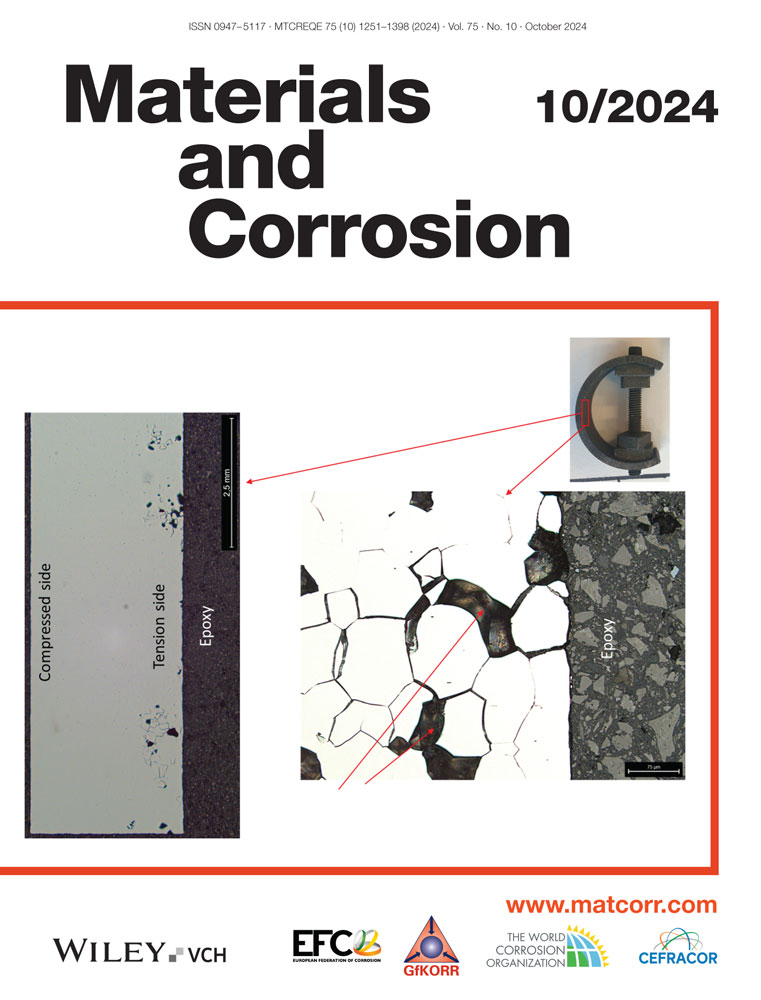

Quantifying intergranular corrosion susceptibility in AA2098-T351 weldments through friction stir welding

Abstract

In this study, the intergranular corrosion (IGC) susceptibility of AA2098-T351 welds, fabricated through friction stir welding (FSW), was systematically evaluated. The evaluation employed American Society for Testing and Materials (ASTM) G110-92 practice and electrochemical impedance measurements, with comparative analyses against unwelded alloys (BS). The key findings depicted that FSW-induced microstructure changes significantly influenced IGC susceptibility across different zones. Zones affected by FSW presented distinct susceptibilities compared with the base metal (BM). The ASTM G110-92 test effectively differentiated the heat-affected zone (HAZ) into segments with changing corrosion resistances based on welding temperature gradients. Cross-sectional analyses using scanning electron microscopy (SEM) techniques correlated corrosion characteristics with microstructural features identified by transmission electron microscopy (TEM). Overall, FSW-induced microstructural alterations emerged as a predominant factor influencing the varying susceptibilities of different zones to IGC, and electrochemical impedance measurements (EIS) validated the findings from ASTM G110-92 practice.

CONFLICT OF INTEREST STATEMENT

The authors declare no conflict of interest.

Open Research

DATA AVAILABILITY STATEMENT

Data that support the findings of this study are available on request from the corresponding author.