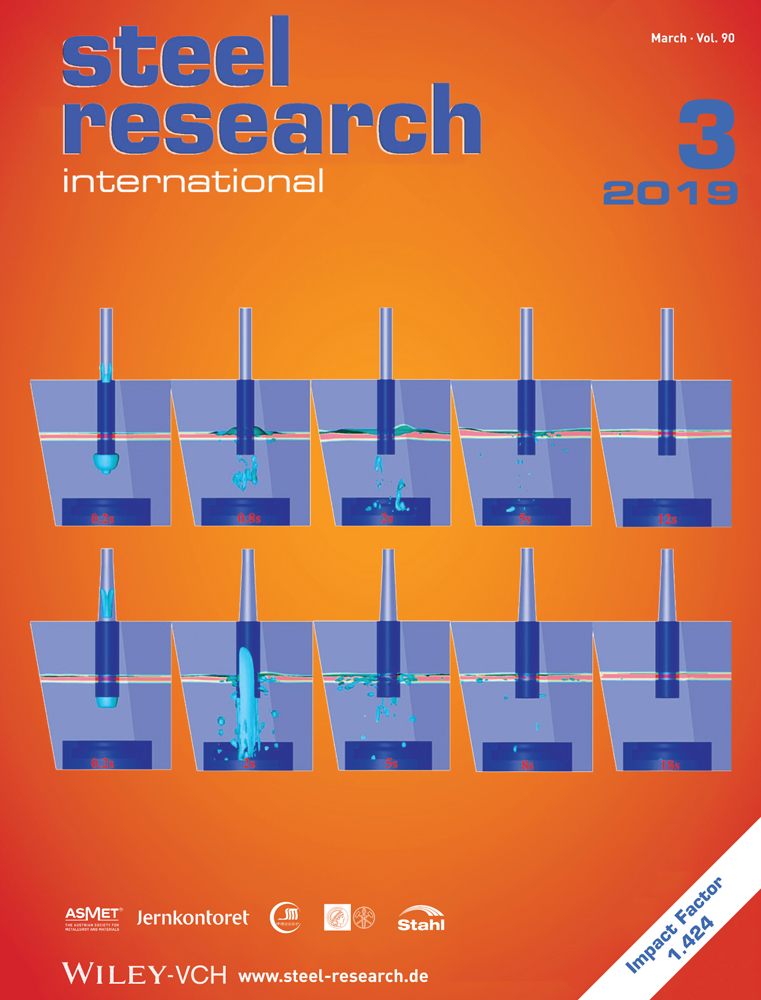

Multiphase Flow in a Five-Strand Tundish Using Trumpet Ladle Shroud during Steady-State Casting and Ladle Change-Over

Abstract

The three-dimensional multiphase flow in a five-strand bloom tundish during both steady-state casting and ladle change-over under normal and two types of trumpet ladle shroud (LS), and turbulence inhibitors (TI) are numerically investigated and compared to improve the flow pattern and cleanness of molten steel. The results show that the optimal combination for the bloom tundish should be the trumpet LS with 1.5 times of the original diameter and optimized circular TI with eaves by comprehensively considering the flow pattern, air and slag behaviors, steel exposure, and slag entrainment both steady-state casting and ladle change-over. By which the turbulent intensity, steel/slag interfacial velocity, chance of slag entrainment, and exposed area of molten steel are obviously decreased, 80% and 58% drops in maximum turbulent kinetics energy and interfacial velocity at steel/slag interface happen during steady state. Meanwhile, the maximum area and duration time of steel exposure are relatively small and the steel level is stable at refilling process of ladle change-over. Furthermore, the qualification rate of flaw detection in the steel rails is increased from 98.1% to 99%, and the disqualification rate caused by ladle change-over operation is decreased from 45.9% to 10.5% when applying the optimized LS and TI.

Conflict of Interest

The authors declare no conflict of interest.