Lignin-Based Polyurethane: Recent Advances and Future Perspectives

Xiaozhen Ma

Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo, 315201 China

University of Chinese Academy of Sciences, Beijing, 100049 China

Search for more papers by this authorCorresponding Author

Jing Chen

Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo, 315201 China

University of Chinese Academy of Sciences, Beijing, 100049 China

E-mail: [email protected]; [email protected]

Search for more papers by this authorJin Zhu

Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo, 315201 China

University of Chinese Academy of Sciences, Beijing, 100049 China

Search for more papers by this authorCorresponding Author

Ning Yan

Department of Chemical Engineering and Applied Chemistry, University of Toronto, Toronto, M5S 3B3 Canada

E-mail: [email protected]; [email protected]

Search for more papers by this authorXiaozhen Ma

Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo, 315201 China

University of Chinese Academy of Sciences, Beijing, 100049 China

Search for more papers by this authorCorresponding Author

Jing Chen

Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo, 315201 China

University of Chinese Academy of Sciences, Beijing, 100049 China

E-mail: [email protected]; [email protected]

Search for more papers by this authorJin Zhu

Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo, 315201 China

University of Chinese Academy of Sciences, Beijing, 100049 China

Search for more papers by this authorCorresponding Author

Ning Yan

Department of Chemical Engineering and Applied Chemistry, University of Toronto, Toronto, M5S 3B3 Canada

E-mail: [email protected]; [email protected]

Search for more papers by this authorAbstract

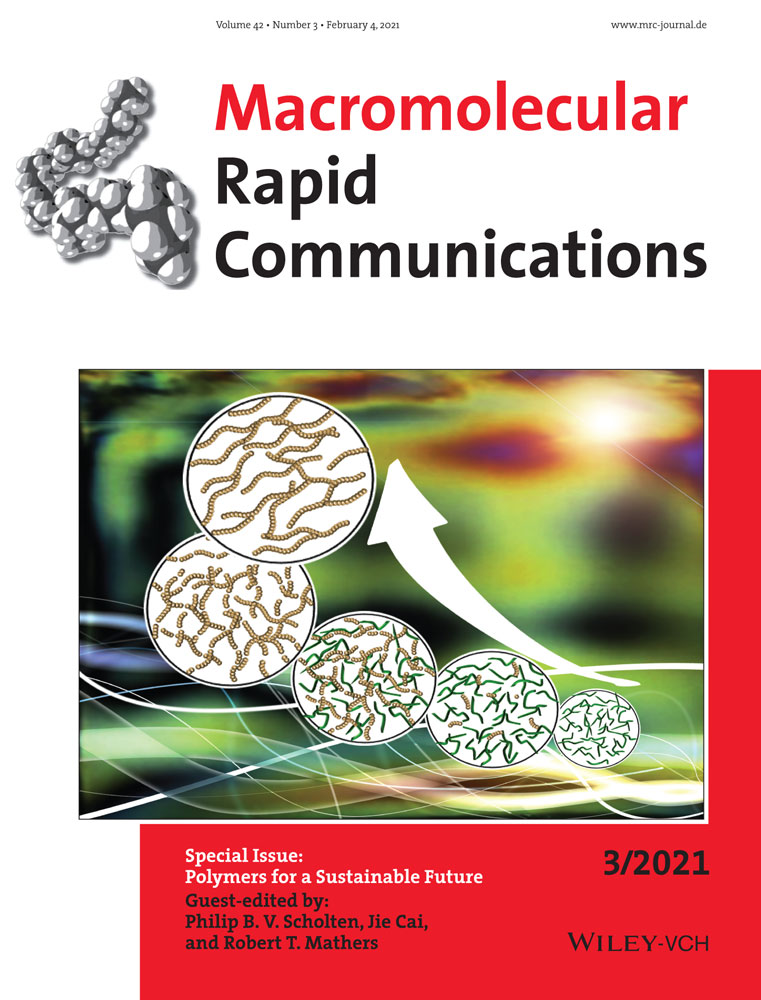

Polyurethane (PU), as a polymer material with versatile product forms and excellent performance, is used in coatings, elastomers, adhesives, and foams widely. However, the raw materials (polyols and isocyanates) of PU are usually made using petroleum-derived chemicals. With the concern for depletion of petroleum resources and the associated negative impact on the environment, developing technologies that can use renewable raw materials as feedstock has become a research hotspot. Lignin, as an abundant, natural, and renewable organic carbon resource, has been explored as raw material for making polyurethanes because it possesses rich hydroxyl groups on its surface. Meanwhile, compared to vegetable oils, lignin does not compete with food supply and performance of the resulting products is superior. Lignin or modified lignin has been shown to impart the polyurethane material with additional functionalities, such as UV-blocking ability, hydrophobicity, and flame retardancy. However, the utilization of lignin has encountered some challenges, such as product isolation, heterogeneity, aggregation, steric hindrance, and low activity. This paper summarizes recent research progress on utilizing lignin and modified lignin for bio-based polyurethane synthesis with a focus on elastomers and foams. Opportunities and challenges for application of the lignin-based polyurethanes in various fields are also discussed.

Conflict of Interest

The authors declare no conflict of interest.

References

- 1C. Prisacariu, Polyurethane Elastomers: From Morphology to Mechanical Aspects, Springer, Vienna 2011.

- 2P. Singhal, W. Small, E. Cosgriff-Hernandez, D. J. Maitland, T. S. Wilson, Acta Biomater. 2014, 10, 67.

- 3J. G. Hardy, M. Palma, S. J. Wind, M. J. Biggs, Adv. Mater. 2016, 28, 5717.

- 4L. Gu, B. Cui, Q. Wu, H. Yu, RSC Adv. 2016, 6, 17888.

- 5T. Ghosh, N. Karak, ACS Omega 2018, 3, 6849.

- 6J. Huang, W. Liu, X. Qiu, ACS Sustainable Chem. Eng. 2019, 7, 6550.

- 7J. S. Leng, X. Lan, Y. J. Liu, S. Y. Du, Prog. Mater. Sci. 2011, 56, 1077.

- 8J. C. Liu, J. C. Cao, Z. Zhou, R. Liu, Y. Yuan, X. Y. Liu, ACS Omega 2018, 3, 11128.

- 9A. M. Borrero-López, A. Blánquez, C. Valencia, M. Hernández, M. E. Arias, M. E. Eugenio, U. Fillat, J. M. Franco, ACS Sustainable Chem. Eng. 2018, 6, 5198.

- 10J. Zhu, X. Q. Liu, Bio-Based Polymer Materials, Science Press, Beijing 2018.

- 11L. Maisonneuve, O. Lamarzelle, E. Rix, E. Grau, H. Cramail, Chem. Rev. 2015, 115, 12407.

- 12Z. Ma, C. Li, H. Fan, J. Wan, Y. Luo, B. G. Li, Ind. Eng. Chem. Res. 2017, 56, 14089.

- 13H. Gang, D. Lee, K.-Y. Choi, H.-N. Kim, H. Ryu, D.-S. Lee, B.-G. Kim, ACS Sustainable Chem. Eng. 2017, 5, 4582.

- 14A. Gandini, T. M. Lacerda, A. J. Carvalho, E. Trovatti, Chem. Rev. 2016, 116, 1637.

- 15Y. Feng, H. Liang, Z. Yang, T. Yuan, Y. Luo, P. Li, Z. Yang, C. Zhang, ACS Sustainable Chem. Eng. 2017, 5, 7365.

- 16V. Pantone, A. G. Laurenza, C. Annese, F. Fracassi, C. Fusco, A. Nacci, A. Russo, L. D'Accolti, Ind. Crops Prod. 2017, 109, 1.

- 17H. Kalita, N. Karak, J. Appl. Polym. Sci. 2014, 131.

10.1002/app.39579 Google Scholar

- 18C. Zhang, S. A. Madbouly, M. R. Kessler, ACS Appl. Mater. Interfaces 2015, 7, 1226.

- 19M. Kurańska, A. Prociak, M. Kirpluks, U. Cabulis, Ind. Crops Prod. 2015, 74, 849.

- 20S. Jayavani, S. Sunanda, T. O. Varghese, S. K. Nayak, J. Cleaner Prod. 2017, 162, 795.

- 21Z. Fang, Z. Yang, D. Ji, N. Zhu, X. Li, L. Wan, K. Zhang, K. Guo, RSC Adv. 2016, 6, 90771.

- 22C. Li, X. Zhao, A. Wang, G. W. Huber, T. Zhang, Chem. Rev. 2015, 115, 11559.

- 23B. M. Upton, A. M. Kasko, Chem. Rev. 2016, 116, 2275.

- 24W. Lu, Q. Li, Y. Zhang, H. Yu, S. Hirose, H. Hatakeyama, Y. Matsumoto, Z. Jin, J. Wood Sci. 2018, 64, 287.

- 25Y. Pan, J. Zhan, H. Pan, W. Wang, G. Tang, L. Song, Y. Hu, ACS Sustainable Chem. Eng. 2016, 4, 1431.

- 26B. Wicklein, A. Kocjan, M. Antonietti, L. Bergström, G. Salazar-Alvarez, F. Carosio, G. Camino, Nat. Nanotechnol. 2015, 10, 277.

- 27H. Wang, W. Lin, X. Qiu, F. Fu, R. Zhong, W. Liu, D. Yang, ACS Sustainable Chem. Eng. 2018, 6, 3696.

- 28Y. Ma, J. Dai, L. Wu, G. Fang, Z. Guo, Polymer 2017, 114, 113.

- 29W. Xiong, X. Q. Qiu, D. Yang, R. Zhong, Y. Qian, Y. Li, H. Wang, Chem. Eng. J. 2017, 326, 803.

- 30W. Xiong, D. Yang, R. Zhong, Y. Li, H. Zhou, X. Q. Qiu, Ind. Crops Prod. 2015, 74, 285.

- 31O. Oribayo, X. Feng, G. L. Rempel, Q. Pan, Chem. Eng. J. 2017, 323, 191.

- 32A. Lee, Y. Deng, Eur. Polym. J. 2015, 63, 67.

- 33N. Mahmood, Z. Yuan, J. Schmidt, C. Xu, Renewable Sustainable Energy Rev. 2016, 60, 317.

- 34E. Dorrestijn, L. J. Laarhoven, I. W. Arends, P. J. Mulder, Anal. Appl. Pyrol. 2000, 54, 153.

- 35T. Nguyen, E. Zavarin, E. M. Barral, J. Macromol. Sci., Polym. Rev. 1981, 20, 1.

10.1080/00222358108080014 Google Scholar

- 36H. Y. Chen, S. S. Nair, P. Chauhan, N. Yan, Chem. Eng. J. 2019, 360, 393.

- 37Q. Yang, J. Shi, L. Lin, L. Peng, J. Zhuang, Bioresour. Technol. 2012, 123, 49.

- 38T. J. McDonough, Tappi 1993, 76, 186.

- 39J. D'Souza, R. Camargo, N. Yan, Polym. Rev. 2017, 57, 668.

- 40Y. Song, Z. Wang, N. Yan, R. Zhang, J. Li, Polymers 2016, 8, 209.

- 41A. Abdulkhani, A. Karimi, A. Mirshokraie, Y. Hamzeh, N. Marlin, G. Mortha, J. Appl. Polym. Sci. 2010, 118, 469.

- 42H. Chung, N. R. Washburn, ACS Appl. Mater. Interfaces 2012, 4, 2840.

- 43S. E. Klein, J. Rumpf, P. Kusch, R. Albach, M. Rehahn, S. Witzlebena, M. Schulze, RSC Adv. 2018, 8, 40765.

- 44A. M. C. Yona, F. Budija, B. Kričej, A. Kutnar, M. Pavlič, P. Pori, Č. Tavzes, M. Petrič, Ind. Crops Prod. 2014, 54, 296.

- 45B. Xue, P. Huang, Y. Sun, X. Lia, R. Sun, RSC Adv. 2017, 7, 6123.

- 46J. D'Souza, B. George, R. Camargo, N. Yan, Ind. Crops Prod. 2015, 76, 1.

- 47J. Lu, X. Li, R. Yang, J. Zhao, Y. Liu, Y. Qu, Chem. Eng. J. 2014, 247, 142.

- 48S. Van den Bosch, W. Schutyser, R. Vanholme, T. Driessen, S. F. Koelewijn, T. Renders, B. De Meester, W. J. J. Huijgen, W. Dehaen, C. M. Courtin, B. Lagrain, W. Boerjan, B. F. Sels, Environ. Sci. Technol. 2015, 8, 1748.

- 49N. Yan, C. Zhao, P. J. Dyson, C. Wang, L. T. Liu, Y. Kou, ChemSusChem 2008, 1, 626.

- 50X. Huang, C. F. D. Hoop, J. Xie, Q. Wu, D. Boldor, J. Qi, Mater. Des. 2018, 138, 11.

- 51M. Ahmad, C. R. Taylor, D. Pink, K. Burton, D. Eastwood, G. D. Bending, T. D. Bugg, Mol. BioSyst. 2010, 6, 815.

- 52V. Molinari, C. Giordano, M. Antonietti, D. Esposito, J. Am. Chem. Soc. 2014, 136, 1758.

- 53X. Wang, R. Rinaldi, ChemSusChem 2012, 5, 1455.

- 54H. Lange, S. Decina, C. Crestini, Eur. Polym. J. 2013, 49, 1151.

- 55Y. Cao, C. Zhang, D. C. W. Tsang, J. Fan, J. H. Clark, S. Zhang, Ind. Eng. Chem. Res. 2020, 5, 28.

- 56E. Terrell, L. D. Dellon, A. Dufour, E. Bartolomei, L. J. Broadbelt, M. G. Perez, Ind. Eng. Chem. Res. 2020, 59, 526.

- 57R. B. Madsen, R. Z. K. Bernberg, P. Biller, J. Becker, B. B. Iversen, M. Glasius, Sustainable Energy Fuels 2017, 1, 789.

- 58J. Yang, H. Niu, A. Dalai, K. Corscadden, N. Zhou, Fuel 2020, 277, 118202.

- 59F. Du, Y. Li, X. Xian, B. Li, P. Tang, B. Lu, J. Lai, Energy Fuels 2019, 33, 7366.

- 60H. Liu, H. Li, M. Li, J. Energy Inst. 2016, 1.

- 61B. M. Matsagar, Z.-Y. Wang, C. Sakdaronnarong, S. S. Chen, D. C. W. Tsang, K. C.-W. Wu, ChemCatChem 2019, 11, 4604.

- 62B.-L. Xue, J.-L. Wen, R.-C. Sun, Materials 2015, 8, 586.

- 63M. M. Margarida, A. N. Finez, B. J. Carlos, R. G. Dos Santos, Ind. Crops Prod. 2015, 74, 9.

- 64S. Belinda, G. Nuno, F. Carmen, B. T. Ana, B. Inês, S. Rui, P. N. Carlos, F. Artur, ACS Sustainable Chem. Eng. 2014, 2, 846.

- 65Z. Jia, C. Lu, P. Zhou, L. Wang, RSC Adv. 2015, 5, 53949.

- 66K. H. Kim, J. Yu, E. Y. Lee, J. Ind. Eng. Chem. 2016, 38, 175.

- 67J. H. Lee, J. H. Lee, D. K. Kim, C. H. Park, J. H. Yu, E. Y. Lee, J. Ind. Eng. Chem. 2016, 34, 157.

- 68J. H. Lee, E. Y. Lee, Bioresour. Technol. 2016, 208, 24.

- 69G. Griffini, V. Passoni, R. Suriano, M. Levi, S. Turri, ACS Sustainable Chem. Eng. 2015, 3, 1145.

- 70B. Xue, Y. Yang, Y. Sun, J. Fan, X. Li, Z. Zhang, Int. J. Biol. Macromol. 2019, 122, 954.

- 71M. Culebras, A. Beaucamp, Y. Wang, M. M. Clauss, E. Frank, M. N. Collins, ACS Sustainable Chem. Eng. 2018, 6, 8816.

- 72N. Yan, Y. Yuan, R. Dykeman, Y. Kou, P. J. Dyson, Angew. Chem., Int. Ed. Engl. 2010, 49, 5549.

- 73S. Sahoo, M. Ö. Seydibeyoğlu, A. K. Mohanty, M. Misra, Biomass Bioenergy 2011, 35, 4230.

- 74G. P. Otto, M. P. Moises, G. Carvalho, A. W. Rinaldi, J. C. Garcia, E. Radovanovic, S. L. Favaro, Composites, Part B 2017, 110, 459.

- 75Y. Kurimoto, M. Takeda, S. Doi, Y. Tamura, H. Ono, Bioresour. Technol. 2001, 77, 33.

- 76M. Visanko, J. A. Sirvio, P. Piltonen, H. Liimatainen, M. Illikainen, Cellulose 2017, 24, 2531.

- 77L. B. Tavares, C. V. Boas, G. R. Schleder, A. M. Nacas, D. S. Rosa, D. J. Santos, eXPRESS Polym. Lett. 2016, 10, 927.

- 78H. Li, J. Sun, C. Wang, S. Liu, D. Yuan, X. Zhou, J. Tan, L. Stubbs, C. He, ACS Sustainable Chem. Eng. 2017, 5, 7942.

- 79Y. Y. Wang, C. E. Wyman, C. M. Cai, A. J. Ragauskas, ACS Appl. Polym. Mater. 2019, 1, 1672.

- 80Y. Zhang, J. Wang, X. Fang, J. Liao, X. Zhou, S. Zhou, F. Bai, S. Peng, Polymer 2019, 178.

- 81J. C. de Haro, C. Allegretti, A. T. Smit, S. Turri, P. D'Arrigo, G. Griffini, ACS Sustainable Chem. Eng. 2019, 7, 11700.

- 82Y. Zhang, J. Liao, X. Fang, F. Bai, K. Qiao, L. Wang, ACS Sustainable Chem. Eng. 2017, 5, 4276.

- 83A. Duval, L. Avérous, ChemSusChem 2017, 10, 1813.

- 84S. Hajirahimkhan, C. C. Xu, P. J. Ragogna, ACS Sustainable Chem. Eng. 2018, 6, 14685.

- 85S. Laurichesse, C. Huillet, L. Avérous, Green Chem. 2014, 16, 3958.

- 86Y. Chen, H. Zhang, Z. Zhu, S. Fu, Int. J. Biol. Macromol. 2020, 152, 775.

- 87X. Zhang, W. F. Liu, D. J. Yang, X. Q. Qiu, Adv. Funct. Mater. 2018, 29, 1806912.

- 88C. Z. Chen, F. F. Li, Y. R. Zhang, B. X. Wang, Y. M. Fan, X. L. Wang, R. C. Sun, Chem. Eng. J. 2018, 350, 173.

- 89W. S. Liu, R. Zhou, D. Zhou, G. Q. Ding, J. M. Soah, C. Y. Yue, X. H. Lu, Carbon 2015, 83, 188.

- 90S. S. S. Ismail, K. Junhua, X. H. Lu, ACS Sustainable Chem. Eng. 2017, 5, 3148.

- 91P. Buono, A. Duval, L. AvØrous, Y. Habibi, ChemSusChem 2018, 11, 2472.

- 92J. Yu, J. Wang, C. Wang, Y. Liu, Y. Xu, C. Tang, F. Chu, Macromol. Rapid Commun. 2015, 36, 398.

- 93L. Hailing, C. Hoyong, Macromolecules 2016, 49, 7246.

- 94T. Saito, R. H. Brown, M. A. Hunt, D. L. Pickel, J. M. Pickel, J. M. Messman, F. S. Baker, M. Kellerd, A. K. Naskar, Green Chem. 2012, 14, 3295.

- 95T. Saito, J. H. Perkins, D. C. Jackson, N. E. Trammel, M. A. Hunt, A. K. Naskar, RSC Adv. 2013, 3, 21832.

- 96W. F. Liu, C. Fang, S. Y. Wang, J. H. Huang, X. Q. Qiu, Macromolecules 2019, 52, 6474.

- 97L. Ugarte, S. Gómez-Fernández, C. Péna-Rodríuez, A. Prociak, M. A. Corcuera, A. Eceiza, ACS Sustainable Chem. Eng. 2015, 3, 3382.

- 98A. Arbenz, A. Frache, F. Cuttica, L. Avérous, Polym. Degrad. Stab. 2016, 132, 62.

- 99G. Sung, J. W. Kim, J. H. Kim, J. Ind. Eng. Chem. 2016, 44, 99.

- 100G. F. Sandra, G. Martin, S. Bernhard, C. M. Angeles, E. Arantxa, Ind. Crops Prod. 2018, 125, 346.

- 101H. B. Zhu, Z. M. Peng, Y. M. Chen, G. Y. Li, L. Wang, Y. Tang, R. Pang, Z. U. H. Khan, P. Y. Wan, RSC Adv. 2014, 4, 55271.

- 102D. S. Jason, C. Rafael, Y. Ning, J. Appl. Polym. Sci. 2014, 131.

- 103H. A. Nemati, E. D. A. Charles, L. Bronwyn, M. D. James, A. P. Kumar, Ind. Crops Prod. 2018, 117, 149.

- 104S. J. Hu, Y. B. Li, Ind. Crops Prod. 2014, 57, 188.

- 105S. Hu, X. Luo, Y. Li, ChemSusChem 2014, 7, 66.

- 106G. Nuno, S. Belinda, F. Carmen, S. Rui, N. Carlos, B. T. Ana, F. Artur, Mater. Des. 2015, 76, 77.

- 107B. L. Xue, J. L. Wen, R. C. Sun, ACS Sustainable Chem. Eng. 2014, 2, 1474.

- 108H. Li, Y. Liang, P. Li, C. He, J. Bioresour. Bioprod. 2020, 5, 163.

- 109X. Zhang, D. Jeremic, Y. Kim, J. Street, R. Shmulsky, Polymers 2018, 10, 706.

- 110S. Wang, W. F. Liu, D. Yang, X. Q. Qiu, Ind. Eng. Chem. Res. 2019, 58, 496.

- 111C. Patrizia, A. Irene, L. Andrea, Eur. Polym. J. 2013, 49, 1174.

- 112M. Nubla, Z. Yuan, S. John, T. Matthew, X. Chunbao, Green Chem. 2016, 18, 2385.

- 113B. Jacopo, C. Patrizia, A. Irene, C. Maria-Beatrice, L. Andrea, Eur. Polym. J. 2015, 64, 147.

- 114M. Nubla, Y. Zhongshun, S. John, X. Chunbao, Eur. Polym. J. 2015, 68, 1.

- 115K. Isabell, S. Bodo, L. Ralph, Ind. Crops Prod. 2017, 101, 75.

- 116X. F. Zhang, Y. S. Kim, E. Islam, T. Madison, E. Thomas, H. Barbary, S. Rubin, Ind. Crops Prod. 2019, 141.

- 117D. Antoine, A. Luc, ACS Sustainable Chem. Eng. 2016, 4, 3103.

- 118B. Li, M. Zhou, W. Huo, D. Cai, P. Qin, H. Cao, T. Tan, Ind. Crops Prod. 2020, 143, 111887.

- 119Z. C. Yin, Y. H. Li, T. W. Song, M. T. Bao, Y. M. Li, J. R. Lu, Y. Li, J. Cleaner Prod. 2020, 253, 120058.

- 120Y. Yang, H. Yi, C. Y. Wang, ACS Sustainable Chem. Eng. 2015, 3, 3012.

- 121O. S. H. Santos, M. C. da Silva, V. R. Silva, W. N. Mussel, M. I. Yoshida, J. Hazard. Mater. 2017, 324, 406.

- 122W. Y. Xing, H. X. Yuan, P. Zhang, H. Y. Yang, L. Song, Y. Hu, J. Polym. Res. 2013, 20, 234.

- 123Y. Wang, Y. Zhang, B. Liu, Q. Zhao, Y. Qi, Y. M. Wang, Z. Y. Sun, B. J. Liu, N. N. Zhang, W. Hu, H. M. Xie, Compos. Commun. 2020, 21, 100382.