Galvanic corrosion behavior and numerical simulation of 5083 aluminum alloy and Q235 steel in 3.5% NaCl solution

Abstract

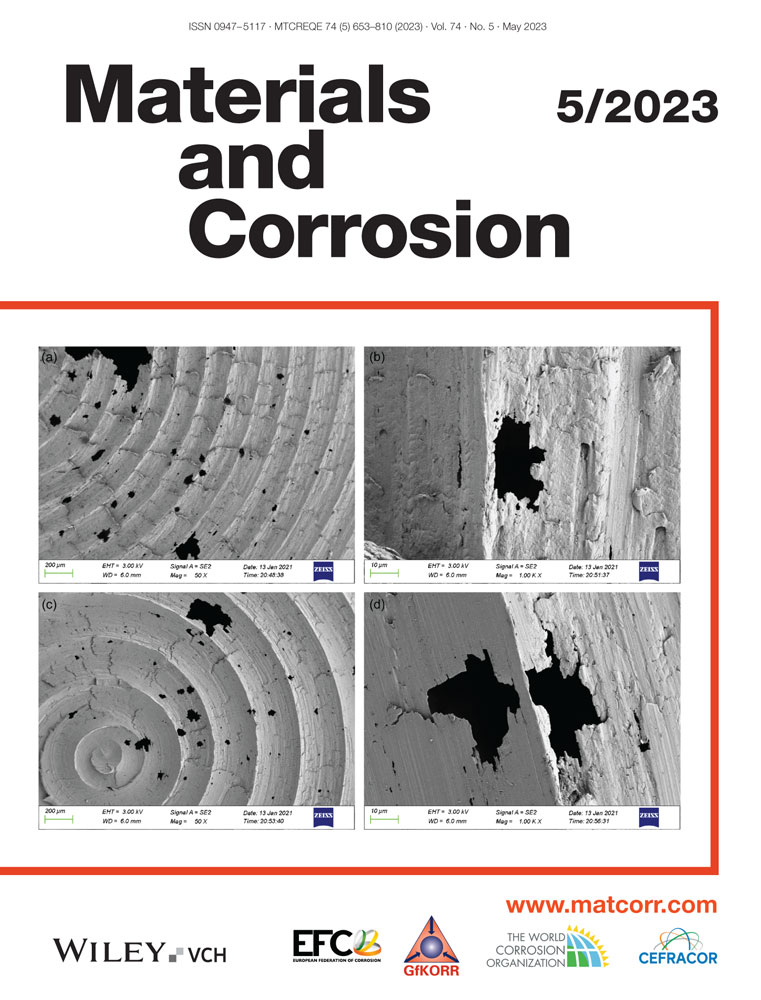

In marine engineering structures, the combination of different materials is inevitable, and the risk of galvanic corrosion is common. In this study, the effects of temperature on the corrosion behavior of 5083 aluminum alloy and Q235 steel in 3.5% NaCl solution were studied by scanning Kelvin probe, stereomicroscopy, X-ray diffraction, and electrochemical analysis. When the 5083 aluminum alloy and Q235 steel were coupled, the 5083 aluminum alloy was the anode, and its corrosion rate was accelerated. Results showed that with increasing temperature, the galvanic potential shifted to slightly more negative values, the galvanic current density increased, and the increase in temperature accelerated the galvanic corrosion rate. A galvanic corrosion simulation model was established, the polarization curve fitting parameters of 5083 aluminum alloy and Q235 steel were used as boundary conditions, and the potential distribution and current density distribution on the electrode surface were simulated by the finite element method. Simulation results were generally consistent with experimental results.

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available from the corresponding author upon reasonable request.