Leveraging the Proximity and Distribution of Cu−Cs Sites for Direct Conversion of Methanol to Esters/Aldehydes

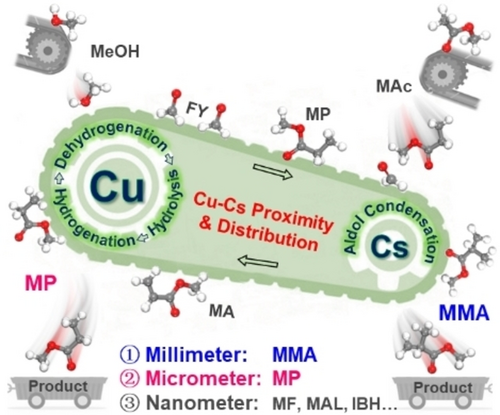

Graphical Abstract

An unprecedented quadruple tandem catalytic production of esters and aldehydes from methanol and methyl acetate/ethanol has been developed, allowing for customized chain length and saturation by leveraging the proximity and distribution of Cu−Cs sites. This approach has the potential to revolutionize the production of value-added methyl methacrylate (MMA), surpassing the current industrial processes to significantly lower the production costs.

Abstract

Methanol serves as a versatile building-block for various commodity chemicals, and the development of industrially promising strategies for its conversion remains the ultimate goal in methanol chemistry. In this study, we design a dual Cu−Cs catalytic system that enables a one-step direct conversion of methanol and methyl acetate/ethanol into high value-added esters/aldehydes, with customized chain length and saturation by leveraging the proximity and distribution of Cu−Cs sites. Cu−Cs at a millimeter-scale intimacy triggers methanol dehydrogenation and condensation, involving proton transfer, aldol formation, and aldol condensation, to obtain unsaturated esters and aldehydes with selectivities of 76.3 % and 31.1 %, respectively. Cu−Cs at a micrometer-scale intimacy significantly promotes mass transfer of intermediates across catalyst interfaces and their subsequent hydrogenation to saturated esters and aldehydes with selectivities of 67.6 % and 93.1 %, respectively. Conversely, Cu−Cs at a nanometer-scale intimacy alters reaction pathway with a similar energy barrier for the rate-determining step, but blocks the acidic-basic sites and diverts the reaction to byproducts. More importantly, an unprecedented quadruple tandem catalytic production of methyl methacrylate (MMA) is achieved by further tailoring Cu and Cs distribution across the reaction bed in the configuration of Cu−Cs||Cs, outperforming the existing industrial processes and saving at least 15 % of production costs.

Conflict of interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.