Synthesis of Graft-Modified Polyolefin Compatibilizers for Compatibilizing Mixed Plastics

Yu Chen

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

These authors contributed equally.

Search for more papers by this authorYuxin Ding

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

These authors contributed equally.

Search for more papers by this authorPei Li

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

Search for more papers by this authorWanlu Tian

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

Search for more papers by this authorCorresponding Author

Yu Wang

CAS Key Laboratory of Soft Matter Chemistry, Department of Polymer Science and Engineering, University of Science and Technology of China, Hefei, Anhui, 230026 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorCorresponding Author

Fuzhou Wang

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorCorresponding Author

Chen Tan

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorYu Chen

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

These authors contributed equally.

Search for more papers by this authorYuxin Ding

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

These authors contributed equally.

Search for more papers by this authorPei Li

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

Search for more papers by this authorWanlu Tian

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

Search for more papers by this authorCorresponding Author

Yu Wang

CAS Key Laboratory of Soft Matter Chemistry, Department of Polymer Science and Engineering, University of Science and Technology of China, Hefei, Anhui, 230026 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorCorresponding Author

Fuzhou Wang

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorCorresponding Author

Chen Tan

Institute of Physical Science and Information Technology, Key Laboratory of Structure and Functional Regulation of Hybrid Materials of Ministry of Education, Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei, Anhui, 230601 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorComprehensive Summary

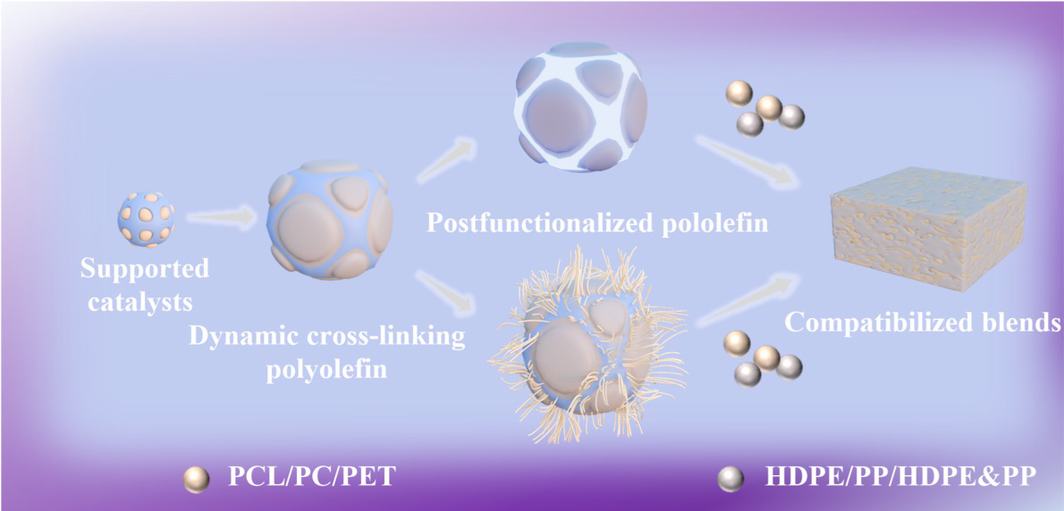

Recycling polyolefin and other plastic mixtures encounters significant obstacles due to the intricate nature and economic inefficiencies of physically separating vast streams of mixed waste. Incorporating compatibilizers emerges as a viable strategy to diminish interfacial energy and bolster compatibility, ultimately yielding homogeneous products. In this contribution, polar polyolefins featuring metal dynamic cross-linking networks were synthesized by tandem polymerizing ionic cluster type polar monomers and olefins. Subsequent treatment with HCl aqueous solution and esterification with polyester precursors yields high-performance grafted polar polyolefins for mixed polymer compatibilizing. For PP/PC melting blends, adding 5 wt% of graft-modified polyolefin results in tougher blends that surpass the performance of corresponding virgin iPP in elongation at break (εb). Polar polyolefins containing sodium carboxylate groups play a dual role in compatibilizing PET/HDPE blends, acting both as compatibilizers and nucleating agents. Moreover, this strategy enables the production of grafted polyolefins comprising ternary polymers, which can be employed in compatibilizing ternary blends.

Supporting Information

| Filename | Description |

|---|---|

| cjoc202401258-sup-0001-supinfo.pdfPDF document, 4.1 MB |

Appendix S1: Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1 Eagan, J. M.; Xu, J.; Girolamo, R. D.; Thurber, C. M.; Macosko C. W.; LaPointe, A. M.; Bates, F. S.; Coates, G. W. Combining polyethylene and polypropylene: Enhanced performance with PE/iPP multiblock polymers. Science 2017, 355, 814–816.

- 2 Liu, B.; Qiao, K.; Fang, J.; Wang, T.; Wang, Z.; Liu, D.; Xie, Z.; Maron, L.; Cui, D. Mechanism and Effect of Polar Styrenes on Scandium-Catalyzed Copolymerization with Ethylene. Angew. Chem. Int. Ed. 2018, 57, 14896–14901.

- 3 Wang, H.; Zhao, Y.; Nishiura, M.; Yang, Y.; Luo, G.; Luo, Y.; Hou, Z. Scandium-Catalyzed Regio- and Stereoselective Cyclopolymerization of Functionalized α,ω-Dienes and Copolymerization with Ethylene. J. Am. Chem. Soc. 2019, 141, 12624–12633.

- 4 Huang, D.; Li, J.; Lu, X.; Zhang, K.; Wang, F.; Wu, D.; Wang, Y.; Pan, L.; Li, Y.; Li, Y. Well-Controlled Block-Type Cyclic Olefin Copolymers with High Heat Resistance, Outstanding Strength and Low-Temperature Toughness. Chin. J. Chem. 2025, 43, 983–994.

- 5 Khan, M. A.; Liu, Y.; Pang, W.; Chen, A.; Chen, M. Hemilabile α-Diimine Nickel Catalyzed Olefin Polymerization. Chin. J. Chem. 2025, 43, 517–523.

- 6 Chung, T. C. M. Functionalization of Polyolefins, Elsevier, Academic Press, San Diego, CA, 2002.

- 7 Zervoudakis, A. J.; Sample, C. S.; Peng, X.; Lake, D.; Hillmyer, M. A.; Ellison, C. J.; Leibfarth, F. A. Dihydroxy Polyethylene Additives for Compatibilization and Mechanical Recycling of Polyethylene Terephthalate/Polyethylene Mixed Plastic Waste. ACS Macro Lett. 2022, 11, 1396–1402.

- 8 The Science and Technology of Flexible Packaging, Ed.: Morris, B. A., William Andrew Publishing, Oxford, 2017, pp. 697–709.

- 9 Jasinska-Walc, L.; Bouyahyi, M.; Kruszynski, J.; Tercjak, A.; Rozanski, A.; Troisi, E. M.; Liu, Y.; Yang, L.; Ivashkiv, O.; Sienkiewicz, M.; Duchateau, R. Preparation of Well-Compatibilized PP/PC Blends and Foams Thereof. ACS Appl. Polym. Mater. 2021, 3, 5509–5516.

- 10 Jasinska-Walc, L.; Bouyahyi, M.; Duchateau, R. Potential of Functionalized Polyolefins in a Sustainable Polymer Economy: Synthetic Strategies and Applications. Acc. Chem. Res. 2022, 55, 1985–1996.

- 11 Wang, X.-Y.; Gao, Y.; Tang, Y. Sustainable developments in polyolefin chemistry: Progress, challenges, and outlook. Prog. Polym. Sci. 2023, 143, 101713.

- 12

Tan, C.; Si, G.; Zou, C.; Chen, C. Functional Polyolefins and Composites. Angew. Chem. Int. Ed. 2025, DOI: https://doi.org/10.1002/anie.202424529.

10.1002/anie.202424529 Google Scholar

- 13 Zhang, M.-Q.; Wang, M.; Sun, B.; Hu, C.; Xiao, D.; Ma, D. Catalytic strategies for upvaluing plastic wastes. Chem 2022, 8, 2912–2923.

- 14 Jehanno, C.; Alty, J. W.; Roosen, M.; De Meester, S.; Dove, A. P.; Chen, E.-Y. X.; Leibfarth, F. A.; Sardon, H. Critical advances and future opportunities in upcycling commodity polymers. Nature 2022, 603, 803–814.

- 15

Zhang, Y.; Wang, G.; Zhang, Q.; Ji, Y.; Xu, H. What determines urban household intention and behavior of solid waste separation? A case study in China. Environ. Impact Assess. Rev. 2022, 93, 106728.

10.1016/j.eiar.2021.106728 Google Scholar

- 16 Sullivan, K. P.; Werner, A. Z.; Ramirez, K. J.; Ellis, L. D.; Bussard, J. R.; Black, B. A.; Brandner, D. G.; Bratti, F.; Buss, B. L.; Dong, X.; Haugen, S. J.; Ingraham, M. A.; Konev, M. O.; Michener, W. E.; Miscall, J.; Pardo, I.; Woodworth, S. P.; Guss, A. M.; Román-Leshkov, Y.; Stahl, S. S.; Beckham, G. T. Mixed plastics waste valorization through tandem chemical oxidation and biological funneling. Science 2022, 378, 207–211.

- 17 Kruszynski, J.; Nowicka, W.; Rozanski, A.; Liu, Y.; Parisi, D.; Yang, L.; Pasha, F. A.; Bouyahyi, M.; Jasinska–Walc, L.; Duchateau, R. iPP/HDPE blends compatibilized by a polyester: An unconventional concept to valuable products. Sci. Adv. 2024, 10, eado1944.

- 18 Lin, T.-W.; Padilla-Vélez, O.; Kaewdeewong, P.; LaPointe, A. M.; Coates, G. W.; Eagan, J. M. Advances in Nonreactive Polymer Compatibilizers for Commodity Polyolefin Blends. Chem. Rev. 2024, 124, 9609–9632.

- 19 Shen, L.; Gorbea, G. D.; Danielson, E.; Cui, S.; Ellison, C. J.; Bates, F. S. Threading-the-Needle: Compatibilization of HDPE/iPP blends with butadiene-derived polyolefin block copolymers. Proc. Natl. Acad. Sci. 2023, 120, e2301352120.

- 20 Wolff, P.; Dickert, A.; Kretschmer, W. P.; Kempe, R. iPP/PE Multiblock Copolymers for Plastic Blend Recycling Synthesized by Coordinative Chain Transfer Polymerization. Macromolecules 2022, 55, 6435–6442.

- 21 Klimovica, K.; Pan, S.; Lin, T.-W.; Peng, X.; Ellison, C. J.; LaPointe, A. M.; Bates, F. S.; Coates, G. W. Compatibilization of iPP/HDPE Blends with PE-g-iPP Graft Copolymers. ACS Macro Lett. 2020, 9, 1161–1166.

- 22 Bertin, S.; Robin, J.-J. Study and characterization of virgin and recycled LDPE/PP blends. Eur. Polym. J. 2002, 38, 2255–2264.

- 23Padilla–Vélez, O.; O’Connor, K. S.; LaPointe, A. M.; MacMillan, S. N.; Coates, G. W. Switchable living nickel(II) α-diimine catalyst for ethylene polymerisation. Chem. Commun. 2019, 55, 7607–7610.

- 24 Kim, S.; Rahman, M. A.; Arifuzzaman, M.; Gilmer, D. B.; Li, B.; Wilt, J. K.; Lara-Curzio, E.; Saito, T. Closed-loop additive manufacturing of upcycled commodity plastic through dynamic cross-linking. Sci. Adv. 2022, 8, eabn6006.

- 25 Self, J. L.; Zervoudakis, A. J.; Peng, X.; Lenart, W. R.; Macosko, C. W.; Ellison, C. J. Linear, Graft, and Beyond: Multiblock Copolymers as Next-Generation Compatibilizers. JACS Au 2022, 2, 310–321.

- 26 Charfeddine, I.; Majesté, J.-C.; Carrot, C.; Lhost, O. Surface tension and interfacial tension of polyolefins and polyolefin blends. J. Appl. Polym. Sci. 2022, 139, 51885.

- 27 Lepage, M. L.; Wulff, J. E. Mixed plastics upcycled dynamically. Nature 2023, 616, 663–664.

- 28 Vialon, T.; Sun, H.; Formon, G. J. M.; Galanopoulo, P.; Guibert, C.; Averseng, F.; Rager, M.-N.; Percot, A.; Guillaneuf, Y.; Van Zee, N. J.; Nicolaÿ, R. Upcycling Polyolefin Blends into High-Performance Materials by Exploiting Azidotriazine Chemistry Using Reactive Extrusion. J. Am. Chem. Soc. 2024, 146, 2673–2684.

- 29 Anagha, M. G.; Chatterjee, T.; Naskar, K. Assessing thermomechanical properties of a reactive maleic anhydride grafted styrene-ethylene-butylene-styrene/thermoplastic polyurethane blend with temperature scanning stress relaxation method. J. Appl. Polym. Sci. 2020, 137, 49598.

- 30

Pietrasanta, Y.; Robin, J.-J.; Torres, N.; Boutevin, B. Reactive compatibilization of HDPE/PET blends by glycidyl methacrylate functionalized polyolefins. Macromol. Chem. Phys. 1999, 200, 142–149.

10.1002/(SICI)1521-3935(19990101)200:1<142::AID-MACP142>3.0.CO;2-W CAS Web of Science® Google Scholar

- 31 Zhang, M.; Colby, R.H.; Milner, S. T.; Chung, T. C. Synthesis and Characterization of Maleic Anhydride GraftedPolypropylene with a Well- Defined Molecular Structure. Macromolecules 2013, 46, 4313–4323.

- 32 Si, G.; Li, C.; Chen, M.; Chen, C. Polymer Multi-Block and Multi-Block+ Strategies for the Upcycling of Mixed Polyolefins and Other Plastics. Angew. Chem. Int. Ed. 2023, 62, e202311733.

- 33 Zou, C.; Chen, J.; Khan, M. A.; Si, G.; Chen, C. Stapler Strategies for Upcycling Mixed Plastics. J. Am. Chem. Soc. 2024, 146, 19449–19459.

- 34 Clarke, R. W.; Sandmeier, T.; Franklin, K. A.; Reich, D.; Zhang, X.; Vengallur, N.; Patra, T. K.; Tannenbaum, R. J.; Adhikari, S.; Kumar, S. K.; Rovis, T.; Chen, E. Y. X. Dynamic crosslinking compatibilizes immiscible mixed plastics. Nature 2023, 616, 731–739.

- 35 Keyes, A.; Basbug Alhan, H. E.; Ordonez, E.; Ha, U.; Beezer, D. B.; Dau, H.; Liu, Y.-S.; Tsogtgerel, E.; Jones, G. R.; Harth, E. Olefins and Vinyl Polar Monomers: Bridging the Gap for Next Generation Materials. Angew. Chem. Int. Ed. 2019, 58, 12370–12391.

- 36 Dau, H.; Jones, G. R.; Tsogtgerel, E.; Nguyen, D.; Keyes, A.; Liu, Y.-S.; Rauf, H.; Ordonez, E.; Puchelle, V.; Basbug Alhan, H.; Zhao, C.; Harth, E. Linear Block Copolymer Synthesis. Chem. Rev. 2022, 122, 14471–14553.

- 37Han, X.–W.; Zhang, X.; Zhou, Y.; Maimaitiming, A.; Sun, X.-L.; Gao, Y.; Li, P.; Zhu, B.; Chen, E. Y. X.; Kuang, X.; Tang, Y. Circular olefin copolymers made de novo from ethylene and α-olefins. Nat. Commun. 2024, 15, 1462.

- 38 Fu, X.-Y.; Yue, T.-J.; Ren, B.-H.; Wang, H.; Ren, W.-M.; Lu, X.-B. A Powerful Strategy for Synthesizing Block Copolymers via Bimetallic Synergistic Catalysis. Angew. Chem. Int. Ed. 2024, 63, e202401926.

- 39 Wang, Y.; Li, C.; Tan, C.; Chen, C. Integrated Ziegler-Natta/Brookhart- Ni Catalysts for the Synthesis of Sutured Polar High-Impact Polypropylenes. Angew. Chem. Int. Ed. 2025, 64, e202417849.

- 40 Wang, Y.; Wang, Q.; Tan, C.; Chen, C. Synthesis of Polar-functionalized Isotactic Polypropylenes Using Commercial Heterogeneous Ziegler-Natta Catalyst. J. Am. Chem. Soc. 2024, 146, 6837–6845.

- 41 Tan, C.; Chen, M.; Zou, C.; Chen, C. Potentially Practical Catalytic Systems for Olefin-Polar Monomer Coordination Copolymerization. CCS Chem. 2024, 6, 882–897.

- 42 Tan, C.; Zou, C.; Chen, C. An Ionic Cluster Strategy for Performance Improvements and Product Morphology Control in Metal-Catalyzed Olefin-Polar Monomer Copolymerization. J. Am. Chem. Soc. 2022, 144, 2245−2254.

- 43 Li, J.; Peng, D.; Tan, C.; Chen, C. Outer-Shell Self-Supported Nickel Catalysts for the Synthesis of Polyolefin Composites. Angew. Chem. Int. Ed. 2023, 62, e202300359.

- 44 Jiang, B.; Liu, X.; Weng, Y.; Fu, Z.; He, A.; Fan, Z. Mechanistic study on comonomer effect in ethylene/1-hexene copolymerization with TiCl4/MgCl2 model Ziegler-Natta catalysts. J. Catal. 2019, 369, 324–334.

- 45 Hu, H.; Chen, Y.; You, F.; Yao, J.; Yang, H.; Jiang, X.; Xia, B. Y. Recycling and Upgrading Utilization of Polymer Plastics. Chin. J. Chem. 2023, 41, 469–480.

- 46 Rahimi, A.; García, J. M. Chemical recycling of waste plastics for new materials production. Nat. Rev. Chem. 2017, 1, 0046.

- 47 Coates, G. W.; Getzler, Y. D. Y. L. Chemical recycling to monomer for an ideal, circular polymer economy. Nat. Rev. Mater. 2020, 5, 501–516.

- 48 Li, K.; Cui, L.; Zhang, Y.; Jian, Z. Amide–Functionalized Polyolefins and Facile Post–Transformations. Macromolecules 2023, 56, 915–922.

- 49 Balzade, Z.; Sharif, F.; Ghaffarian Anbaran, S. R. Tailor-Made Functional Polyolefins of Complex Architectures: Recent Advances, Applications, and Prospects. Macromolecules 2022, 55, 6938–6972.

- 50 Nomura, K.; Peng, X.; Kim, H.; Jin, K.; Kim, H. J.; Bratton, A. F.; Bond, C. R.; Broman, A. E.; Miller, K. M.; Ellison, C. J. Multiblock Copolymers for Recycling Polyethylene-Poly(ethylene terephthalate) Mixed Waste. ACS Appl. Mater. Interfaces 2020, 12, 9726–9735.

- 51 Zhang, W.; Zhang, H.; Yang, Y.; Tang, P. Poly(maleic acid-co-acrylic acid) ionomer as nucleating agent on the crystallization behavior and properties of poly(ethylene terephthalate). Polym. Bull. 2022, 79, 3803–3827.

- 52 Zou, C.; Wang, Q.; Si, G.; Chen, C. A Co-anchoring Strategy for the Synthesis of Polar Bimodal Polyethylene. Nat. Commun. 2023, 14, 1442.

- 53 Li, J.; Wang, Y.; Cai, W.; Yang, G.; Tian, Q.; Huang, Y.; Peng, D.; Zou, C.; Tan, C. Dual-Site Polymeric Heterogeneous α-Diimine Ni Catalysts with Tailored Spatial Distribution for Ethylene Polymerization. Macromolecules 2023, 56, 3015–3023.

- 54

Wang, G.; Peng, D.; Sun, Y.; Chen, C. Interplay of Supramolecular Chemistry and Photochemistry with Palladium-Catalyzed Ethylene Polymerization. CCS Chem. 2020, 2, 2025–2034.

10.31635/ccschem.020.202000414 Google Scholar

- 55 Nan, C.; Pang, T.; Zhao, J.; Fan, L.; Zou, C.; Hao, X.; Song, M.; Gong, J.; Chen, C.; Jiang, H. Novel photoresponsive dinuclear nickel catalysts for ethylene (co)polymerization. Sci. China Chem. 2025, 68, 714–722.

- 56 Wang, Y.; Nan, C.; Zhuo, W.; Zou, C.; Jiang, H.; Hao, X.; Chen, C.; Song, M. Amine-Imine Nickel Catalysts with Pendant O-Donor Groups for Ethylene (Co)Polymerization. Inorg. Chem. 2023, 62, 5105–5113.

- 57 Yu, Y.; Yu, Y.; Jin, M.; Bu, H. Nucleation mechanism and crystallization behavior of poly(ethylene terephthalate) containing ionomers. Macromol. Chem. Phys. 2000, 201, 1894–1900.

- 58 Yin, Y.; Wang, Y.; Meng, L. UIO-66 as Nucleating Agent on the Crystallization Behavior and Properties of Poly(Ethylene Terephthalate). Polymers 2021, 13, 2266.