Manipulation of Hydrogen Transfer Behaviors by RhCu Alloying Enables an All-in-one Sustainable “Furfural-Nitrate” System

Xin Long

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorCorresponding Author

Prof. Dr. Bin Zhao

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

E-mails: [email protected]; [email protected]

Search for more papers by this authorDanni Liu

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorGuodong Fu

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorHang Yang

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorDr. Renfei Feng

Canadian Light Source Inc., Saskatoon, Saskatchewan, S7N 0X4 Canada

Search for more papers by this authorDr. Ning Chen

Canadian Light Source Inc., Saskatoon, Saskatchewan, S7N 0X4 Canada

Search for more papers by this authorHekun Ding

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorJiayi Wu

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorYuanfeng Liao

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorProf. Dr. Shaoqing Liu

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorYu Zhang

Instrumental Analysis Center of Shenzhen University (Lihu Campus), Shenzhen University, Shenzhen, 518055 China

Search for more papers by this authorProf. Dr. Xian-Zhu Fu

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorCorresponding Author

Prof. Dr. Jing-Li Luo

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

E-mails: [email protected]; [email protected]

Search for more papers by this authorXin Long

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorCorresponding Author

Prof. Dr. Bin Zhao

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

E-mails: [email protected]; [email protected]

Search for more papers by this authorDanni Liu

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorGuodong Fu

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorHang Yang

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorDr. Renfei Feng

Canadian Light Source Inc., Saskatoon, Saskatchewan, S7N 0X4 Canada

Search for more papers by this authorDr. Ning Chen

Canadian Light Source Inc., Saskatoon, Saskatchewan, S7N 0X4 Canada

Search for more papers by this authorHekun Ding

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorJiayi Wu

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorYuanfeng Liao

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorProf. Dr. Shaoqing Liu

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorYu Zhang

Instrumental Analysis Center of Shenzhen University (Lihu Campus), Shenzhen University, Shenzhen, 518055 China

Search for more papers by this authorProf. Dr. Xian-Zhu Fu

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

Search for more papers by this authorCorresponding Author

Prof. Dr. Jing-Li Luo

Shenzhen Key Laboratory of Energy Electrocatalytic Materials, Guangdong Research Center for Interfacial Engineering of Functional Materials, Guangdong Provincial Key Laboratory of New Energy Materials Service Safety, College of Materials Science and Engineering, Shenzhen University, Shenzhen, 518060 China

E-mails: [email protected]; [email protected]

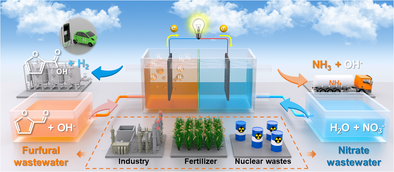

Search for more papers by this authorGraphical Abstract

We report an all-in-one electrochemical energy system by coupling the rational conversions from nitrogen-oxysalts and biomass-derived-aldehydes (industrial/agricultural wastes). The poor reaction kinetics are efficaciously optimized by RhCu alloy electrocatalyst with dual-directional H*-modulation properties. So, nitrate and furfural can be simultaneously converted into multiple non-mixed valuable products (NH3, H2, etc.) with electricity output.

Abstract

Nitrate and furfural are typical wastes mainly from industrialization and agriculturalization progresses, and their clean conversions are still very challenging for a sustainable future. Nevertheless, scant attention has been devoted to the core issues: the rational integration of two wastes recycling and the targeted manipulation of hydrogen (H*) transfer behaviors to address their sluggish reaction kinetics. Herein, we report an all-in-one electrochemical energy system that is thermodynamically designed by coupling nitrate reduction (NO3RR) and furfural oxidation reactions (FORs) together. Particularly, the poor kinetics for both electrode reactions are efficaciously optimized by the bifunctional electrocatalyst of RhCu alloy nanowires on copper foam (RhCu NW/CF) with highly improved dual-directional H*-modulation performances, thus initializing NO3RR for NH3 synthesis at +0.31 V and driving FOR for H2 harvest at an onset potential lower than 0 V. Eventually, such integrated “Furfural-Nitrate” system can simultaneously effectuate the electricity energy supply (10.76 mW cm−2), wastewater purification, cathodic hydrogen storage (NH3), anodic H2 production, and biomass upgrading. Hence, it provides a promising perspective of “turning waste into treasure” in a rational manner, justifying its all-in-one property in addressing the global challenge of sustainable energy.

Conflict of Interests

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Supporting Information

| Filename | Description |

|---|---|

| anie202503424-sup-0001-SuppMat.pdf6.3 MB | Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1W. Chen, X. Yang, Z. Chen, Z. Ou, J. Hu, Y. Xu, Y. Li, X. Ren, S. Ye, J. Qiu, J. Liu, Q. Zhang, Adv. Funct. Mater. 2023, 33, 2300512.

- 2Y. Xiong, Y. Wang, J. Zhou, F. Liu, F. Hao, Z. Fan, Adv. Mater. 2024, 36, 2304021.

- 3G.-F. Chen, Y. Yuan, H. Jiang, S.-Y. Ren, L.-X. Ding, L. Ma, T. Wu, J. Lu, H. Wang, Nat. Energy. 2020, 5, 605–613.

- 4S. Han, H. Li, T. Li, F. Chen, R. Yang, Y. Yu, B. Zhang, Nat. Catal. 2023, 6, 402–414.

- 5P. H. van Langevelde, I. Katsounaros, M. T. M. Koper, Joule 2021, 5, 290–294.

- 6C. Tian, R. Dorakhan, J. Wicks, Z. Chen, K.-S. Choi, N. Singh, J. A. Schaidle, A. Holewinski, A. Vojvodic, D. G. Vlachos, L. J. Broadbelt, E. H. Sargent, Nat. Catal. 2024, 7, 350–360.

- 7M. Yang, Z. Yuan, R. Peng, S. Wang, Y. Zou, Energy. Environ. Mater. 2022, 5, 1117–1138.

- 8J. Yang, L. Huai, C. Chen, J. Zhang, ACS Appl. Mater. Interfaces. 2025, 17, 10168–10178.

- 9H. Liu, X. Lang, C. Zhu, J. Timoshenko, M. Ruscher, L. Bai, N. Guijarro, H. Yin, Y. Peng, J. Li, Z. Liu, W. Wang, B. R. Cuenya, J. Luo, Angew. Chem. Int. Ed. 2022, 61, e202202556.

- 10M. Yang, Y. Li, C. L. Dong, S. Li, L. Xu, W. Chen, J. Wu, Y. Lu, Y. Pan, Y. Wu, Y. Luo, Y. Huang, S. Wang, Y. Zou, Adv. Mater. 2023, 35, 2304203.

- 11T. Wang, Z. Huang, T. Liu, L. Tao, J. Tian, K. Gu, X. Wei, P. Zhou, L. Gan, S. Du, Y. Zou, R. Chen, Y. Li, X. Z. Fu, S. Wang, Angew. Chem. Int. Ed. 2022, 61, e202115636.

- 12F. Y. Chen, Z. Y. Wu, S. Gupta, D. J. Rivera, S. V. Lambeets, S. Pecaut, J. Y. T. Kim, P. Zhu, Y. Z. Finfrock, D. M. Meira, G. King, G. Gao, W. Xu, D. A. Cullen, H. Zhou, Y. Han, D. E. Perea, C. L. Muhich, H. Wang, Nat. Nanotechnol. 2022, 17, 759–767.

- 13L. Jiang, K. Liu, S. F. Hung, L. Zhou, R. Qin, Q. Zhang, P. Liu, L. Gu, H. M. Chen, G. Fu, N. Zheng, Nat. Nanotechnol. 2020, 15, 848–853.

- 14Z. X. Ge, T. J. Wang, Y. Ding, S. B. Yin, F. M. Li, P. Chen, Y. Chen, Adv. Energy Mater. 2022, 12, 2103916.

- 15Q. Qian, Y. Zhu, N. Ahmad, Y. Feng, H. Zhang, M. Cheng, H. Liu, C. Xiao, G. Zhang, Y. Xie, Adv. Mater. 2024, 36, 2306108.

- 16Y. Lim, S. Surendran, W. So, S. Shanmugapriya, C. Jo, G. Janani, H. Choi, H. S. Han, H. Choi, Y.-H. Yun, T.-H. Kim, M.-J. Kim, K. Jin, J. K. Kim, U. Sim, Mater. Chem. Front. 2023, 7, 5843–5857.

- 17Y. Feng, Q. Shi, J. Lin, E. Chai, X. Zhang, Z. Liu, L. Jiao, Y. Wang, Adv. Mater. 2022, 34, 2207747.

- 18Y. Guo, R. Zhang, S. Zhang, Y. Zhao, Q. Yang, Z. Huang, B. Dong, C. Zhi, Energy. Environ. Sci. 2021, 14, 3938–3944.

- 19J. Zhou, Y. Xiong, M. Sun, Z. Xu, Y. Wang, P. Lu, F. Liu, F. Hao, T. Feng, Y. Ma, J. Yin, C. Ye, B. Chen, S. Xi, Y. Zhu, B. Huang, Z. Fan, Proc. Nat. Acad. Sci. 2023, 120, e2311149120.

- 20T. Wang, L. Tao, X. Zhu, C. Chen, W. Chen, S. Du, Y. Zhou, B. Zhou, D. Wang, C. Xie, P. Long, W. Li, Y. Wang, R. Chen, Y. Li, X. Duan, S. Wang, Nat. Catal. 2021, 5, 66–73.

- 21Y. Yang, X. Wu, M. Ahmad, F. Si, S. Chen, C. Liu, Y. Zhang, L. Wang, J. Zhang, J. L. Luo, X. Z. Fu, Angew. Chem. Int. Ed. 2023, 62, e202302950.

- 22H. Liu, J. Timoshenko, L. Bai, Q. Li, M. Rüscher, C. Sun, B. Roldan Cuenya, J. Luo, ACS. Catal. 2023, 13, 1513–1521.

- 23X. Shi, M. Xie, K. Yang, Y. Niu, H. Ma, Y. Zhu, J. Li, T. Pan, X. Zhou, Y. Cui, Z. Li, Y. Yu, X. Yu, J. Ma, H. Cheng, Angew. Chem. Int. Ed. 2024, 63, e202406750.

- 24X. Long, B. Zhao, Q. Zhao, X. Wu, M.-N. Zhu, R. Feng, M. Shakouri, Y. Zhang, X. Xiao, J. Zhang, X.-Z. Fu, J.-L. Luo, Appl. Catal. B -Environ. 2024, 343, 123559.

- 25H. Fei, J. Dong, M. J. Arellano-Jimenez, G. Ye, N. D. Kim, E. L. Samuel, Z. Peng, Z. Zhu, F. Qin, J. Bao, M. J. Yacaman, P. M. Ajayan, D. Chen, J. M. Tour, Nat. Commun. 2015, 6, 8668.

- 26H. Lu, K. N. Opoku, Z. Wang, R. Ni, M. Liu, Y. Wang, Y. Zhang, C. Yu, A. Yuan, F. Yang, W. Shi, Chem. Eng. J. 2025, 503, 158536.

- 27J. Y. Fang, Q. Z. Zheng, Y. Y. Lou, K. M. Zhao, S. N. Hu, G. Li, O. Akdim, X. Y. Huang, S. G. Sun, Nat. Commun. 2022, 13, 7899.

- 28W. Gao, K. Xie, J. Xie, X. Wang, H. Zhang, S. Chen, H. Wang, Z. Li, C. Li, Adv. Mater. 2023, 35, 2202952.

- 29W. Yu, J. Yu, M. Huang, Y. Wang, Y. Wang, J. Li, H. Liu, W. Zhou, Energy. Environ. Sci. 2023, 16, 2991–3001.

- 30K. Liu, H. Li, M. Xie, P. Wang, Z. Jin, Y. Liu, M. Zhou, P. Li, G. Yu, J. Am. Chem. Soc. 2024, 146, 7779–7790.

- 31C. Pasquini, I. Zaharieva, D. Gonzalez-Flores, P. Chernev, M. R. Mohammadi, L. Guidoni, R. D. L. Smith, H. Dau, J. Am. Chem. Soc. 2019, 141, 2938–2948.

- 32S. Zhang, J. Wu, M. Zheng, X. Jin, Z. Shen, Z. Li, Y. Wang, Q. Wang, X. Wang, H. Wei, J. Zhang, P. Wang, S. Zhang, L. Yu, L. Dong, Q. Zhu, H. Zhang, J. Lu, Nat. Commun. 2023, 14, 3634.

- 33Y. Liu, B. Deng, K. Li, H. Wang, Y. Sun, F. Dong, J. Colloid Interface Sci. 2022, 614, 405–414.

- 34K. Chen, J. Xiang, Y. Guo, X. Liu, X. Li, K. Chu, Nano Lett. 2024, 24, 541–548.

- 35X. Guo, P. Wang, T. Wu, Z. Wang, J. Li, K. Liu, J. Fu, M. Liu, J. Wu, Z. Lin, L. Chai, Z. Bian, H. Li, M. Liu, Angew. Chem. Int. Ed. 2024, 63, e202318792.

- 36Y. Lu, T. Liu, C. L. Dong, Y. C. Huang, Y. Li, J. Chen, Y. Zou, S. Wang, Adv. Mater. 2021, 33, 2007056.

- 37S.-Q. Liu, M.-R. Gao, S. Wu, R. Feng, Y. Wang, L. Cui, Y. Guo, X.-Z. Fu, J.-L. Luo, Energy. Environ. Sci. 2023, 16, 5305–5314.

- 38Y. Qi, Y. Zhang, L. Yang, Y. Zhao, Y. Zhu, H. Jiang, C. Li, Nat. Commun. 2022, 13, 4602.

- 39P. Zhou, G. Hai, G. Zhao, R. Li, X. Huang, Y. Lu, G. Wang, Appl. Catal. B -Environ. 2023, 325, 122364.

- 40C. G. Swain, A. L. Powell, W. A. Sheppard, C. R. Morgan, J. Am. Chem. Soc. 1979, 101, 3576–3583.

- 41G. Fu, X. Kang, Y. Zhang, Y. Guo, Z. Li, J. Liu, L. Wang, J. Zhang, X. Z. Fu, J. L. Luo, Nat. Commun. 2023, 14, 8395.

- 42W. Zhang, Y. Qi, Y. Zhao, W. Ge, L. Dong, J. Shen, H. Jiang, C. Li, Sci. Bull. 2023, 68, 2190–2199.

- 43Y. Pan, Y. Li, C.-L. Dong, Y.-C. Huang, J. Wu, J. Shi, Y. Lu, M. Yang, S. Wang, Y. Zou, Chem 2023, 9, 963–977.

- 44W. Zhu, X. Zhang, F. Yao, R. Huang, Y. Chen, C. Chen, J. Fei, Y. Chen, Z. Wang, H. Liang, Angew. Chem. Int. Ed. 2023, 62, e202300390.

- 45J. Li, K. Ji, B. Li, M. Xu, Y. Wang, H. Zhou, Q. Shi, H. Duan, Angew. Chem. Int. Ed. 2023, 62, e202304852.

- 46S. An, Z. H. Zhao, J. Bu, J. He, W. Ma, J. Lin, R. Bai, L. Shang, J. Zhang, Angew. Chem. Int. Ed. 2024, 63, e202318989.