The effect of graphene-based nanofillers on the structure, thermal, and mechanical properties of poly(vinyl alcohol)

Faezeh Rahbarshendi

Nanostructured and Novel Materials Laboratory (NNML), Department of Materials Engineering, University of Tabriz, Tabriz, Iran

Contribution: Data curation (lead), Investigation (lead)

Search for more papers by this authorAyda Baybordiani

Nanostructured and Novel Materials Laboratory (NNML), Department of Materials Engineering, University of Tabriz, Tabriz, Iran

Contribution: Conceptualization (lead), Data curation (equal), Investigation (equal), Methodology (equal)

Search for more papers by this authorCorresponding Author

Hamed Asgharzadeh

Nanostructured and Novel Materials Laboratory (NNML), Department of Materials Engineering, University of Tabriz, Tabriz, Iran

Correspondence

Hamed Asgharzadeh, Nanostructured and Novel Materials Laboratory (NNML), Department of Materials Engineering, University of Tabriz, 51666-16471 Tabriz, Iran.

Email: [email protected]

Contribution: Conceptualization (lead), Project administration (lead), Supervision (lead), Writing - review & editing (lead)

Search for more papers by this authorMilad Badr

Research Center for Advanced Materials, Faculty of Materials Engineering, Sahand University of Technology, Tabriz, Iran

Contribution: Validation (lead), Writing - original draft (lead)

Search for more papers by this authorKosar Hassannezhad

Materials Science and Nano Engineering, Sabanci University, Istanbul, Turkey

Contribution: Data curation (equal), Investigation (equal), Methodology (equal), Visualization (lead)

Search for more papers by this authorFaezeh Rahbarshendi

Nanostructured and Novel Materials Laboratory (NNML), Department of Materials Engineering, University of Tabriz, Tabriz, Iran

Contribution: Data curation (lead), Investigation (lead)

Search for more papers by this authorAyda Baybordiani

Nanostructured and Novel Materials Laboratory (NNML), Department of Materials Engineering, University of Tabriz, Tabriz, Iran

Contribution: Conceptualization (lead), Data curation (equal), Investigation (equal), Methodology (equal)

Search for more papers by this authorCorresponding Author

Hamed Asgharzadeh

Nanostructured and Novel Materials Laboratory (NNML), Department of Materials Engineering, University of Tabriz, Tabriz, Iran

Correspondence

Hamed Asgharzadeh, Nanostructured and Novel Materials Laboratory (NNML), Department of Materials Engineering, University of Tabriz, 51666-16471 Tabriz, Iran.

Email: [email protected]

Contribution: Conceptualization (lead), Project administration (lead), Supervision (lead), Writing - review & editing (lead)

Search for more papers by this authorMilad Badr

Research Center for Advanced Materials, Faculty of Materials Engineering, Sahand University of Technology, Tabriz, Iran

Contribution: Validation (lead), Writing - original draft (lead)

Search for more papers by this authorKosar Hassannezhad

Materials Science and Nano Engineering, Sabanci University, Istanbul, Turkey

Contribution: Data curation (equal), Investigation (equal), Methodology (equal), Visualization (lead)

Search for more papers by this authorAbstract

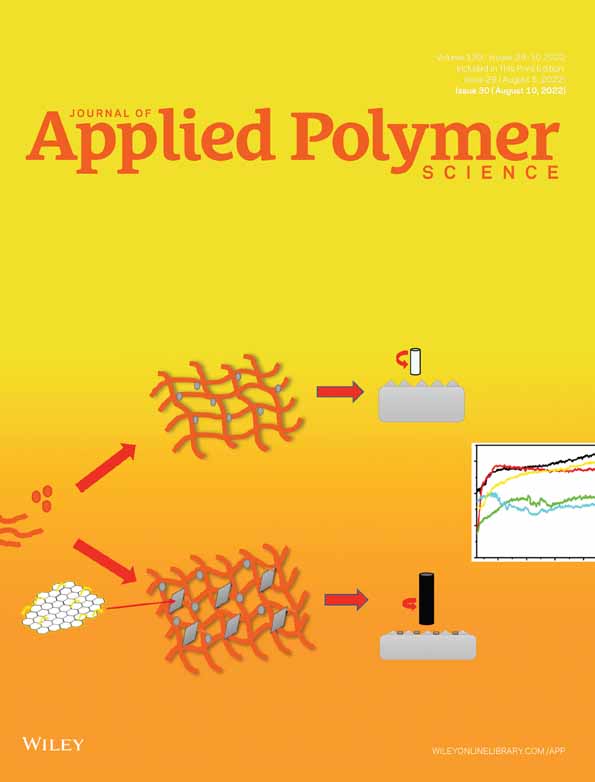

PVA matrix composite films reinforced with graphene oxide (GO) and reduced graphene oxide (rGO) nanoplatelets are prepared by water-solution processing. The structure and properties of the composites are investigated by field-emission scanning electron microscopy, Raman spectroscopy, Fourier-transform infrared spectroscopy, differential scanning calorimetry, and dynamic mechanical analysis. The results indicate a 22% improvement in the storage modulus and a 12°C increase in the glass transition temperature by the addition of only 0.5 wt% rGO into the PVA. The enhancement of the mechanical and thermal properties of the composite films is attributed to the hydrogen bond barrier and molecule movement restriction effects. The higher amount of the hydrogen bonds in the PVA/rGO composite compared to the PVA/GO sample cause its higher thermal stability and mechanical performance.

CONFLICT OF INTEREST

There is no conflicts of interest.

Open Research

DATA AVAILABILITY STATEMENT

Research data are not shared.

REFERENCES

- 1C. A. Finch, Poly(Vinyl Alcohol): Properties and Applications, John Wiley and Sons, London, UK 1973.

- 2A. Koski, K. Yim, S. J. M. L. Shivkumar, Mater. Lett. 2004, 58, 493.

- 3S. Abdolhosseinzadeh, H. Asgharzadeh, H. S. Kim, Sci. Rep. 2015, 5, 1.

- 4A. Abbasnezhad, H. Asgharzadeh, A. Ansari Hamedani, S. Hayat Soytas, Dalton Trans. 2020, 49, 5890.

- 5S. R. Charandabinezhad, H. Asgharzadeh, N. Arsalani, J. Mater. Sci. Mater. Electron. 2021, 32, 1864.

- 6P. Dhanasekaran, S. Vinod Selvaganesh, A. Shukla, S. D. Bhat, Mater. Lett. 2021, 282, 128837.

- 7E. Hajialilou, H. Asgharzadeh, S. K. Asl, Appl. Surf. Sci. 2021, 544, 148832.

- 8S. Thakur, A. Verma, W. F. Alsanie, G. Christie, V. K. Thakur, Mater. Lett. 2022, 307, 130971.

- 9M. C. Biswas, M. T. Islam, P. K. Nandy, M. M. Hossain, ACS Mater. Lett. 2021, 3, 889.

- 10S. Abdolhosseinzadeh, H. Asgharzadeh, S. Sadighikia, A. Khataee, Res. Chem. Intermed. 2016, 42, 4479.

- 11H. Jafarlou, K. Hassannezhad, H. Asgharzadeh, G. R. Marami, Mater. Sci. Technol. 2018, 34, 455.

- 12T. Kuilla, S. Bhadra, D. Yao, N. H. Kim, S. Bose, J. H. Lee, Prog. Polym. Sci. 2010, 35, 1350.

- 13S. Pourmand, Nima, and Hamed Asgharzadeh., Crit. Rev. Solid State Mater. Sci. 2020, 45, 289.

- 14J. Ma, Q. Meng, A. Michelmore, N. Kawashima, Z. Izzuddin, C. Bengtsson, H.-C. Kuan, J. Mater. Chem. A 2013, 1, 4255.

- 15H. Asgharzadeh, S. Eslami, J. Alloys Compd. 2019, 806, 553.

- 16J. L. Vickery, A. J. Patil, S. Mann, Adv. Mater. 2009, 21, 2180.

- 17C. F. P. de Oliveira, P. A. R. Muñoz, M. C. C. dos Santos, G. S. Medeiros, A. Simionato, D. A. Nagaoka, E. A. T. de Souza, S. H. Domingues, G. J. M. Fechine, Polym. Compos. 2019, 40, E312.

- 18X. Wang, X. Liu, H. Yuan, H. Liu, C. Liu, T. Li, C. Yan, X. Yan, C. Shen, Z. Guo, Mater. Des. 2018, 139, 372.

- 19J. Liang, Y. Huang, L. Zhang, Y. Wang, Y. Ma, T. Guo, Y. Chen, Adv. Funct. Mater. 2009, 19, 2297.

- 20L. Jiang, X.-P. Shen, J.-L. Wu, K.-C. Shen, J. Appl. Polym. Sci. 2010, 118, 275.

- 21Y. Xu, W. Hong, H. Bai, C. Li, G. Shi, Carbon 2009, 47, 3538.

- 22X. Yang, L. Li, S. Shang, X.-m. Tao, Polymer 2010, 51, 3431.

- 23C. Bao, Y. Guo, L. Song, Y. Hu, J. Mater. Chem. 2011, 21, 13942.

- 24H. J. Salavagione, G. Martínez, M. A. Gómez, J. Mater. Chem. 2009, 19, 5027.

- 25G. Kandhol, H. Wadhwa, S. Chand, S. Mahendia, S. Kumar, Vacuum 2019, 160, 384.

- 26J. Xu, Y. Hu, L. Song, Q. Wang, W. Fan, G. Liao, Z. Chen, Polym. Degrad. Stab. 2001, 73, 29.

- 27H. Kaczmarek, A. Podgórski, Polym. Degrad. Stab. 2007, 92, 939.

- 28H. Asgharzadeh, M. Sedigh, J. Alloys Compd. 2017, 728, 47.

- 29G. M. Joshi, K. Deshmukh, J. Mater. Sci.: Mater. Electron. 2016, 27, 3397.

- 30C. J. Shih, S. Lin, R. Sharma, M. S. Strano, D. Blankschtein, Langmuir 2012, 28, 235.

- 31S. K. Marka, B. Sindam, K. C. James Raju, V. V. S. S. Srikanth, RSC Adv 2015, 5, 36498.

- 32T. Zhou, F. Chen, C. Tang, H. Bai, Q. Zhang, H. Deng, Q. Fu, Compos Sci Technol 2011, 71, 1266.

- 33Z. Yao, N. Braidy, G. A. Botton, A. Adronov, J. Am. Chem. Soc. 2003, 125, 16015.

- 34T. Ramanathan, A. A. Abdala, S. Stankovich, D. A. Dikin, M. Herrera-Alonso, R. D. Piner, et al., Nat. Nanotechnol. 2008, 3, 327.

- 35L. Liu, A. H. Barber, S. Nuriel, H. D. Wagner, Adv. Funct. Mater. 2005, 15, 975.

- 36J. N. Coleman, M. Cadek, R. Blake, V. Nicolosi, K. P. Ryan, C. Belton, A. Fonseca, J. B. Nagy, Y. K. Gun'ko, W. J. Blau, Adv. Funct. Mater. 2004, 14, 791.

- 37S.-D. Jiang, Z.-M. Bai, G. Tang, Y. Hu, L. Song, Compos Sci Technol 2014, 102, 51.