and n-Butyl Acrylate from Semi-Batch to a Continuous Tubular Reactor

- Pages: 324-338

- First Published: 29 June 2016

The transfer of a semi-batch emulsion copolymerization (styrene/n-butyl acrylate) to a single feed continuous tubular reactor is investigated. It is shown that a direct transfer is advantageous compared to an intermediate step via a batch reactor in which the specific heat transfer is much more limited than in a tubular reactor.

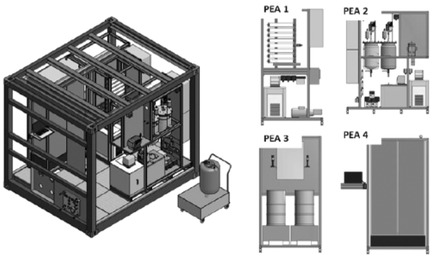

Modular, Flexible, and Continuous Plant for Radical Polymerization in Aqueous Solution

- Pages: 339-353

- First Published: 28 April 2016

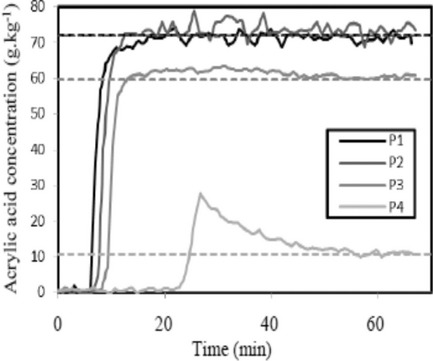

A continuous and flexible pilot-scale plant is designed for the production of acrylic acid homo- and copolymer in aqueous solution. On the basis of previous experimental lab-scale studies the plant is built and equipped with Raman probes for monitoring the consumption of monomers. Demonstration experiments are carried out and results are satisfactorily depicted by theoretical calculations.

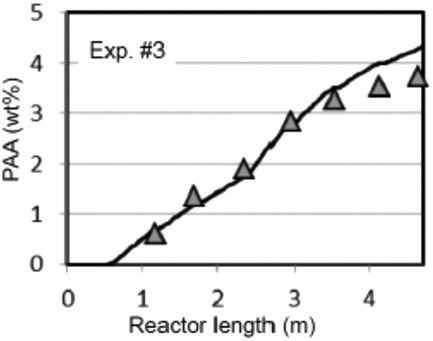

Continuous Pilot-Scale Tubular Reactor for Acrylic Acid Polymerization in Solution Designed Using Lab-Scale Rheo-Raman data

- Pages: 354-363

- First Published: 23 February 2016

A continuous pilot-scale tubular reactor equipped with CSE-X static mixers from Fluitec is designed for polymerization of acrylic acid in aqueous solution. Experimental results are satisfactorily described by the model of perfect plug-flow reactor. This work provides the first demonstration of applicability of CSE-X static mixer elements in a continuous process producing high molar mass water-soluble polymer.

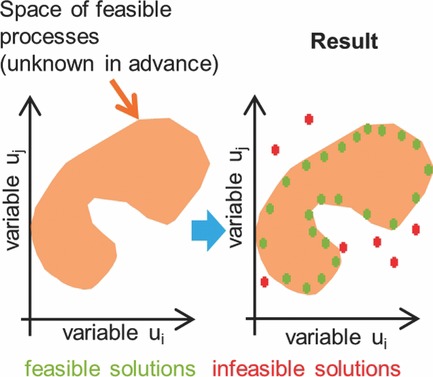

Transfer of Semibatch Processes to Continuous Processes with Side Injections—Opportunities and Limitations

- Pages: 364-388

- First Published: 20 June 2016

On the Modeling of Acrylic Acid Copolymerization in an Aqueous Solution: A Modular, Integrated Approach

- Pages: 389-405

- First Published: 07 March 2016

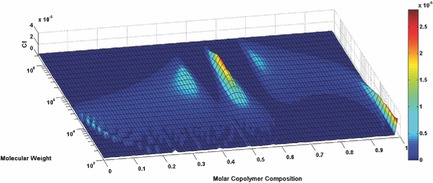

A mechanistic mathematical model of the free-radical copolymerization of acrylic acid in an aqueous solution, taking place in a pilot-scale tubular reactor equipped with static mixers, is presented. A powerful and flexible coupled deterministic/stochastic simulator, combining the advantages of speed, efficiency, and increased predictive capabilities, is developed on the basis of the proposed mathematical model. These advantages are proven through a series of comparisons with experimental measurements, under a wide range of process conditions, as well as through a thorough analysis of the compositional characteristics of the produced copolymer in terms of different bivariate distributed properties.

Application of Raman Spectroscopy to Characterization of Residence Time Distribution and Online Monitoring of a Pilot-Scale Tubular Reactor for Acrylic Acid Solution Polymerization

- Pages: 406-414

- First Published: 04 January 2016

A pilot-scale tubular reactor containing static mixers is equipped with Raman probes for online monitoring of radical copolymerization of acrylic acid in aqueous solution. Using sodium nitrate as a tracer, residence time distribution is established in reactive and nonreactive media with viscosities up to 1 Pa s. Calculations assuming a perfect plug flow are in good agreement with experimental results.

Optimizing Control and State Estimation of a Continuous Polymerization Process in a Tubular Reactor with Multiple Side-Streams

- Pages: 415-434

- First Published: 29 January 2016

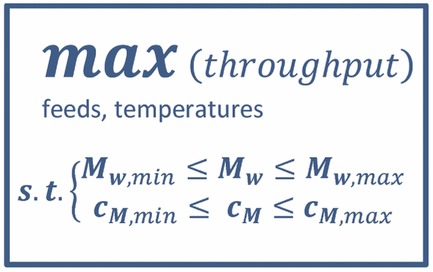

Production of polymers in modular continuous reactors was one of the goals of the European F3-factory project. The control of such plants is not an easy task as the process is described by nonlinear complex partial differential equations and the available measurements are few. In this work, we propose an optimizing control scheme to control such plants and maximize the plant throughput, while the product quality constraints are met.

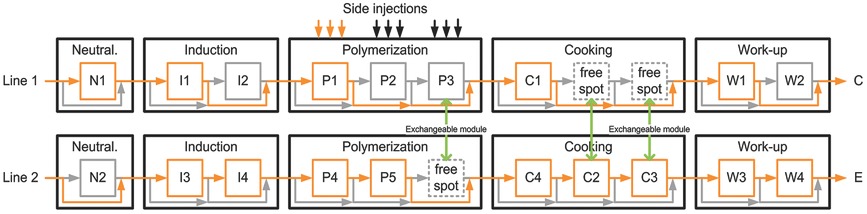

Operation of Flexible Multiproduct Modular Continuous Polymerization Plants

- Pages: 435-457

- First Published: 06 April 2016