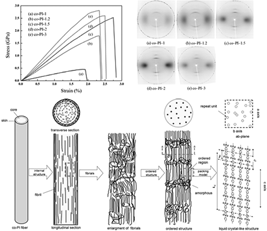

Preparation of High Performance Copolyimide Fibers via Increasing Draw Ratios

Mengying Zhang

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorHongqing Niu

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorZhiwei Lin

College of Polymer Science and Polymer Engineering, The University of Akron, Akron, Ohio, 44325-3909 USA

Search for more papers by this authorShengli Qi

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorJingjing Chang

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorQiyan Ge

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorCorresponding Author

Dezhen Wu

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorMengying Zhang

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorHongqing Niu

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorZhiwei Lin

College of Polymer Science and Polymer Engineering, The University of Akron, Akron, Ohio, 44325-3909 USA

Search for more papers by this authorShengli Qi

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorJingjing Chang

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorQiyan Ge

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorCorresponding Author

Dezhen Wu

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing, 100029 China

Search for more papers by this authorAbstract

High performance fibers based on copolyimide (co-PI) containing benzimidazole and ether moieties were prepared via a two-step wet spinning method. The effects of draw ratio on the structures and properties of the fibers are investigated. The mechanical properties of the co-PI fibers are improved greatly by increasing draw ratio at temperatures above 400 °C, reaching the optimum tensile strength of 2.8 GPa and modulus of 136 GPa, which is due to the development of the molecular orientation along the fiber direction. The hot drawing process roughens the fiber surface and stretches the molecules in the fibers. Moreover, the fiber structure evolutions during the drawing process were also discussed and a “smectic A liquid crystal-like” model was proposed.

References

- 1 W. H. Li, Z. Q. Wu, H. Jiang, M. Eashoo, F. W. Harris, S. Z. D. Cheng, J. Mater. Sci. 1996, 31, 4423.

- 2 Z. X. Jiang, L. Geng, Y. D. Huang, Appl. Surf. Sci. 2011, 257, 3455.

- 3 I. Sasaki, H. Itatani, M. Kashima, H. Yoshimoto, S. Yamamoto, Y. Sasaki, US Patent 4247443 1981.

- 4 H. Makino, Y. Kusuki, T. Harada, H. Shimazaki, US Patent 4460526 1981.

- 5 M. M. Koton, F. S. Florinsky, S. Y. Frenkel, L. N. Korzhavin, T. P. Pushikina, N. R. Prokopchuk, Br Patent 2025311 1980.

- 6 K. L. Mittal, Polyimides: synthesis, characterization and applications, Plenum, New York 1984.

- 7 M. Hasegawa, K. Horie, Prog. Polym. Sci. 2001, 26, 259.

- 8 E. Mazoniene, J. Bendoraitiene, L. Peciulyte, S. Diliunas, A. Zemaitaitis, Prog. Solid State Chem. 2006, 34, 201.

- 9 A. A. M. Ali, Z. Ahmad, J. Mater. Sci. 2007, 42, 8363.

- 10 I. K. Varma, R. N. Goel, D. S. Varma, Macromol. Mater. Eng. 2003, 1, 101.

- 11 Q. H. Zhang, M. Dai, M. X. Ding, D. J. Chen, L. X. Gao, J. Appl. Polym. Sci. 2004, 93, 669.

- 12 C. Neuber, H. W. Schmidt, R. Giesa, Macromol. Mater. Eng. 2006, 11, 1315.

- 13 M. Eashoo, Z. Wu, A. Zhang, D. Shen, C. Tse, F. W. Harris, S. Z. D. Cheng, K. H. Gardner, B. S. Hsiao, Macromol. Chem. Phys. 1994, 195, 2207.

- 14 T. Kaneda, T. Katsura, K. Nakagawa, H. Makino, M. Horio, J. Appl. Polym. Sci. 1986, 32, 3151.

- 15 S. Z. D. Cheng, Z. Wu, M. Eashoo, S. L. C. Hsu, F. W. Harris, Polymer 1991, 32, 1803.

- 16 M. Eashoo, D. Shen, Z. Wu, C. J. Lee, F. W. Harris, S. Z. D. Cheng, Polymer 1993, 34, 3209.

- 17 J. Dong, C. Q. Yin, Z. X. Zhang, X. Y. Wang, H. B. Li, Q. H. Zhang, Macromol. Mater. Eng. 2014, 10, 1170.

- 18 W. M. Edwards, I. M. Robinso, US Patent 3179614 1955.

- 19 S. K. Park, R. J. Farris, Polymer 2001, 42, 10087.

- 20 X. Y. Liu, W. Xu, G. D. Ye, Y. Gu, Polym. Eng. Sci. 2005, 46, 123.

- 21 J. W. E. Dorogy, A. K. S. Clair, J. Appl. Polym. Sci. 1991, 43, 501.

- 22 J. W. E. Dorogy, A. K. S. Clair, J. Appl. Polym. Sci. 1993, 49, 501.

- 23 G. Q. Gao, L. Dong, X. Y. Liu, G. D. Ye, Y. Gu, Polym. Eng. Sci. 2008, 10, 912.

- 24 X. Y. Liu, G. Q. Gao, L. Dong, G. D. Ye, Y. Gu, Polym. Adv. Technol. 2009, 20, 362.

- 25 H. Q. Niu, S. L. Qi, E. L. Han, G. F. Tian, X. D. Wang, D. Z. Wu, Mater. Lett. 2012, 89, 63.

- 26 H. Q. Niu, M. J. Huang, S. L. Qi, E. L. Han, G. F. Tian, X. D. Wang, D. Z. Wu, Polymer 2013, 54, 1700.

- 27 Y. H. Kim, F. W. Harris, S. Z. D. Cheng, Thermochim. Acta 1996, 283, 411.

- 28 S. Z. D. Cheng, F. W. Harris, Polyimide fibers, Aromatic, in International Encyclopedia of Polymer Composites, VCH Publishers, New York 1996, 6, p. 293.

- 29 J. Dong, C. Q. Yin, W. Q. Luo, Q. H. Zhang, J. Mater. Sci. 2013, 48, 7594.

- 30 J. F. E. Arnold, K. R. Bruno, D. X. Shen, M. Eashoo, C. J. Lee, F. W. Harris, S. Z. D. Cheng, Polym. Eng. Sci. 1993, 33, 1373.

- 31 S. Yoshida, A. S. Hay, Macromolecules 1997, 30, 5979.

- 32 J. Dong, C. Q. Yin, J. Y. Lin, D. B. Zhang, Q. H. Zhang, RSC Adv. 2014, 4, 44666.

- 33 J. J. Chang, H. Q. Niu, M. Y. Zhang, Q. Y. Ge, Y. Li, D. Z. Wu, J. Mater. Sci. 2015, 50, 4104.

- 34 R. Pardey, S. S. Wu, J. Chen, F. W. Harris, S. Z. D. Cheng, A. Keller, J. Aducci, J. V. Facinelli, R. W. Lenz, Macromolecules 1994, 27, 5794.

- 35 T. M. Wu, S. Chvalun, J. Blackwell, S. Z. D. Cheng, Z. Wu, F. W. Harris, Polymer 1995, 36, 2123.

- 36 K. Takizawa, H. Fukudome, Y. Kozaki, S. Ando, Macromolecules 2014, 47, 3951.

- 37 N. Takahashi, D. Y. Yoon, P. Parrish, Macromolecules 1984, 17, 2583.

- 38 K. Wakabayashi, T. Uchida, S. Yamazaki, K. Kimmura, K. Shimamura, Macromolecules 2007, 40, 239.

- 39 Y. B. Zhuang, X. Y. Liu, Y. Gu, Polym. Chem. 2012, 3, 1517.

- 40 T. Takekoshi, Polyimides-Fundamentals and Applications, Marcel Dekker, New York 1996.

- 41 T. M. Birshtein, V. A. Zubkov, I. S. Milevskaya, V. E. Eskin, I. A. Baranovskaya, M. M. Koton, V. V. Kudryavtzev, V. P. Skizkova, Eur. Polym. J. 1977, 13, 375.

- 42 M. I. Bessonov, V. A. Zubkov, Polyamic acids and Polyimides: Synthesis, Transformations, and Structure, CRC Press, Boca Raton, LA 1993.

- 43 Q. H. Zhang, M. Dai, M. X. Ding, D. J. Chen, L. X. Gao, Eur. Polym. J. 2004, 40, 2487.

- 44 M. Eashoo, L. J. Buckley, A. K. S. Clair, J. Polym. Sci: Part B: Polym. Phys. 1997, 35, 173.

- 45 T. E. Sukhanova, Y. G. Baklagina, V. V. Kudryavtsev, T. A. Maricheva, F. Lednicky, Polymer 1999, 40, 6265.