Biodegradable Dual-Network Cellulosic Composite Bioplastic Metafilm for Plastic Substitute

Dong Wang

Department of Biomedical Engineering, City University of Hong Kong Kowloon, Hong Kong SAR, 999077 China

Key Laboratory of Eco-Textile, College of Textile Science and Engineering, Jiangnan University, Jiangsu, 214122 China

Search for more papers by this authorShuo Shi

Department of Biomedical Engineering, City University of Hong Kong Kowloon, Hong Kong SAR, 999077 China

Search for more papers by this authorYanyun Mao

Key Laboratory of Eco-Textile, College of Textile Science and Engineering, Jiangnan University, Jiangsu, 214122 China

Search for more papers by this authorLeqi Lei

Department of Biomedical Engineering, City University of Hong Kong Kowloon, Hong Kong SAR, 999077 China

Search for more papers by this authorShaohai Fu

Key Laboratory of Eco-Textile, College of Textile Science and Engineering, Jiangnan University, Jiangsu, 214122 China

Search for more papers by this authorCorresponding Author

Jinlian Hu

Department of Biomedical Engineering, City University of Hong Kong Kowloon, Hong Kong SAR, 999077 China

Search for more papers by this authorDong Wang

Department of Biomedical Engineering, City University of Hong Kong Kowloon, Hong Kong SAR, 999077 China

Key Laboratory of Eco-Textile, College of Textile Science and Engineering, Jiangnan University, Jiangsu, 214122 China

Search for more papers by this authorShuo Shi

Department of Biomedical Engineering, City University of Hong Kong Kowloon, Hong Kong SAR, 999077 China

Search for more papers by this authorYanyun Mao

Key Laboratory of Eco-Textile, College of Textile Science and Engineering, Jiangnan University, Jiangsu, 214122 China

Search for more papers by this authorLeqi Lei

Department of Biomedical Engineering, City University of Hong Kong Kowloon, Hong Kong SAR, 999077 China

Search for more papers by this authorShaohai Fu

Key Laboratory of Eco-Textile, College of Textile Science and Engineering, Jiangnan University, Jiangsu, 214122 China

Search for more papers by this authorCorresponding Author

Jinlian Hu

Department of Biomedical Engineering, City University of Hong Kong Kowloon, Hong Kong SAR, 999077 China

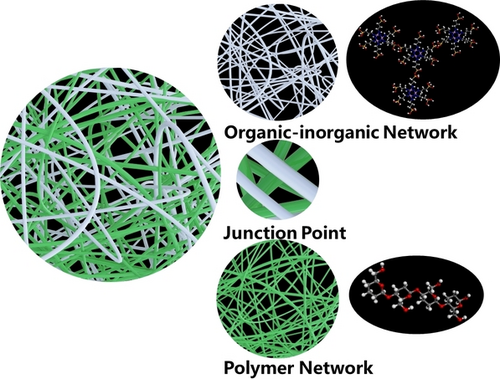

Search for more papers by this authorGraphical Abstract

The novel dual-network design strategy is proposed to prepare a high-performance cellulosic composite bioplastic metafilm with exceptional mechanical toughness (23.5 MJ m−3), flame retardance, and solvent resistance. Moreover, it has a high maximum usage temperature (245 °C), lower thermal expansion coefficient (15.19 ppm °C−1), good biocompatibility, and natural biodegradation, which is competitive for plastic substitute.

Abstract

With the escalating environmental and health concerns over petroleum-based plastics, sustainable and biodegradable cellulosic materials are a promising alternative to plastics, yet remain unsatisfied properties such as fragility, inflammability and water sensitivity for practical usage. Herein, we present a novel dual-network design strategy to address these limitations and fabricate a high-performance cellulosic composite bioplastic metafilm with the exceptional mechanical toughness (23.5 MJ m−3), flame retardance, and solvent resistance by in situ growth of cyclotriphosphazene-bridged organosilica network within bacterial cellulose matrix. The phosphorus, nitrogen-containing organosilica network, verified by the experimental and theoretical results, plays a triple action on significantly enhancing tensile strength, toughness, flame retardance and water resistance of composite bioplastic metafilm. Furthermore, cellulosic bioplastic composite metafilm demonstrates a higher maximum usage temperature (245 °C), lower thermal expansion coefficient (15.19 ppm °C−1), and better solvent resistance than traditional plastics, good biocompatibility and natural biodegradation. Moreover, the composite bioplastic metafilm have a good transparency of average 74 % and a high haze over 80 %, which can serve as an outstanding substrate substitute for commercial polyethylene terephthalate film to address the demand of flexible ITO films. This work paves a creative way to design and manufacture the competitive bioplastic composite to replace daily-used plastics.

Conflict of interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available in the supplementary material of this article.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| anie202310995-sup-0001-misc_information.pdf1.8 MB | Supporting Information |

| anie202310995-sup-0001-Movie_S1.mp415.2 MB | Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1

- 1aS. B. Borrelle, J. Ringma, K. L. Law, C. C. Monnahan, L. Lebreton, A. McGivern, E. Murphy, J. Jambeck, G. H. Leonard, M. A. Hilleary, Science 2020, 369, 1515–1518;

- 1bD. M. Mitrano, P. Wick, B. Nowack, Nat. Nanotechnol. 2021, 16, 491–500.

- 2

- 2aJ. Su, K. Zhao, Y. Ren, L. Zhao, B. Wei, B. Liu, Y. Zhang, F. Wang, J. Li, Y. Liu, Angew. Chem. Int. Ed. 2022, 61, e202117538;

- 2bG. Zhou, H. Zhang, Z. Su, X. Zhang, H. Zhou, L. Yu, C. Chen, X. Wang, Adv. Mater. 2023, 35, 2301398;

- 2cQ. Xia, C. Chen, Y. Yao, J. Li, S. He, Y. Zhou, T. Li, X. Pan, Y. Yao, L. Hu, Nat. Sustainability 2021, 4, 627–635;

- 2dA. M. Duraj-Thatte, A. Manjula-Basavanna, N.-M. D. Courchesne, G. I. Cannici, A. Sánchez-Ferrer, B. P. Frank, L. van't Hag, S. K. Cotts, D. H. Fairbrother, R. Mezzenga, Nat. Chem. Biol. 2021, 17, 732–738;

- 2eS. Shi, P. Lv, C. Valenzuela, B. Li, Y. Liu, L. Wang, W. Feng, Small 2023, 19, 2301957;

- 2fS. Zhang, M. Chi, J. Mo, T. Liu, Y. Liu, Q. Fu, J. Wang, B. Luo, Y. Qin, S. Wang, Nat. Commun. 2022, 13, 4168.

- 3

- 3aQ.-F. Guan, Z.-C. Ling, Z.-M. Han, H.-B. Yang, S.-H. Yu, Matter 2020, 3, 1308–1317;

- 3bQ.-F. Guan, H.-B. Yang, Z.-M. Han, Z.-C. Ling, K.-P. Yang, C.-H. Yin, S.-H. Yu, Nano Lett. 2021, 21, 8999–9004;

- 3cQ.-F. Guan, H.-B. Yang, Z.-M. Han, Z.-C. Ling, S.-H. Yu, Nat. Commun. 2020, 11, 5401;

- 3dH. Zhang, Z. Su, X. Wang, ACS Sustainable Chem. Eng. 2022, 10, 8650–8657;

- 3eS. K. Burgess, J. E. Leisen, B. E. Kraftschik, C. R. Mubarak, R. M. Kriegel, W. J. Koros, Macromolecules 2014, 47, 1383–1391;

- 3fS. Shi, M. Cui, F. Sun, K. Zhu, M. I. Iqbal, X. Chen, B. Fei, R. K. Y. Li, Q. Xia, J. Hu, Adv. Mater. 2021, 33, 2101005;

- 3gS. Shi, K. Zhu, X. Chen, J. Hu, L. Zhang, ACS Sustainable Chem. Eng. 2019, 7, 19799–19806.

- 4

- 4aQ.-F. Guan, H.-B. Yang, Z.-M. Han, L.-C. Zhou, Y.-B. Zhu, Z.-C. Ling, H.-B. Jiang, P.-F. Wang, T. Ma, H.-A. Wu, Sci. Adv. 2020, 6, eaaz1114;

- 4bH. Abdul Khalil, A. Bhat, A. I. Yusra, Carbohydr. Polym. 2012, 87, 963–979.

- 5

- 5aZ. Zhu, W. Wang, Z. Liu, C. Gao, N. Xia, P. Fatehi, F. Kong, S. Wang, Ind. Crops Prod. 2022, 185, 115106;

- 5bH. Nadeem, M. Athar, M. Dehghani, G. Garnier, W. Batchelor, Sci. Total Environ. 2022, 836, 155654.

- 6

- 6aK. Li, C. M. Clarkson, L. Wang, Y. Liu, M. Lamm, Z. Pang, Y. Zhou, J. Qian, M. Tajvidi, D. J. Gardner, ACS Nano 2021, 15, 3646–3673;

- 6bQ.-F. Guan, Z.-M. Han, T.-T. Luo, H.-B. Yang, H.-W. Liang, S.-M. Chen, G.-S. Wang, S.-H. Yu, Natl. Sci. Rev. 2019, 6, 64–73;

- 6cQ. Ma, K. Wang, D. Mohawk, Y. Chen, R. Hazra, L. Jiang, ACS Sustainable Chem. Eng. 2021, 9, 10749–10760;

- 6dS. Deng, R. Huang, M. Zhou, F. Chen, Q. Fu, Carbohydr. Polym. 2016, 154, 129–138;

- 6eE. Subbotina, F. Ram, S. V. Dvinskikh, L. A. Berglund, P. Olsén, Nat. Commun. 2022, 13, 6924;

- 6fS. Wang, L. Yu, S. Wang, L. Zhang, L. Chen, X. Xu, Z. Song, H. Liu, C. Chen, Nat. Commun. 2022, 13, 3408;

- 6gI. Leppänen, T. Lappalainen, T. Lohtander, C. Jonkergouw, S. Arola, T. Tammelin, Nat. Commun. 2022, 13, 1814.

- 7

- 7aT. Li, C. Chen, A. H. Brozena, J. Zhu, L. Xu, C. Driemeier, J. Dai, O. J. Rojas, A. Isogai, L. Wågberg, Nature 2021, 590, 47–56;

- 7bR. Wang, J. M. Ma, S. Ma, Q. R. Zhang, N. Li, M. M. Ji, T. F. Jiao, X. Cao, Chem. Eng. J. 2022, 450, 137985;

- 7cX. Yang, E. Jungstedt, M. S. Reid, L. A. Berglund, Macromolecules 2021, 54, 4443–4452.

- 8

- 8aD. Wang, H. Peng, Y. Wu, L. Zhang, M. Li, M. Liu, Y. Zhu, A. Tian, S. Fu, ACS Sustainable Chem. Eng. 2020, 8, 4331–4336;

- 8bX. Wang, E. N. Kalali, J. T. Wan, D. Y. Wang, Prog. Polym. Sci. 2017, 69, 22–46.

- 9M. Farooq, T. Zou, G. Riviere, M. H. Sipponen, M. Österberg, Biomacromolecules 2019, 20, 693–704.

- 10S. Torgbo, P. Sukyai, Polym. Degrad. Stab. 2020, 179, 109232.

- 11D. Wang, X. Feng, L. Zhang, M. Li, M. Liu, A. Tian, S. Fu, Chem. Eng. J. 2019, 375, 121933.

- 12W. Huang, M. Shishehbor, N. Guarín-Zapata, N. D. Kirchhofer, J. Li, L. Cruz, T. Wang, S. Bhowmick, D. Stauffer, P. Manimunda, K. N. Bozhilov, R. Caldwell, P. Zavattieri, D. Kisailus, Nat. Mater. 2020, 19, 1236–1243.

- 13

- 13aM. A. Khan, U. S. Bhansali, H. N. Alshareef, Org. Electron. 2011, 12, 2225–2229;

- 13bH. Lindström, A. Holmberg, E. Magnusson, S.-E. Lindquist, L. Malmqvist, A. Hagfeldt, Nano Lett. 2001, 1, 97–100.

- 14M. Ramezanzadeh, A. Tati, G. Bahlakeh, B. Ramezanzadeh, Chem. Eng. J. 2021, 408, 127366.

- 15

- 15aO. C. Andronesi, S. Becker, K. Seidel, H. Heise, H. S. Young, M. Baldus, J. Am. Chem. Soc. 2005, 127, 12965–12974;

- 15bO. Beckonert, M. Coen, H. C. Keun, Y. Wang, T. M. D. Ebbels, E. Holmes, J. C. Lindon, J. K. Nicholson, Nat. Protoc. 2010, 5, 1019–1032.

- 16J. Wang, C. Zhang, C. Yang, C. Zhang, M. Wang, J. Zhang, Y. Xu, ACS Appl. Mater. Interfaces 2017, 9, 5468–5476.

- 17

- 17aB. Soundiraraju, B. K. George, ACS Nano 2017, 11, 8892–8900;

- 17bL. Liu, J. Wu, L. Wu, M. Ye, X. Liu, Q. Wang, S. Hou, P. Lu, L. Sun, J. Zheng, L. Xing, L. Gu, X. Jiang, L. Xie, L. Jiao, Nat. Mater. 2018, 17, 1108–1114;

- 17cZ.-K. Yuan, S. Chen, H. Xiang, X.-G. Gong, A. Walsh, J.-S. Park, I. Repins, S.-H. Wei, Adv. Funct. Mater. 2015, 25, 6733–6743.

- 18

- 18aP. Song, H. Wang, Adv. Mater. 2020, 32, 1901244;

- 18bK. Chen, B. Shi, Y. Yue, J. Qi, L. Guo, ACS Nano 2015, 9, 8165–8175.

- 19

- 19aH.-L. Gao, S.-M. Chen, L.-B. Mao, Z.-Q. Song, H.-B. Yao, H. Cölfen, X.-S. Luo, F. Zhang, Z. Pan, Y.-F. Meng, Y. Ni, S.-H. Yu, Nat. Commun. 2017, 8, 287;

- 19bF. Bouville, E. Maire, S. Meille, B. Van de Moortèle, A. J. Stevenson, S. Deville, Nat. Mater. 2014, 13, 508–514;

- 19cL.-B. Mao, H.-L. Gao, H.-B. Yao, L. Liu, H. Cölfen, G. Liu, S.-M. Chen, S.-K. Li, Y.-X. Yan, Y.-Y. Liu, S.-H. Yu, Science 2016, 354, 107–110.

- 20

- 20aY. Feng, X. Zhang, Y. Shen, K. Yoshino, W. Feng, Carbohydr. Polym. 2012, 87, 644–649;

- 20bR. Mi, T. Li, D. Dalgo, C. Chen, Y. Kuang, S. He, X. Zhao, W. Xie, W. Gan, J. Zhu, Adv. Funct. Mater. 2020, 30, 1907511;

- 20cH.-D. Huang, C.-Y. Liu, L.-Q. Zhang, G.-J. Zhong, Z.-M. Li, ACS Sustainable Chem. Eng. 2015, 3, 317–324;

- 20dR. Xiong, K. Hu, A. M. Grant, R. Ma, W. Xu, C. Lu, X. Zhang, V. V. Tsukruk, Adv. Mater. 2016, 28, 1501–1509;

- 20eC.-J. Kim, W. Khan, D.-H. Kim, K.-S. Cho, S.-Y. Park, Carbohydr. Polym. 2011, 86, 903–909.

- 21L. Liu, M. Zhu, X. Xu, X. Li, Z. Ma, Z. Jiang, A. Pich, H. Wang, P. Song, Adv. Mater. 2021, 33, 2105829.

- 22P. Song, J. Dai, G. Chen, Y. Yu, Z. Fang, W. Lei, S. Fu, H. Wang, Z.-G. Chen, ACS Nano 2018, 12, 9266–9278.

- 23B. W. Liu, H. B. Zhao, Y. Z. Wang, Adv. Mater. 2022, 34, 2107905.

- 24Q. Guan, X. Deng, H. Zhang, S. Zhong, P. Liu, Y. Zhuang, X. Hu, M. Yao, R. E. Neisiany, Z. You, Chem. Eng. J. 2023, 453, 139329.

- 25B. W. Liu, L. Chen, D. M. Guo, X. F. Liu, Y. F. Lei, X. M. Ding, Y. Z. Wang, Angew. Chem. Int. Ed. 2019, 58, 9188–9193.

- 26T. Kashiwagi, F. Du, J. F. Douglas, K. I. Winey, R. H. Harris Jr, J. R. Shields, Nat. Mater. 2005, 4, 928–933.

- 27B. Wicklein, A. Kocjan, G. Salazar-Alvarez, F. Carosio, G. Camino, M. Antonietti, L. Bergström, Nat. Nanotechnol. 2015, 10, 277–283.

- 28M.-C. Choi, Y. Kim, C.-S. Ha, Prog. Polym. Sci. 2008, 33, 581–630.

- 29Z. Yu, Y. Yao, J. Yao, L. Zhang, Z. Chen, Y. Gao, H. Luo, J. Mater. Chem. A 2017, 5, 6019–6024.

- 30M. H. Al-Saleh, U. Sundararaj, Carbon 2009, 47, 1738–1746.