Journal list menu

Export Citations

Download PDFs

Cover Picture

Macromol. React. Eng. 5/2016

- Page: 459

- First Published: 12 October 2016

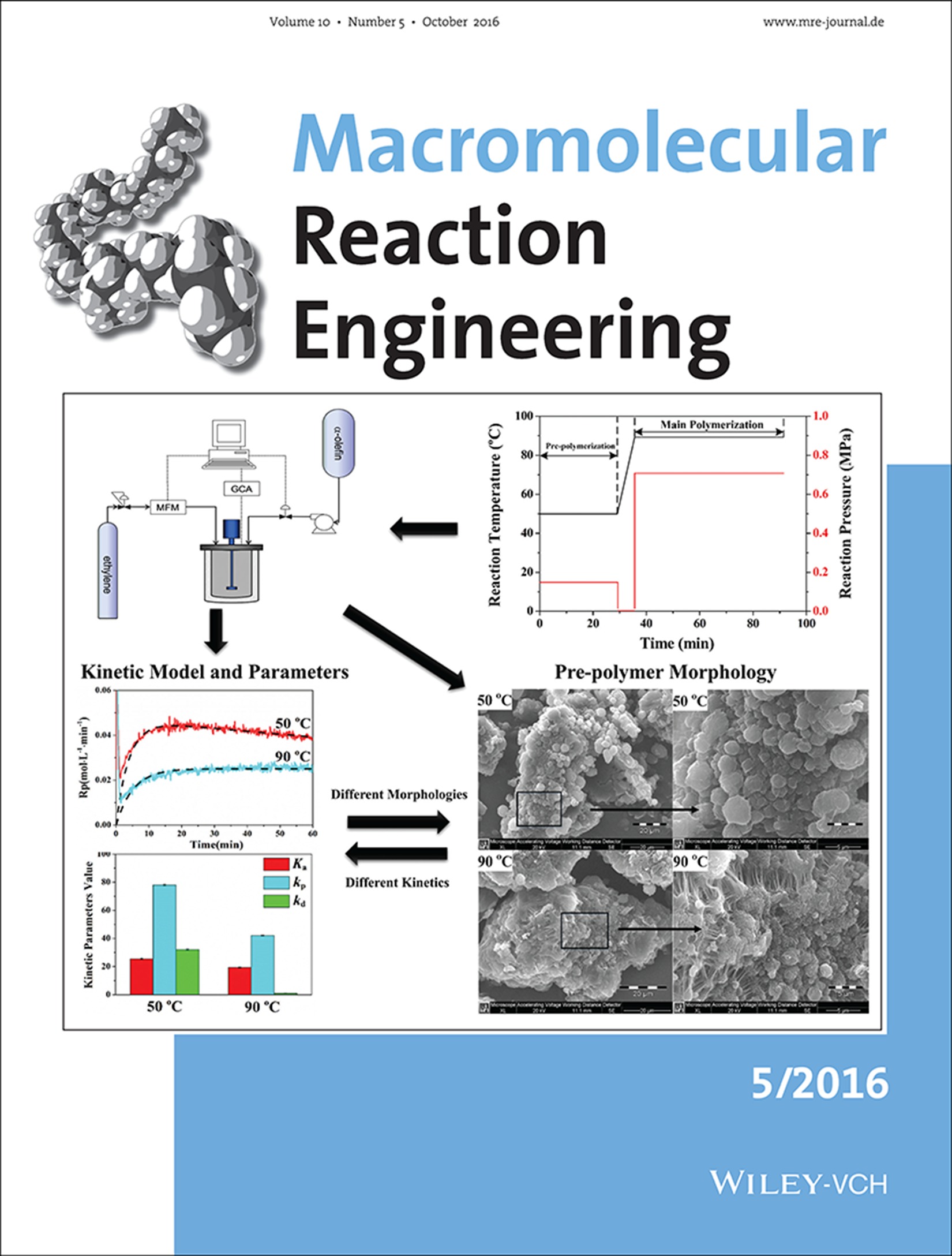

Front Cover: A simple mathematical model is used to quantify the effect of several pre-polymerization conditions (temperature, ethylene pressure, time and 1-hexene/ethylene molar ratio) on the apparent kinetic constants of ethylene homopolymerization and ethylene/1-hexene copolymerization with a 4th generation Ziegler-Natta catalyst. These changes are also correlated to the surface morphology of the pre-polymer particles. Further details can be found in the article by Keran Chen, João B. P. Soares* and co-workers on page 463.

Masthead

Contents

Contents: Macromol. React. Eng. 5/2016

- Pages: 461-462

- First Published: 12 October 2016

Full Papers

Effect of Prepolymerization on the Kinetics of Ethylene Polymerization and Ethylene/1-Hexene Copolymerization with a Ziegler–Natta Catalyst in Slurry Reactors

- Pages: 463-478

- First Published: 29 January 2016

The effect of prepolymerization conditions is quantified on ethylene homopolymerization and ethylene/1-hexene copolymerization using a lumped-parameter polymerization kinetics model. The apparent kinetic constants correlates not only to the prepolymerization conditions, but also to the morphology of the prepolymer particles: prepolymer particles with better fragmentation and less polymer fibrils activate faster and polymerize at higher rates in the main polymerization reactor.

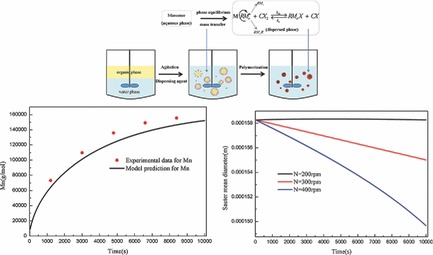

Modeling of the Methyl Methacrylate Atom Transfer Radical Suspension Polymerization Process: Polymerization and Particle Kinetics

- Pages: 479-489

- First Published: 07 March 2016

The first time, the morphological and molecular properties of particles, as well as their dynamics in the methyl methacrylate atom transfer radical batch suspension polymerization can be simultaneously simulated by solving the model that consists of polymerization kinetic equations, moment equations, a phase equilibrium equation and a particle population balance model in this work.

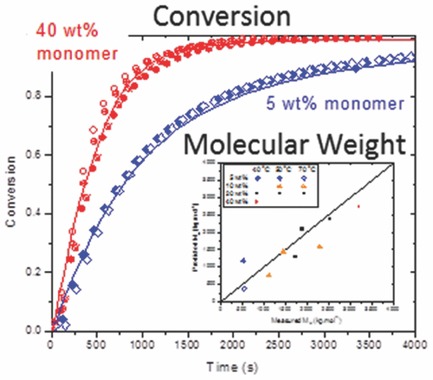

Modeling the Radical Batch Homopolymerization of Acrylamide in Aqueous Solution

- Pages: 490-501

- First Published: 15 March 2016

The complexities of aqueous-phase polymerization of acrylamide are captured in a model that considers the formation of midchain radicals and the influence of monomer concentration on propagation kinetics. The model is verified against batch polymerization monomer conversion profiles and molar mass distributions collected over a range of experimental conditions, as well as previous published data.

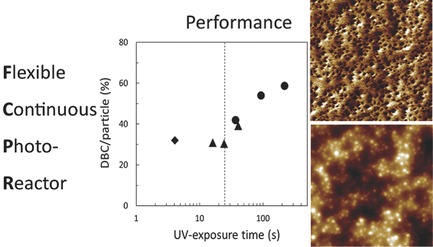

Dispersion Photopolymerization of Acrylated Oligomers Using a Flexible Continuous Reactor

- Pages: 502-509

- First Published: 06 April 2016

A flexible continuous photoreactor is introduced for the preparation of crosslinked colloids using dispersion photopolymerization. The performance of the reactor is established as functional conversion per particle following a detailed light scattering and infrared analysis. Crosslinked particles are visualized by peak force tapping atomic force microscopy.