Fabrication of Hollow Materials by Fast Pyrolysis of Cellulose Composite Fibers with Heterogeneous Structures

Dr. Yue Dong

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorDr. Baoquan Jia

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorDr. Feiya Fu

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorDr. Heyou Zhang

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorProf. Lina Zhang

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorCorresponding Author

Prof. Dr. Jinping Zhou

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorDr. Yue Dong

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorDr. Baoquan Jia

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorDr. Feiya Fu

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorDr. Heyou Zhang

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorProf. Lina Zhang

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

Search for more papers by this authorCorresponding Author

Prof. Dr. Jinping Zhou

Department of Chemistry and Key Laboratory of Biomedical Polymers of Ministry of Education, Wuhan University, Wuhan, 430072 China

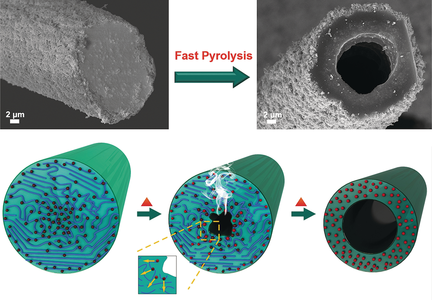

Search for more papers by this authorGraphical Abstract

Hollow structural materials were fabricated from cuprammonium cellulose composite filaments by fast pyrolysis. The whole process could be completed within 100 s. The formation mechanism is related to the heterogeneous structure of the fibers and the gradient distribution of the metal oxides in the cellulose matrix.

Abstract

A facile method for the fabrication of inorganic hollow materials from cuprammonium cellulose composite filaments based on fast pyrolysis has been developed. Unlike Ostwald ripening, approaches based on the Kirkendall effect, and other template methods, this process yielded hollow materials within 100 s. The heterogeneous structure of the cellulose composite fibers and the gradient distribution of the metal oxides are the main reasons for the formation of the hollow structure. The diameter, wall thickness, and length of the hollow microfibers could be conveniently controlled. With their perfect morphology, these hollow structural materials have great potential for use in various fields.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| anie201607455-sup-0001-misc_information.pdf796.1 KB | Supplementary |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1

- 1aY. Zhao, L. Jiang, Adv. Mater. 2009, 21, 3621–3638;

- 1bX. Liu, X. Jin, P. X. Ma, Nat. Mater. 2011, 10, 398–406;

- 1cZ. Zhang, Y. Chen, X. Xu, J. Zhang, G. Xiang, W. He, X. Wang, Angew. Chem. Int. Ed. 2014, 53, 429–433; Angew. Chem. 2014, 126, 439–443;

- 1dE. G. Moschetta, S. Negretti, K. M. Chepiga, N. A. Brunelli, Y. Labreche, Y. Feng, F. Rezaei, R. P. Lively, W. J. Koros, H. M. L. Davies, C. W. Jones, Angew. Chem. Int. Ed. 2015, 54, 6470–6474; Angew. Chem. 2015, 127, 6570–6574;

- 1eG. Zhang, X. W. Lou, Angew. Chem. Int. Ed. 2014, 53, 9041–9044; Angew. Chem. 2014, 126, 9187–9190.

- 2

- 2aL. Yu, L. Zhang, H. Wu, X. W. Lou, Angew. Chem. Int. Ed. 2014, 53, 3711–3714; Angew. Chem. 2014, 126, 3785–3788;

- 2bJ. Liu, N. P. Wickramaratne, S. Z. Qiao, M. Jaroniec, Nat. Mater. 2015, 14, 763–774.

- 3

- 3aX. B. Cao, L. Gu, L. J. Zhuge, W. J. Gao, W. C. Wang, S. F. Wu, Adv. Funct. Mater. 2006, 16, 896–902;

- 3bH. Yu, J. Yu, S. Liu, S. Mann, Chem. Mater. 2007, 19, 4327–4334;

- 3cA. Pan, H. B. Wu, L. Yu, X. W. Lou, Angew. Chem. Int. Ed. 2013, 52, 2226–2230; Angew. Chem. 2013, 125, 2282–2286.

- 4T. Jaumann, M. Herklotz, M. Klose, K. Pinkert, S. Oswald, J. Eckert, L. Giebeler, Chem. Mater. 2015, 27, 37–43.

- 5

- 5aH. J. Fan, M. Knez, R. Scholz, K. Nielsch, E. Pippel, D. Hesse, M. Zacharias, U. Gösele, Nat. Mater. 2006, 5, 627–631;

- 5bH. J. Fan, M. Knez, R. Scholz, D. Hesse, K. Nielsch, M. Zacharias, U. Gösele, Nano Lett. 2007, 7, 993–997;

- 5cG. Song, C. Liang, X. Yi, Q. Zhao, L. Cheng, K. Yang, Z. Liu, Adv. Mater. 2016, 28, 2716–2723.

- 6

- 6aX. Sun, J. Liu, Y. Li, Chem. Mater. 2006, 18, 3486–3494;

- 6bC. C. Yec, H. C. Zeng, J. Mater. Chem. A 2014, 2, 4843–4851;

- 6cL. Cao, D. Chen, R. A. Caruso, Angew. Chem. Int. Ed. 2013, 52, 10986–10991; Angew. Chem. 2013, 125, 11192–11197.

- 7Y. Zhao, C. Jiang, C. Hu, Z. Dong, J. Xue, Y. Meng, N. Zheng, P. Chen, L. Qu, ACS Nano 2013, 7, 2406–2412.

- 8K. Müller, J. F. Quinn, A. P. R. Johnston, M. Becker, A. Greiner, F. Caruso, Chem. Mater. 2006, 18, 2397–2403.

- 9

- 9aX. Huang, J. Zhang, Z. Liu, T. Sang, B. Song, H. Zhu, C. Wong, J. Alloys Compd. 2015, 648, 1072–1075;

- 9bH. Guo, R. Mao, X. Yang, S. Wang, J. Chen, J. Power Sources 2012, 219, 280–284;

- 9cX. Zhang, D. K. Wang, D. R. S. Lopez, J. C. D. da Costa, Chem. Eng. J. 2014, 236, 314–322.

- 10

- 10aJ. Huo, L. Wang, E. Irran, H. Yu, J. Gao, D. Fan, B. Li, J. Wang, W. Ding, A. Amin, C. Li, L. Ma, Angew. Chem. Int. Ed. 2010, 49, 9237–9241; Angew. Chem. 2010, 122, 9423–9427;

- 10bR. J. White, K. Tauer, M. Antonietti, M.-M. Titirici, J. Am. Chem. Soc. 2010, 132, 17360–17363;

- 10cR. Liu, S. M. Mahurin, C. Li, R. R. Unocic, J. C. Idrobo, H. Gao, S. J. Pennycook, S. Dai, Angew. Chem. Int. Ed. 2011, 50, 6799–6802; Angew. Chem. 2011, 123, 6931–6934;

- 10dL. Li, C. Yuan, D. Zhou, A. E. Ribbe, K. R. Kittilstved, S. Thayumanavan, Angew. Chem. Int. Ed. 2015, 54, 12991–12995; Angew. Chem. 2015, 127, 13183–13187.

- 11D. Fabbri, C. Torri, V. Baravelli, J. Anal. Appl. Pyrolysis 2007, 80, 24–29.

- 12

- 12aE. Ghadiri, N. Taghavinia, S. M. Zakeeruddin, M. Gratzel, J. E. Moser, Nano Lett. 2010, 10, 1632–1638;

- 12bR. Mao, H. Guo, D. X. Tian, X. J. Yang, S. X. Wang, J. Chen, J. Inorg. Mater. 2013, 28, 1213–1217.

- 13

- 13aB. Jia, Y. Mei, L. Cheng, J. Zhou, L. Zhang, ACS Appl. Mater. Interfaces 2012, 4, 2897–2902;

- 13bB. Jia, Y. Dong, J. Zhou, L. Zhang, J. Mater. Chem. C 2014, 2, 524–529;

- 13cB. Jia, L. Yu, F. Fu, L. Li, J. Zhou, L. Zhang, RSC Adv. 2014, 4, 9112–9117.

- 14H. Miyamoto, C. Yamane, M. Mori, K. Okajima, J. Sugiyama, Text. Res. J. 2009, 79, 694–701.

- 15

- 15aJ. Huang, N. Matsunaga, K. Shimanoe, N. Yamazoe, T. Kunitake, Chem. Mater. 2005, 17, 3513–3518;

- 15bJ. Huang, K. Toyoki, J. Mater. Chem. 2006, 16, 4257–4264;

- 15cS. Liu, L. Zhang, J. Zhou, J. Xiang, J. Sun, J. Guan, Chem. Mater. 2008, 20, 3623–3628;

- 15dN. Kang, J. H. Park, M. Jin, N. Park, S. M. Lee, H. J. Kim, J. M. Kim, S. U. Son, J. Am. Chem. Soc. 2013, 135, 19115–19117.

- 16I. Miyamoto, M. Inamoto, T. Matsui, M. Saito, K. Okajima, Polym. J. 1995, 27, 1113–1122.

- 17

- 17aG. Dobele, G. Rossinskaja, T. Dizhbite, G. Telysheva, D. Meier, O. Faix, J. Anal. Appl. Pyrolysis 2005, 74, 401–405;

- 17bM. Zhao, N. H. Florin, A. T. Harris, Appl. Catal. B 2009, 92, 185–193.

- 18

- 18aH. Li, J. Liao, T. Zeng, Catal. Commun. 2014, 46, 169–173;

- 18bH. Shi, Y. Zhao, N. Li, K. Wang, X. Hua, M. Chen, F. Teng, Catal. Commun. 2014, 47, 7–12.

- 19

- 19aW. Ren, C. Zhu, E. Wang, Nanoscale 2012, 4, 5902–5909;

- 19bL. Manganiello, A. Ríos, M. Valcárcel, Anal. Chem. 2002, 74, 921–925;

- 19cL. Deng, X. Ouyang, J. Jin, C. Ma, Y. Jiang, J. Zheng, J. Li, Y. Li, W. Tan, R. Yang, Anal. Chem. 2013, 85, 8594–8600;

- 19dV. Chakrapani, K. B. Ayaz Ahmed, V. Kumar, V. Ganapathy, S. P. Anthony, V. Anbazhagan, RSC Adv. 2014, 4, 33215–33221.