Efficient Chemical Prelithiation with Modificatory Li+ Solvation Structure Enabling Spatially Homogeneous SEI toward High Performance SiOx Anode†

Ruoyang Wang

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorYuqing Wu

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorYifan Niu

Chengdu No.7 High School, Chengdu, Sichuan, 6100412 China

Search for more papers by this authorQing Yang

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorHaoyu Li

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorYang Song

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorBenhe Zhong

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorLiwen Yang

Institute for Applied Materials (IAM), Karlsruhe Institute of Technology (KIT), Hermann-von-Helmholtz-Platz 1, D-76344 Eggenstein-Leopoldshafen, Germany

Search for more papers by this authorTing Chen

Institute for Advanced Study, Chengdu University, Chengdu, Sichuan, 610106 China

Search for more papers by this authorCorresponding Author

Zhenguo Wu

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

E-mail: [email protected]; [email protected]Search for more papers by this authorCorresponding Author

Xiaodong Guo

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Institute for Advanced Study, Chengdu University, Chengdu, Sichuan, 610106 China

E-mail: [email protected]; [email protected]Search for more papers by this authorRuoyang Wang

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorYuqing Wu

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorYifan Niu

Chengdu No.7 High School, Chengdu, Sichuan, 6100412 China

Search for more papers by this authorQing Yang

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorHaoyu Li

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorYang Song

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorBenhe Zhong

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Search for more papers by this authorLiwen Yang

Institute for Applied Materials (IAM), Karlsruhe Institute of Technology (KIT), Hermann-von-Helmholtz-Platz 1, D-76344 Eggenstein-Leopoldshafen, Germany

Search for more papers by this authorTing Chen

Institute for Advanced Study, Chengdu University, Chengdu, Sichuan, 610106 China

Search for more papers by this authorCorresponding Author

Zhenguo Wu

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

E-mail: [email protected]; [email protected]Search for more papers by this authorCorresponding Author

Xiaodong Guo

School of Chemical Engineering, Sichuan University, Chengdu, Sichuan, 610065 China

Institute for Advanced Study, Chengdu University, Chengdu, Sichuan, 610106 China

E-mail: [email protected]; [email protected]Search for more papers by this author† Dedicated to the Special Issue of Batteries.

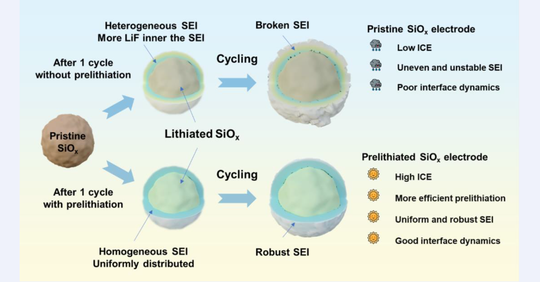

Comprehensive Summary

Chemical prelithiation is widely proven to be an effective strategy to address the low initial coulombic efficiency (ICE) of promising SiOx anode. Though the reagent composition has been widely explored, the Li+ solvation structure, which practically plays the cornerstone role in the prelithiation ability, rate, uniformility, has rarely been explored. A novel environmentally-friendly reagent with weak solvent cyclopentyl methyl ether (CPME) is proposed that enables both improved ICE and spatial homogeneous solid electrolyte interphase (SEI). And the prelithiation behavior and mechanism were explored focused on the Li+ solvation structure. Both theoretical investigation and spectroscopic results suggest that weak solvent feature of CPME reduces the solvent coordination number and decreases the Li+ desolvation energy. The optimized Li+ solvation structure enables high-efficiency prelithiation that ensures the horizontal homogenization and mechanical properties of SEI. Moreover, the accompanied CPME molecules preferentially occupy positions in initial SEI, reducing the likelihood of LiPF6 decomposition and promoting longitudinal homogenization of SEI. Consequently, the efficient and homogenous prelithiation enables impressive ICE of 109.52% and improved cycling performance with 80.77% retained after 300 cycles via just 5 min soaking. Furthermore, the full cells with LiNi0.83Co0.12Mn0.05O2 (NCM831205) cathode display an enhancement in the energy density of 179.74% and up to 648.35 Wh·kg–1.

Supporting Information

| Filename | Description |

|---|---|

| cjoc202400226-sup-0001-Supinfo.pdfPDF document, 1.8 MB |

Appendix S1: Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1 Choi, S.; Kwon, T.; Coskun, A.; Choi, J. W. Highly Elastic Binders Integrating Polyrotaxanes for Silicon Microparticle Anodes in Lithium Ion Batteries. Science 2017, 357, 279–283.

- 2 Cao, Z.; Zheng, X.; Qu, Q.; Huang, Y.; Zheng, H. Electrolyte Design Enabling a High-Safety and High-Performance Si Anode with a Tailored Electrode–Electrolyte Interphase. Adv. Mater. 2021, 33, 2103178.

- 3 Chae, S.; Choi, S.-H.; Kim, N.; Sung, J.; Cho, J. Integration of Graphite and Silicon Anodes for the Commercialization of High-Energy Lithium-Ion Batteries. Angew. Chem. Int. Ed. 2020, 59, 110–135.

- 4 Li, H.; Li, H.; Lai, Y.; Yang, Z.; Yang, Q.; Liu, Y.; Zheng, Z.; Liu, Y.; Sun, Y.; Zhong, B.; Wu, Z.; Guo, X. Revisiting the Preparation Progress of Nano-Structured Si Anodes toward Industrial Application from the Perspective of Cost and Scalability. Adv. Energy Mater. 2022, 12, 2102181.

- 5 Jia, H.; Li, X.; Song, J.; Zhang, X.; Luo, L.; He, Y.; Li, B.; Cai, Y.; Hu, S.; Xiao, X.; Wang, C.; Rosso, K. M.; Yi, R.; Patel, R.; Zhang, J.-G. Hierarchical Porous Silicon Structures with Extraordinary Mechanical Strength as High-Performance Lithium-Ion Battery Anodes. Nat. Commun. 2020, 11, 1474.

- 6 Li, H.; Li, H.; Yang, Z.; Yang, L.; Gong, J.; Liu, Y.; Wang, G.; Zheng, Z.; Zhong, B.; Song, Y.; Zhong, Y.; Wu, Z.; Guo, X. SiOx Anode: From Fundamental Mechanism toward Industrial Application. Small 2021, 17, 2102641.

- 7 Liu, Z.; Yu, Q.; Zhao, Y.; He, R.; Xu, M.; Feng, S.; Li, S.; Zhou, L.; Mai, L. Silicon Oxides: A Promising Family of Anode Materials for Lithium-Ion Batteries. Chem. Soc. Rev. 2019, 48, 285–309.

- 8 Meng, T.; Li, B.; Wang, Q.; Hao, J.; Huang, B.; Gu, F. L.; Xu, H.; Liu, P.; Tong, Y. Large-Scale Electric-Field Confined Silicon with Optimized Charge-Transfer Kinetics and Structural Stability for High-Rate Lithium-Ion Batteries. ACS Nano 2020, 14, 7066–7076.

- 9

Zhang, M.; Liang, N.; Hao, D.; Chen, Z.; Zhang, F.; Yin, J.; Yang, Y.; Yang, L. Recent Advances of SiOx-Based Anodes for Sustainable Lithium-Ion Batteries. Nano Res. Energy 2023, 2, e9120077.

10.26599/NRE.2023.9120077 Google Scholar

- 10 Jin, L.; Shen, C.; Wu, Q.; Shellikeri, A.; Zheng, J.; Zhang, C.; Zheng, J. P. Pre-Lithiation Strategies for Next-Generation Practical Lithium-Ion Batteries. Adv. Sci. 2021, 8, 2005031.

- 11 Bai, S.; Bao, W.; Qian, K.; Han, B.; Li, W.; Sayahpour, B.; Sreenarayanan, B.; Tan, D. H. S.; Ham, S.; Meng, Y. S. Elucidating the Role of Prelithiation in Si-Based Anodes for Interface Stabilization. Adv. Energy Mater. 2023, 13, 2301041.

- 12 Zhang, H.; Cheng, J.; Liu, H.; Li, D.; Zeng, Z.; Li, Y.; Ji, F.; Guo, Y.; Wei, Y.; Zhang, S.; Bai, T.; Xu, X.; Peng, R.; Lu, J.; Ci, L. Prelithiation: A Critical Strategy Towards Practical Application of High-Energy-Density Batteries. Adv. Energy Mater. 2023, 13, 2300466.

- 13 Xiao, Z.; Lin, X.; Zhang, C.; Shen, J.; Zhang, R.; He, Z.; Lin, Z.; Jiang, H.; Wei, F. Insights into the Coating Integrity and Its Effect on the Electrochemical Performance of Core–Shell Structure SiOx@C Composite Anodes. Small Methods 2023, 7, 2201623.

- 14 Yue, X.-Y.; Yao, Y.-X.; Zhang, J.; Li, Z.; Yang, S.-Y.; Li, X.-L.; Yan, C.; Zhang, Q. The Raw Mixed Conducting Interphase Affords Effective Prelithiation in Working Batteries. Angew. Chem. Int. Ed. 2022, 61, e202205697.

- 15 Yue, X.-Y.; Yao, Y.-X.; Zhang, J.; Yang, S.-Y.; Li, Z.; Yan, C.; Zhang, Q. Unblocked Electron Channels Enable Efficient Contact Prelithiation for Lithium-Ion Batteries. Adv. Mater. 2022, 34, 2110337.

- 16 Zheng, L.; Yi, R.; Zheng, N.; Shen, Y.; Chen, L. Review—Lithium Carbon Composite Material for Practical Lithium Metal Batteries. Chin. J. Chem. 2023, 41, 814–824.

- 17 Kulkarni, P.; Jung, H.; Ghosh, D.; Jalalah, M.; Alsaiari, M.; Harraz, F. A.; Balakrishna, R. G. A Comprehensive Review of Pre-Lithiation/Sodiation Additives for Li-Ion and Na-Ion Batteries. J. Energy Chem. 2023, 76, 479–494.

- 18 Zhang, Y.; Wu, B.; Mu, G.; Ma, C.; Mu, D.; Wu, F. Recent Progress and Perspectives on Silicon Anode: Synthesis and Prelithiation for LIBs Energy Storage. J. Energy Chem. 2022, 64, 615–650.

- 19 Chen, S.; Wang, Z.; Zhang, M.; Shi, X.; Wang, L.; An, W.; Li, Z.; Pan, F.; Yang, L. Practical Evaluation of Prelithiation Strategies for Next- Generation Lithium-Ion Batteries. Carbon Energy 2023, 5, e323.

- 20 Huang, Z.; Deng, Z.; Zhong, Y.; Xu, M.; Li, S.; Liu, X.; Zhou, Y.; Huang, K.; Shen, Y.; Huang, Y. Progress and Challenges of Prelithiation Technology for Lithium-Ion Battery. Carbon Energy 2022, 4, 1107–1132.

- 21 Huang, Y.-E.; Huang, P.-W.; Zhong, Y.; Zhong, H.-Y.; Lin, W.-L.; Lu, X.; Qi, X.-H.; Huang, X.-Y.; Du, K.-Z.; Wu, X.-H. Achieving High Initial Coulombic Efficiencies and Cycle Stability of Free-Standing Anodes by Chemical Prelithiation of Carbon Matrix. Appl. Surf. Sci. 2023, 612, 155691.

- 22 Gong, S.; Lee, Y.; Choi, J.; Lee, M.; Chung, K. Y.; Jung, H.-G.; Jeong, S.; Kim, H.-S. In Situ Mesopore Formation in SiOx Nanoparticles by Chemically Reinforced Heterointerface and Use of Chemical Prelithiation for Highly Reversible Lithium-Ion Battery Anode. Small 2023, 19, 2206238.

- 23 Wang, R.; Li, H.; Wu, Y.; Li, H.; Zhong, B.; Sun, Y.; Wu, Z.; Guo, X. How to Promote the Industrial Application of SiOx Anode Prelithiation: Capability, Accuracy, Stability, Uniformity, Cost, and Safety. Adv. Energy Mater. 2022, 12, 2202342.

- 24 Shen, H.; An, Y.; Man, Q.; Wang, J.; Liu, C.; Xi, B.; Xiong, S.; Feng, J.; Qian, Y. Controlled Prelithiation of Siloxene Nanosheet Anodes Enables High Performance 5 V-Class Lithium-Ion Batteries. Chem. Eng. J. 2023, 454, 140136.

- 25 Li, F.; Cao, Y.; Wu, W.; Wang, G.; Qu, D. Prelithiation Bridges the Gap for Developing Next-Generation Lithium-Ion Batteries/Capacitors. Small Methods 2022, 6, 2200411.

- 26 Su, Y.-S.; Chang, J.-K. Polycyclic Aromatic Hydrocarbon-Enabled Wet Chemical Prelithiation and Presodiation for Batteries. Batteries 2022, 8, 99.

- 27 He, W.; Xu, H.; Chen, Z.; Long, J.; Zhang, J.; Jiang, J.; Dou, H.; Zhang, X. Regulating the Solvation Structure of Li+ Enables Chemical Prelithiation of Silicon-Based Anodes Toward High-Energy Lithium-Ion Batteries. Nano-Micro Lett. 2023, 15, 107.

- 28 Choi, J.; Jeong, H.; Jang, J.; Jeon, A.-R.; Kang, I.; Kwon, M.; Hong, J.; Lee, M. Weakly Solvating Solution Enables Chemical Prelithiation of Graphite–SiOx Anodes for High-Energy Li-Ion Batteries. J. Am. Chem. Soc. 2021, 143, 9169–9176.

- 29 Sun, Y.; Zhang, K.; Chai, R.; Wang, Y.; Rui, X.; Wang, K.; Deng, H.; Xiang, H. In Situ Artificial Hybrid SEI Layer Enabled High-Performance Prelithiated SiOx Anode for Lithium-Ion Batteries. Adv. Funct. Mater. 2023, 33, 2303020.

- 30 Chen, J.; Fan, X.; Li, Q.; Yang, H.; Khoshi, M. R.; Xu, Y.; Hwang, S.; Chen, L.; Ji, X.; Yang, C.; He, H.; Wang, C.; Garfunkel, E.; Su, D.; Borodin, O.; Wang, C. Electrolyte Design for LiF-Rich Solid–Electrolyte Interfaces to Enable High-Performance Microsized Alloy Anodes for Batteries. Nat. Energy 2020, 5, 386–397.

- 31 Tan, J.; Matz, J.; Dong, P.; Shen, J.; Ye, M. A Growing Appreciation for the Role of LiF in the Solid Electrolyte Interphase. Adv. Energy Mater. 2021, 11, 2100046.

- 32 Wang, Z.; Han, R.; Huang, D.; Wei, Y.; Song, H.; Liu, Y.; Xue, J.; Zhang, H.; Zhang, F.; Liu, L.; Weng, S.; Lu, S.; Xu, J.; Wu, X.; Wei, Z. Co-Intercalation-Free Ether-Based Weakly Solvating Electrolytes Enable Fast-Charging and Wide-Temperature Lithium-Ion Batteries. ACS Nano 2023, 17, 18103–18113.

- 33 Zhang, H.; Zeng, Z.; Ma, F.; Wu, Q.; Wang, X.; Cheng, S.; Xie, J. Cyclopentylmethyl Ether, a Non-Fluorinated, Weakly Solvating and Wide Temperature Solvent for High-Performance Lithium Metal Battery. Angew. Chem. Int. Ed. 2023, 62, e202300771.

- 34Nagmani; Das, D.; Puravankara, S. Role of Cyclopentyl Methyl Ether Co-Solvent in Improving SEI Layer Stability in Hard Carbon Anode for Sodium-Ion Batteries. ChemRxiv 2023, 10.26434/chemrxiv-2023-z1hq1.

- 35 Ramasamy, H. V.; Kim, S.; Adams, E. J.; Rao, H.; Pol, V. G. A Novel Cyclopentyl Methyl Ether Electrolyte Solvent with a Unique Solvation Structure for Subzero (−40 °C) Lithium-Ion Batteries. Chem. Commun. 2022, 58, 5124–5127.

- 36 Gasparetto, H.; Carolina Ferreira Piazzi Fuhr, A.; Paula Gonçalves Salau, N. Forecasting Soybean Oil Extraction Using Cyclopentyl Methyl Ether through Soft Computing Models with a Density Functional Theory Study. J. Ind. Eng. Chem. 2023, 123, 297–310.

- 37 Zhang, C.; Wang, Y.; Yang, W.; Zheng, J. Biobased 2,5-Dimethyltetrahydrofuran as a Green Aprotic Ether Solvent. Org. Process Res. Dev. 2022, 26, 2685–2693.

- 38 Majdanski, T. C.; Vitz, J.; Meier, A.; Brunzel, M.; Schubert, S.; Nischang, I.; Schubert, U. S. “Green” Ethers as Solvent Alternatives for Anionic Ring-Opening Polymerizations of Ethylene Oxide (EO): In-Situ Kinetic and Advanced Characterization Studies. Polymer 2018, 159, 86–94.

- 39 Duan, C.-J.; Zhang, Y.; Yu, L.; Chang, Y.-H.; Xu, J.; Yue, G.-L.; Han, X.; Wang, C.-L.; Fu, Y.-J. The Simultaneous Extraction and Separation of Hydrophobic and Hydrophilic Phytochemicals from Eucommia Ulmoides Seeds with Green Solvent CPME System. Chem. Pap. 2023, 77, 5357–5369.

- 40 Zhang, J.; Li, Q.; Zeng, Y.; Tang, Z.; Sun, D.; Huang, D.; Tang, Y.; Wang, H. Weakly Solvating Cyclic Ether Electrolyte for High-Voltage Lithium Metal Batteries. ACS Energy Lett. 2023, 8, 1752–1761.

- 41 Liang, H.-J.; Gu, Z.-Y.; Zhao, X.-X.; Guo, J.-Z.; Yang, J.-L.; Li, W.-H.; Li, B.; Liu, Z.-M.; Li, W.-L.; Wu, X.-L. Ether-Based Electrolyte Chemistry Towards High-Voltage and Long-Life Na-Ion Full Batteries. Angew. Chem. Int. Ed. 2021, 60, 26837–26846.

- 42 Wang, Y.; Cao, Z.; Ma, Z.; Liu, G.; Cheng, H.; Zou, Y.; Cavallo, L.; Li, Q.; Ming, J. Weak Solvent–Solvent Interaction Enables High Stability of Battery Electrolyte. ACS Energy Lett. 2023, 8, 1477–1484.

- 43 Wu, Y.; Hu, Q.; Liang, H.; Wang, A.; Xu, H.; Wang, L.; He, X. Electrostatic Potential as Solvent Descriptor to Enable Rational Electrolyte Design for Lithium Batteries. Adv. Energy Mater. 2023, 13, 2300259.

- 44 Ma, T.; Ni, Y.; Wang, Q.; Zhang, W.; Jin, S.; Zheng, S.; Yang, X.; Hou, Y.; Tao, Z.; Chen, J. Optimize Lithium Deposition at Low Temperature by Weakly Solvating Power Solvent. Angew. Chem. Int. Ed. 2022, 61, e202207927.

- 45 Li, T.; Zhang, X.-Q.; Yao, N.; Yao, Y.-X.; Hou, L.-P.; Chen, X.; Zhou, M.-Y.; Huang, J.-Q.; Zhang, Q. Stable Anion-Derived Solid Electrolyte Interphase in Lithium Metal Batteries. Angew. Chem. Int. Ed. 2021, 60, 22683–22687.

- 46 Xu, S.; Fang, Q.; Wu, J.; Weng, S.; Li, X.; Liu, Q.; Wang, Q.; Yu, X.; Chen, L.; Li, Y.; Wang, Z.; Wang, X. Interphase Engineering Enhanced Electro-chemical Stability of Prelithiated Anode. Small 2023, 20, 2305639.

- 47 Chen, S.; Wang, Z.; Wang, L.; Song, Z.; Yang, K.; Zhao, W.; Liu, L.; Fang, J.; Qian, G.; Pan, F.; Yang, L. Constructing a Robust Solid–Electrolyte Interphase Layer via Chemical Prelithiation for High-Performance SiOx Anode. Adv. Energy Sustain. Res. 2022, 3, 2200083.

- 48 Yoo, S.; Kim, J.; Kang, B. Characterizing Local Structure of SiOx Using Confocal μ-Raman Spectroscopy and Its Effects on Electrochemical Property. Electrochim. Acta 2016, 212, 68–75.

- 49 Marinov, M.; Zotov, N. Model Investigation of the Raman Spectra of Amorphous Silicon. Phys. Rev. B 1997, 55, 2938–2944.

- 50 Li, Y.; Qian, Y.; Zhao, Y.; Lin, N.; Qian, Y. Revealing the Interface-Rectifying Functions of a Li-Cyanonaphthalene Prelithiation System for SiO Electrode. Sci. Bull. 2022, 67, 636–645.

- 51 Hernández, S.; Martínez, A.; Pellegrino, P.; Lebour, Y.; Garrido, B.; Jordana, E.; Fedeli, J. M. Silicon Nanocluster Crystallization in SiOx Films Studied by Raman Scattering. J. Appl. Phys. 2008, 104, 044304.

- 52 Sun, Q.; Li, J.; Hao, C.; Ci, L. Focusing on the Subsequent Coulombic Efficiencies of SiOx: Initial High-Temperature Charge after Over-Capacity Prelithiation for High-Efficiency SiOx-Based Full-Cell Battery. ACS Appl. Mater. Interfaces 2022, 14, 14284–14292.

- 53 Hong, F.; Zhou, R.; Gao, C.; Liu, Y.; Sun, Z.; Jiang, Y. Fabrication of Porous SiOx/nanoSi@C Composites with Homogeneous Silicon Distribution for High-Performance Li-Ion Battery Anodes. J. Alloys Compd. 2023, 947, 169511.

- 54 Sun, Y.; Zhang, K.; Chai, R.; Wang, Y.; Rui, X.; Wang, K.; Deng, H.; Xiang, H. In Situ Artificial Hybrid SEI Layer Enabled High-Performance Prelithiated SiOx Anode for Lithium-Ion Batteries. Adv. Funct. Mater. 2023, 33, 2303020.

- 55 Jang, J.; Kang, I.; Choi, J.; Jeong, H.; Yi, K.; Hong, J.; Lee, M. Molecularly Tailored Lithium–Arene Complex Enables Chemical Prelithiation of High-Capacity Lithium-Ion Battery Anodes. Angew. Chem. Int. Ed. 2020, 59, 14473–14480.

- 56 Huang, B.; Huang, T.; Wan, L.; Yu, A. Pre-Lithiating SiO Anodes for Lithium-Ion Batteries by a Simple, Effective, and Controllable Strategy Using Stabilized Lithium Metal Powder. ACS Sustainable Chem. Eng. 2021, 9, 648–657.

- 57 Zhang, Q.-K.; Zhang, X.-Q.; Wan, J.; Yao, N.; Song, T.-L.; Xie, J.; Hou, L.-P.; Zhou, M.-Y.; Chen, X.; Li, B.-Q.; Wen, R.; Peng, H.-J.; Zhang, Q.; Huang, J.-Q. Homogeneous and Mechanically Stable Solid–Electrolyte Interphase Enabled by Trioxane-Modulated Electrolytes for Lithium Metal Batteries. Nat. Energy 2023, 8, 725–735.

- 58 Zhang, Z.; Zhang, Y.; Ye, M.; Tang, Y.; Wen, Z.; Liu, X.; Li, C. C. A B- and F-Enriched Buffering Interphase Enables a High-Rate and High-Stability SiOx/C Anode. Chem. Commun. 2023, 59, 10980–10983.