Analytical study on plastic loosening zone of weak surrounding rocks tunnel in high cold areas

Abstract

The analysis of plastic loosening zone of tunnels with cold condition, high in situ stress, and weak stratum is the key scientific problem of tunnel construction in cold areas. Based on the unified strength theory and considering the coupling effect of high in situ stress and low-temperature field, the analytical model of the plastic loosening zone of tunnel surrounding rocks was proposed, and the influence laws of physical parameters (initial ground stress, freezing temperature, excavation radius, and intermediate principal stress) was explored. The results illustrate that: (1) with the coupling of low temperature and stress fields, the in-situ stress has a more significant effect on the radius of the plastic loosening zone of the tunnel surrounding rocks, showing a nonlinear correlation. When the in situ stress is small, the influence of the temperature field on the radius of the plastic loosening zone is more obvious. (2) The radius of the plastic loosening zone of the tunnel surrounding rocks increases synchronously with the excavation radius and gradually decreases with the increase of the intermediate principal stress. (3) The greater the temperature difference in the low-temperature field, the tunnel stability has a more significant response to the intermediate principal stress and is positively correlated with the coefficient of the intermediate principal stress. (4) In the actual project, the proposed model can well describe the mechanical behavior and deformation characteristics of tunnel surrounding rocks in low-temperature environment, showing applicability. The research results are expected to provide a theoretical basis for the study of tunnel stability in cold areas.

1 INTRODUCTION

In the construction of major projects in the high cold region of the plateau, the coupling effect of high in situ stress and high cold freeze-thaw poses a challenge to the projects and causes many disasters. The disasters in high in situ stress environment are rock bursts, collapses, and large deformations (Cao, Xia, et al., 2024; Li, 2023, 2024; Zhao & Dai, 2023; Zuo et al., 2024). In cold areas with large temperature difference, engineering disasters such as freezing damage and aggravation of surrounding rock deformation are manifested (Wang, Xu, et al., 2024; Xia et al., 2020; Yang et al., 2023; Zeng et al., 2024; Zhao et al., 2020). Therefore, the study on the development, distribution, and stress state of plastic loosening zone of tunnel surrounding rocks with the coupling effect of low temperature and stress fields can provide positive significance for engineering design and safety construction.

Up to now, the methods for determining the radius of the loosening zone of tunnel surrounding rocks can be summarized into three categories: field test, theoretical calculation, and numerical simulation (Huang et al., 2018; Wang et al., 2022; Yang et al., 2022; Zhang et al., 2023, 2024; Zhu et al., 2021). The completion of the loosening zone is affected by many factors, such as stratigraphic lithology, stress development, and rock mass structural characteristics, so the cultivation process takes a long time. Due to time and practical operation, field tests and numerical simulation are limited in the study of tunnel surrounding rock loosening zone. The theoretical calculation method is efficient and accurate, and has been applied to the study of tunnel stability by many scholars (Chen et al., 2019; Kolawole et al., 2023; Yu et al., 2021; Zhang et al., 2021). Based on the unified strength theory, Yu et al. (2018) improved the double-shear unified strength theory, and then obtained the radius analytic expression involving the parameters of tunnel surrounding rock stress, tunnel wall displacement, and loosening zone radius. Li et al. (2019) conducted field tests on the evolution law of the fracture zone range of tunnel surrounding rocks by the digital speckle method (DSM), revealing the distribution characteristics of the tunnel volume expansion zone and compression zone. Su et al. (2020) derived the formula for calculating the loosening zone radius of tunnel surrounding rocks under different strength criteria, considering the elastic-plastic behavior of surrounding rocks. Tao et al. (2020) conducted field measurement and numerical simulation of the large deformation loosening zone range of the layered slate tunnel and carried out parameter analysis. Zhu (2022) studied the formation mechanism of the loosening zone in the surrounding rocks of deep-buried layered soft rock tunnel. The loosening zone first appears in the tunnel arch, then develops to both sides, and finally, the loosening range is much larger than other parts. Wu et al. (2023) studied the radius of the loosening zone under a high ground temperature environment and explored the influence of temperature effect on the radius of the loosening zone of surrounding rocks.

In the process of tunnel construction and operation in low-temperature environment, the change laws of the stress field will be more complicated, thus affecting the deformation behavior of surrounding rocks. In view of the study on the range of loosening zone of tunnel surrounding rocks in low-temperature field, Xia et al. (2018) found that the nonuniform freeze-heave property of rocks with unidirectional freezing conditions is the key influencing factor for the difference of freeze-heave force, and put forward a theory to calculate the nonuniform freeze-heave force of surrounding rocks considering the orientation. Huang and Yang (2010) used the H-B criterion to derive the elastic–plastic stress and displacement expressions of circular tunnels considering the effect of osmotic force. Huang et al. (2015) obtained an analytical solution of the loosening zone range of the tunnel surrounding rocks with the conditions of damage and expansion by considering the rock elastic-plastic damage constitutive model and the nonuniform frost heave characteristics. Feng et al. (2019) investigated the elastic-plastic solution based on the D-P criterion and compared the magnitude of frost heave force under different D-P expressions. Gao et al. (2020) derived strain-softened elastoplastic solutions of deep-buried tunnels based on different strength criteria and explored the deformation characteristics of tunnels. In summary, the analytical solution of the loosening zone of tunnel surrounding rocks is mainly aimed at the plastic deformation process with different strength criteria, and the theoretical study under the multi-factor coupling is not in-depth (Dou et al., 2024; Liu et al., 2024; Wang et al., 2023; Wang, Zhou, et al., 2024; Yang et al., 2024).

The objective of this study is to investigate the characteristics of the plastic loosening zone in tunnels passing through weak strata. Based on the unified strength theory and considering the influence of the intermediate principal stress, an analytical model of the plastic deformation of the circular tunnel surrounding rocks with the coupling effect of low temperature and stress fields was established, and the plastic deformation radius and stress evolution law of the soft surrounding rock tunnel were analyzed. This analytical solution takes into account the coupling effect of temperature and stress fields, and can more accurately describe the mechanical behavior of the tunnels under special geological conditions. The accuracy and applicability of this model are verified by practical tunnel engineering cases.

2 TEMPERATURE–STRESS CHARACTERISTICS

The temperature field of the tunnel in the cold area has typical nonequilibrium characteristics, and its distribution has obvious spatial differences and is affected by multiple factors such as formation lithology and groundwater. Therefore, in the study of the plastic loosening zone of tunnel surrounding rocks with the coupled effect of temperature and stress, the following basic assumptions are made about the temperature exchange between the air and the surrounding rock mass in tunnels: (a) The tunnel is a circular horizontal tunnel of infinite length, the radius is expressed as , the surrounding rock mass is isotropic, and the frost heave coefficients in different directions are consistent. (b) The temperature field in the tunnel is stable, and the radius of the surrounding rock affected by air is . (c) The air temperature in the tunnel is consistent with the tunnel wall temperature , and the temperature of the original rock mass is . (d) The temperature of surrounding rocks changes along the radial direction of the tunnel, and there is no longitudinal temperature difference.

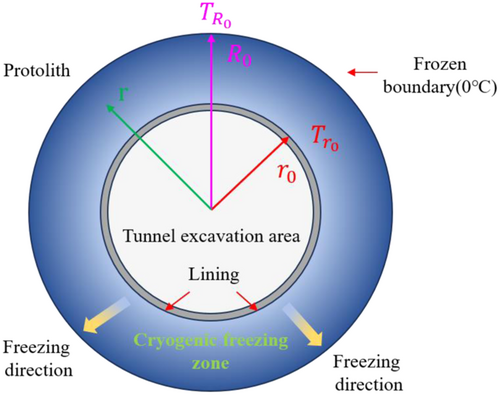

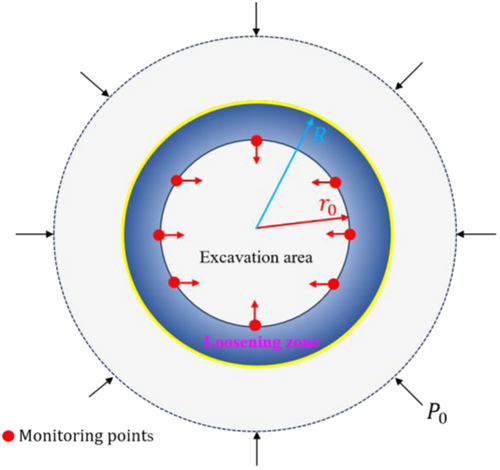

Based on these assumptions, the complex problem of solving the unsteady temperature field is simplified, and the solution of the temperature field distribution of the tunnel surrounding rocks in the cold area is transformed into the thermodynamic conduction problem of the thick-walled cylinder, whose inner radius is and the outer radius is . The calculation diagram is shown in Figure 1.

3 ANALYTICAL CALCULATION OF RADIUS IN PLASTIC LOOSENING ZONE

3.1 Plastic loosening zone

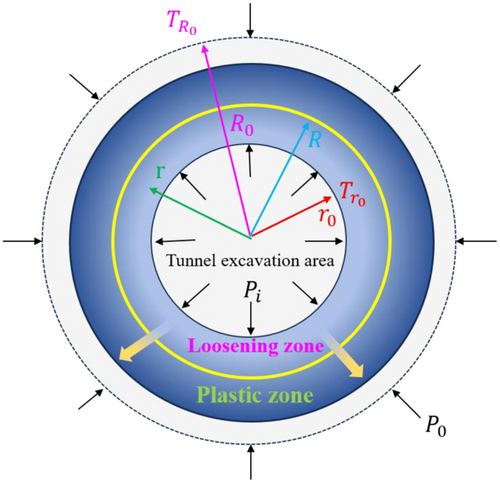

The stress redistribution of the tunnel surrounding rocks after excavation with ideal elastic-plastic stress state can be divided into three parts: the initial in situ stress zone, the elastic zone, and the plastic zone, wherein the plastic zone includes the loosening zone and the plastic zone (Wu et al., 2023). Based on the unified strength theory, this study analyzes the mechanical characteristics of the loosening zone of surrounding rocks. The circumferential stress of the loosening zone is less than the in-situ stress (Figure 2). It is assumed that the circular tunnel in the cold area is located in the infinite elastic body, the radius of the loosening circle is , the elastic parameters of the surrounding rock are and , the cohesion force and internal friction Angle of the surrounding rock are divided into and , and the supporting stress is .

3.2 Stress field of tunnel surrounding rocks

3.3 Calculation of loosening zone radius

4 PARAMETER ANALYSIS

4.1 Tunnel parameters

Based on the water diversion tunnel under construction in a hydropower station in Xizang, this paper analyzes the complex geological problems encountered in the actual construction process, such as low temperature environment and high ground stress. According to the investigation report of the tunnel, the strata are mainly basalt, slate, limestone, siltstone and mudstone interlayers, etc. This study discusses the weak strata. The cross-section of the tunnel is circular, the buried depth is about 1000 m, the tunnel excavation radius r0 = 6 m, the temperature of the original rock mass TR0 = −12.4°C, and the temperature of the tunnel wall Tr0 = 0°C, then the difference between the temperature of the original rock mass and the temperature of the tunnel wall T = 12.4°C.

Combined with relevant data (Xia et al., 2018, 2020), the influence coefficient of intermediate principal stress b = 0.2, influence radius of low temperature freezing zone R0 = 10r0, lining thickness t = 0.50 m, and in situ stress is calculated according to the self-weight stress. The parameters required by the theoretical calculation formula of other physical parameters of surrounding rocks are as follows (Table 1).

| Elasticity modulus | Poisson's ratio | In situ stress | Tunnel radius | |

|---|---|---|---|---|

| E/MPa | μ | P0/MPa | r0/m | Intermediate principal stress coefficient b |

| 3900 | 0.30 | 26 | 6 | 0.2 |

| Cohesion c/MPa | Internal friction angle φ/° | Frost heaving coefficient per unit temperature ξ/(1/°C) | Temperature difference T/°C | Volume-weight w/(kN/m3) |

| 0.52 | 39 | 0.000045 | 12.4 | 25.4 |

4.2 Loosening zone characteristic

4.2.1 Influence of in situ stress and temperature difference

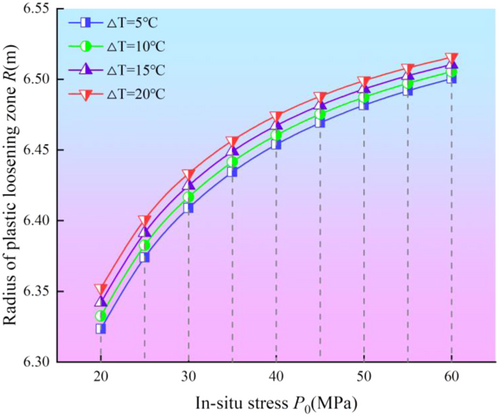

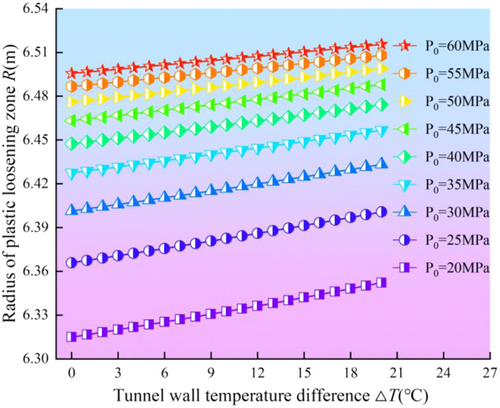

The tunnel parameters (Table 1) are substituted into Equations (7) and (18). When the initial ground stress is satisfied, the surrounding rock will produce plastic failure. Equation (16) was used to calculate the radius of the loosening ring, analyze the parameters, and draw the influence curve. By substituting tunnel parameters (Table 1) into Equations (7) and (18), plastic failure of surrounding rocks occurs when the in-situ stress is satisfied. Equation (16) was used to calculate the radius of the loosening zone, analyze the parameters, and draw the influence curves (Figures 3 and 4).

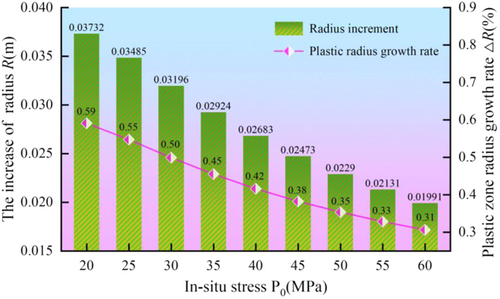

The results show that: (1) With the coupling effect of low temperature and stress, the radius of the plastic loosening zone increases with the increase of the in situ stress and the temperature difference between the rock mass and the tunnel wall. (2) Taking T = 5°C, when increasing from 20 to 60 MPa, the radius R of plastic loosening zone of tunnel surrounding rocks increases from 6.32348 to 6.50044 m, increasing by 0.17696 m. Taking P0 = 20 MPa, when T increases from 5°C to 20°C, the radius of plastic loosening zone increases from 6.32348 to 6.352323 m, increasing by 0.02875 m. With the coupling effect of low temperature and stress, the influence of in situ stress on the radius of the plastic loosening zone is more significant than that of temperature difference. (3) When the local stress is 20 Mpa < P0 < 60 MPa, the plastic loosening zone radius increases gradually with the ground stress increasing, but the growth rate is first fast and then slow. Therefore, the more sensitive change of the tunnel surrounding the rock plastic loosens the zone with smaller ground stress.

Figures 4 and 5 show that: (1) With the increase of temperature difference at low temperature, the radius of plastic loosening zone of surrounding rocks shows an approximate linear increase trend. When P0 = 20 MPa, T increased from 0°C to 20°C, R increased from 6.314909 m to 6.352230 m, an increase of 0.0373207 m, or 0.59%. When P0 = 60 MPa, T increased from 0°C to 20°C, R increased from 6.495613 to 6.515519 m, an increase of 0.31%. (2) The influence of in-situ stress on the radius of plastic loosening zone of tunnel surrounding rocks is aggravated by the existence of a low-temperature field.

At low temperature, the surrounding rock mineral composition produces a differential frost heave effect, and the void structure between mineral components changes, which leads to the surrounding rock mechanical properties deterioration. Under the action of stress, the expansion rate of the void between mineral components increases, which aggravates the surrounding rock's mechanical properties deterioration at low temperature.

4.2.2 Tunnel radius and intermediate principal stress coefficient

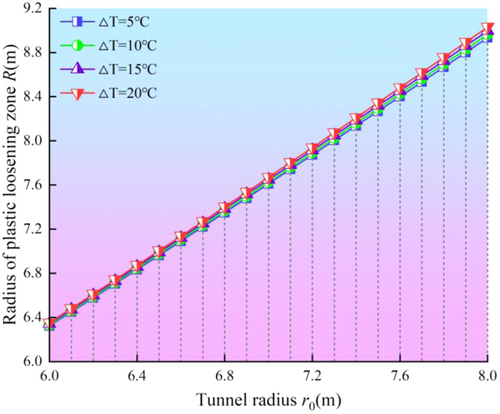

Figure 6 shows that the radius of the plastic loosening zone increases approximately linearly with the increase of the tunnel radius under the coupling effect of low temperature-stress. When the in situ stress P0 = 20 MPa, the larger the temperature difference, the larger the radius of the loosening zone.

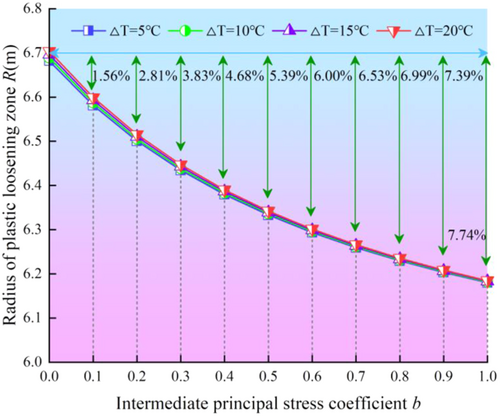

The radius of the plastic loosening ring decreases with the increase of the intermediate principal stress coefficient, and the decrease is 7.74%, which indicates that the stability of the surrounding rock is positively correlated with the intermediate principal stress coefficient. At the same time, the change rate of the radius of the plastic loosening ring gradually decreases with the increase of the intermediate principal stress coefficient, and the influence of the sensitivity of the intermediate principal stress coefficient on the stability of surrounding rock gradually decreases (Figure 7). (1) Taking P0 = 20 MPa, ΔT = 5°C, and when b increases from 0 to 1.0, the radius R of the plastic relaxation zone of the tunnel surrounding rocks decreases from 6.668179 to 6.180018 m, a decrease of 0.501770 m, a decrease of about 7.51%. (2) Taking P0 = 20 MPa and ΔT = 10°C, when b increases from 0 to 1.0, the radius R of the plastic loosening zone of the tunnel surrounding rocks decreases from 6.688984 to 6.181543 m, a decrease of 0.507442 m, a decrease of about 7.59%. (3) Taking P0 = 20 MPa and ΔT = 15°C, when b increases from 0 to 1.0, the radius R of the plastic loosening zone of tunnel surrounding rocks decreases from 6.696335 m to 6.183093 m, decreasing by 0.513243 m, or about 7.66%. (4) Taking P0 = 20 MPa and ΔT = 20°C, when b increases from 0 to 1.0, the radius R of the plastic loosening zone of tunnel surrounding rocks decreases from 6.703847 to 6.184670 m, decreasing by 0.519177 m, or about 7.74%. It shows that the influence of the intermediate principal stress coefficient on the radius of the plastic loosening zone is slight, but the greater the temperature difference at low temperature, the greater the influence of the intermediate principal stress coefficient on the radius of the plastic loosening zone. At the same time, the change of intermediate principal stress coefficient b is related to tensile strength, shear strength, and compressive strength. When b increases, the tensile strength, compressive strength, and shear strength increase, and the deformation of the surrounding rock decreases. When the temperature difference ΔT increases, the tensile, compressive, and shear strength decreases, and the deformation of surrounding rock increases.

5 CASE STUDY

The Dabanshan Tunnel in Qinghai province, with an altitude of 3750 m, has an annual average temperature of −3.2°C, an annual minimum temperature of −15.3°C and an extreme minimum temperature of −34°C. Surrounding rock cracks are developed and pore water is basically saturated. The surrounding rock of monitoring section K106+400 is mainly schist, the maximum freezing depth is 2.10 m, and the maximum tunnel burial depth is 1085 m. According to the in situ ground temperature and stress testing and inversion results, the minimum temperature of the original rock mass in the study section is −15.1°C, the horizontal in situ stress is 24.58 MPa, the vertical in situ stress is 30.72 MPa, and the tunnel excavation radius is 4.55 m. Assuming that the tunnel wall temperature is 0°C, the temperature difference between the original rock mass and tunnel wall T = 15°C. Take the middle principal stress coefficient b = 0.20, and the radius of variable temperate zone action R0 = 10r0. Other physical parameters of the tunnel surrounding rocks are shown in Table 2.

| Elasticity modulus | Poisson's ratio | Cohesion | Internal friction angle |

|---|---|---|---|

| E/MPa | μ | c/MPa | φ/° |

| 3100 | 0.2 | 0.68 | 38 |

| Support stress Pi/MPa | Volume-weight w/(kN/m3) | Frost heaving coefficient per unit temperature ξ/(1/°C) | – |

|---|---|---|---|

| 0.50 | 28.31 | 0.000045 | – |

To master the deformation characteristics of the surrounding rock and keep the stability of the free surface during tunnel excavation, monitoring points were arranged at the key points of the tunnel (Figure 8). According to the tunnel data, the maximum thickness of the plastic loosening zone of surrounding rocks is 0.35 m, and the minimum thickness is 0.12 m, that is, the radius R of the loosening zone is 4.67–4.90 m. The radius of the plastic loosening zone of the tunnel was calculated by substituting the physical parameters of surrounding rocks with the Equation (16), and compared with the test results and the calculation results without considering the temperature effect (Table 3).

| Methods | Construction state | Plastic loosening zone radius R/m | |

|---|---|---|---|

| Horizontal direction | Vertical direction | ||

| Theoretical calculation | High in situ stress | 4.56 | 4.61 |

| High in situ stress + low temperature | 4.69 | 4.83 | |

| Field measurement | High in situ stress + low temperature | 4.67 | 4.90 |

As shown in Table 3: (1) Calculated based on the unified strength criterion, the radius of the plastic loosening zone under the coupling effect of low temperature and stress is larger than that under the condition of single stress field, with a horizontal difference of 0.13 m and a vertical difference of 0.22 m. The temperature field has a significant influence on the radius of the plastic loosening zone of tunnel surrounding rocks. (2) Under the coupling effect of low temperature and stress, the radius of the surrounding rock loosening zone calculated based on the unified strength criterion is close to the field measured results.

The calculated radius of the horizontal plastic loosening zone is 4.69 m, which is 0.02 m lower than the field measured result of 4.67 m, and the calculated radius of the vertical plastic loosening zone is 4.83 m, which is 0.07 m lower than the field measured result of 4.90 m. The comparison between the calculated and measured results shows that the analytical solution of the radius of the plastic loosening zone based on the unified strength criterion with the coupling effect of low temperature and stress is reasonable, which can better describe the mechanical behavior and deformation laws of the tunnel surrounding rocks in low-temperature environment.

6 CONCLUSIONS

Based on the unified strength theory, combined with the characteristics of tunnel temperature field and high ground stress in low-temperature environment, this study proposes a calculation method for the radius of plastic loosening zone of tunnel surrounding rocks, establishes a theoretical calculation model, and discusses the influence laws of parameters. The applicability of this model is verified by comparing the calculation results with the actual tunnel field measured results, and the following conclusions are drawn.

- 1.

With the coupling effect of low temperature and stress, the radius of the plastic loosening zone increases gradually with the increase of the in situ stress and temperature difference. The influence of the in situ stress on the radius of the loosening zone is mainly nonlinear correlation.

- 2.

With the coupling effect of low temperature and stress, the radius of the plastic loosening zone and the excavation radius show an approximate linear increase trend and gradually decrease with the increase of the intermediate principal stress coefficient.

- 3.

The difference between the results obtained by the proposed method and the measured results is slight, which proves that the calculation model can describe the mechanical behavior and deformation laws of tunnel-surrounding rocks well in low-temperature environment.

ACKNOWLEDGMENTS

This work was supported by the Postdoctoral Fellowship Program of CPSF under Grant Number GZC20240167, the Chengdu University of Technology Postgraduate Innovative Cultivation Program (CDUT2022BJCX007), and this research was also financially supported by the Huzhou Key Laboratory Fund (HGB23E002).

ETHICS STATEMENT

None declared.

Open Research

DATA AVAILABILITY STATEMENT

All data generated or analyzed during this study are included within the article.