Boosting CO2 Hydrogenation to Formate over Edge-Sulfur Vacancies of Molybdenum Disulfide

Zifeng Wang

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

These authors contributed equally to this work.

Search for more papers by this authorYiran Kang

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

These authors contributed equally to this work.

Search for more papers by this authorJingting Hu

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorQinqin Ji

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

Search for more papers by this authorZhixuan Lu

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

Search for more papers by this authorGuilan Xu

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorYutai Qi

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorMo Zhang

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorWangwang Zhang

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorRui Huang

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorCorresponding Author

Liang Yu

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

Search for more papers by this authorZhong-qun Tian

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

Search for more papers by this authorCorresponding Author

Dehui Deng

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

Search for more papers by this authorZifeng Wang

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

These authors contributed equally to this work.

Search for more papers by this authorYiran Kang

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

These authors contributed equally to this work.

Search for more papers by this authorJingting Hu

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorQinqin Ji

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

Search for more papers by this authorZhixuan Lu

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

Search for more papers by this authorGuilan Xu

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorYutai Qi

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorMo Zhang

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorWangwang Zhang

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorRui Huang

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

Search for more papers by this authorCorresponding Author

Liang Yu

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

Search for more papers by this authorZhong-qun Tian

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

Search for more papers by this authorCorresponding Author

Dehui Deng

State Key Laboratory of Physical Chemistry of Solid Surfaces, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005 China

State Key Laboratory of Catalysis, Collaborative Innovation Center of Chemistry for Energy Materials (iChEM), Dalian Institute of Chemical Physics, Chinese Academy of Science, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

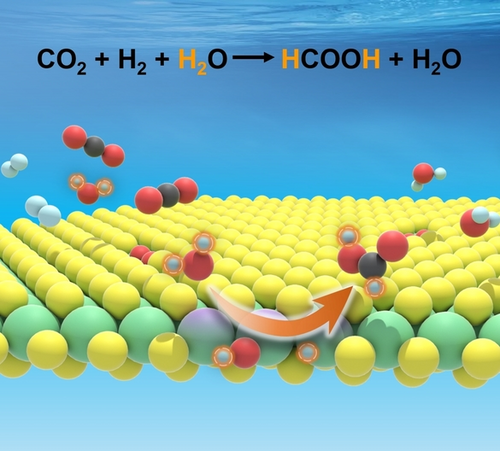

Search for more papers by this authorGraphical Abstract

Abstract

Synthesis of formate from hydrogenation of carbon dioxide (CO2) is an atom-economic reaction but is confronted with challenges in developing high-performance non-precious metal catalysts for application of the process. Herein, we report a highly durable edge-rich molybdenum disulfide (MoS2) catalyst for CO2 hydrogenation to formate at 200 °C, which delivers a high selectivity of over 99 % with a superior turnover frequency of 780.7 h−1 surpassing those of previously reported non-precious metal catalysts. Multiple experimental characterization techniques combined with theoretical calculations reveal that sulfur vacancies at MoS2 edges are the active sites and the selective production of formate is enabled via a completely new water-mediated hydrogenation mechanism, in which surface OH* and H* species in dynamic equilibrium with water serve as moderate hydrogenating agents for CO2 with residual O* reduced by hydrogen. This study provides a new route for developing low-cost high-performance catalysts for CO2 hydrogenation to formate.

Conflict of interest

The authors declare no competing interests.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| anie202307086-sup-0001-misc_information.pdf16.4 MB | Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1

- 1aW. Wang, S. Wang, X. Ma, J. Gong, Chem. Soc. Rev. 2011, 40, 3703–3727;

- 1bA. Álvarez, A. Bansode, A. Urakawa, A. V. Bavykina, T. A. Wezendonk, M. Makkee, J. Gascon, F. Kapteijn, Chem. Rev. 2017, 117, 9804–9838.

- 2

- 2aJ. H. Lee, J. Ryu, J. Y. Kim, S.-W. Nam, J. H. Han, T.-H. Lim, S. Gautam, K. H. Chae, C. W. Yoon, J. Mater. Chem. A 2014, 2, 9490–9495;

- 2bH. Park, J. H. Lee, E. H. Kim, K. Y. Kim, Y. H. Choi, D. H. Youn, J. S. Lee, Chem. Commun. 2016, 52, 14302–14305;

- 2cH. Song, N. Zhang, C. Zhong, Z. Liu, M. Xiao, H. Gai, New J. Chem. 2017, 41, 9170–9177.

- 3Q. Liu, X. Yang, L. Li, S. Miao, Y. Li, Y. Li, X. Wang, Y. Huang, T. Zhang, Nat. Commun. 2017, 8, 1407.

- 4H. Zhong, M. Iguchi, M. Chatterjee, T. Ishizaka, M. Kitta, Q. Xu, H. Kawanami, ACS Catal. 2018, 8, 5355–5362.

- 5S. Masuda, K. Mori, Y. Futamura, H. Yamashita, ACS Catal. 2018, 8, 2277–2285.

- 6

- 6aB. An, L. Zeng, M. Jia, Z. Li, Z. Lin, Y. Song, Y. Zhou, J. Cheng, C. Wang, W. Lin, J. Am. Chem. Soc. 2017, 139, 17747–17750;

- 6bZ. Xu, N. D. McNamara, G. T. Neumann, W. F. Schneider, J. C. Hicks, ChemCatChem 2013, 5, 1769–1771.

- 7

- 7aG. H. Gunasekar, K.-D. Jung, S. Yoon, Inorg. Chem. 2019, 58, 3717–3723;

- 7bG. H. Gunasekar, J. Shin, K.-D. Jung, K. Park, S. Yoon, ACS Catal. 2018, 8, 4346–4353;

- 7cC. Wu, F. Irshad, M. Luo, Y. Zhao, X. Ma, S. Wang, ChemCatChem 2019, 11, 1256–1263;

- 7dK. Mori, T. Taga, H. Yamashita, ACS Catal. 2017, 7, 3147–3151;

- 7eA. Jaleel, S.-H. Kim, P. Natarajan, G. H. Gunasekar, K. Park, S. Yoon, K.-D. Jung, J. CO2 Util. 2020, 35, 245–255.

- 8

- 8aX.-P. Fu, L. Peres, J. Esvan, C. Amiens, K. Philippot, N. Yan, Nanoscale 2021, 13, 8931–8939;

- 8bH.-H. Wang, S.-N. Zhang, T.-J. Zhao, Y.-X. Liu, X. Liu, J. Su, X.-H. Li, J.-S. Chen, Sci. Bull. 2020, 65, 651–657;

- 8cL. Zhou, L. Peng, J. Ji, W. Ma, J. Hu, Y. Wu, J. Geng, X. Hu, J. CO2 Util. 2022, 58, 101910;

- 8dB. J. Akinbile, L. C. Matsinha, A. A. Ambushe, B. C. E. Makhubela, ACS Earth Space Chem. 2021, 5, 2846–2854;

- 8eJ. Wang, H. Jin, W.-H. Wang, Y. Zhao, Y. Li, M. Bao, ACS Appl. Mater. Interfaces 2020, 12, 19581–19586;

- 8fN. Jiang, H. Sun, D. Ren, Q. Pang, F. Jin, Z. Huo, J. CO2 Util. 2017, 20, 218–223;

- 8gC. E. Mitchell, D. Santos-Carballal, A. M. Beale, W. Jones, D. J. Morgan, M. Sankar, N. H. de Leeuw, Faraday Discuss. 2021, 230, 30–51;

- 8hN. Makuve, J. Darkwa, G. Mehlana, B. C. E. Makhubela, Inorganics 2022, 10, 30;

- 8iC. E. Mitchell, U. Terranova, A. M. Beale, W. Jones, D. J. Morgan, M. Sankar, N. H. de Leeuw, Catal. Sci. Technol. 2021, 11, 779–784.

- 9

- 9aY.-N. Li, X.-F. Liu, L.-N. He, J. CO2 Util. 2019, 29, 74–81;

- 9bC. Hao, S. Wang, M. Li, L. Kang, X. Ma, Catal. Today 2011, 160, 184–190;

- 9cS. Semwal, A. Kumar, J. Choudhury, Catal. Sci. Technol. 2018, 8, 6137–6142;

- 9dS. Wang, S. Hou, C. Wu, Y. Zhao, X. Ma, Chin. Chem. Lett. 2019, 30, 398–402;

- 9eX. Shao, X. Yang, J. Xu, S. Liu, S. Miao, X. Liu, X. Su, H. Duan, Y. Huang, T. Zhang, Chem 2019, 5, 693–705;

- 9fG. A. Filonenko, W. L. Vrijburg, E. J. M. Hensen, E. A. Pidko, J. Catal. 2016, 343, 97–105;

- 9gS. Masuda, K. Mori, Y. Kuwahara, H. Yamashita, J. Mater. Chem. A 2019, 7, 16356–16363;

- 9hY. Kuwahara, Y. Fujie, H. Yamashita, ChemCatChem 2017, 9, 1906–1914;

- 9iK. Mori, T. Sano, H. Kobayashi, H. Yamashita, J. Am. Chem. Soc. 2018, 140, 8902–8909;

- 9jR. Sun, Y. Liao, S.-T. Bai, M. Zheng, C. Zhou, T. Zhang, B. F. Sels, Energy Environ. Sci. 2021, 14, 1247–1285.

- 10J. Hu, L. Yu, J. Deng, Y. Wang, K. Cheng, C. Ma, Q. Zhang, W. Wen, S. Yu, Y. Pan, J. Yang, H. Ma, F. Qi, Y. Wang, Y. Zheng, M. Chen, R. Huang, S. Zhang, Z. Zhao, J. Mao, X. Meng, Q. Ji, G. Hou, X. Han, X. Bao, Y. Wang, D. Deng, Nat. Catal. 2021, 4, 242–250.

- 11T. Weber, J. C. Muijsers, J. H. M. C. van Wolput, C. P. J. Verhagen, J. W. Niemantsverdriet, J. Phys. Chem. 1996, 100, 14144–14150.

- 12H. Li, Q. Zhang, C. C. R. Yap, B. K. Tay, T. H. T. Edwin, A. Olivier, D. Baillargeat, Adv. Funct. Mater. 2012, 22, 1385–1390.

- 13W. Xie, G. Reid, P. Hu, JACS Au 2022, 2, 328–334.