Fabrication of a Highly Sensitive Stretchable Strain Sensor Utilizing a Microfibrous Membrane and a Cracking Structure on Conducting Polymer

Abstract

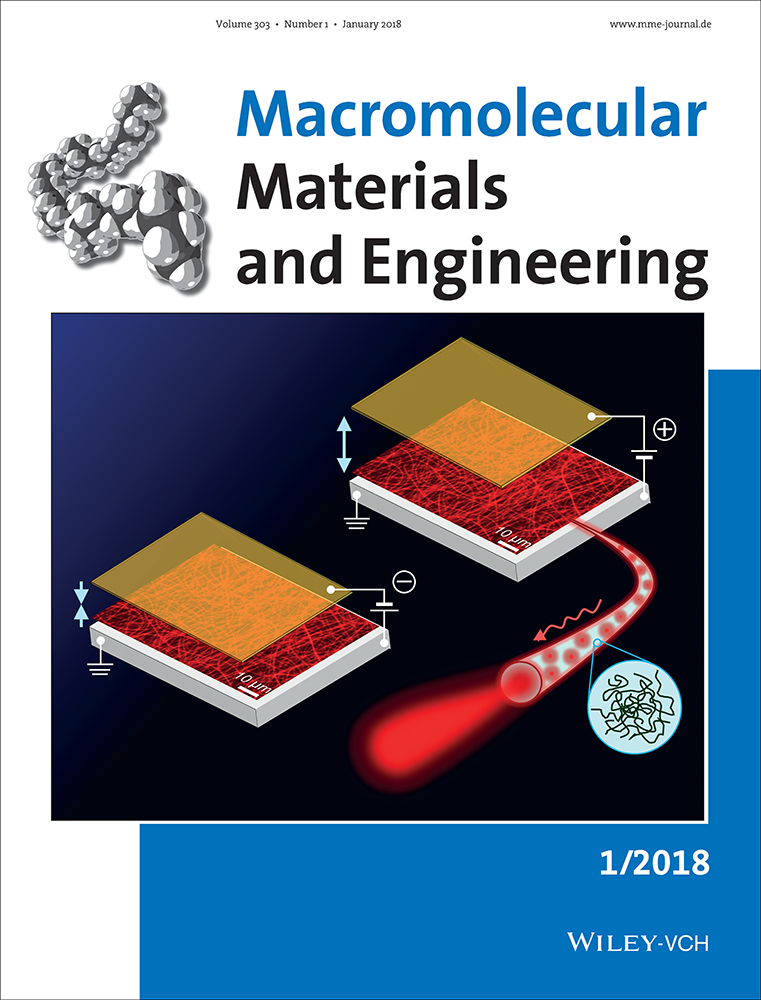

Recently, the detection of human motion has attracted considerable attention for the development of smart healthcare systems. Flexible or stretchable strain sensors are required to measure deformations on arbitrarily shaped human skin areas caused by human motion, and numerous studies have explored the development of such sensors. Here, a highly sensitive stretchable strain sensor is introduced, which consists of elastic fibrous membrane coated with conducting polymer. The membrane can be utilized to detect applied strain by measuring the conductance change caused by the change in the nanocracking structure on the coated conducting polymer layer. Furthermore, by collecting aligned microfibers as the fibrous membrane during electrospinning process, the sensor exhibits higher sensitivity (more than 40-fold higher than the nonaligned version). Although limitations still remain in the repeatability and the applicability of the sensor, the developed sensor will demonstrate great potential for measuring applied strain and stress over a wide sensing range with high sensitivity is expected.

Conflict of Interest

The authors declare no conflict of interest.