Journal list menu

Export Citations

Download PDFs

Cover Picture

Issue Information

Contents

Review

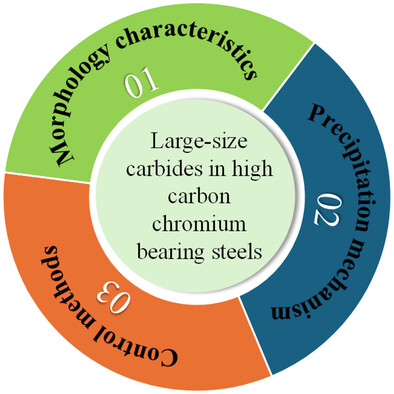

Research Status of Large-Size Carbides in High-Carbon Chromium Bearing Steel

- First Published: 05 November 2024

This article reviews the current status of research on large-size carbides in high carbon chromium bearing steels. Firstly, the morphological characteristics of three kinds of large-size carbides in steel are described. Secondly, the precipitation mechanisms of these three carbides are summarized. Finally, the common methods for regulating large-size carbides in steel are summarized.

Research Article

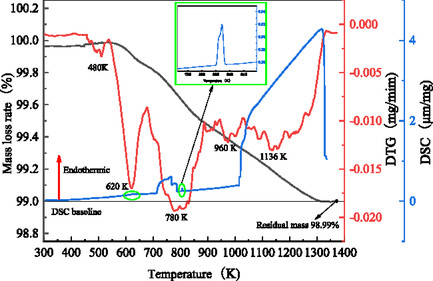

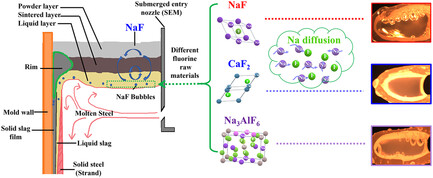

Kinetic Study of NaF Gas Formation During Mold Flux Melting Based on Different Fluorides by Experimental and Computational Methods

- First Published: 22 October 2024

Low-basicity fluorine-containing mold flux with NaF pores slag film is expected to solve the contradiction between heat transfer and lubrication during the continuous casting of peritectic steel. Studying the kinetic mechanism of NaF gas formation based on the NaF, CaF2, and Na3AlF6 raw materials, the results show NaF material produces the most NaF gas with the lowest activation energy.

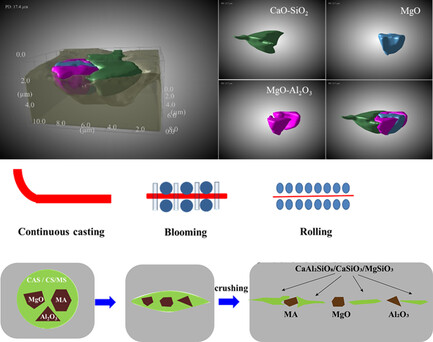

Characterization and 3D Reconstruction of the Crushing Behavior of SiO2–CaO–Al2O3–MgO Complex Inclusions in Spring Steel with High Basicity Slag Treatment

- First Published: 23 October 2024

Effect of Partition Temperature on Microstructure and Mechanical Properties of Cold-Rolled Medium-Manganese Steel

- First Published: 15 October 2024

In this article, a two-step Q&P process is carried out for cold-rolled medium-manganese steel (MMnS) (Fe–7.69Mn–2.76Al–0.12C wt%) to analyze the effect of composition temperature on the structure and mechanical properties of cold-rolled MMnS. In the results, it is shown that the stability of austenite is significantly affected by different partitioning temperatures. The density of face centered cubic phase error decreases obviously with the increase of partition temperature. The influence factors of austenite stability and the effect of martensitic transformation type on the deformation process are studied.

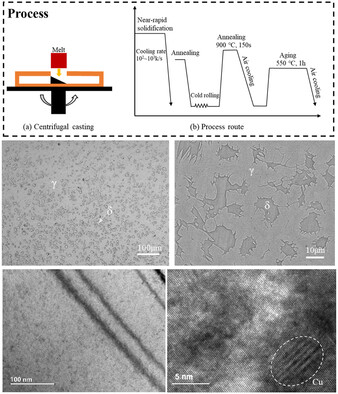

Microstructure and Precipitation of a Cu–Ni Alloyed Medium-Mn Duplex Low-Density Steel Prepared by Near-Rapid Solidification

- First Published: 15 October 2024

Cu and Ni elements are alloyed to an Fe–9Mn–5.5Al–0.3C low-density steel, prepared by near-rapid solidification. In the results, it is shown that nanoscale precipitates and Cu enrichment are found in the microstructure of near-rapid solidification. The precipitation strengthening and twinning strengthening contribute comparably to the strength of the alloy.

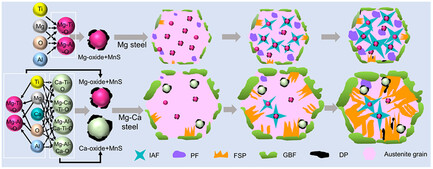

Effect of Ca Addition on Inclusions, Microstructures, and Impact Toughness of Coarse-Grained Heat-Affected Zone After High-Heat Input Welding in Mg-Deoxidized Shipbuilding Steel Plates

- First Published: 31 October 2024

The effect of Ca addition on the evolution of inclusions, microstructures, and impact toughness of the coarse-grained heat-affected zone in the Mg-deoxidized shipbuilding steel plates after high-heat input welding of 400 kJ cm−1 is investigated. Ca addition reduces the number of effective inclusions inducing the intragranular acicular ferrites formation, resulting in a deterioration of low-temperature impact toughness.

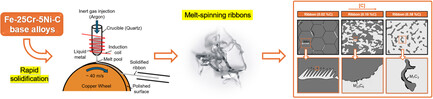

The Role of Carbon Content on the Microstructure of Rapidly Solidified Fe–Cr–Ni Duplex Steels

- First Published: 24 October 2024

In this study, the effect of carbon content on the microstructure of three Fe–Cr–Ni duplex steels produced by rapid solidification is evaluated. In this research, using scanning electron microscopy and transmission electron microscopy for microstructural analyses, it is revealed that carbon additions change the microstructure formation from primary ferrite to primary austenite and promote the formation of M23C6 and M7C3 carbides.

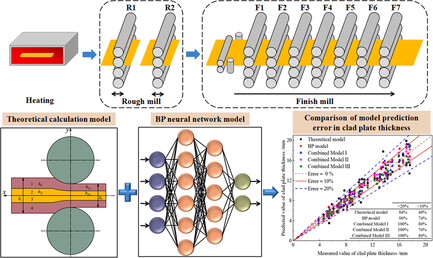

Rolled Thickness Prediction for Titanium/Steel-Clad Plates Based on Combined Method of Theoretical and Neural Network

- First Published: 21 October 2024

To address the issue of low precision in rolled thickness prediction for titanium/steel-clad plates, theoretical calculation and back propagation neural network prediction models are established, respectively. In addition, three combined prediction models are built by making use of each model's advantages. By comparing the relative errors, it is shown that the Combined Model III performs better and predicts more accurately.

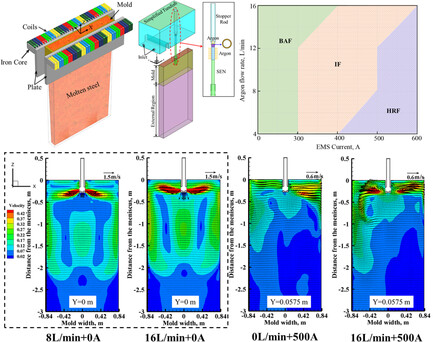

Analysis of Flow Pattern and Bubble Behavior in Slab Continuous Casting with Mold Electromagnetic Stirring

- First Published: 14 October 2024

The flow pattern and bubble characteristics in a slab mold under argon blowing and electromagnetic stirring (EMS) are investigated using mathematical model. The flow regime within the mold shifts from bubble ascent flow to intermediate flow to horizonal recirculation flow as EMS current increases. For obtaining rational horizonal recirculation flow, it should balance the argon flow rate and EMS current.

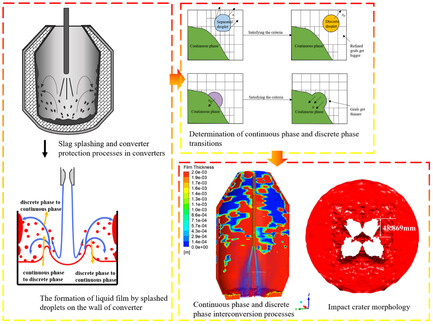

Numerical Study on Droplet Splashing Behavior of Slag-Splashing for Converter Protection Using Volume of Fluid-Discrete Phase Model Two-Way Conversion Model

- First Published: 28 October 2024

A 3D two-phase flow model coupling volume of fluid-discrete phase model bi-directional conversion method is developed to investigate droplet behavior during slag splashing, including tracking droplet trajectories and analyzing splash rates, locations, and size distribution. The model accounts for slag-droplet interactions from top oxygen blowing, leading to the identification of an optimal flow rate of 8.80 Nm3 h−1 and oxygen lance height of 233.2 mm.

Hydrogen Embrittlement of a Prerolled High-Mn Steel with Different Cut-Edge Characteristics

- First Published: 17 October 2024

Hydrogen embrittlement behavior of a prerolled Fe–15Mn–0.65C–2Al–2Si high-Mn steel with five cutting methods is investigated via hydrogen precharging and slow strain rate test. Corresponding fracture surfaces are linked to the cut-edge properties and microstructures at cutting-affected zones. The laser-cut specimens show the highest tensile ductility while the blanked specimens show the lowest tensile elongation. Previous findings imply that mechanical twinning plays a critical role in transgranular cleavage features.

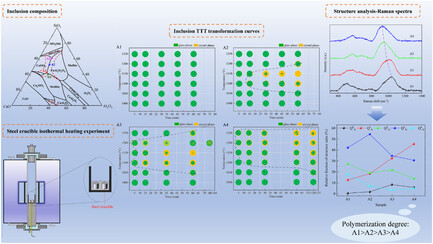

Crystallization Behavior and Structure of CaO–SiO2–Al2O3 Melts Representing the Oxide Inclusions in Si-Mn Deoxidized Steel

- First Published: 21 October 2024

From the perspective of crystallization behavior of inclusions, the eutectic region of tridymite, pseudowollastonite, and anorthite in the ternary phase diagram is the target area of CaO–SiO2–Al2O3 inclusion's composition control in Si-Mn deoxidized steel. The temperature and the holding time during the hot rolling process need to be reasonably selected to avoid serious crystallization of glassy inclusions.

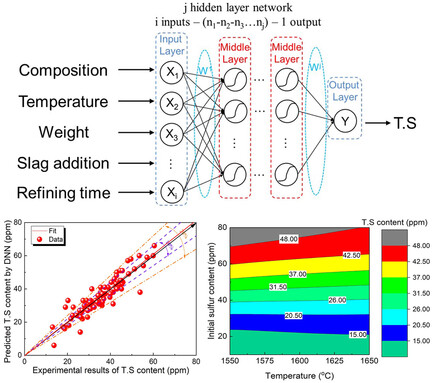

Prediction of Sulfur Content during Steel Refining Process Based on Machine Learning Methods

- First Published: 31 October 2024

The neural network technology combining genetic algorithm is utilized to predict the sulfur content and optimize the desulfurization operation during the refining process. Three types of prediction models are developed to achieve the optimal model. The optimal amount of slag addition with various initial sulfur contents is also calculated.

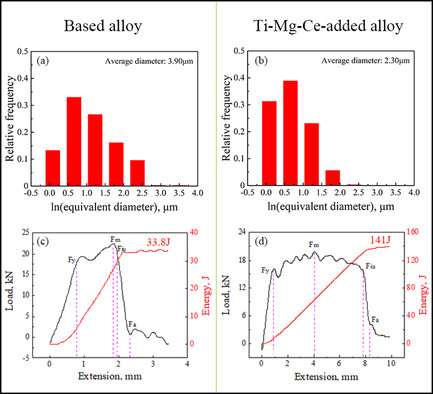

Effect of Ti–Mg–Ce Complex Deoxidation on the Inclusions and Mechanical Properties of S355 Steel

- First Published: 22 October 2024

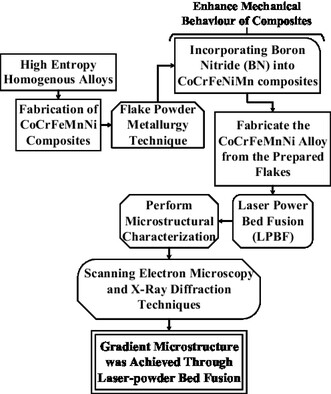

Investigating the Effects of Boron Nitride on Mechanical Properties of CoCrFeNiMn Composites

- First Published: 28 October 2024

The CoCrFeMnNi high-entropy alloy powder, produced through gas atomization, is introduced into a graphite die measuring 40 mm in diameter. Spark plasma sintering (SPS) is engrossed at a vacuum pressure of 0.001 Pa on HP D 25/3 SPS apparatus. These laser parameters commonly encompass factors such as scanning speed, layer thickness, and laser power, which play pivotal roles in shaping the final product's quality and properties.

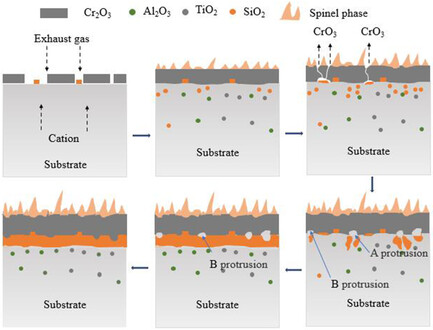

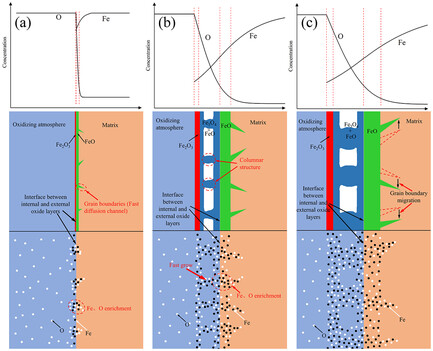

High-Temperature Oxidation Response of 444 Ferritic Stainless Steel in a Synthetic Automotive Exhaust Gas

- First Published: 31 October 2024

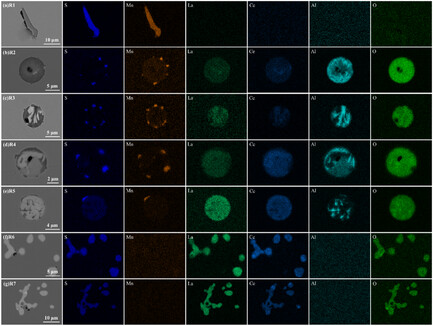

The Effect of La, Ce Rare-Earth Elements on the MnS Inclusion Precipitation and Distribution in U75V Heavy-Rail Steel

- First Published: 31 October 2024

The effects of rare-earth (RE) inclusions on MnS precipitation and distribution characteristics during the solidification process are clarified through experimental methods and thermodynamic predictions, additionally, the synergistic relationship between the RE inclusions and MnS inclusions is verified with the aid of crystallography, which serves as a reference for related research on RE inclusions.

Functionally Gradient H13 Tool Steel/Oxygen-Free High Thermal Conductivity Cu Composites Manufactured by Laser-Directed Energy Deposition

- First Published: 24 October 2024

The feasibility of printing a high density, functionally gradient material (H13 tool steel–Cu) onto a wrought H13 substrate using laser-directed energy deposition, with proprietary back reflection laser technology, is investigated through varying the laser power and powder feed rates. Fundamental assessment of the compatibility of these materials is performed through differential scanning calorimetry and both optical and electron microscopy.

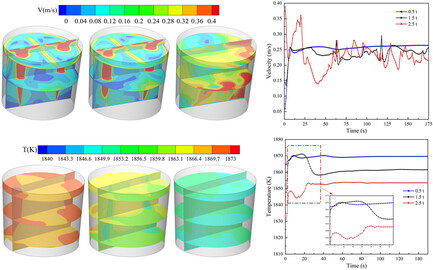

Flow, Heat-Transfer, and Mixing Behaviors of Scrap Steel in a Refining Ladle with Bottom Blowing

- First Published: 31 October 2024

The flow, heat-transfer, and mixing behaviors of steel scraps with different amounts, positions, and sizes added from the top of the bottom-blown 300 t ladle are numerically investigated and compared through a coupled model. In this research, theoretical guidance can be provided for the addition of scrap in refining ladle during practical production processes.

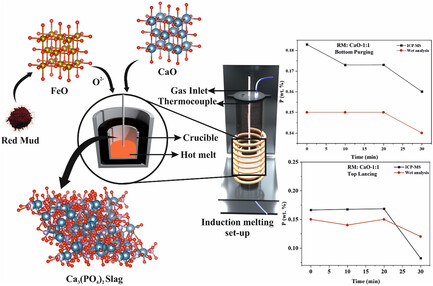

Applicability of Waste from Al Industry toward Dephosphorization of Hot Metal in Primary Steel Making

- First Published: 21 October 2024

The performance of low-grade (P2O5 containing) red mud-based flux in the dephosphorization of hot metal with high Si content has been evaluated with the aid of thermodynamic calculations and metal–slag equilibrium experiments in induction furnace. A substantial dephosphorization of 40% has been observed with red mud as a flux in hot metal dephosphorization processes.

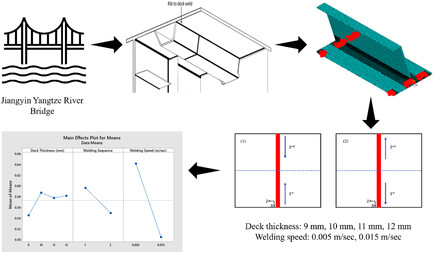

Multi-Response Optimization of an Orthotropic Steel Deck Section with Thermo-Mechanical Tensioning

- First Published: 26 October 2024

In this study, orthotropic steel deck sections are optimized using Taguchi's grey relational analysis and finite-element analysis. Herein, the effects of deck thickness, welding sequence, and speed on structural performance are examined. In these findings, the critical role of welding speed, with optimal conditions identified for improved stress management and deflection control, is highlighted.

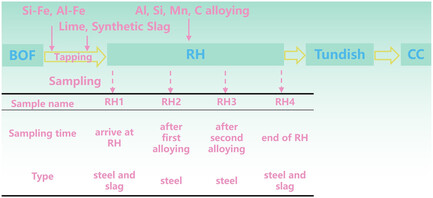

Effect of Refining Slag Composition on the Cleanliness of Oriented Silicon Steel

- First Published: 26 October 2024

To improve the cleanliness of oriented silicon steel, industrial experiments are performed under different refining slag composition conditions. The results show that the use of medium-basicity refining slag (w(CaO)/w(SiO2) = 2.3–2.6, w(CaO)/w(Al2O3) = 2.3–2.6) result in higher steel cleanliness with lower Al2O3 volume fraction, and smaller inclusions.

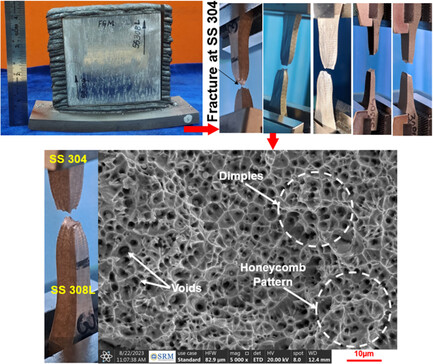

Microstructure and Mechanical Properties of Bimetallic Structure Fabricated through Wire Plus Arc Additive Manufacturing

- First Published: 22 October 2024

The scope of this research is to provide relationship between mechanical properties and microstructural characterization of bimetallic structure (BMS) fabricated through wire plus additive manufacturing. BMS shows better mechanical properties than wrought alloy, moreover, microstructural changes promote its use in industries requiring high-performance materials.

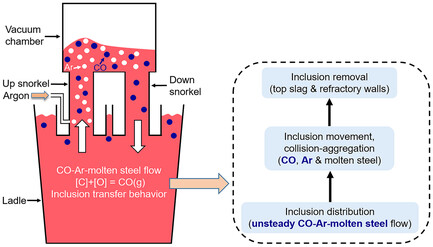

Inclusion Transfer Phenomenon under Unsteady Multiphase Flow during Rheinstahl–Heraeus Vacuum Treatment Process

- First Published: 28 October 2024

The inclusion transfer phenomenon under unsteady CO–Ar–molten steel flow in Rheinstahl–Heraeus (RH) is investigated in this article. The inclusion convection velocity is determined by CO/argon bubble slip velocity, inclusion slip velocity, and molten steel velocity. CO bubble plays a key role in the inclusion transfer behavior, which prompts the inclusion transport, the collision-aggregation and the removal process in RH.

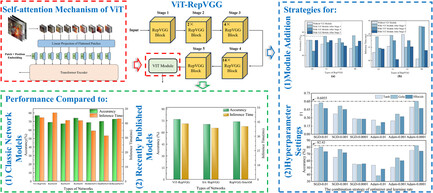

Surface Defect Identification of Strip Steel Using ViT-RepVGG

- First Published: 31 October 2024

The study presents an automated deep learning approach for surface defect identification using an improved RepVGG model (ViT-RepVGG), incorporating the self-attention mechanism of ViT. Various strategies for module addition and hyperparameter settings are explored, with performance compared to classic network models and recently published models, highlighting the model's effectiveness in complex industrial environments.

Decomposition Behavior of Limestone Powder in Converter Flue Gas: Effect of Fe-Oxide Dust on Calcium Ferrite Formation

- First Published: 25 October 2024

To improve the utilization level and energy conversion efficiency of converter flue gas, a novel technology is proposed for the online production of dephosphorization agent by utilizing the waste heat of converter flue gas. The results provide a theoretical basis for the production of slagging and dephosphorization agents, thereby achieving energy conservation and CO2 reduction in steel industries.

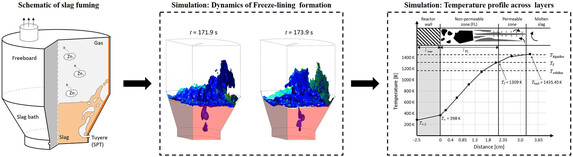

Modeling Freeze-Lining Formation: A Case Study in the Slag Fuming Process

- First Published: 27 October 2024

A novel computational-fluid-dynamics-based model is proposed to simulate freeze-lining (FL) formation in a slag fuming furnace, coupling multiphase fluid dynamics with slag solidification. The model captures FL formation in both the slag bath and freeboard due to slag splashing. Herein, good agreement with industrial data is demonstrated, providing valuable insights into the fuming process dynamics and heat transfer.

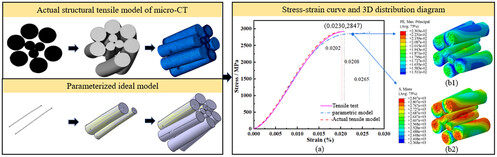

Mesoscopic Tensile Deformation of Steel Cord with Diverse Layered Nonuniformity Based on Microcomputed Tomography Optimizing Simulation Model

- First Published: 13 November 2024

This study presents a new method for nondestructive modeling of cord characteristics using microcomputed tomography (micro-CT). By analyzing stress–strain behavior and layered nonuniformity, the actual tensile model proves more accurate than parametric models. The findings highlight micro-CT's potential for optimizing steel cord models and predicting tensile properties, with significant industrial implications.

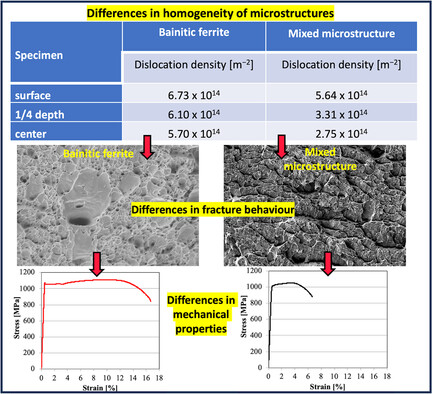

Comparison of Novel 1 GPa Low-Carbon, Low-Alloyed Steel Produced with Simulated and Laboratory-Scale Thermomechanical Controlled Processes

- First Published: 05 November 2024

A laboratory-scale hot-rolled Ti–Mo–V–Nb steel with 1 GPa tensile strength is produced, and its microstructure and tensile properties are characterized using advanced analysis techniques and tensile testing. A Gleeble 3800 thermomechanical simulator is used to determine a process window. Results show significant differences in mechanical properties and fracture behavior due to the microstructural differences in different plate locations.

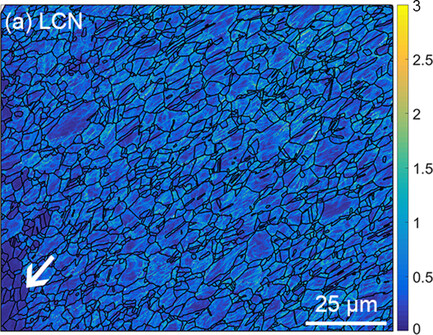

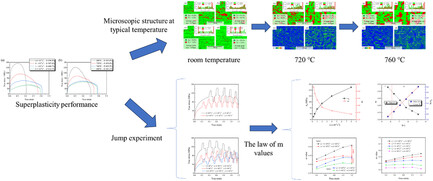

Strain Rate Sensitivity of Low-Temperature Superplastic Heterogeneous Medium-Mn Steel Fabricated by a Novel High-Ratio Differential Speed Rolling

- First Published: 05 November 2024

In this article, insights into the high-temperature deformation behavior of medium-Mn steel, which is prepared via high-ratio differential speed rolling, are provided. The microstructure of samples at typical deformation temperatures is studied using electron backscatter diffraction characterization. Moreover, through innovative bidirectional jump experiments, variations in the strain rate sensitivity index m under various conditions are obtained.

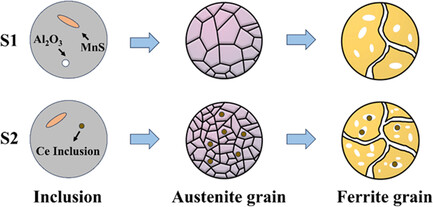

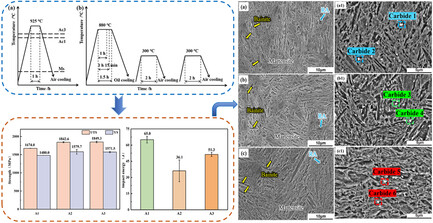

Optimization of Inclusion and Microstructure of As-Cast Nonquenched and Tempered Steel F38MnVS with Trace Ce

- First Published: 31 October 2024

Effects of Different Austenitizing Times on the Microstructure and Properties of Cr-Ni-Mo-V Series High-Strength Steels

- First Published: 31 October 2024

By controlling the austenitizing time, the microstructure of the subsequent heat treatment is improved, thereby improving the overall mechanical properties. Moreover, the austenitizing time can change the microstructure structure and the distribution of carbides, so that the material reduces the crack expansion area, effectively prevents crack expansion, and enhances the mechanical properties of the material.

Early Stages of High-Temperature Oxidation Behavior and Its Phase Evolution of 9% Ni Steel

- First Published: 05 November 2024

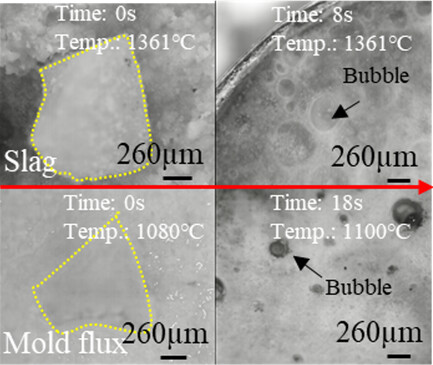

Investigation of the Dissolution Behavior of AlN in CaO–Al2O3–MgO Refining Slag and CaO–Al2O3–F–Li2O–BaO Mold Flux

- First Published: 02 November 2024

This study initially uses confocal scanning laser microscopy to observe the dissolution characteristics of AlN in situ in slag/flux. Subsequently, scanning electron microscopy with energy-dispersive X-ray spectroscopy, X-ray diffraction, and X-ray fluorescence analyses are conducted to examine the impact of AlN dissolution slag/flux. For slag, AlN undergoes self-decomposition at 1361 °C, releasing N2(g). For mold flux, AlN dissolution involves self-decomposition and reaction with Li2O at 1080 °C, releasing N2(g) and Li(g).

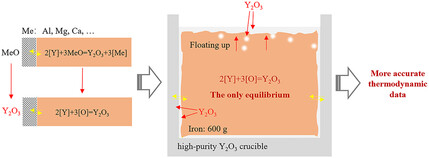

Assessment of Equilibrium between Yttrium and Oxygen in Liquid Iron

- First Published: 05 November 2024

This work assesses thermodynamic data for the yttrium–oxygen equilibrium in liquid iron through high-temperature experiments by utilizing high-purity Y2O3 crucibles as the smelting container. More reliable equilibrium constants and first-order interaction coefficients are obtained by suppressing the reactions between yttrium and the crucible and ensuring favorable kinetic conditions.

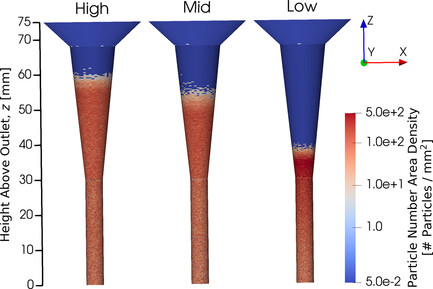

Modeling the Impact of Varying Levels of Inclusion Adhesion on Deposition in a Pilot-Scale Nozzle

- First Published: 15 November 2024

Inclusion deposition is the dominant mechanism in nozzle clogging of submerged entry nozzles. Previous modeling attempts of inclusion deposition have assumed that any contact between the inclusion and nozzle wall results in adhesion. In this work, an Eulerian-Lagrangian simulation with a stochastic adhesion model is used to study the effects of different inclusion-wall sticking probabilities on inclusion deposition.

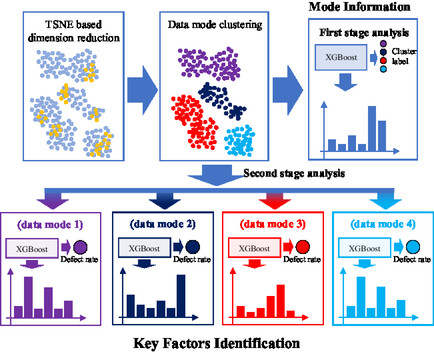

XAIP: An eXplainable AI-Based Pipeline for Identifying Key Factors of Surface Defects in Strip Steel

- First Published: 05 November 2024

This article proposes an eXplainable AI-based Pipeline for identifying key factors of surface defects in strip steel, which is achieved by combining data mode clustering and local model construction. The final identification results are presented by a two-stage explainable method to reveal the information of data modes and key variables and provide specific defect-related information.

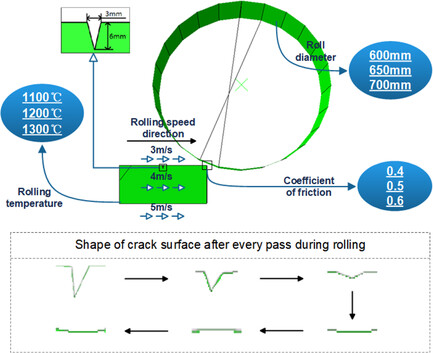

Effect of Rolling Process Parameters on Transverse Cracks on the Surface of Q345 Steel

- First Published: 03 November 2024

This article investigates the evolution of surface transverse cracks in Q345 steel during the hot-rolling process. A slab rolling model is established based on the onsite rolling process parameters to analyze the effects of different rolling processes on the morphology and aspect ratio of surface cracks. The study summarizes the evolutionary behavior of surface transverse cracks under various rolling process parameters.

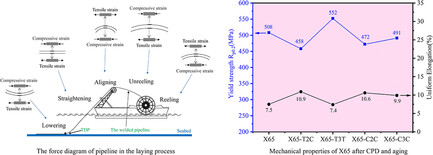

Microstructural Evolution and Mechanical Properties of Reeled X65 Pipeline Steel during Cyclic Plastic Deformation and Natural Aging

- First Published: 05 November 2024

Microstructural evolution and mechanical properties of X65 seamless pipeline are investigated in the actual processes of reel-laying technology, including reel-laying installation, the lowering process, and natural aging. Little research has been conducted on a comprehensive understanding of the actual processes. The experimental results show that X65 steel is the ideal pipeline for the reel-laying technology.

Desulfurization Behavior of Magnetite Pellets Reduced by Isothermal Pure Hydrogen

- First Published: 31 October 2024

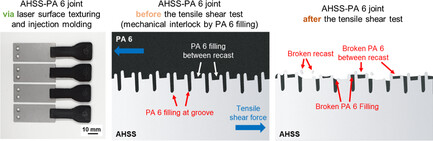

Investigation of Laser Surface Texturing and Injection Molding Parameters in Advanced High-Strength Steel-Polyamide Direct Joining

- First Published: 12 November 2024

The dissimilar materials joining of advanced high-strength steel (AHSS) and glass fiber-reinforced polyamide 6 (PA 6) is achieved via laser surface texturing and injection molding. The PA 6 filling at the laser-textured AHSS creates mechanical interlocks, and the maximum joint strength is measured at 72.3 MPa.

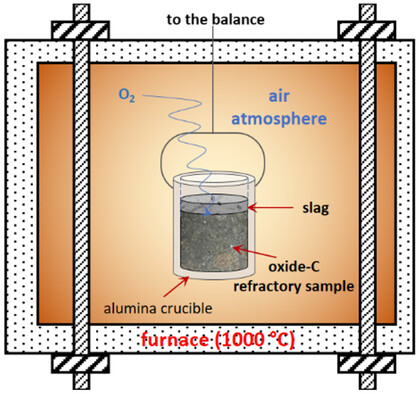

A Novel Methodology to Quantify the Slag Protective Effect on the Oxidation Behavior of Oxide-C Refractories

- First Published: 05 November 2024

This study introduces a novel methodology for evaluating and quantifying the protective effect that adhered slag can have on the oxidation of the refractory lining of steelmaking ladles. The article details the ad-hoc methodology itself, including the technique for adhering the slag to the refractory sample and the specifically developed equipment.