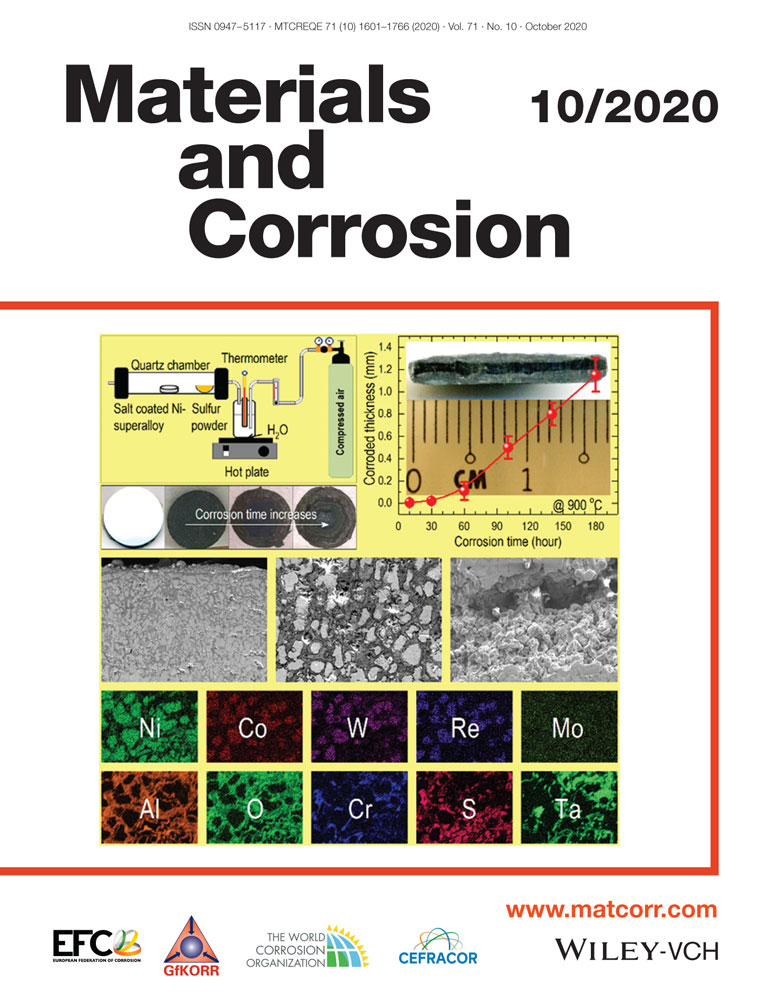

Hot corrosion studies of a salt-coated Ni-based superalloy under flowing wet air and sulfur vapor ambient

Corresponding Author

Hongfei Liu

Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), Singapore, Singapore

Correspondence Hongfei Liu, Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), 2 Fusionopolis Way, Singapore 138634, Singapore.

Email: [email protected]

Search for more papers by this authorShuting Chen

Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), Singapore, Singapore

Search for more papers by this authorDennis C. C. Tan

Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), Singapore, Singapore

Search for more papers by this authorCoryl J. J. Lee

Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), Singapore, Singapore

Search for more papers by this authorKui Yao

Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), Singapore, Singapore

Search for more papers by this authorCorresponding Author

Hongfei Liu

Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), Singapore, Singapore

Correspondence Hongfei Liu, Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), 2 Fusionopolis Way, Singapore 138634, Singapore.

Email: [email protected]

Search for more papers by this authorShuting Chen

Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), Singapore, Singapore

Search for more papers by this authorDennis C. C. Tan

Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), Singapore, Singapore

Search for more papers by this authorCoryl J. J. Lee

Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), Singapore, Singapore

Search for more papers by this authorKui Yao

Institute of Materials Research and Engineering (IMRE), A*STAR (Agency for Science, Technology and Research), Singapore, Singapore

Search for more papers by this authorAbstract

Corrosion of a salt-coated Ni-superalloy has been studied at 900°C under a wet air and sulfur vapor ambient. The corrosion thickness, after an incubation of ~60 hr, linearly increases with the corrosion time t and the onset of surface spallation occurred at t ≈ 60 hr. The corroded layer consists of a corrosion front dominated by Cr3S4 scales and linear precipitate structures, an inner corrosion layer dominated by Ni3S2 and NiO, and an outer corrosion layer dominated by Al2O3 networks surrounding the Ni3S2 and/or NiO scale structures. The corrosion mechanism is discussed based on the coexistence of H2O, sulfur, and oxygen.

REFERENCES

- 1A. F. Giamei, Adv. Mater. Processes 2013, 171, 26.

- 2T. M. Pollock, J. Propul. Power 2006, 22, 361.

- 3O. Font, X. Querol, M. Izquierdo, E. Alvarez, N. Moreno, S. Diez, R. Álvarez-Rodríguez, C. Clemente-Jul, P. Coca, F. Garcia-Peña, Fuel 2010, 89, 3250.

- 4C. G. Levi, J. W. Hutchinson, M. H. Vidal-Sétif, C. A. Johnson, MRS Bull. 2012, 37, 932.

- 5T. Ohtani, H. Ogi, M. Hirao, Intern. J. Solids Struct. 2005, 42, 2911.

- 6J. Stringer, Mater. Sci. Technol. 1987, 3, 482.

- 7N. Eliaz, G. Shemesh, R. M. Latanison, Eng. Fail. Anal. 2002, 9, 31.

- 8E. Rocca, L. Aranda, M. Vilasi, P. Steinmetz, Mater. Sci. Forum 2004, 461–464, 917.

- 9B. Bordenet, H. P. Bossmann, Mater. Sci. Forum 2004, 461–464, 907.

- 10N. J. Simms, A. Encinas-Oropesa, J. R. Nicholls, Mater. Corros. 2008, 59, 476.

- 11M. Qiao, C. Zhou, Corros. Sci. 2012, 63, 239.

- 12P. Lortrakul, R. W. Trice, K. P. Trumble, M. A. Dayananda, Corros. Sci. 2014, 80, 408.

- 13P. Knutsson, H. Lai, K. Stiller, Corros. Sci. 2013, 73, 230.

- 14V. Mannava, A. S. Rao, N. Paulose, M. Kamaraj, R. S. Kottada, Corros. Sci. 2016, 105, 109.

- 15Y. Wu, T. Narita, Surf. Coat. Technol. 2007, 202, 140.

- 16B. Bouchaud, J. Balmain, D. Barrere, T. Delannoye, F. Pedraza, Corros. Sci. 2013, 68, 176.

- 17H. F. Liu, C. K. I. Tan, W. S. Cheng, G. W. Lim, D. C. Tan, C. J. Lee, J. J. Cheng, H. K. F. Cheng, L. C. Lee, Metall. Mater. Trans. A 2020, 51, 3180.

- 18G. Kreysa, M. Schütze, Dechema, Corrosion Handbook, Sodium Dioxide, Sodium Sulfate, Wiley, Weinheim, Germany 2008.

- 19J. X. Chang, D. Wang, T. Liu, G. Zhang, L. H. Lou, J. Zhang, Corros. Sci. 2015, 98, 585.

- 20Z. Cheng, H. Abernathy, M. Liu, J. Phys. Chem. C 2007, 111, 17997.

- 21Y. Wu, Y. Liu, G. Li, X. Zou, X. Lian, D. Wang, L. Sun, T. Asefa, X. Zou, Nano Energy 2017, 35, 161.

- 22J. Li, P. K. Shen, Z. Tian, Int. J. Hydrogen Energy 2017, 42, 7136.

- 23N. Feng, D. Hu, P. Wang, X. Sun, X. Li, D. He, Phys. Chem. Chem. Phys. 2013, 15, 9924.

- 24N. Dharmaraj, P. Prabu, S. Nagarajan, C. H. Kim, J. H. Park, Hy Kim, Mater. Sci. Eng. B 2006, 128, 111.

- 25C. Luo, D. Li, W. Wu, Y. Zhang, C. Pan, RSC Adv. 2014, 4, 3090.

- 26B. Zhao, J. Song, P. Liu, W. Wu, T. Fang, Z. Jiao, H. Zhang, Y. Jiang, J. Mater. Chem. 2011, 21, 18792.

- 27H. Zhu, H. Dong, P. Laveille, Y. Saih, V. Caps, J. Basset, Catal. Today 2014, 228, 58.

- 28P. M. Sousa, A. J. Silvestre, N. Popovici, O. Conde, Appl. Surf. Sci. 2005, 247, 423.

- 29O. Monnereau, L. Tortet, C. E. A. Grigorescu, D. Savastru, C. R. Iordanescu, F. Guinneton, R. Notonier, A. Tonetto, T. Zhang, I. N. Mihailescu, D. Stanoi, H. J. Trodah, J. Optoelectron. Adv. Mater. 2010, 12, 1752.

- 30S. R. Shatynski, Oxid. Met. 1977, 11, 307.

- 31K. Onal, M. C. Maris-Sida, G. H. Meier, F. S. Pettit, Superalloys 2004, 10, 607.

10.7449/2004/Superalloys_2004_607_615 Google Scholar