Thermo-Moldable Nanocomposite Hydrogels

Yiqing Yang

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorCorresponding Author

Tao Wang

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorWeixiang Sun

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorChaoyang Wang

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorXinxing Liu

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorCorresponding Author

Zhen Tong

- [email protected]

- | Fax: (86)-20-87110273

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorYiqing Yang

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorCorresponding Author

Tao Wang

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorWeixiang Sun

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorChaoyang Wang

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorXinxing Liu

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorCorresponding Author

Zhen Tong

- [email protected]

- | Fax: (86)-20-87110273

Research Institute of Materials Science, State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou, 510640 China

Search for more papers by this authorAbstract

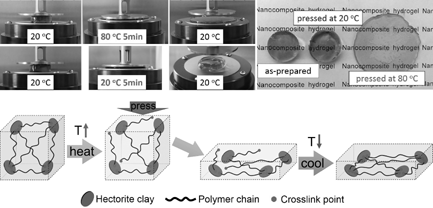

The present paper reports an interesting and versatile thermo-moldable property of poly(N,N-dimethylacrylamide)-clay nanocomposite hydrogels (NC gel). The NC gel can be thermo-pressed and molded to a desired shape at 80 °C, and the shape can be fixed by cooling to 20 °C. Mechanical test and small-angle X-ray scattering demonstrate that the molded NC gel still exhibits high strength with an elastic network structure. Viscoelastic measurements show that with increasing the temperature, the equilibrium shear modulus Ge decreases, and the creep and permanent deformation increases obviously, suggesting a decrease in the cross-linking density. Ge recovers when the gel is cooled down to room temperature, reflecting the recovery of the cross-linking density. This thermo-moldable property is attributed to reversible cross-linking in such NC gels by changing the temperature. This work provides a facile method to deform or pattern the tough NC gels after synthesis.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| mame201400110-sup-0001-SuppData-S1.doc890.5 KB | Supporting Data |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1 J. L. Drury, D. J. Mooney, Biomaterials 2003, 24, 4337.

- 2 C. W. Peak, J. J. Wilker, G. Schmidt, Colloid Polym. Sci. 2013, 291, 2031.

- 3 A. Nakayama, A. Kakugo, J. P. Gong, Y. Osada, M. Takai, T. Erata, S. Kawano, Adv. Funct. Mater. 2004, 14, 1124.

- 4 K. Yasuda, J. P. Gong, Y. Katsuyama, A. Nakayama, Y. Tanabe, E. Kondo, M. Ueno, Y. Osada, Biomaterials 2005, 26, 4468.

- 5 J. P. Gong, Y. Osada, Adv. Polym. Sci. 2010, 236, 203.

- 6 S. Naficy, H. R. Brown, J. M. Razal, G. M. Spinks, P. G. Whitten, Aust. J. Chem. 2011, 64, 1007.

- 7 M. Shibayama, Soft Matter 2012, 8, 8030.

- 8 K. Haraguchi, T. Takehisa, Adv. Mater. 2002, 14, 1120.

- 9 K. Haraguchi, R. Farnworth, A. Ohbayashi, T. Takehisa, Macromolecules 2003, 36, 5732.

- 10 T. Wang, D. Liu, C. Lian, S. Zheng, X. Liu, Z. Tong, Soft Matter 2012, 8, 774.

- 11 M. Zhu, L. Xiong, T. Wang, X. Liu, C. Wang, Z. Tong, React. Funct. Polym. 2010, 70, 267.

- 12 K. Haraguchi, T. Takehisa, M. Ebato, Biomacromolecules 2006, 7, 3267.

- 13 T. Wang, D. Liu, C. Lian, S. Zheng, X. Liu, C. Wang, Z. Tong, React. Funct. Polym. 2011, 71, 447.

- 14 T. Wang, W. Sun, X. Liu, C. Wang, S. Fu, Z. Tong, React. Funct. Polym. 2013, 73, 683.

- 15 D. Guduru, M. Niepel, J. Vogel, T. Groth, Int. J. Artif. Organs 2011, 34, 963.

- 16 A. Curtis, C. Wilkinson, Biomaterials 1997, 18, 1573.

- 17 M. S. Niepel, B. Fuhrmann, H. S. Leipner, T. Groth, Langmuir 2013, 29, 13278.

- 18 S. Abdurrahmanoglu, V. Can, O. Okay, J. Appl. Polym. Sci. 2008, 109, 3714.

- 19 Q. Wang, J. L. Mynar, M. Yoshida, E. Lee, M. Lee, K. Okuro, K. Kinbara, T. Aida, Nature 2010, 463, 339.

- 20 Y. Chen, N. Ballard, S. A. F. Bon, Chem. Commun. 2013, 49, 1524.

- 21 Y. J. Oh, I. H. Cho, H. Lee, K.-J. Park, H. Lee, S. Y. Park, Chem. Commun. 2012, 48, 11895.

- 22 Z. Tong, F. Zeng, X. Zheng, T. Sato, Macromolecules 1999, 32, 4488.

- 23 K. Haraguchi, T. Takehisa, S. Fan, Macromolecules 2002, 35, 10162.

- 24 X. Hu, L. Xiong, T. Wang, Z. Lin, X. Liu, Z. Tong, Polymer 2009, 50, 1933.

- 25 K. Haraguchi, K. Uyama, H. Tanimoto, Macromol. Rapid Commun. 2011, 32, 1253.

- 26 C. Lian, Z. Lin, T. Wang, W. Sun, X. Liu, Z. Tong, Macromolecules 2012, 45, 7220.

- 27 T. Nishida, H. Endo, N. Osaka, H-j. Li, K. Haraguchi, M. Shibayama, Phys. Rev. E 2009, 80, 030801.

- 28 J. Nie, B. Du, W. Oppermann, Macromolecules 2005, 38, 5729.

- 29 O. Okay, W. Oppermann, Macromolecules 2007, 40, 3378.

- 30 L. Xiong, X. Hu, X. Liu, Z. Tong, Polymer 2008, 49, 5064.

- 31 S. Zheng, T. Wang, D. Liu, X. Liu, C. Wang, Z. Tong, Polymer 2013, 54, 1846.

- 32 M. Shibayama, J. Suda, T. Karino, S. Okabe, T. Takehisa, K. Haraguchi, Macromolecules 2004, 37, 9606.

- 33 S. Miyazaki, H. Endo, T. Karino, K. Haraguchi, M. Shibayama, Macromolecules 2007, 40, 4287.