A pilot-scale dry bean canning and evaluation protocol

Funding information

This research work is supported by the funding resource from U.S. Department of Agriculture Organic Agriculture Research and Extension Initiative (OREI) under award number 2018-51300-28433. This research was also supported by funding from the U.S. Department of Agriculture, Agriculture Research Services Projects 5050-21430-01000D (K.A.C.). WW is also supported by C.S. Mott Predoctoral Fellowships in Sustainable Agriculture from Michigan State University. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

Abstract

Dry beans are a nutrient dense food that generally requires long cooking times. Canned beans provide consumers safe and convenient access to this nutritious food. Canning quality is a measure of how well beans withstand the canning process and is affected by many factors including bean genotype, growing conditions, and post-harvest seed handling. The evaluation of canning quality has long been an important consideration for variety improvement in bean breeding programs. This pilot-scale dry bean canning and evaluation protocol provides a detailed step-by-step method of canning and quality evaluation for major U.S. dry bean market classes. The post-canning process evaluation includes appearance rating by a trained sensory panel and objective measures of water uptake, color, and texture. In addition, virtual canning quality training and evaluation methods have been implemented for enhanced data quality, flexibility, and engagement in the process.

Novelty impact statement

This detailed, state-of-the-art-method for small-scale dry bean canning and evaluation, with the option for virtual evaluation by panelists is useful for bean breeding programs. An in-depth panelist training video is included via link on how to evaluate canning quality in each of the major market classes.

1 INTRODUCTION

The common bean (Phaseolus vulgaris L.), also known as dry bean, represents a wide range of dry edible bean seed market classes that vary in size, color, and shape. Dry beans are a nutrient dense food, rich in protein, dietary fiber, minerals, and folate (Azarpazhooh & Boye, 2012). Consumption of dry beans is associated with many health benefits, including reduced risk of heart disease, managing blood sugar levels, and preventing certain cancers (Hall et al., 2017). However, consumer utilization of dry beans is limited by the inconvenience of preparation and long cooking times (Doma et al., 2019; Winham et al., 2020). Canned beans are an important form of delivery of fully cooked, shelf-stable, whole beans to consumers. The canning process for beans is largely used to precook, preserve, and in some cases, add flavor to beans (Poti et al., 2015). Through this type of processing, the beans are maintained as whole seed in the same form as the raw agricultural commodity.

1.1 Canned beans: History and relevance to today's consumer

The inventions of steam retort and automated can manufacture promoted the industrialization of canning products in the late nineteenth and early twentieth century (Petrick, 2010). Canned beans were among those early canned foods in the market and became increasingly common as a safe and convenient food product with the development of science and technology (Petrick, 2010). Notably, navy beans have a long history as a canned product, which gained importance and popularity with the advent of a patent for canned pork and beans referred to as baked beans by W.K. Lewis of Boston in 1877 (Bitting, 1937). Canned beans were a popular food to carry on fishing fleets in the U.S. and Great Britain as early as the 1870’s (Bitting, 1937; Stilwell, 1982). The first navy bean breeding program in the U.S. was established in 1907 at the Michigan State College Agricultural Experiment Station and canning quality was a major consideration for varietal development (Andersen et al., 1960; Hedrick et al., 1931).

Cans are highly effective for the delivery of prepared foods. More processed fruit and vegetables are consumed overall than their fresh products in the United States. Canned beans consumption is nearly two times than that of fresh or frozen forms (3.7 vs. 1.9 pounds per capita) (Rickman et al., 2007). Research has indicated canned vegetables are as nutritious as their fresh or frozen products but are lower or comparably priced per edible amount (Miller & Knudson, 2014). Canned products require less preparation time for healthy homemade meals and reduce food waste from unconsumed and spoiled fresh produce (Can Manufacturers Institute, 2021). The canning process also destroys illness-causing microorganisms, which is an important benefit as 48 million Americans suffer from foodborne illnesses each year (CDC, 2020).

Cans are highly sustainable and versatile in food packaging. It is recognized by industry leaders that up to 70 percent of cans are recycled and that more than 30 percent of steel used in cans is derived from recycled material (Williams, 2020). The steel in food cans is 100% recyclable and recycles without loss of strength or quality, while other food containers made of multiple materials can be hard to recycle and/or have significantly lower recycling rates (Can Manufacturers Institute, 2021). In general, canned foods provide convenient, safe, and affordable quality food that is delivered in an environmentally friendly food package. Canned beans have the advantage of saving preparation time while providing nutritious meals.

1.2 Preparation and thermal processing of dry beans

The impact of numerous factors associated with the preparation and thermal processing of dry beans is well documented (Downing, 1996; Siddiq et al., 2010; Uebersax & Hosfield, 1985; Uebersax et al., 1991). Dry beans are hydrated with a soaking/blanching process that is prerequisite for further processing. Individual processors have established proprietary procedures that include dry bean post-harvest storage and handling (Aguilera & Rivera, 1992; Berrios et al., 1999; Paredes- López et al., 1989; Reyes-Moreno et al., 1993; Yousif et al., 2003), soaking time (Moscoso et al., 1984), soak water temperature (Hoff & Nelson, 1965; Kon, 1979; Quast DC & da Silva, 1977), blanching conditions (Drake & Kinman, 1984; Larsen et al., 1988), and water chemistry (e.g., mono and divalent cations such as calcium and sodium concentrations, or measures of total water hardness) (Uebersax & Bedford, 1980; Wiese & Jackson, 1993).

Further, dry beans are classified as a “low acid food” (pH > 4.6) and require a high temperature retort process to assure commercial sterility (USFDA, 2019). Factors that impact the thermal process must be understood and controlled in a standardized procedure. The numerous factors that influence heat penetration (e.g., bean moisture, bean fill weight, bean sauce/brine volume and can size) may be critical control points (USFDA, 2019). Numerous retort systems are designed for uniform heating of cans and may include factors such as continuous or intermittent agitation and controlled can cooling to facilitate the adequacy of the process. The overall process conditions to assure “commercial sterility” (process time and temperature) must be established by a “process authority” to assure sufficient accumulated lethality required for food safety. A food process authority is usually a food or chemical engineer who apply their knowledge and experience to validate the process and the product. It is essential that a qualified process authority be engaged in the establishment of the process conditions.

Many innovations have been developed to improve canned beans in regard to seed handling, chemical additives such as calcium chloride, and retort temperature, time, and type. Nordstrom and Sistrunk (1979) found that beans (including pink, red kidney, navy and pinto) tend to have less splits after soaking when they had initially higher seed moisture content (16% compared with 10%) before processing. Junek et al. (1980) found that kidney and pinto beans soaked in solutions at 25°C had higher quality ratings than those soaked at 15°C and 35°C. Beans are usually blanched after being hydrated during the canning process. The purpose of blanching is to eliminate respiratory gases (i.e., improved uniformity of bean density), reduce the presence of foreign material, improve color, inactivate enzymes, and achieve desirable texture of the products (Cain, 1950; Crafts, 1944; Nordstrom & Sistrunk, 1979). Research has suggested that the establishment of a blanching method should be considered separately according to bean seed type (Davis, 1976). The effects of blanching methods on drained weight, texture, and split rate varied between seed types. Beans not cooled after blanching had higher drained weights than those cooled after blanching (Davis et al., 1980). Calcium chloride is commonly added at various stages of the preparation (soak water, blanch water, or cover brine) to improve firmness of the beans. The pectin-calcium complexes formed during soaking in bean seeds create the firmness (Uebersax & Bedford, 1980), and the firmness increases with the increase of calcium level (Balasubramanian et al., 2000). Uebersax and Bedford (1980) also found that calcium in soak water had a greater effect on the processed bean firmness than calcium in brine. However, consumers today are less interested in additives and prefer a clean label, which is also a reason people choose organic products (Kaptan & Kayısoglu, 2015; Naspetti & Zanoli, 2009). Commercial thermal process delivery systems (e.g., continuous and discontinuous retorts, with and without mechanical agitation, or hydrostatic cookers etc.) provide differential process conditions (temperature and time) that may be optimized to obtain best product quality of distinctive attributes while meeting the industrial sterilization standards to achieve food safety. Uebersax and Hosfield (1985) suggested a retort at 115.6°C for 45 min while Wang et al. (1988) used 121°C for 14 min (navy bean) and 16 min (pinto bean) to achieve the equivalent results.

Selection of a test procedure for screening the processing potential of diverse beans (i.e., cultivars and breeding lines) must consider these preparation and preservation conditions. They must also be designed to transcend the numerous specific proprietary procedures used commercially. Thus, the process must be standardized and sufficiently universal to provide appropriate rigor to be useful for the screening of beans that will withstand the typical canning process. It is frequently noted that dry bean processes exceed requirements for “commercial sterility” and, thus, beans are “cooked in the can” to achieve sufficient tenderization of the seed to yield desired palatable texture and appearance.

1.3 Canned bean quality attributes

Pilot-scale canning and evaluation protocols are essential for the evaluation of bean characteristics that are not readily apparent in the dry seeds. It also allows bean breeders to assess canning quality in their breeding lines and to characterize genetic and environmental variability for canning quality. Canning quality regarding appearance, color, and texture can be defined as how well beans withstand the canning process. After harvest and prior to canning, seeds are cleaned to remove defects that are visible on the dry seeds. The canning process ideally begins with dry seeds that fit market class expectations for seed size, shape, and color. There are 10 major market classes of dry bean produced in the U.S., each with a specific dry seed size, shape, and color. They are dark red kidney, light red kidney, white kidney, cranberry, pinto, small red, pink, great northern, black, and navy. The evaluation of canning quality includes a sensory evaluation for the appearance and objective quality traits measurements. The sensory evaluation requires a group of trained panelists to score the samples with specific standards. The quality traits measurements provide data on hydration of the seeds, and texture and color of the canned samples.

Canning quality remains a key trait in the development of new navy bean varieties and it is also important for other market classes. The black bean cultivar “Zenith” released by Michigan State University was developed specifically for improved canning quality and anthracnose resistance while retaining the other grower preferred agronomic performance traits (Kelly et al., 2015). The recently released light red kidney bean cultivar “Coho,” navy bean cultivar “AAC Shock,” and slow-darkening (SD) pinto beans have all been tested for canning quality as an important quality trait (Balasubramanian et al., 2017; Kelly et al., 2020; Miklas et al., 2020).

The goal of this paper is to provide a detailed pilot-scale bean canning protocol for the major U.S. dry bean market classes (but can be adapted to other classes as well) and a post-canning evaluation and analysis protocol that is suitable for research purposes. This protocol adopted the major steps from the protocol developed by Hosfield and Uebersax (1980) which simulated common industrial canning processes with a small sample size. Modifications have been made according to current research results and experience in the past years and to fit a wider range of bean types. This revised protocol provides greater analytical sensitivity of key quality measures and encompasses a broader range of preparation procedures (soak/blanch time and temperature conditions) that are optimized for different commercial classes of beans based primarily on seed size than that reported by Hosfield and Uebersax (1980). The sensory evaluation has been adapted to video format and is suitable for broad review by interested individuals. This aspect of a virtual “can cutting” style assessment adds considerable flexibility, engagement, and utility to the protocol.

2 MATERIALS AND METHODS

2.1 Equipment and materials

Equipment and materials needed for canning preparation, processing, and post-canning analysis are listed in Table 1.

| Name | Model, size | Manufacturers |

|---|---|---|

| Pre-canning preparation | ||

| Moisture analyzer | DICKEY-John GAC 2500UGMA | DICKEY-john |

| Scale | Ohaus Scout Pro SP−401 | Ohaus |

| Laptop computer and barcode scanner | ||

| Mesh bags and strip tags | MIDCO Global mesh harvest bags (8″×8″, 20.3 cm × 20.3 cm); MIDCO Global heavy-duty side to side strip tag (1/2″ × 7″,1.3 cm × 17.8 cm) | MIDCO |

| Canning process | ||

| Steam kettles | 80 gallons and 40 gallons; Model: DL Accu-Temp | Crown Food Equipment |

| Strainers | 10 × 10″ with 3/16″ perforations | |

| Seamer | Model: 2006 RCM4 Closing Machine | Silgan Containers |

| Retort | Model: Versatort | Allpax |

| Cans | Size: 307 × 407 | Silgan Containers |

| Water/Heat-resistant labels for cans | Laser Cryo-Babies(R), white, L × W:1.0″ × 1.0″ | Diversified Biotech |

| Post-canning analysis | ||

| Scale | ||

| Camera box | A Cannon digital camera remotely controlled by computer software and a stable illumination source in the box | Cannon |

| Texture analyzer | TA.XTPlus | Texture Technologies Corp., USA |

| Colorimeter | Hunter Labscan XE | Hunter Associates Laboratory Inc., USA |

| Paper food tray | Size: 5lb | |

| Others | ||

| Plastic buckets (20gal) for soaking beans; Insulated gloves; Small pitchers to pour brine into cans; Rubber boots to protect feet. | ||

2.2 Procedure

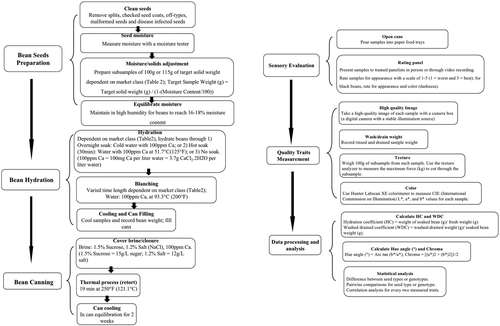

The canning preparation and processing steps and post-canning evaluation procedure are presented in flow chart format (Figure 1) with details explained below. The procedure is also presented as photos in Figure S1.

2.3 Bean seeds preparation

- Start with a 250 g sample of dry beans.

- Clean the dry beans manually to eliminate splits, checked seed coats, off-types, malformed beans and disease-infected beans (Figure S1).

- Measure moisture content of seeds with a moisture analyzer.

- Prepare subsamples of 100 or 115 g of target solid weight (moisture free basis) depending on market class (Table 2) based on the measured moisture content. The formula to calculate the target sample weight is: Target Sample Weight (g) = Target solid weight (g)/(1−(Moisture Content/100)). Record actual sample weight (within ± 0.5 g of target sample weight) of each subsample.

- Place the subsamples in mesh bags. Close bag with drawstring and attach a yellow tag with assigned bag number and corresponding barcode.

- Place labeled bags in a moist environment such as cooler at high humidity to equilibrate moisture so that the moisture content of the seeds reaches to about 16%–18% at canning.

| Market class | Blanchc | Fill Weight(g) |

|---|---|---|

| Overnight soaka | ||

| Dark red kidney | 5 min | 100 |

| Light red kidney | 5 min | 100 |

| Cranberry | 5 min | 100 |

| Pinto | 5 min | 100 |

| Hot soakb | ||

| Navy | 5 min | 115 |

| Great Northern | 15 min | 115 |

| Small red | 15 min | 115 |

| Pink | 15 min | 115 |

| White kidney | 15 min | 100 |

| Yellow | 15 min | 100 |

| No soak | ||

| Black | 90 s | 115 |

- a Overnight soak: 12 hr in cold tap water with 100 ppm calcium added.

- b Hot soak: 30 min at 51.7°C (125°F) in tap water with 100 ppm calcium added.

- c Blanch is at 93.3°C (200°F) in tap water with 100 ppm calcium added.

2.4 Soaking and canning process

- Group samples by market class. Place 25 mesh bags in a larger mesh bag to ensure sufficient soaking for the samples.

- Fill one large plastic bucket for each large bag of samples with tap water containing 100 ppm added calcium in the form of CaCl2. “Overnight soak” (ambient temperature) kidney (except white kidney), cranberry, and pinto beans for 12 hr. Ideally, beans segregated by color classes for soaking.

- Set up tables with cans placed upside down. Place labels on each can in numerical order.

- On the day of canning, prepare soaking water (with 100 ppm calcium) for the samples that need hot soak at 125°F (51.7°C) (Table 2). Two kettles may be needed to separate the colors. Start soaking and take samples out from kettle after 30 min.

- Change the water for blanching (as described in Figure 1a) and increase the temperature to 200°F (93.3°C). Blanch the lighter colored beans first and followed by beans with darker color for the time length described in Table 2. Submerge each large mesh bag in the blanching water and start the timer.

- Place bags on table to cool down. Remove small mesh bags from larger bags. Measure the soaked weight for samples if needed.

- Match each small mesh bag to pre-numbered can. Transfer contents of bag into can, fold bag, place on top of the can to keep sample moist (and allow for double checking sample number if needed).

- Prepare brine water with 1.5% sucrose, 1.2% salt (NaCl), 100 ppm calcium (CaCl2). Heat brine to 200°F (93.3°C). Once all cans are filled with beans, collect bags. Fill one can to within ~¼ inch of top with gently boiling brine. About one gallon (3.79 L) of brine is needed for every 10 cans.

- Closure of cans through automatic seamer, followed by inversion of cans (code label up) and stacking into basket for retort.

- Retort process the cans for 19 min at 250°F (121.1°C) with a 180° inversion of the cans during the cooling cycle (a single retort holds 522 cans). Store cans for at least 2 weeks at room temperature before opening them for evaluation. (Note: the time of the retort process was determined specifically to the can size (nominal size 407 × 307; dimensions 4–7/16” [112.7 mm] height by 3–7/16” [87.3 mm] diameter) and based on can internal temperature for food safety.)

2.5 Post-canning evaluation

2.5.1 Appearance and color evaluation

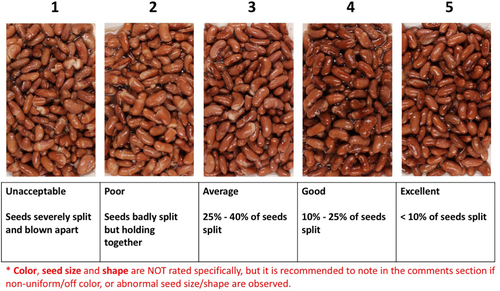

Rating of canned bean appearance and color is conducted by a group of trained panelists. The panelists are trained via a training video that describes the dry bean market classes, rating scales, and attributes (Supplementary video files). A canning quality exercise video provides further instructions on rating (Supplementary video files). The samples are rated by at least 10 panelists on a scale of 1 to 5 (Figure 2). Canning quality evaluation by trained panelists may be conducted in-person or through live/prerecorded videos whereby the trained panelists evaluate the samples by watching a video recording of samples (Figure S2). The use of video to conduct evaluations is a recent addition to the method and offers multiple benefits over in-person evaluations including that each sample is presented under consistent lightning conditions and the video can be sent out to a broader group of participants.

In person

- Open cans and pour the content of each sample into labeled paper food trays (Figure 1b; Figure S2).

- A group of trained panelists (at least 10 people) rate each sample with a scale of 1–5 (1 = worst and 5 = best) as described in Figure 2.

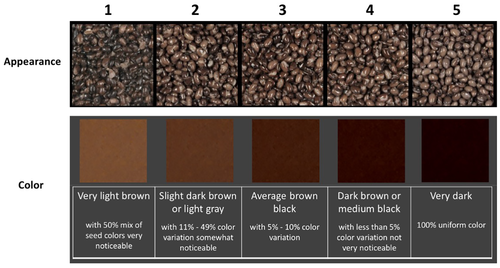

- Evaluate black beans for appearance and color (darkness) according to Figure 3.

Video recording

- Open can and pour the content into a sieve to drain out the brine. Pour each sample into its labeled paper food tray.

- Record video for each sample using the “camera box” (Mendoza et al., 2017).

- Trained panelists watch the recorded video and rate the samples with the evaluation scales (Figures 2 and 3).

2.5.2 Canning quality-related traits measurement

Digital high-quality image

- Drain and rinse the beans with tap water after sensory evaluation.

- Take a high-quality image of each sample with the camera box.

- Images can be used for further analysis such as automatic bean split detection with computer program (Long et al., 2019).

Water uptake

- Measure the washed drained weight for each sample.

- Calculate hydration coefficient (HC) as HC = weight of soaked bean (g)/ fresh weight (g) of beans (the recorded sample weight at preparation). This ratio indicates the weight increase of beans after soaking relative to the initial fresh weight.

- Calculate washed-drained coefficient (WDC) as WDC = washed-drained weight (g)/ soaked bean weight (g). WDC indicates the water uptake of the beans during the canning process.

Texture

- Weigh 100 g of subsample for each sample.

- Use the texture analyzer (Texture Technologies Corp., USA) with the Kramer shear cell (which simulates single bite on foodstuffs) attached to measure the maximum force (kg) to cut through the subsample. This measurement is an indicator of firmness and softness of the beans.

Color

- Use Hunter Labscan XE colorimeter to measure CIE (International Commission on Illumination) L*, a*, and b* values for each sample. L* measures the lightness or darkness on a scale of 0 (pure black) to 100 (pure white). a* measures the redness or greenness of a sample where positive values are more red and negative values are more green. b* measures the yellowness or blueness of a sample where positive values are more yellow and negative values are more blue.

- Calculate Hue angle (°) as Arc tan (b*/a*). Each market class of thermally processed beans has a specific range of Hue angle (Table 3).

- Calculate chroma as Chroma = [(a*)2 + (b*)2]1/2. The higher the chroma, the brighter the color.

| Market class | Hue angle range |

|---|---|

| Dark red kidney | 10° to 25° |

| Light red kidney | 35° to 50° |

| Small red | 35° to 45° |

| Pink | 40° to 50° |

| Cranberry | 50° to 60° |

| Pinto | 50° to 60° |

| Navy | 70° to 80° |

| Great Northern | 70° to 80° |

| White kidney | 70° to 85° |

| Black | 20° to 40° |

- a Hue angle is calculated with the a* and b* values from colorimeter measurements, which converts the surface color values of an object to an expression of human perception for the primary colors (table adapted from Bean Processing http://arsftfbean.uprm.edu/bic/wp-content/uploads/2018/04/Bean_Processing.pdf).

2.6 Statistical analysis

Post-canning evaluation data can be analyzed using linear mixed model with seed type as fixed variable, and genotype and panelist (for sensory evaluation data only) as random effect variable to detect the difference between seed types. Use simple linear model with genotype as fixed variable to detect the variation among genotypes for canning quality measurements. Use linear mixed model with genotype as fixed variables and panelist as a random effect variable for sensory data.

Use Tukey's Honestly Significant Difference (Tukey's HSD) post-hoc test to run pairwise comparisons for seed type or genotype. Use Pearson's correlation analysis to detect the correlation between measured traits.

3 RESULTS AND DISCUSSION

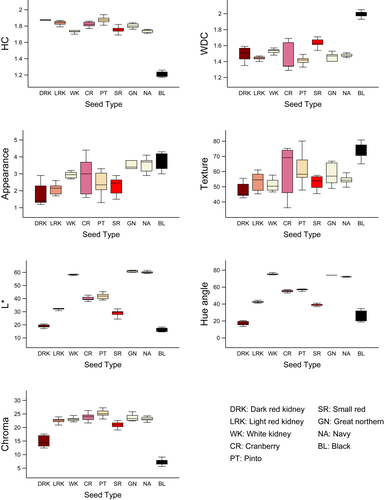

A total of 28 bean varieties from nine of the 10 major U.S. dry bean market classes (dark red kidney, light red kidney, white kidney, cranberry, pinto, small red, great northern, navy and black) were canned using the pilot-scale canning method. These varieties were obtained from dry bean farms in Michigan from 2020 growing season. The canning quality-related traits measurement and sensory evaluation results of the 28 canned varieties are given in Table 4. The difference of each trait among the tested seed types is shown in Figure 4.

| Market class | Variety | HC1 | WDC2 | Appearance3 | Texture (kg) | Hue angle (°) | Chroma | L* |

|---|---|---|---|---|---|---|---|---|

| Dark red kidney | Dynasty | 1.87a5 | 1.40a | 2.4b | 52.3b | 19.7b | 17.1b | 19.3a |

| Talon | 1.88a | 1.55b | 1.3a | 44.2a | 15.2a | 13.3a | 18.6a | |

| Light red kidney | California Early | 1.84a | 1.49b | 1.8a | 46.4a | 41.9a | 23.5a | 32.0a |

| Coho | 1.84a | 1.41a | 2.2b | 59.6c | 44.4b | 21.9a | 33.7a | |

| Rosie | 1.84a | 1.45ab | 2.3b | 54.0b | 41.9a | 22.3a | 31.5a | |

| White kidney | Beluga | 1.73a | 1.54a | 3.1b | 52.4a | 75.8a | 23.0a | 58.2a |

| ND Whitetail | 1.74a | 1.52a | 2.8a | 49.9a | 75.2a | 23.1a | 58.3a | |

| Cranberry | Bellagio | 1.85a | 1.32a | 4.0c | 71.2b | 56.8b | 24.9a | 40.0a |

| Chianti | 1.80a | 1.34a | 3.0b | 72.9b | 53.9a | 24.4a | 38.8a | |

| Etna | 1.80a | 1.66b | 1.7a | 41.5a | 55.3ab | 22.3a | 41.5a | |

| Pinto | Charro | 1.87a | 1.38a | 2.9bc | 67.4 cd | 57.3b | 25.7ab | 43.2a |

| LaPaz | 1.85a | 1.43ab | 2.1ab | 59.0bc | 57.2b | 24.7ab | 41.5a | |

| ND Falcon | 1.92a | 1.49b | 1.7a | 49.3a | 57.4b | 24.1a | 41.3a | |

| ND Palomino | 1.90a | 1.37a | 3.1c | 56.9ab | 60.2c | 25.8ab | 43.5a | |

| Windbreaker | 1.83a | 1.42ab | 2.4ab | 75.9d | 54.7a | 26.5b | 39.4a | |

| Small red | Caldera | 1.75a | 1.59a | 2.7b | 57.0c | 37.2a | 19.5a | 25.8a |

| Ruby | 1.76a | 1.68a | 2.1ab | 45.8a | 39.8ab | 21.5b | 30.2b | |

| Viper | 1.72a | 1.67a | 1.7a | 54.0b | 40.2b | 20.8b | 30.7b | |

| Cayenne | 1.78a | 1.60a | 2.7b | 54.3b | 39.2b | 22.1c | 28.8b | |

| Great Northern | ND Pegasus | 1.78a | 1.51b | 3.4a | 50.7a | 74.0a | 23.0a | 60.8a |

| Powderhorn | 1.82a | 1.40a | 3.6a | 66.3c | 74.7a | 25.2a | 60.5a | |

| Aries | 1.81a | 1.47ab | 3.5a | 57.2b | 73.7a | 22.9a | 61.1a | |

| Navy | Merlin | 1.72a | 1.48a | 3.1a | 53.0a | 72.0a | 23.9a | 59.9a |

| Nautica | 1.74a | 1.48a | 3.8b | 53.7a | 72.5a | 22.8a | 60.8a | |

| Medalist | 1.75a | 1.47a | 3.8b | 57.8a | 72.0a | 22.7a | 59.4a |

| Market class | Variety | HC | WDC | Appearance (Color4) | Texture(kg) | Hue angles | Chroma | L* |

|---|---|---|---|---|---|---|---|---|

| Black | Eclipse | 1.25c | 1.93a | 3.3a (3.0a) | 78.8b | 33.6c | 8.4b | 17.8b |

| Zenith | 1.18a | 2.03a | 4.2b (4.5b) | 68.5a | 19.3a | 6.1a | 14.6a | |

| Zorro | 1.21b | 2.02a | 3.4a (3.2a) | 71.3a | 24.6b | 7.3b | 17.3b | |

| Average CV(%) | 1.18 | 1.84 | 8.25 (6.74) | 4.10 | 1.91 | 3.52 | 2.85 |

- 1 HC: Hydration Coefficient = Soak Weight/ Dry Solid Weight.

- 2 WDC: Washed Drained Coefficient = Drained Weight/ Soak Weight.

- 3 Appearance rating scale: 1–5 (5 = Excellent).

- 4 Color score is for black beans only, with rating scale1-5 (5 = Very dark).

- 5 Different letters indicate statistically significant difference within each seed type, p = .05.

Hydration coefficient (HC) measures the water-uptake during soaking. The HC values for black beans were much lower than other types since the black beans were not soaked but only had a 90 s blanch. The HC values of other types of beans varied from 1.72 to 1.92, which means the beans took up about 1.8 times of water of their dry seed weight. There was no significant difference of HC among varieties, with the exception of black beans. Washed drained coefficient (WDC), which measures weight gain during canning process, can vary between and within seed types with the tested varieties. The average WDC value was about 2 for black beans which indicates that black beans gained 2 times of its blanched seed weight in the can. The WDC values varied from 1.32 to 1.68 for other seed types. A correlation between HC and WDC was identified with R2 = −0.9, which means the seeds that take up more water during soaking will take up less water in the cooking process in the cans.

The appearance score reflects the overall appearance and bean splits of each genotype in the sensory evaluation as described in Figure 2. Scores ranged from 1.3 to 4.2 in the tested varieties. A score of 3 is usually considered acceptable. Texture, which measures the firmness of the canned beans, reflects the effort required to chew the beans and the mouthfeel (Mendoza et al., 2018). The texture values of these lines can be significantly different within seed type or between seed types. The black bean samples were the firmest and dark red kidney samples were the least firm among the varieties. Cranberry bean samples had highest variability for texture (Figure 4). A significant correlation between appearance and texture was also identified (R2 = 0.5) among all samples, which indicates that the samples with higher appearance score tend to be firmer in texture.

Hue angles, chroma, and L* values are seed coat color indicators of the varieties. Hue angle converts the surface color values of an object on the a* and b* scales to an expression of human perception for the primary colors. The hue angles of the tested varieties are within the range of the expected values (Table 3). Beans with darker seed coat color (dark red kidney and black beans) have lower chroma and L* values than the other seed types (Table 4), which indicates less intensity and lightness of the seed color. In black beans, color scores are negatively correlated with chroma and L* values (R2 = −0.78 and −0.98 respectively). Panelist color ratings for black beans have also correlated with measured L* values in previous studies (Bornowski et al., 2020; Cichy et al., 2014). Detailed sensory studies of color associated with the complexities of Hunter lab coordinates across all commercial bean classes are limited. However, direct associations of white bean color measured on the L lightness scale and degree of discernment were reported by Uebersax and Hosfield (1979), and that white beans that differ in one unit in L* value were visually distinguishable using a standard triangle difference test procedure (Wassimi et al., 1982).

In general, variations were seen in most of the tested dry bean market classes (seed types) for WDC, appearance, and texture. Genetic variability could be identified using this canning protocol which is important for the selection of germplasm with improved canning quality.

In this study, a commercial retort was used for thermal processing of the cans; however, an alternative procedure for manually sealed Ball glass jars and a stove top pressure cooker to assess dry bean processing quality has been discussed by Uebersax et al. (2012) for those without access to a retort.

4 CONCLUSION

Canning quality is a quantitatively inherited trait, and the assessment of canning quality combines a series of sensory and physical measurements. It is known that the quality of canned bean products can be affected by seed type, storage time, and condition, and processing method (Davis, 1976; Junek et al., 1980; Nordstrom & Sistrunk, 1979), while environmental factors and genotype × environment interactions can also have significant effects (Khanal et al., 2014; Miklas et al., 2020).

Although canning quality evaluation is challenging, a standardized and reliable canning protocol can help researchers to get consistent results and assist breeders to make selections for ideal bean varieties. The protocol presented in this paper inherited the major steps developed by Hosfield and Uebersax (1980) with adjusted soaking and blanching conditions, and the solid fill weight per can specified for different seed types. The thermal process (retort) condition was adjusted to 19 min at 121.1°C. This updated canning processing protocol enables detection of variation among bean varieties for their water up-take ability, appearance, texture, and color. The modified soak and blanch method specified for each seed type has minimized the effects from the canning process on the quality of canned beans, so that their genetic variations can be reliably studied. The shortened retort time at a higher temperature makes the process more efficient and improves the general texture and appearance of the canned products.

This small-scale canning protocol is useful for breeding; however, there are still limitations and opportunities for improvement. It is noted that a relatively large sample size (100-115g solid weight, depending on seed type) is needed for each genotype to fill the standard can using this protocol. Only a single retort time and temperature is implemented for all cans regardless of seed type in this protocol. Research by Durance (1997) indicated that loss of food quality during heat sterilization can happen and the time/heat required for sterilization is usually more than needed for inactivation of deteriorative enzymes or modification of texture and flavor. Bassett et al. (2020) also found that canning quality of fast-cooking yellow beans was improved by reducing retort processing time. However, it is challenging to set varied retort time and temperature based on seed type due to that a single retort holds 522 cans and our goal is to maximize efficiency with fewer retort runs. The canning and evaluation process is reserved for advanced breeding lines for which 250 g of seed is available. Earlier generations are not well suited for this analysis due to lack of seed and the likelihood that there is still residual heterozygosity (~12.5% in an F4 generation) that may influence the seed characteristics related to canning quality.

It can be challenging to work with trained panel in sensory evaluation since people's perception varies and can be affected by multiple factors (Ares, 2015). A standard training video for every participant in the sensory evaluation can minimize the variation caused by human error. An increased panel size is also useful for more precise sensory results. The virtual evaluation method can potentially involve trained panelists from anywhere in the world over an asynchronous schedule.

Adjustments continue to be made to this protocol from year to year according to experience and canning results. The objective has been to optimize the canning procedure so that it can best fulfill the specific needs for canning quality research.

ACKNOWLEDGMENTS

Our acknowledgement goes to MSU Food Processing and Innovation Center (FPIC), Jason Hoffman, and Kirk Dolan for providing canning facilities and assistance in the canning process. Thank you to Scott Bales (MSU Dry Bean Specialist) for providing identity preserved samples of specified varieties.

CONFLICT OF INTEREST

The authors declare that they have no conflict of interest.

AUTHOR CONTRIBUTIONS

Weijia Wang: Conceptualization; Formal analysis; Investigation; Methodology; Visualization; Writing—original draft. Evan Wright: Provided soaking and blanching methods for specific seed types and assisted in the canning process. Mark Uebersax: Conceptualization; Methodology; Writing—review & editing. Karen Cichy: Conceptualization; Data curation; Funding acquisition; Methodology; Project administration; Resources; Supervision; Writing—review & editing.

PERMISSION TO REPRODUCE MATERIAL FROM OTHER SOURCES

Permission to reproduce Figure 3, which originally appeared in Mendoza et al., 2017, has been granted.

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available within the article and its supplementary materials. Raw data are available from the corresponding author on request.