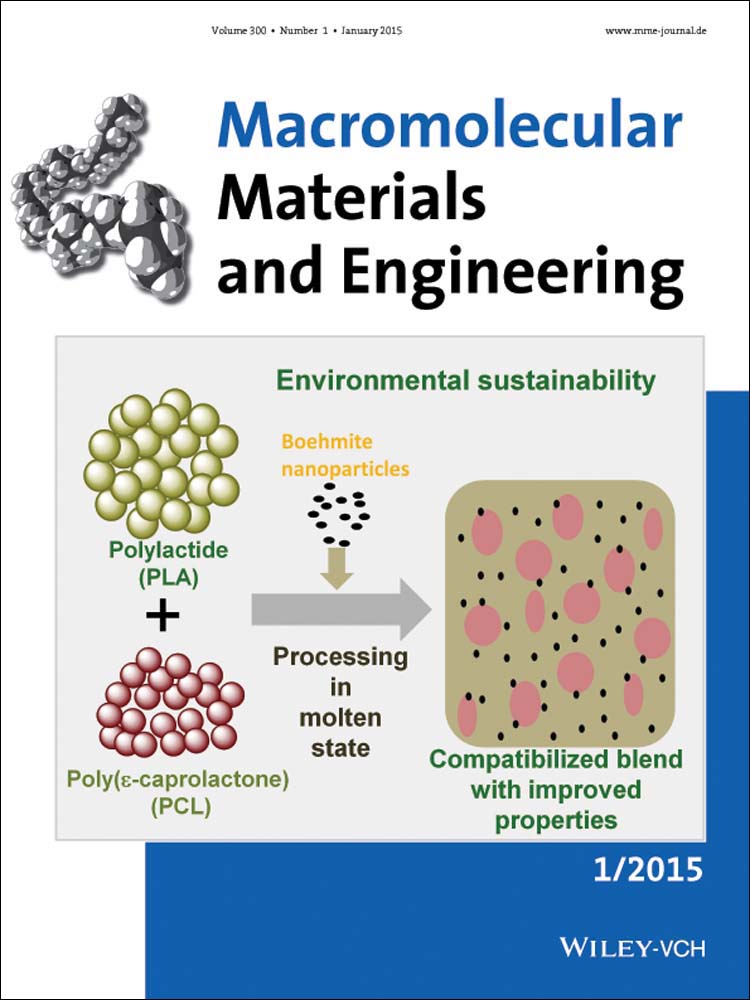

Influence of Boehmite Nanoparticle Loading on the Mechanical, Thermal, and Rheological Properties of Biodegradable Polylactide/Poly(ϵ-caprolactone) Blends

Stephen C. Agwuncha

DST/CSIR National Centre for Nanostructured Materials, Council for Scientific and Industrial Research, Pretoria, 0001 South Africa

Division of Polymer Technology, Department of Chemical, Metallurgical, Material Engineering, Tshwane University of Technology, Pretoria 0001 South Africa

Search for more papers by this authorCorresponding Author

Suprakas Sinha Ray

- [email protected]

- | Fax: +27 12 841 2229

DST/CSIR National Centre for Nanostructured Materials, Council for Scientific and Industrial Research, Pretoria, 0001 South Africa

Department of Applied Chemistry, University of Johannesburg, Doornfontein, 2028 Johannesburg, South Africa

Search for more papers by this authorJarugala Jayaramudu

DST/CSIR National Centre for Nanostructured Materials, Council for Scientific and Industrial Research, Pretoria, 0001 South Africa

Search for more papers by this authorCaroline Khoathane

Division of Polymer Technology, Department of Chemical, Metallurgical, Material Engineering, Tshwane University of Technology, Pretoria 0001 South Africa

Search for more papers by this authorRotimi Sadiku

Division of Polymer Technology, Department of Chemical, Metallurgical, Material Engineering, Tshwane University of Technology, Pretoria 0001 South Africa

Search for more papers by this authorStephen C. Agwuncha

DST/CSIR National Centre for Nanostructured Materials, Council for Scientific and Industrial Research, Pretoria, 0001 South Africa

Division of Polymer Technology, Department of Chemical, Metallurgical, Material Engineering, Tshwane University of Technology, Pretoria 0001 South Africa

Search for more papers by this authorCorresponding Author

Suprakas Sinha Ray

- [email protected]

- | Fax: +27 12 841 2229

DST/CSIR National Centre for Nanostructured Materials, Council for Scientific and Industrial Research, Pretoria, 0001 South Africa

Department of Applied Chemistry, University of Johannesburg, Doornfontein, 2028 Johannesburg, South Africa

Search for more papers by this authorJarugala Jayaramudu

DST/CSIR National Centre for Nanostructured Materials, Council for Scientific and Industrial Research, Pretoria, 0001 South Africa

Search for more papers by this authorCaroline Khoathane

Division of Polymer Technology, Department of Chemical, Metallurgical, Material Engineering, Tshwane University of Technology, Pretoria 0001 South Africa

Search for more papers by this authorRotimi Sadiku

Division of Polymer Technology, Department of Chemical, Metallurgical, Material Engineering, Tshwane University of Technology, Pretoria 0001 South Africa

Search for more papers by this authorAbstract

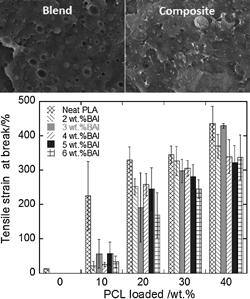

Blends of polylactide (PLA) and poly(ϵ-caprolactone) (PCL) were melt-processed with boehmite (BAI) nanoparticles to produce ternary biocomposites with the intent of broadening the potential applications of PLA. The mechanical properties of the prepared composites exhibited remarkable improvement in the elongation-at-break of between 60 and 430% for increasing loadings of PCL and BAI in the blends. Furthermore, the melting temperatures of PLA and PCL were observed to shift approximately 2 °C toward each other in the composites, an indication of improved compatibility. This partial compatibility was also observed from the electron microscopy images, which also revealed a good dispersion of PCL in the PLA. The composite with balanced properties was found to be consisting of 70 wt% PLA, 30 wt% PCL, and 4 wt% BAI.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| mame201400212-sup-0001-SuppData.docx3.9 MB |

Figure S1. Plot of dynamic storage modulus (G′) and dynamic loss modulus (G″) of selected samples from 70/30 group as indicated on each plot. Figure S2. The formation of PLA crystals in the neat PLA polymer with respect to treatment condition, A is melt-quenched while B, C and D were isothermally held at 115, 120 and 125oC, respectively for 80 min. Figure S3. POM images showing the effect of change in the isothermal temperature on the rate and number of crystals formed with respect to the amount of BAI added. The three columns represent 0%, 2% and 4% BAI additions in group 70/30 respectively from the left. Figure S4. Dynamic time sweep data for the neat PLA, PCL, 70/30 blend and 70/30/4 composite samples. Figure S5. ART-FTIR results for neat PLA, neat PCL, 70/30/0, 70/30/2, 70/30/4, 70/30/6, 60/40/0, and 60/40/4 from top, respectively. Table S1. XRD results showing the peak angles and calculated % crystallinity for major peaks in each sample Table S2. DSC data for all samples. |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1 H. S. Cho, H. S. Moon, M. Kim, K. Nama, J. Y. Kim, Waste Manage. 2011, 31, 475.

- 2 F. P. La Mantia, M. Morreale, Composites A 2011, 42, 579.

- 3 I. Vroman, L. Tighzert, Materials 2009, 2, 307. DOI:10.3390/ma2020307.

- 4 L. Xiao, B. Wang, G. Yang, M. Gauthier, in: Biomedical Science, Engineering and Technology (Ed: D. N. Ghista), InTech, Rijeka, Croatia 2012, p. 247.

- 5 M. Murariu, A. L. Dechief, L. Bonnaud, Y. Paint Gallos, G. Fontaine, S. Bourbigot, P. Dubois, Polym. Degrad. Stab. 2010, 95, 889.

- 6 C. Choochottiros, I. Chin, Eur. Polym. J. 2013, 49, 957.

- 7 E. M. Saffer, G. N. Tew, S. R. Bhatia, Curr. Med. Chem. 2011, 18, 5676.

- 8 J. W. Rhim, Food Res. Int. 2013, 51, 714.

- 9 J. Zhang, J. Xu, H. Wang, W. Jin, J. Li, Mater. Sci. Eng. C 2009, 29, 889.

- 10 S. S. Ray, Acc. Chem. Res. 2012, 45, 1710.

- 11 R. Pantani, A. Sorrentino, Polym. Degrad. Stab. 2013, 98, 1089.

- 12 V. L. Finkenstadt, C.-K. Liu, R. Evangelista, L. Liu, S. C. Cermakc, M. Hojilla-Evangelista, J. L. Willett, Ind. Crops Prod. 2007, 26, 36.

- 13 F. Vilaplana, E. Strömberg, S. Karlsson, Polym. Degrad. Stab. 2010, 95, 2147.

- 14 A. C. Vieira, J. C. Vieira, J. M. Ferra, F. D. Magalhães, R. M. Guedes, A. T. Marques, J. Mech. Behav. Biomed. Mater. 2011, 4, 451.

- 15 T. Kemala, E. Budianto, B. Soegiyono, Arabian J. Chem. 2012, 5, 103.

- 16 F. Tuba, L. Oláh, P. Nagy, Eng. Fract. Mech. 2011, 78, 3123.

- 17 V. Ojijo, S. S. Ray, R. Sadiku, ACS Appl. Mater. Interfaces 2012, 4, 2395.

- 18 V. Ojijo, S. S. Ray, R. Sadiku, ACS Appl. Mater. Interfaces 2012, 4, 6690.

- 19 Z. Su, Q. Li, Y. Liu, G.-H. Hub, C. Wu, Eur. Polym. J. 2009, 45, 2428.

- 20 C. Choochottiros, E. Park, I. Chin, J. Ind. Eng. Chem. 2012, 18, 993.

- 21 J. Yang, Y. Liang, J. Luo, C. Zhao, C. C. Han, Macromolecules 2012, 45, 4254.

- 22 A. Pandey, G. C. Pandey, P. B. Aswath, J. Mech. Behav. Biomed. Mater. 2008, 1, 227.

- 23 A. Meng, J. Deng, Q. Liu, Z. Wu, W. Yang, Eur. Polym. J. 2012, 48, 127.

- 24 T. Takayama, M. Todo, H. Tsuji, J. Mech. Behav. Biomed. Mater. 2011, 4, 255.

- 25 M. J. John, S. Thomas, Carbohydr. Polym. 2008, 71, 343.

- 26 N.-S. Choi, C.-H. Kim, K. Y. Cho, J.-K. Park, J. Appl. Polym. Sci. 2002, 86, 1892.

- 27 V. N. Malheiro, S. G. Caridade, N. M. Alves, J. F. Mano, Acta Biomater. 2010, 6, 418.

- 28 S. C. Neves, L. S. M. Teixeira, L. Moroni, R. L. Reis, C. A. Van Blitterswijk, N. M. Alves, Biomaterials 2011, 32, 1068.

- 29 X. Y. Li, X. Y. Kong, S. Shi, X. H. Wang, G. Guo, F. Luo, X. Zhao, Y. Q. Wei, Z. Y. Qian, Carbohydr. Polym. 2010, 82, 904.

- 30 K. Chavalitpanya, S. Phattanarudee, Energy Proc. 2013, 34, 542.

- 31 D. Wu, Y. Zhang, M. Zhang, W. Yu, Biomacromolecules 2009, 10, 417.

- 32

L. M. Robeson,

Polymer Blends: A Comprehensive Review,

Hanser,

Munich

2007.

10.3139/9783446436503 Google Scholar

- 33 (a) K. Das, S. S. Ray, S. Chapple, J. Wesley-Smith, Ind. Eng. Chem. Res. 2013, 52, 6083; (b) J. Z. Liang, D. R. Duan, C. Y. Tang, C. P. Tsui, D. Z. Chen, Polym. Test. 2013, 32, 617; (c) M. J. Hato, S. S. Ray, A. S. Luyt, Macromol. Mater. Eng. 2008, 293, 752.

- 34 S. S. Ray, S. Pouliot, M. Bousmina, L. A. Utracki, Polymer 2004, 45, 8403.

- 35 Y. S. Lipatov, Polymer Reinforcement, ChemTec Publishing, Toronto, Canada 1995.

- 36 V. V. Ginzburg, F. Qiu, M. Paniconi, G. Peng, D. Jasnow, A. C. Balazs, Phys. Rev. Lett. 1999, 42, 4026.

- 37 (a) E. S. Ogunniran, R. Sadiku, S. S. Ray, N. Luruli, Macromol. Mater. Eng. 2012, 297, 237; (b) E. S. Ogunniran, R. Sadiku, S. S. Ray, N. Luruli, Macromol. Mater. Eng. 2012, 297, 627.

- 38 V. Khumalo, J. Karger-Kocsis, R. Thomann, J. Mater. Sci. 2010, 46, 422.

- 39 R. C. Streller, R. Thomann, O. Torno, R. Mulhaupt, Macromol. Mater. Eng. 2008, 293, 218.

- 40 R. C. Streller, R. Thomann, O. Torno, R. Mulhaupt, Macromol. Mater. Eng. 2009, 294, 380.

- 41 C. Özdilek, K. Kazimierczak, D. Van der beek, S. J. Picken, Polymer 2004, 45, 5207.

- 42 J. Zhang, Q. Ji, P. Zhang, Y. Xia, Q. Kong, Polym. Degrad. Stab. 2010, 95, 1211.

- 43 H.-T. Liao, C.-S. Wu, Mater. Sci. Eng. A 2009, 515, 207.

- 44 J. Odent, P. Leclère, J.-M. Raquez, P. Dubois, Eur. Polym. J. 2013, 49, 914.

- 45 H. Xiao, W. Lu, J.-T. Yeh, J. Appl. Polym. Sci. 2009, 112, 3754.

- 46 G. Stoclet, R. Seguela, C. Vanmansart, C. Rochas, J.-M. Lefebvre, Polymer 2012, 53, 519.

- 47 S. H. Tabatabaei, A. Ajji, Polym. Eng. Sci. 2011, 51, 2151.

- 48 D. Battegazzore, S. Bocchin, A. Frache, Express Polym. Lett. 2011, 5, 849.

- 49 L. G. M. Beekmans, R. Vallée, G. J. Vancso, Macromolecules 2002, 35, 9383.

- 50 J. Cai, M. Liu, L. Wang, K. Yao, S. Li, H. Xiong, Carbohydr. Polym. 2011, 86, 941.

- 51 V. Ojijo, S. S. Ray, R. Sadiku, ACS Appl. Mater. Interfaces 2013, 5, 4266.

- 52 D. Wu, Y. Zhang, M. Zhang, W. Zhou, Eur. Polym. J. 2008, 44, 2171.

- 53 M. Kowalczyk, E. Piorkowska, P. Kulpinski, M. Pracella, Composites A 2011, 42, 1509.

- 54 V. Ojijo, T. Malwela, S. S. Ray, R. Sadiku, Polymer 2012, 53, 505.

- 55 D. M. Fox, J. Lee, C. J. Citro, M. Novy, Polym. Degrad. Stab. 2013, 98, 590.

- 56 T. Lin, X.-Y. Liu, C. He, J. Phys. Chem. B 2010, 114, 3133.

- 57 H.-T. Chiu, S.-Y. Huang, Y.-F. Chen, M.-T. Kuo, T.-Y. Chiang, C.-Y. Chang, Y.-H. Wang, Int. J. Polym. Sci. 2013, 2013, Article ID 951696, 11p.

- 58 T. Patrício, M. Domingos, A. Gloria, P. Bártolo, Proc. CIRP 2013, 5, 110.

- 59 X. Ou, M. Cakmak, Polymer 2010, 51, 783.

- 60 S. S. Ray, K. Okamoto, M. Okamoto, Macromolecules 2003, 36, 2355.

- 61 C. González-Sánchez, C. Fonseca-Valero, A. Ochoa-Mendoza, A. Garriga-Meco, E. Rodríguez-Hurtado, Composites A 2011, 42, 1075.

- 62 Y. H. Hyun, S. T. Lim, J. Choi, M. S. Jhon, Macromolecules 2001, 34, 8084.