On the Modeling of Acrylic Acid Copolymerization in an Aqueous Solution: A Modular, Integrated Approach

Corresponding Author

Dimitrios Meimaroglou

CNRS, LRGP, UMR 7274, 1 Rue Grandville, Nancy, F-54001 France

Université de Lorraine, LRGP, UMR 7274, Nancy, F-54001 France

E-mail: [email protected]Search for more papers by this authorMarie-Claire Chevrel

CNRS, LRGP, UMR 7274, 1 Rue Grandville, Nancy, F-54001 France

Université de Lorraine, LRGP, UMR 7274, Nancy, F-54001 France

Search for more papers by this authorSandrine Hoppe

CNRS, LRGP, UMR 7274, 1 Rue Grandville, Nancy, F-54001 France

Université de Lorraine, LRGP, UMR 7274, Nancy, F-54001 France

Search for more papers by this authorAlain Durand

CNRS, LCPM, FRE 3564, Nancy, F-54001 France

Université de Lorraine, LCPM, FRE 3564, Nancy, F-54001 France

Search for more papers by this authorLaurent Falk

CNRS, LRGP, UMR 7274, 1 Rue Grandville, Nancy, F-54001 France

Université de Lorraine, LRGP, UMR 7274, Nancy, F-54001 France

Search for more papers by this authorCorresponding Author

Dimitrios Meimaroglou

CNRS, LRGP, UMR 7274, 1 Rue Grandville, Nancy, F-54001 France

Université de Lorraine, LRGP, UMR 7274, Nancy, F-54001 France

E-mail: [email protected]Search for more papers by this authorMarie-Claire Chevrel

CNRS, LRGP, UMR 7274, 1 Rue Grandville, Nancy, F-54001 France

Université de Lorraine, LRGP, UMR 7274, Nancy, F-54001 France

Search for more papers by this authorSandrine Hoppe

CNRS, LRGP, UMR 7274, 1 Rue Grandville, Nancy, F-54001 France

Université de Lorraine, LRGP, UMR 7274, Nancy, F-54001 France

Search for more papers by this authorAlain Durand

CNRS, LCPM, FRE 3564, Nancy, F-54001 France

Université de Lorraine, LCPM, FRE 3564, Nancy, F-54001 France

Search for more papers by this authorLaurent Falk

CNRS, LRGP, UMR 7274, 1 Rue Grandville, Nancy, F-54001 France

Université de Lorraine, LRGP, UMR 7274, Nancy, F-54001 France

Search for more papers by this authorAbstract

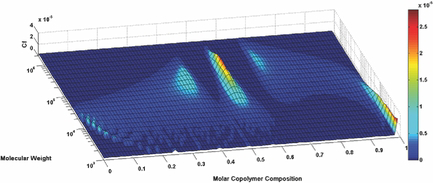

A complete mathematical model of the free-radical copolymerization of acrylic acid in an aqueous solution, taking place in a pilot-scale tubular reactor equipped with static mixers, is presented. The developed kinetic/reactor model is numerically integrated in terms of a coupled deterministic–stochastic numerical approach that combines the advantages of speed, efficiency, and increased predictive capabilities. A series of experimental measurements on the monomer conversion and the molecular weight characteristics of the produced copolymer, under a wide range of process conditions, are used for the identification of the kinetic model parameters while a thorough analysis of the compositional characteristics of the produced copolymers is also carried out in terms of a series of bivariate distributed properties.

References

- 1P. A. Williams, Handbook of Industrial Water Soluble Polymers, Blackwell Publishing; Blackwell Publishing: Oxford; Ames, Iowa, 2007.

10.1002/9780470988701 Google Scholar

- 2K. S. Anseth, R. A. Scott, N. A. Peppas, Macromolecules 1996, 29, 8308.

- 3F. L. Buchholz, Encycl. Polym. Sci. Technol. 2002, 8, 106.

- 4G. Swift, Encycl. Polym. Sci. Technol. 2002, 1, 79.

- 5C. Kiparissides, J. Process Control 2006, 16, 205.

- 6H. Catalgil-Giz, A. Giz, A. M. Alb, W. F. Reed, J. Appl. Polym. Sci. 2004, 91, 1352.

- 7V. A. Kabanov, D. A. Topchiev, T. M. Karaputadze, L. A. Mkrtchian, Eur. Polym. J. 1975, 11, 153.

- 8V. A. Kabanov, D. A. Topchiev, T. M. Karaputadze, J. Polym. Sci. Polym. Symp. 1973, 42, 173.

10.1002/polc.5070420120 Google Scholar

- 9R. J. Minari, G. Caceres, P. Mandelli, M. M. Yossen, M. Gonzalez-Sierra, J. R. Vega, L. M. Gugliotta, Macromol. React. Eng. 2011, 5, 223.

- 10I. Rintoul, C. Wandrey, Macromolecules 2005, 38, 8108.

- 11R. A. Scott, N. A. Peppas, AIChE J. 1997, 43, 135.

- 12H. Ito, A. Shimizu, S. Suzuki, J. Chem. Soc. Jpn. 1955, 58, 194.

- 13S. S. Cutie, P. B. Smith, D. E. Henton, T. L. Staples, C. Powell, J. Polym. Sci. Part B : Polym. Phys. 1997, 35, 2029.

10.1002/(SICI)1099-0488(19970930)35:13<2029::AID-POLB4>3.0.CO;2-R CAS Web of Science® Google Scholar

- 14N. F. G. Wittenberg et al., Macromol. React. Eng. 2015, DOI: 10.1002/mren.201500017.

10.1002/mren.201500017 Google Scholar

- 15P. D. Iedema, H. C. J. Hoefsloot, Macromol. Theory Simul. 2005, 14, 505.

- 16A. Krallis, D. Meimaroglou, C. Kiparissides, Chem. Eng. Sci. 2008, 63, 4342.

- 17V. Saliakas, C. Chatzidoukas, A. Krallis, D. Meimaroglou, C. Kiparissides, Macromol. React. Eng. 2007, 1, 119.

- 18M. Wulkow, Macromol. Theory Simul. 1996, 5, 393.

- 19D. Meimaroglou, A. Krallis, C. A. Kiparissides, Chem. Prod. Process Model. 2008, 3, 1.

- 20D. T. Gillespie, J. Phys. Chem. 1977, 81, 2340.

- 21D. Meimaroglou, A. Krallis, V. Saliakas, C. Kiparissides, Macromolecules 2007, 40, 2224.

- 22C. Schütte, M. Wulkow, Macromol. React. Eng. 2010, 4, 562.

- 23D. Meimaroglou, P. Pladis, A. Baltsas, C. Kiparissides, Chem. Eng. Sci. 2011, 66, 1685.

- 24E. Neuhaus, T. Herrmann, I. Vittorias, D. Lilge, G. Mannebach, A. Gonioukh, M. Busch, Macromol. Theory Simul. 2014, 23, 415.

- 25J. Barth, W. Meiser, M. Buback, Macromolecules 2012, 45, 1339.

- 26C. Preusser, R. A. Hutchinson, Macromol. Symp. 2013, 333, 122.

- 27M. Buback, P. Hesse, I. Lacík, Macromol. Rapid Commun. 2007, 28, 2049.

- 28C. Kiparissides, D. Meimaroglou, P. Pladis, A. Baltsas, Ind. Eng. Chem. Res. 2005, 44, 2592.

- 29C. Kiparissides, G. Verros, J. F. Macgregor, J. Macromol. Sci. Part C: Polym. Rev. 1993, 33, 437.

- 30W. L. McCabe, J. C. Smith, P. Harriott, 1993.

- 31M. A. Al-Harthi, J. K. Masihullah, S. H. Abbasi, J. B. P. Soares, Macromol. Theory Simul. 2009, 18, 307.

- 32H. Tobita, J. Polym. Sci. Part B: Polym. Phys. 1993, 31, 1363.

- 33D. Meimaroglou, C. Kiparissides, Ind. Eng. Chem. Res. 2014, 53, 8963.

- 34D. E. Henton, C. Powell, R. E. Reim, J. Appl. Polym. Sci. 1997, 64, 591.

- 35I. Lacík, S. Beuermann, M. Buback, Macromolecules 2003, 36, 9355.

- 36I. Lacík, S. Beuermann, M. Buback, Macromolecules 2001, 34, 6224.

- 37G. G. Odian, Principles of Polymerization; Wiley: Hoboken, N.J. 2004.

10.1002/047147875X Google Scholar