Journal list menu

Export Citations

Download PDFs

Cover

Cover Picture: (Materialwiss. Werkstofftech. 5/2025)

- Page: 629

- First Published: 05 June 2025

Masthead

Impressum: Materialwiss. Werkstofftech. 5/2025

- Page: 630

- First Published: 05 June 2025

Contents/Inhalt

Preface

Article

Influence of the manufacturing process on the fatigue strength of threads

Einfluss des Herstellungsprozesses auf die Dauerfestigkeit von Gewinden

- Pages: 638-645

- First Published: 13 May 2025

Determination of heat transfer coefficients in wood-based panel finishing

Bestimmung der Wärmeübergangskoeffizienten in der Veredelung von Holzwerkstoffplatten

- Pages: 646-653

- First Published: 23 May 2025

Use of hydroxyethyl cellulose in the preparation of thermoplastic blends with polycaprolactone

Verwendung von Hydroxyethylcellulose bei der Herstellung thermoplastischer Mischungen mit Polycaprolacton

- Pages: 654-665

- First Published: 21 May 2025

Replacing part of the content of the polycaprolactone matrix with a biopolymer is one of the possibilities of using hydroxyethyl cellulose as a filler. A compatibilizer - a copolymer of ethylene with acrylic acid was used to improve interfacial adhesion, which affects the morphology and mechanical properties of thermoplastic blends.

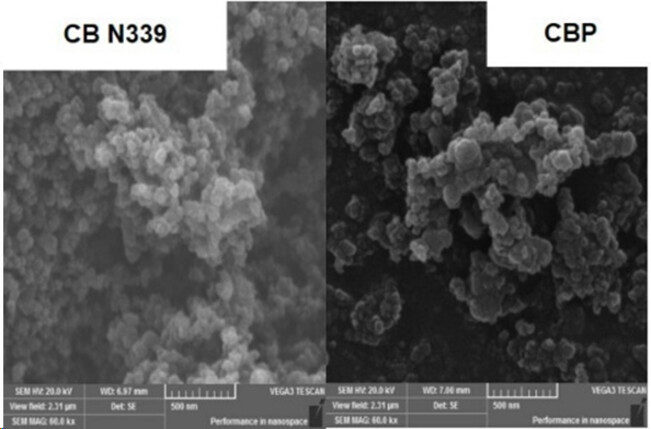

Influence of carbon black from pyrolysis of waste tires in a polymer matrix

Einfluss von Ruß aus der Pyrolyse von Altreifen in einer Polymermatrix

- Pages: 666-675

- First Published: 21 May 2025

Waste tire pyrolysis carbon black was used as a filler to replace conventional carbon blacks in the polymer matrix with aim to reduce costs and waste from waste tire pyrolysis. The reduction fraction of carbon black from waste tire pyrolysis is necessary to improve the reinforcement of the polymer matrix.

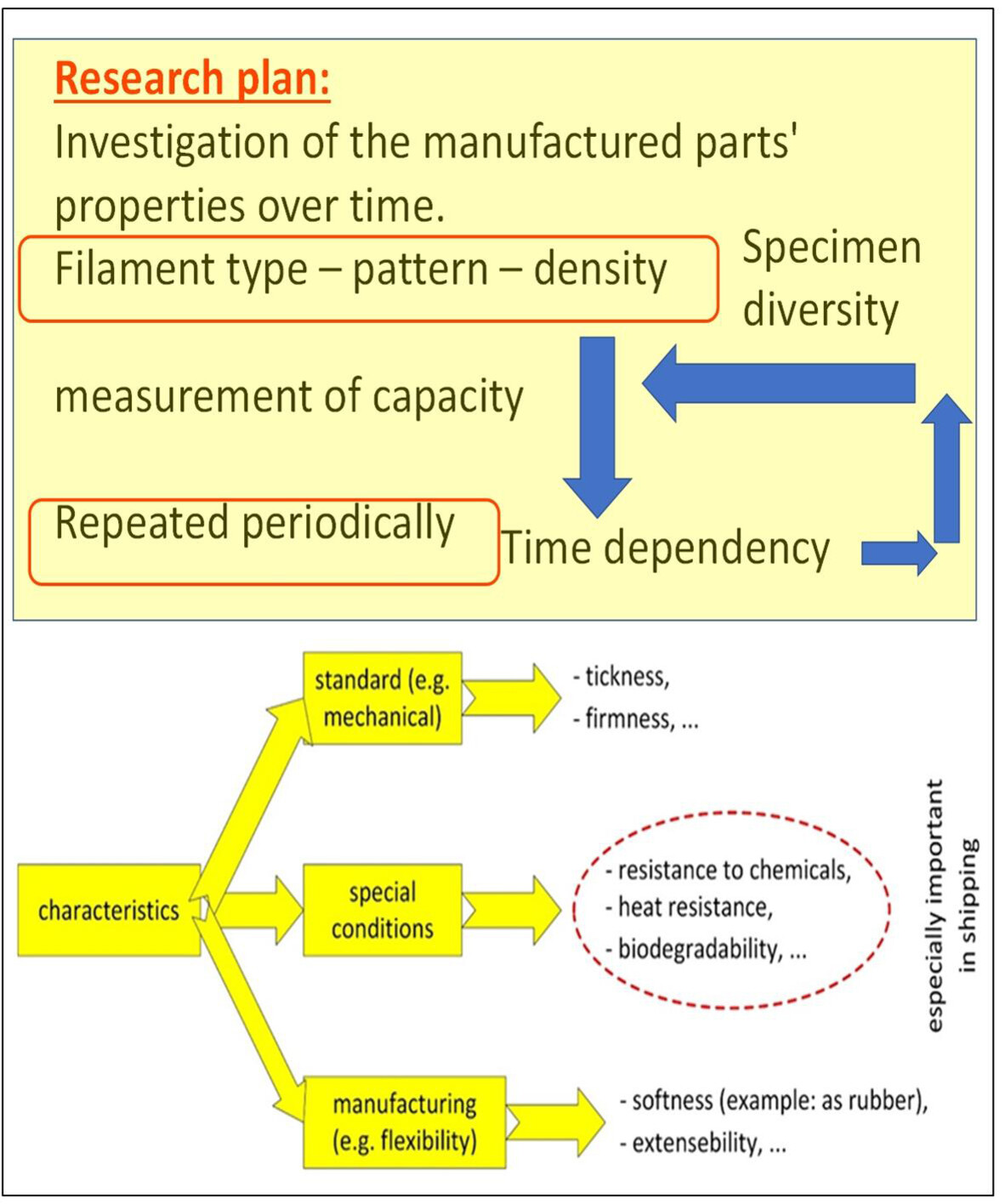

The need for new infills in the application of 3D printing in the maritime sector

Bedarf an neuen Füllmaterialien bei der Anwendung des 3D-Drucks im maritimen Sektor

- Pages: 676-683

- First Published: 12 May 2025

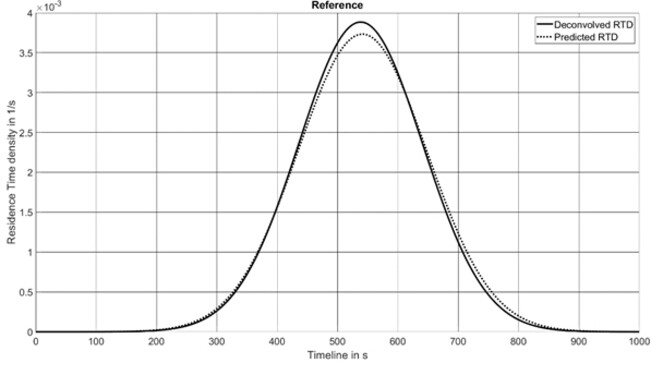

Prediction of residence time distribution of a single-screw rubber extruder by parameterizing the transfer function using experimental data

Vorhersage der Verweilzeitverteilung eines Einschnecken-Kautschukextruders durch Parametrisierung der Übertragungsfunktion anhand experimenteller Daten

- Pages: 684-696

- First Published: 22 May 2025

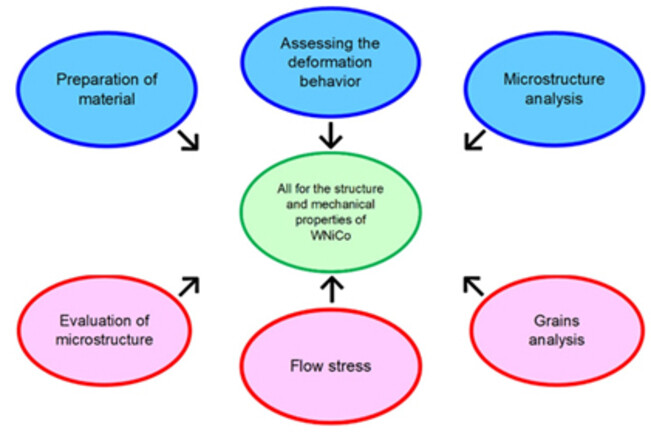

Effect of thermomechanical processing on structure and mechanical properties of WNiCo

Einfluss der thermomechanischen Veredelung auf Struktur und mechanische Eigenschaften der Wolframschwerlegierung WNiCo

- Pages: 697-704

- First Published: 05 June 2025

The presented study evaluated the effects of intensive plastic deformation, realized by rotary swaging under hot conditions, on the deformation behavior of a WNiCo tungsten heavy alloy. The sintered microstructures exhibited a more or less homogeneous distribution of tungsten agglomerates and nickel-cobalt matrix.

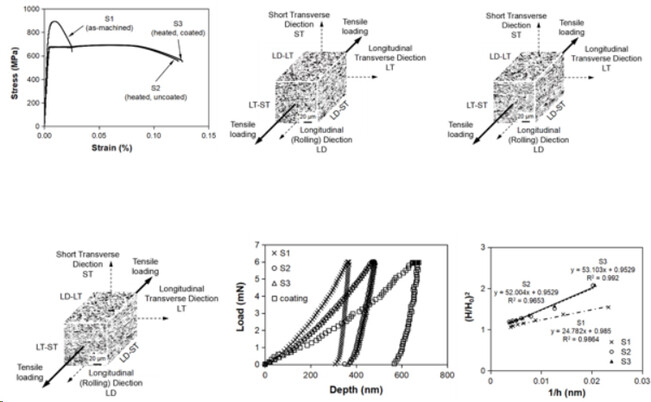

Influence of Galfan coating on tensile properties, microstructure and dislocation densities of CRS 1018 steel

Einfluss der Galfan-Beschichtung auf die Zugfestigkeitseigenschaften, das Gefüge und die Versetzungsdichte von CRS 1018-Stahl

- Pages: 705-714

- First Published: 21 May 2025

Galfan coating prepared by the hot dipping process reduced the ultimate tensile strength and yield strength of the cold rolled CRS 1018 steel, whereas the elongation was significantly increased. The results of the nano indentation testing implied that the dislocation density of the coated steel might be lower than that of the uncoated specimen, which led to the change of mechanical properties.

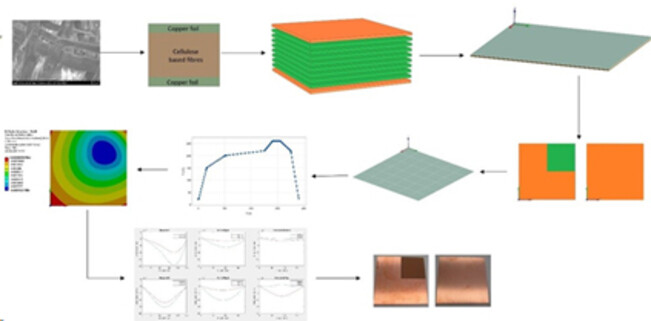

Simulation studies of printed circuit board using finite element method to evaluate the potential of cellulose fibres to replace glass fibres

Simulationsstudien an Leiterplatten mithilfe der Finite-Elemente-Methode zur Bewertung des Potenzials von Zellulosefasern als Ersatz für Glasfasern

- Pages: 715-725

- First Published: 21 May 2025

The aim is to access the potential for replacing glass fibers with natural fibers in the manufacturing of printed circuit boards. Finite element method was used to evaluate the influence of the main structural parameters on their thermomechanical properties. The objective is to predict and quantify the warpage, following the temperature profiles that are important to the soldering process.

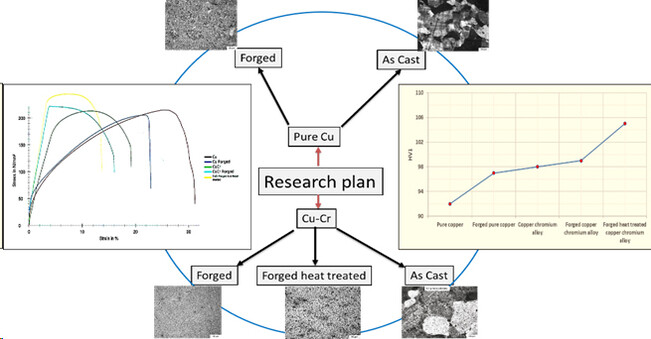

Effect of chromium addition on mechanical behaviour of Cu-Cr alloy for spot welding applications

Einfluss der Chromzugabe auf das mechanische Verhalten einer Kupfer-Chrom-Legierung bei Punktschweißanwendungen

- Pages: 726-733

- First Published: 21 May 2025

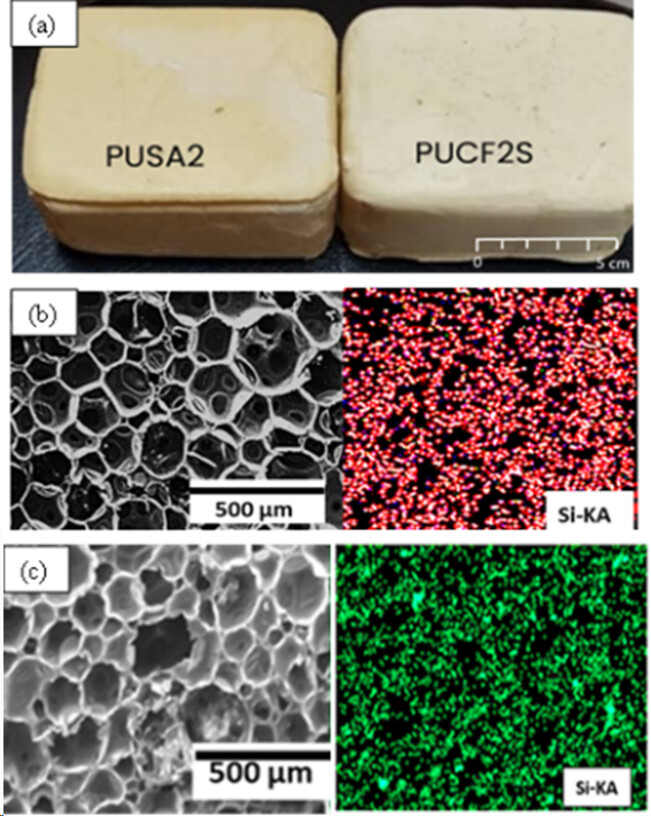

Influence of cellulose fiber reinforcement in mechanical and morphological properties of polyurethane-silica aerogel composites for thermal insulation applications

Einfluss der Zellulosefaserverstärkung auf die mechanischen und morphologischen Eigenschaften von Polyurethan-Silica Aerogel-Verbundwerkstoffen für Wärmedämmanwendungen

- Pages: 734-742

- First Published: 21 May 2025

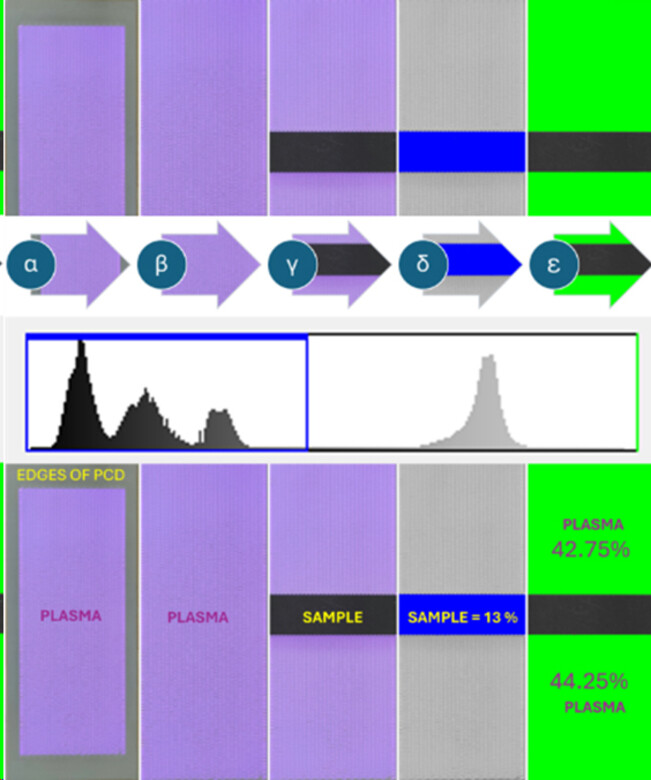

Surface characteristics of thermoplastic films indirectly modified by plasma under static conditions

Oberflächeneigenschaften von thermoplastischen Filmen, die indirekt durch Plasma unter statischen Bedingungen modifiziert wurden

- Pages: 743-756

- First Published: 21 May 2025

This study examines the surface modification of polyvinyl chloride, polyethylene terephthalate, and PP films via diffuse plasma, highlighting the backside treatment effect-changes in areas not directly exposed. Plasma activation altered surface energy, wettability, and adhesion. Contact angle analysis confirmed improved wettability. Findings are key for precise surface engineering.

Evaluation of the possibility of preparing geopolymer materials based on slags and fly ashes from the thermal treatment of municipal waste

Bewertung der Möglichkeit der Herstellung geopolymerer Werkstoffe auf Grundlage von Schlacken und Flugaschen aus der thermischen Behandlung kommunaler Abfälle

- Pages: 757-769

- First Published: 21 May 2025

The research aimed to synthesize and determine the properties of the geopolymer materials from industrial byproducts. The research confirms the applicability of the process of geopolymerization to stabilize slags and ashes from municipal waste incineration plants. The material's potential can be useful for some basic civil engineering applications.