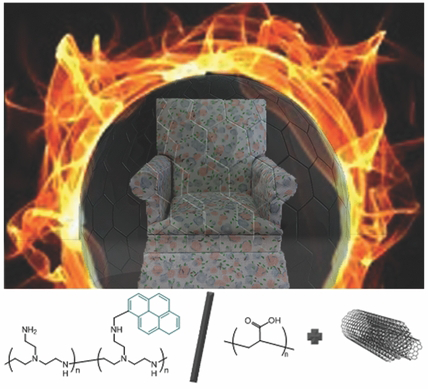

Carbon Nanotube Multilayer Nanocoatings Prevent Flame Spread on Flexible Polyurethane Foam

Abstract

In an effort to protect polyurethane foam (commonly used as cushioning in upholstered furniture) from fire using environmentally benign chemistries, nanocomposite thin films are deposited using water-based solutions of cationic- and anionic-stabilized multiwalled carbon nanotubes (MWCNTs). The open-celled foam is coated using layer-by-layer (LbL) assembly to produce uniform protective layers up to 600 nm thick, comprised of cationic polyethylenimine modified with pyrene (PEI-Py), anionic poly(acrylic acid) (PAA), and MWCNT. Film thickness is found to rely heavily on the PAA-stabilized MWCNT solution. Coatings of only six [PEI-Py/PAA+MWCNT] bilayers (BL) show tremendous reductions in peak heat release rate (up to 67%) and total smoke release (up to 80%) for the polyurethane foam. This same coating significantly improves the performance of the polyurethane when exposed to horizontal and vertical flame tests. With 9 BL, the foam successfully withstands a vertical burn test, self-extinguishing immediately after removal of the test flame. These dramatic reductions in foam flammability are unprecedented and are attributed to the protective nature of the carbon-based char formed from the coating that acts as a protective barrier.