Fabrication of Polymer Film with Extraordinary Conductive Anisotropy by Forming Parallel Conductive Vorticity-Aligned Stripes and Its Formation Mechanism

Corresponding Author

Jinrui Huang

Key Laboratory of Biomass Energy and Material, Jiangsu Province, Key and Open Laboratory on Forest Chemical Engineering, State Forestry Administration, National Engineering Laboratory for Biomass Chemical Utilization, Institute of Chemical Industry of Forest Products, Chinese Academy of Forestry, Nanjing, 210042 Jiangsu Province, P. R. China

E-mail: [email protected], [email protected]Search for more papers by this authorJunbao Xu

State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Changchun, 130022 P. R. China

Search for more papers by this authorYuping Sheng

Analytical and Testing Center, Sichuan University of Science and Engineering, Zigong, 643000 P. R. China

Search for more papers by this authorCorresponding Author

Yutian Zhu

State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Changchun, 130022 P. R. China

E-mail: [email protected], [email protected]Search for more papers by this authorWei Jiang

State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Changchun, 130022 P. R. China

Search for more papers by this authorDonghua Xu

State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Changchun, 130022 P. R. China

Search for more papers by this authorQingxin Tang

Key Laboratory of UV Light Emitting Materials and Technology under Ministry of Education, Northeast Normal University, Changchun, 130024 P. R. China

Search for more papers by this authorXiaoan Nie

Key Laboratory of Biomass Energy and Material, Jiangsu Province, Key and Open Laboratory on Forest Chemical Engineering, State Forestry Administration, National Engineering Laboratory for Biomass Chemical Utilization, Institute of Chemical Industry of Forest Products, Chinese Academy of Forestry, Nanjing, 210042 Jiangsu Province, P. R. China

Search for more papers by this authorCorresponding Author

Jinrui Huang

Key Laboratory of Biomass Energy and Material, Jiangsu Province, Key and Open Laboratory on Forest Chemical Engineering, State Forestry Administration, National Engineering Laboratory for Biomass Chemical Utilization, Institute of Chemical Industry of Forest Products, Chinese Academy of Forestry, Nanjing, 210042 Jiangsu Province, P. R. China

E-mail: [email protected], [email protected]Search for more papers by this authorJunbao Xu

State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Changchun, 130022 P. R. China

Search for more papers by this authorYuping Sheng

Analytical and Testing Center, Sichuan University of Science and Engineering, Zigong, 643000 P. R. China

Search for more papers by this authorCorresponding Author

Yutian Zhu

State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Changchun, 130022 P. R. China

E-mail: [email protected], [email protected]Search for more papers by this authorWei Jiang

State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Changchun, 130022 P. R. China

Search for more papers by this authorDonghua Xu

State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Changchun, 130022 P. R. China

Search for more papers by this authorQingxin Tang

Key Laboratory of UV Light Emitting Materials and Technology under Ministry of Education, Northeast Normal University, Changchun, 130024 P. R. China

Search for more papers by this authorXiaoan Nie

Key Laboratory of Biomass Energy and Material, Jiangsu Province, Key and Open Laboratory on Forest Chemical Engineering, State Forestry Administration, National Engineering Laboratory for Biomass Chemical Utilization, Institute of Chemical Industry of Forest Products, Chinese Academy of Forestry, Nanjing, 210042 Jiangsu Province, P. R. China

Search for more papers by this authorAbstract

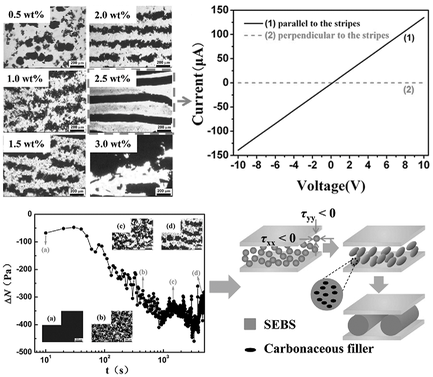

In this work, anisotropic conductive film (ACF) is fabricated by shear-flow induced assembly. It is found that an appropriate content of carbonaceous filler is needed for forming well-ordered parallel vorticity-aligned stripes and the content depends on the category of the filler. Interestingly, the lowest aspect ratio carbon black (CB) with lowest electrical conductivity is the best candidate for fabricating ACF. The film with CB stripes shows excellent conductive anisotropy: the electrical resistivity in the direction parallel to the CB stripes is almost eight orders of magnitude lower than that in the perpendicular direction. The formation mechanism of the vorticity-aligned stripe is also investigated by the rheological measurement and the study of morphological evolution. It is found that the coalescence of dispersed phase or aggregates dominates the formation and growth of the stripe and negative value of the first normal stress difference drives the stripe to align along the vorticity direction.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| mame201600026-sup-0001-S1.pdf13.4 MB | Supplementary |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1X. Y. Huang, C. Y. Zhi, P. K. Jiang, J. Phys. Chem. C 2012, 116, 23812.

- 2C. Mao, Y. T. Zhu, W. Jiang, ACS Appl. Mater. Interfaces 2012, 4, 5281.

- 3K. Dai, S. G. Zhao, W. Zhai, G. Q. Zheng, C. T. Liu, J. B. Chen, C. Y. Shen, Composites, Part A 2013, 55, 11.

- 4B. M. Amoli, E. Marzbanrad, A. M. Hu, Y. N. Zhou, B. X. Zhao, Macromol. Mater. Eng. 2014, 299, 739.

- 5J. R. Huang, C. Mao, Y. T. Zhu, W. Jiang, X. D. Yang, Carbon 2014, 73, 267.

- 6L. Valentini, S. B. Bon, J. M. Kenny, Macromol. Mater. Eng. 2008, 293, 867.

- 7Z. Y. Tang, N. A. Kotov, Adv. Mater. 2005, 17, 951.

- 8S. Tawfick, M.De Volder, D. Copic, S. J. Park, C. R. Oliver, E. S. Polsen, M. J. Roberts, A. J. Hart, Adv. Mater. 2012, 24, 1628.

- 9W. A.de Heer, W. S. Bacsa, A. Châtelain, T. Gerfin, R. Humphrey-Baker, L. Forro, D. Ugarte, Science 1995, 268, 845.

- 10Q. Wang, J. F. Dai, W. X. Li, Z. Q. Wei, J. L. Jiang, Compos. Sci. Technol. 2008, 68, 1644.

- 11H. Cebeci, R. G.de Villoria, A. J. Hart, B. L. Wardle, Compos. Sci. Technol. 2009, 69, 2649.

- 12M. K. Liu, Y. F. Du, Y. E. Miao, Q. W. Ding, S. X. He, W. W. Tjiu, J. S. Pan, T. X. Liu, Nanoscale 2015, 7, 1037.

- 13Q. L. Ma, J. X. Wang, X. T. Dong, W. S. Yu, G. X. Liu, Adv. Funct. Mater. 2015, 25, 2436.

- 14Q. L. Ma, W. S. Yu, X. T. Dong, M. Yang, J. X. Wang, G. X. Liu, Sci. Rep. 2015, 5, 14583.

- 15S. H. Yun, S. M. Yoo, B. H. Sohn, J. C. Jung, W. C. Zin, S. Y. Kwak, T. S. Lee, Langmuir 2005, 21, 3625.

- 16B. Li, H. Y. Jung, H. L. Wang, Y. L. Kim, T. Kim, M. G. Hahm, A. Busnaina, M. Upmanyu, Y. J. Jung, Adv. Funct. Mater. 2011, 21, 1810.

- 17S. Jin, T. H. Tiefel, R. Wolfe, R. C. Sherwood, J. J. Mottine, Science 1992, 255, 446.

- 18T. Kimura, H. Ago, M. Tobita, S. Ohshima, M. Kyotani, M. Yumura, Adv. Mater. 2002, 14, 1380.

- 19D. Fragouli, R. Buonsanti, G. Bertoni, C. Sangregorio, C. Innocenti, A. Falqui, D. Gatteschi, P. D. Cozzoli, A. Athanassiou, R. Cingolani, ACS Nano 2010, 4, 1873.

- 20J. H. Shen, Y. H. Zhu, K. F. Zhou, X. L. Yang, C. Z. Li, J. Mater. Chem. 2012, 22, 545.

- 21N. Li, G. W. Huang, H. M. Xiao, S. Y. Fu, Composites, Part A 2015, 77, 87.

- 22T. Prasse, J. Y. Cavaillé, W. Bauhofer, Compos. Sci. Technol. 2003, 63, 1835.

- 23C. A. Martin, J. K. W. Sandler, A. H. Windle, M.-K. Schwarz, W. Bauhofer, K. Schulte, M. S. P. Shaffer, Polymer 2005, 46, 877.

- 24M. Cardinali, L. Valentini, J. M. Kenny, J. Phys. Chem. C 2011, 115, 16652.

- 25J. R. Lu, W. G. Weng, X. F. Chen, D. J. Wu, C. L. Wu, G. H. Chen, Adv. Funct. Mater. 2005, 15, 1358.

- 26L. J. Lanticse, Y. Tanabe, K. Matsui, Y. Kaburagi, K. Suda, M. Hoteida, M. Endo, E. Yasuda, Carbon 2006, 44, 3078.

- 27C. Mao, J. R. Huang, Y. T. Zhu, W. Jiang, Q. X. Tang, X. J. Ma, J. Phys. Chem. Lett. 2013, 4, 43.

- 28J. R. Huang, Y. T. Zhu, W. Jiang, J. H. Yin, Q. X. Tang, X. D. Yang, ACS Appl. Mater. Interfaces 2014, 6, 1754.

- 29J. R. Huang, Y. T. Zhu, W. Jiang, Q. X. Tang, Composites, Part A 2015, 69, 240.

- 30P. Pötschke, M. Abdel-Goad, I. Alig, S. Dudkin, D. Lellinger, Polymer 2004, 45, 8863.

- 31I. Alig, T. Skipa, D. Lellinger, P. Pötschke, Polymer 2008, 49, 3524.

- 32I. Alig, P. Pötschke, D. Lellinger, T. Skipa, S. Pegel, G. R. Kasaliwal, T. Villmow, Polymer 2012, 53, 4.

- 33C. D. Han, Rheology and Processing of Polymeric Materials: Polymer Rheology, Vol. 1, Oxford University Press, USA 2007.