Polyolefin Microfiber Based Antibacterial Fibrous Membrane by Forced Assembly Coextrusion

Corresponding Author

Arifur Rahman

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

E-mail: [email protected]Search for more papers by this authorParker W. Lee

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

Search for more papers by this authorXinting Wang

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

Search for more papers by this authorCong Zhang

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

Search for more papers by this authorJonathan K. Pokorski

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

Search for more papers by this authorEric Baer

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

Search for more papers by this authorCorresponding Author

Arifur Rahman

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

E-mail: [email protected]Search for more papers by this authorParker W. Lee

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

Search for more papers by this authorXinting Wang

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

Search for more papers by this authorCong Zhang

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

Search for more papers by this authorJonathan K. Pokorski

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

Search for more papers by this authorEric Baer

Center for Layered Polymeric Systems, Department of Macromolecular Science and Engineering, Case Western Reserve University, Cleveland, OH, 44106–7202 USA

Search for more papers by this authorAbstract

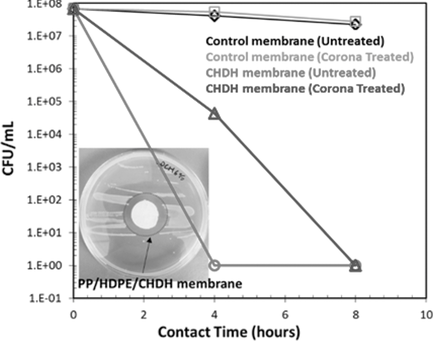

There is a burgeoning demand for polyolefin based fibrous membranes with antibacterial properties due to the increasing awareness about recyclable materials for air and water purification. This paper presents a systematic study on the development of dual component, polypropylene (PP), and high density polyethylene (HDPE) fibrous membranes based on a continuous coextrusion and multiplication manufacturing technique. Chlorhexidine dihydrochloride (CHDH), an organic low molecular weight antibacterial additive, is melt-compounded to impart antibacterial characteristics to the fibrous membranes. The PP/HDPE membranes are hydrophobic and possess 77% porosity, whereas inclusion of CHDH increases the porosity to 91% and the surface area increases almost twofold. In addition, the membranes possess a mean flow pore size of 7 μm. ATR-FTIR study on the PP/CHDH/HDPE membranes indicate the presence of CHDH on the fiber surface, which imparts antibacterial character to the membrane. Investigations carried out on the CHDH containing PP/HDPE fibrous membranes using E. Coli indicate that the presence of CHDH on the fiber surface results in a bacterial growth inhibition zone on solid growth media. In addition, quantitative studies result in the complete reduction of colony forming units after 4 h of contact time.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| mame201600304-sup-0001-S1.pdf1.8 MB | Supplementary |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1S. C. O. Ugbolue. Polyolefin Fibres: Industrial and Medical Applications, Elsevier, Great Abington, Cambridge, England 2009.

10.1201/9781420099867 Google Scholar

- 2Olefin fiber. Updated: April, 2004—Raghavendra R. Hegde, Atul Dahiya, M. G. Kamath, http://www.engr.utk.edu/mse/Textiles/Olefin%20fibers.htm (accessed: May 2016).

- 3E. Berber, N. Horzum, B. Hazer, M. M. Demir, Fibers Polym. 2016, 17, 760.

- 4A.J.van Reenen, L. Keulder, Macromol. Mater. Eng. 2010, 295, 666.

- 5S. R. Givens, K. H. Gardner, J. F. Rabolt, D. B. Chase, Macromolecules 2007, 40, 608.

- 6C. Wang, T. C. Hsieh, Y. W. Cheng, Macromolecules 2010, 43, 9022.

- 7S. Liu, Y. Liang, Y. Quan, K. Dai,G. Zheng, C. Liu, J. Chen, C. Shen, Polymer 2013, 54, 3117.

- 8K. H. Lee, O. Ohsawa, K. Watanabe, I. S. Kim, S. R. Givens, B. Chase, J. F. Rabolt, Macromolecules 2009, 42, 5215.

- 9P. D. Dalton, D. Grafahrend, K. Klinkhammer, D. Klee, M. Möller, Polymer 2007, 48, 6823.

- 10R. Rangkupan, H. D. H. Reneker, J. Met., Mater. Miner. 2003, 12, 81.

- 11J. Fang, L. Zhang, D. Sutton, X. Wang, T. Lin, J. Nanomater. 2012, 16, 16.

- 12J. M. Samet, F. Dominici, F. C. Curriero, I. Coursac, S. L. Zeger, N. Engl. J. Med. 2000, 343, 1742.

- 13A. Peters, D. W. Dockery, J. E. Muller, M. A. Mittleman, Circulation 2001, 103, 2810.

- 14R. Balamurugan, S. Sundarrajan, S. Ramakrishna, Membranes 2011, 1, 232.

- 15K. Yoon, B. S. Hsiao, B. Chu, J. Mater. Chem. 2008, 18, 5326.

- 16W. Mueller, B. Buettgenbach, I. Jakob, H. Mann, Geotextiles Geomembr. 2003, 21, 289.

- 17C. Vasile, Handbook of Polyolefins, CRC Press, New York, NY, USA 2000.

10.1201/9780203908716 Google Scholar

- 18S. S. Zhang, J. Power Sources 2007, 164, 351.

- 19X. Huang, J. Solid State Electrochem. 2011, 15, 649.

- 20P. Arora, Z. Zhang, Chem. Rev. 2004, 104, 4419.

- 21P. Kritzer, J. A. Cook, J. Electrochem. Soc. 2007, 154, A481.

- 22J. Huang, H. Murata, R. R. Koepsel, A. J. Russell, K. Matyjaszewski, Biomacromolecules 2007, 8, 1396.

- 23S. E. Kim, C. Zhang, A. A. Advincula, E. Baer, J. K. Pokorski, ACS Applied Mater. Interfaces 2016, 8, 8928.

- 24W. Yandi, S. Mieszkin, P. Martin-Tanchereau, M. E. Callow, J. A. Callow, L. Tyson,B. Liedberg, T. Ederth, ACS Applied Mater. Interfaces 2014, 6, 11448.

- 25N. L. Lala, R. Ramaseshan, L. Bojun, S. Sundarrajan, R. S. Barhate, L. Ying-jun, S. Ramakrishna, Biotechnol. Bioeng. 2007, 97, 1357.

- 26S. Sundarrajan, A. R. Chandrasekaran, S. Ramakrishna, J. Am. Ceram. Soc. 2010, 93, 3955.

- 27A. R. Abbasi, H. Kalantary, M. Yousefi, A. Ramazani, A. Morsali, Ultrason. Sonochem. 2012, 19, 853.

- 28Y. L. F. Musico, C. M. Santos, M. L. P. Dalida, D. F. Rodrigues, ACS Sustainable Chem. Eng. 2014, 2, 1559.

- 29K. Kim, Y. K. Luu, C. Chang, D. Fang, B. S. Hsiao, B. Chu, M. Hadjiargyrou, J. Controlled Release 2004, 98, 47.

- 30H. S. Choi, V. V. Rybkin, V. A. Titov, T. G. Shikova, T. A. Ageeva, Surf. Coat. Technol. 2006, 200, 4479.

- 31V. N. Vasilets, A. V. Kuznetsov, V. I. Sevastianov, J. Biomed. Mater. Res., Part A 2004, 69, 428.

- 32H. Y. Nie, M. J. Walzak, B. Berno, N. S. McIntyre, Appl. Surf. Sci. 1999, 144, 627.

- 33J. Wang, D. Langhe, M. Ponting, G. E. Wnek, L. T. Korley, E. Baer, Polymer 2014, 55, 673.

- 34J. Wang, R. Ayyar, A. Olah, E. Baer. J. Mater. Sci. 2016, 51, 188.

- 35E. Baer, D. Langhe, J. Wang (Case Western Reserve University), US20150064413 A1 2013.

- 36S. E. Kim, J. D. Wallat, E. C. Harker, A. A. Advincula, J. K. Pokorski, Polym. Chem. 2015, 6, 5683.

- 37S. E. Kim, E. C. Harker, A. C.De Leon, R. C. Advincula, J. K. Pokorski, Biomacromolecules 2015, 16, 860.

- 38S. E. Kim, C. Zhang, A. A. Advincula, E. Baer, J. K. Pokorski, ACS Appl. Mater. Interfaces 2016, 8, 8928.

- 39D. R. Salem, R. A. F. Moore, H. D. Weigmann, J. Polym. Sci., Part B 1987, 25, 567.

- 40F Sadeghi, S. H. Tabatabaei, A. Ajji, P. J. Carreau. Can. J. Chem. Eng. 2010, 88, 1091.

- 41F. Sadeghi, P. J. Carreau, Can. J. Chem. Eng. 2008, 86, 1103.

- 42A. M. Jordan, L. T. Korley, Macromolecules 2015, 48, 2614.

- 43C. Sun, D. Zhang, L. C. Wadsworth, Adv. Polym. Technol. 1999, 18, 171.

- 44I. Novák, V. Pollak, I. Chodak, Plasma Processes Polym. 2006, 3, 355.

- 45D. Zhang, Q. Sun, L. C. Wadsworth, Polym. Eng. Sci. 1998, 38, 965.

- 46A. D. Russell, M. J. Day, J. Hosp. Infect. 1993, 25, 229.

- 47T. D. Hennessey, J. Periodontal Res. 1973, 12, 61.

- 48F. L. Rose, G. Swain, J. Chem. Soc. (Resumed) 1956, 4422.

- 49Z. Mohammadi, P. V. Abbott, Int. Endod. J. 2009, 42, 288.