Fast and Minimal-Solvent Production of Superinsulating Silica Aerogel Granulate

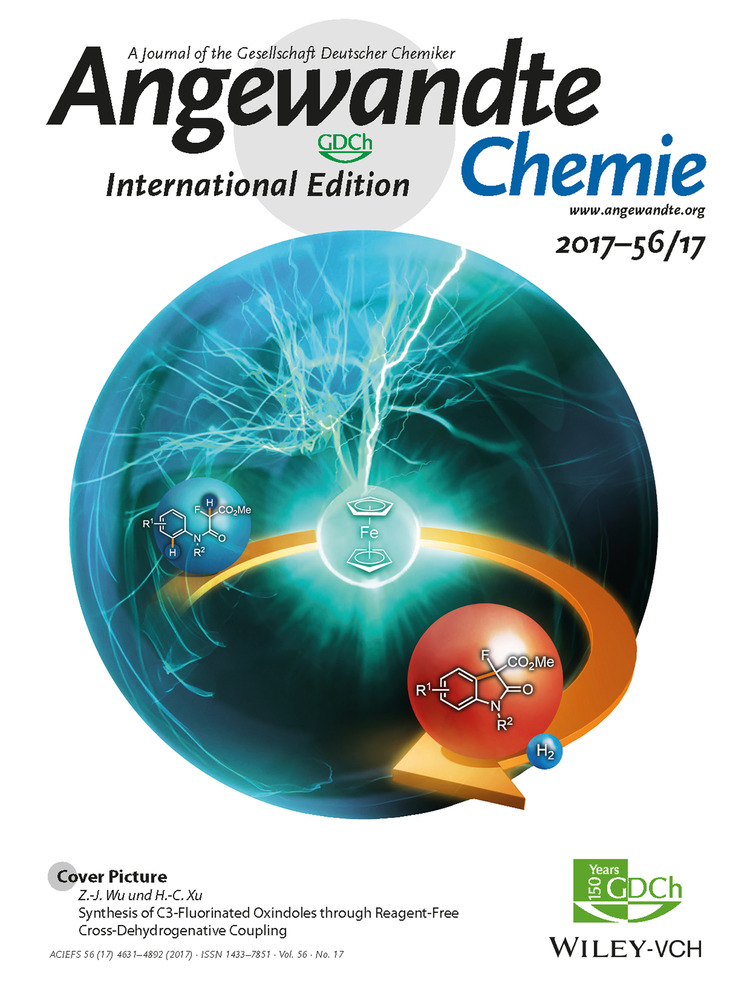

Graphical Abstract

Solving the solvent problem: Silica aerogels are ideal thermal insulation materials, but are expensive owing to the large solvent consumption during their production. A simplified synthesis combines all reagents in a single step and minimizes the production time, solvent use, and carbon footprint, but retains the outstanding properties associated with silica aerogels.

Abstract

With their low thermal conductivity (λ), silica aerogels can reduce carbon emissions from heating and cooling demands, but their widespread adoption is limited by the high production cost. A one-pot synthesis for silica aerogel granulate is presented that drastically reduces solvent use, production time, and global warming potential. The inclusion of the hydrophobization agent prior to gelation with a post-gelation activation step, enables a complete production cycle of less than four hours at the lab scale for a solvent use close to the theoretical minimum, and limits the global warming potential. Importantly, the one-pot aerogel granulate retains the exceptional properties associated with silica aerogel, mostly λ=14.4±1.0 mW m−1⋅K−1 for the pilot scale materials, about half that of standing air (26 mW m−1⋅K−1). The resource-, time-, and cost-effective production will allow silica aerogels to break out of its niche into the mainstream building and industrial insulation markets.