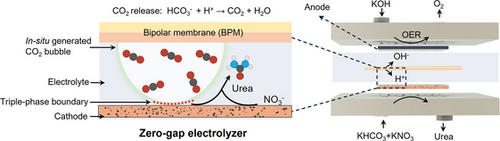

Triple-Phase Boundaries Enable Selective Urea Production From Simulated Flue Gas in a Zero-Gap Electrolyzer

Meng Wang

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

These authors contributed equally to this work.

Search for more papers by this authorChenxi Luo

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

These authors contributed equally to this work.

Search for more papers by this authorZiyu Mi

Institute of Sustainability for Chemicals, Energy and Environment (ISCE2), Agency for Science, Technology and Research (A*STAR), 1 Pesek Road, Singapore, 627833 Republic of Singapore

These authors contributed equally to this work.

Search for more papers by this authorYu-Chia Chang

Department of Applied Chemistry and Center for Emergent Functional Matter Science, National Yang Ming Chiao Tung University, Hsinchu, 300 Taiwan

Search for more papers by this authorYu-Ting Chueh

Department of Applied Chemistry and Center for Emergent Functional Matter Science, National Yang Ming Chiao Tung University, Hsinchu, 300 Taiwan

Search for more papers by this authorPing Luo

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

Search for more papers by this authorMingsheng Zhang

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

Search for more papers by this authorJiguang Zhang

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

Search for more papers by this authorRuoou Yang

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Search for more papers by this authorQin Yang

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Search for more papers by this authorSibo Wang

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Centre for Hydrogen Innovations, National University of Singapore, Singapore, 117580 Republic of Singapore

Search for more papers by this authorShuo Chen

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Search for more papers by this authorJinfeng Jia

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Search for more papers by this authorWan Ru Leow

Institute of Sustainability for Chemicals, Energy and Environment (ISCE2), Agency for Science, Technology and Research (A*STAR), 1 Pesek Road, Singapore, 627833 Republic of Singapore

Search for more papers by this authorZainul Aabdin

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

Search for more papers by this authorSung-Fu Hung

Department of Applied Chemistry and Center for Emergent Functional Matter Science, National Yang Ming Chiao Tung University, Hsinchu, 300 Taiwan

National Synchrotron Radiation Research Center, Hsinchu, 300 Taiwan

Search for more papers by this authorCorresponding Author

Yanwei Lum

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

Centre for Hydrogen Innovations, National University of Singapore, Singapore, 117580 Republic of Singapore

E-mail: [email protected]

Search for more papers by this authorMeng Wang

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

These authors contributed equally to this work.

Search for more papers by this authorChenxi Luo

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

These authors contributed equally to this work.

Search for more papers by this authorZiyu Mi

Institute of Sustainability for Chemicals, Energy and Environment (ISCE2), Agency for Science, Technology and Research (A*STAR), 1 Pesek Road, Singapore, 627833 Republic of Singapore

These authors contributed equally to this work.

Search for more papers by this authorYu-Chia Chang

Department of Applied Chemistry and Center for Emergent Functional Matter Science, National Yang Ming Chiao Tung University, Hsinchu, 300 Taiwan

Search for more papers by this authorYu-Ting Chueh

Department of Applied Chemistry and Center for Emergent Functional Matter Science, National Yang Ming Chiao Tung University, Hsinchu, 300 Taiwan

Search for more papers by this authorPing Luo

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

Search for more papers by this authorMingsheng Zhang

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

Search for more papers by this authorJiguang Zhang

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

Search for more papers by this authorRuoou Yang

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Search for more papers by this authorQin Yang

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Search for more papers by this authorSibo Wang

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Centre for Hydrogen Innovations, National University of Singapore, Singapore, 117580 Republic of Singapore

Search for more papers by this authorShuo Chen

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Search for more papers by this authorJinfeng Jia

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Search for more papers by this authorWan Ru Leow

Institute of Sustainability for Chemicals, Energy and Environment (ISCE2), Agency for Science, Technology and Research (A*STAR), 1 Pesek Road, Singapore, 627833 Republic of Singapore

Search for more papers by this authorZainul Aabdin

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

Search for more papers by this authorSung-Fu Hung

Department of Applied Chemistry and Center for Emergent Functional Matter Science, National Yang Ming Chiao Tung University, Hsinchu, 300 Taiwan

National Synchrotron Radiation Research Center, Hsinchu, 300 Taiwan

Search for more papers by this authorCorresponding Author

Yanwei Lum

Department of Chemical and Biomolecular Engineering, National University of Singapore, Singapore, 117585 Republic of Singapore

Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), 2 Fusionopolis Way, Innovis #08-03, Singapore, 138634 Republic of Singapore

Centre for Hydrogen Innovations, National University of Singapore, Singapore, 117580 Republic of Singapore

E-mail: [email protected]

Search for more papers by this authorGraphical Abstract

Abstract

Renewable energy-powered co-electrolysis of CO2 and NO3− offers a promising pathway toward sustainable urea production. However, achieving high urea selectivity is challenging due to substantial competing side reactions. Here, we show that engendering a high density of CO2 bubbles on the catalyst surface creates numerous triple-phase boundaries that are key toward enhancing CO2 versus NO3− availability for selective urea production. We implemented this strategy using a bipolar membrane in a zero-gap electrolyzer, which allows for the in situ conversion of (bi)carbonate to CO2 bubbles at the catalyst/electrolyte interface. Notably, we demonstrate that this electrolyzer system can utilize simulated flue gas (20% CO2 + 5% O2) for urea production. With a Cu95Ru5 catalyst, we achieve a urea Faradaic efficiency of 58% at 2 V full-cell voltage over an extended 30-h period and a peak production rate of 35.46 mmol h−1 gcat−1. Under these conditions, the Faradaic efficiency to hydrogen evolution and nitrate reduction are 14.7% and 21.6%, respectively. Strikingly, these results with simulated flue gas are comparable to previously reported systems that employ pure CO2. Our results introduce a simple yet effective design approach toward developing efficient electrolyzer systems for urea production.

Conflict of Interests

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data supporting the findings of this study are available within the article and its Supplementary Information files. Should any raw data files be needed in another format, they are available from the corresponding author upon reasonable request.

Supporting Information

| Filename | Description |

|---|---|

| anie202505987-supp-0001-SuppMat.pdf7.7 MB | Supporting Information |

| anie202505987-supp-0002-VideoS1.mov18.8 MB | Supporting Information |

| anie202505987-supp-0003-VideoS2.mp41.3 MB | Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1S. K. Masjedi, A. Kazemi, M. Moeinnadini, E. Khaki, S. I. Olsen, Sci. Total Environ. 2024, 908, 168225.

- 2J. H. J. Spiertz, Agron. Sustain. Dev. 2010, 30, 43–55.

- 3E. Walling, C. Vaneeckhaute, J. Environ. Manage. 2020, 276, 111211.

- 4N. Gruber, J. N. Galloway, Nature 2008, 451, 293–296.

- 5J. Lim, C. A. Fernández, S. W. Lee, M. C. Hatzell, ACS Energy Lett. 2021, 6, 3676–3685.

- 6Y. Kohlhaas, Y. S. Tschauder, W. Plischka, U. Simon, R.-A. Eichel, M. Wessling, R. Keller, Joule 2024, 8, 1579–1600.

- 7M. Appl, Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, Germany 2011.

- 8M. Hattori, S. Iijima, T. Nakao, H. Hosono, M. Hara, Nat. Commun. 2020, 11, 2001.

- 9D. Saravanakumar, J. Song, S. Lee, N. H. Hur, W. Shin, ChemSusChem 2017, 10, 3999–4003.

- 10C. Lv, L. Zhong, H. Liu, Z. Fang, C. Yan, M. Chen, Y. Kong, C. Lee, D. Liu, S. Li, J. Liu, L. Song, G. Chen, Q. Yan, G. Yu, Nat. Sustain. 2021, 4, 868–876.

- 11J. Li, Y. Zhang, K. Kuruvinashetti, N. Kornienko, Nat. Rev. Chem. 2022, 6, 303–319.

- 12Z. Tao, C. L. Rooney, Y. Liang, H. Wang, J. Am. Chem. Soc. 2021, 143, 19630–19642.

- 13Y. Zhao, Y. Ding, W. Li, C. Liu, Y. Li, Z. Zhao, Y. Shan, F. Li, L. Sun, F. Li, Nat. Commun. 2023, 14, 4491.

- 14Y. Luo, K. Xie, P. Ou, C. Lavallais, T. Peng, Z. Chen, Z. Zhang, N. Wang, X.-Y. Li, I. Grigioni, B. Liu, D. Sinton, J. B. Dunn, E. H. Sargent, Nat. Catal. 2023, 6, 939–948.

- 15Y. Li, S. Zheng, H. Liu, Q. Xiong, H. Yi, H. Yang, Z. Mei, Q. Zhao, Z.-W. Yin, M. Huang, Y. Lin, W. Lai, S.-X. Dou, F. Pan, S. Li, Nat. Commun. 2024, 15, 176.

- 16X. Huang, Y. Li, S. Xie, Q. Zhao, B. Zhang, Z. Zhang, H. Sheng, J. Zhao, Angew. Chem. Int. Ed. 2024, 63, e202403980.

- 17Q. Hu, W. Zhou, S. Qi, Q. Huo, X. Li, M. Lv, X. Chen, C. Feng, J. Yu, X. Chai, H. Yang, C. He, Nat. Sustain. 2024, 7, 442–451.

- 18C. Lv, C. Lee, L. Zhong, H. Liu, J. Liu, L. Yang, C. Yan, W. Yu, H. H. Hng, Z. Qi, L. Song, S. Li, K. P. Loh, Q. Yan, G. Yu, ACS Nano 2022, 16, 8213–8222.

- 19X. Zhang, X. Zhu, S. Bo, C. Chen, M. Qiu, X. Wei, N. He, C. Xie, W. Chen, J. Zheng, P. Chen, S. P. Jiang, Y. Li, Q. Liu, S. Wang, Nat. Commun. 2022, 13, 5337.

- 20H. Li, L. Xu, S. Bo, Y. Wang, H. Xu, C. Chen, R. Miao, D. Chen, K. Zhang, Q. Liu, J. Shen, H. Shao, J. Jia, S. Wang, Nat. Commun. 2024, 15, 8858.

- 21J. Zhang, L. Huang, W. W. Tjiu, C. Wu, M. Zhang, S. Bin Dolmanan, S. Wang, M. Wang, S. Xi, Z. Aabdin, Y. Lum, J. Am. Chem. Soc. 2024, 146, 30708–30714.

- 22X. Song, X. Ma, T. Chen, L. Xu, J. Feng, L. Wu, S. Jia, L. Zhang, X. Tan, R. Wang, C. Chen, J. Ma, Q. Zhu, X. Kang, X. Sun, B. Han, J. Am. Chem. Soc. 2024, 146, 25813–25823.

- 23D.-S. Huang, X.-F. Qiu, J.-R. Huang, M. Mao, L. Liu, Y. Han, Z.-H. Zhao, P.-Q. Liao, X.-M. Chen, Nat. Synth. 2024, 3, 1404–1413.

- 24X. Wei, Y. Liu, X. Zhu, S. Bo, L. Xiao, C. Chen, T. T. T. Nga, Y. He, M. Qiu, C. Xie, D. Wang, Q. Liu, F. Dong, C. Dong, X. Fu, S. Wang, Adv. Mater. 2023, 35, 2300020.

- 25Y. Xu, J. P. Edwards, J. Zhong, C. P. O'Brien, C. M. Gabardo, C. McCallum, J. Li, C.-T. Dinh, E. H. Sargent, D. Sinton, Energy Environ. Sci. 2020, 13, 554–561.

- 26M. Wang, B. Wang, J. Zhang, S. Xi, N. Ling, Z. Mi, Q. Yang, M. Zhang, W. R. Leow, J. Zhang, Y. Lum, Nat. Commun. 2024, 15, 1218.

- 27R. F. Service, Science 2016, 354, 1362–1363.

- 28M. T. Ho, G. W. Allinson, D. E. Wiley, Energy Procedia 2009, 1, 763–770.

- 29Y. C. Li, G. Lee, T. Yuan, Y. Wang, D.-H. Nam, Z. Wang, F. P. García De Arquer, Y. Lum, C.-T. Dinh, O. Voznyy, E. H. Sargent, ACS Energy Lett. 2019, 4, 1427–1431.

- 30M. Sassenburg, M. Kelly, S. Subramanian, W. A. Smith, T. Burdyny, ACS Energy Lett. 2023, 8, 321–331.

- 31D. Wakerley, S. Lamaison, F. Ozanam, N. Menguy, D. Mercier, P. Marcus, M. Fontecave, V. Mougel, Nat. Mater. 2019, 18, 1222–1227.

- 32T. N. Huan, G. Rousse, S. Zanna, I. T. Lucas, X. Xu, N. Menguy, V. Mougel, M. Fontecave, Angew. Chem. Int. Ed. 2017, 56, 4792–4796.

- 33T. N. Huan, P. Simon, G. Rousse, I. Génois, V. Artero, M. Fontecave, Chem. Sci. 2017, 8, 742–747.

- 34Z. Yan, J. L. Hitt, Z. Zeng, M. A. Hickner, T. E. Mallouk, Nat. Chem. 2021, 13, 33–40.

- 35X. Lu, C. Zhou, R. S. Delima, E. W. Lees, A. Soni, D. J. Dvorak, S. Ren, T. Ji, A. Bahi, F. Ko, C. P. Berlinguette, Nat. Chem. 2024, 16, 979–987.

- 36Y. Yu, Y. Sun, J. Han, Y. Guan, H. Li, L. Wang, J. Lai, Energy Environ. Sci. 2024, 17, 5183–5190.

- 37J. Liu, S. Zhang, Y. Jiang, W. Li, M. Jin, J. Ding, Y. Zhang, G. Wang, H. Zhang, Chem. Commun. 2024, 60, 11592–11595.

- 38F. Wang, S. Shang, Z. Li, Z. Zhang, K. Chu, ACS Energy Lett. 2024, 9, 4624–4632.

- 39A. Stoddart, Nat. Synth. 2024, 3, 800–800.

- 40D. P. Butcher, A. A. Gewirth, Nano Energy 2016, 29, 457–465.

- 41M. Xu, F. Wu, Y. Zhang, Y. Yao, G. Zhu, X. Li, L. Chen, G. Jia, X. Wu, Y. Huang, P. Gao, W. Ye, Nat. Commun. 2023, 14, 6994.

- 42M. Zheng, P. Wang, X. Zhi, K. Yang, Y. Jiao, J. Duan, Y. Zheng, S.-Z. Qiao, J. Am. Chem. Soc. 2022, 144, 14936–14944.

- 43J. Gao, H. Zhang, X. Guo, J. Luo, S. M. Zakeeruddin, D. Ren, M. Grätzel, J. Am. Chem. Soc. 2019, 141, 18704–18714.

- 44X. Chang, S. Vijay, Y. Zhao, N. J. Oliveira, K. Chan, B. Xu, Nat. Commun. 2022, 13, 2656.

- 45J. B. Bossa, P. Theulé, F. Duvernay, F. Borget, T. Chiavassa, Astron. Astrophys. 2008, 492, 719–724.

- 46Y. Lum, J. W. Ager, Angew. Chem. Int. Ed. 2018, 57, 551–554.

- 47X. Wei, X. Wen, Y. Liu, C. Chen, C. Xie, D. Wang, M. Qiu, N. He, P. Zhou, W. Chen, J. Cheng, H. Lin, J. Jia, X.-Z. Fu, S. Wang, J. Am. Chem. Soc. 2022, 144, 11530–11535.

- 48M. Sun, G. Wu, J. Jiang, Y. Yang, A. Du, L. Dai, X. Mao, Q. Qin, Angew. Chem. Int. Ed. 2023, 62, e202301957.

- 49J. Leverett, T. Tran-Phu, J. A. Yuwono, P. Kumar, C. Kim, Q. Zhai, C. Han, J. Qu, J. Cairney, A. N. Simonov, R. K. Hocking, L. Dai, R. Daiyan, R. Amal, Adv. Energy Mater. 2022, 12, 2201500.

- 50K. Chen, D. Ma, Y. Zhang, F. Wang, X. Yang, X. Wang, H. Zhang, X. Liu, R. Bao, K. Chu, Adv. Mater. 2024, 36, 2402160.

- 51Y. Zhang, Z. Li, K. Chen, X. Yang, H. Zhang, X. Liu, K. Chu, Adv. Energy Mater. 2024, 14, 2402309.

- 52D. J. D. Pimlott, A. Jewlal, Y. Kim, C. P. Berlinguette, J. Am. Chem. Soc. 2023, 145, 25933–25937.