Journal list menu

Export Citations

Download PDFs

Cover Picture

Cover Picture: steel research int. 7/2019

- First Published: 02 July 2019

Cover Photo:

The precipitation mechanism of primary carbides in H13 steel is investigated. Rich-Ti-V carbide precipitates first at the last-to-solidify region because of the microsegragetion of alloying elements, and then acts as the nucleation core of rich-V carbide. There is a huge difference between 2D observation and 3D observation of primary carbides. Further details can be found in the article 1900035 by Guoguang Cheng and co-workers.

Masthead

Contents

Full Papers

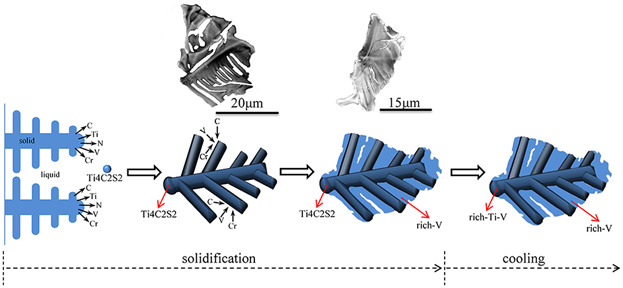

Precipitation Behavior of Large Primary Carbides in Cast H13 Steel

- First Published: 28 March 2019

The precipitation mechanism of primary carbides in H13 steel is investigated. Rich-Ti-V carbide precipitates first at the last-to-solidify region because of the microsegragetion of alloying elements, and then acts as the nucleation core of rich-V carbide. There is a huge difference between 2D observation and 3D observation of primary carbides.

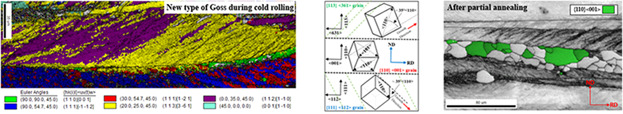

The Origins of the Goss Orientation in Non-Oriented Electrical Steel and the Evolution of the Goss Texture during Thermomechanical Processing

- First Published: 25 March 2019

The Goss texture in non-oriented electrical steel exists with varying volume fractions during different thermomechanical stages. Three types of the Goss orientation occur during cold rolling. The first two types occur in the shear bands and micro bands of the {111}<112> deformed orientation, while the third type occurs at the grain boundary between the {111}<112> and {113}<361> orientations.

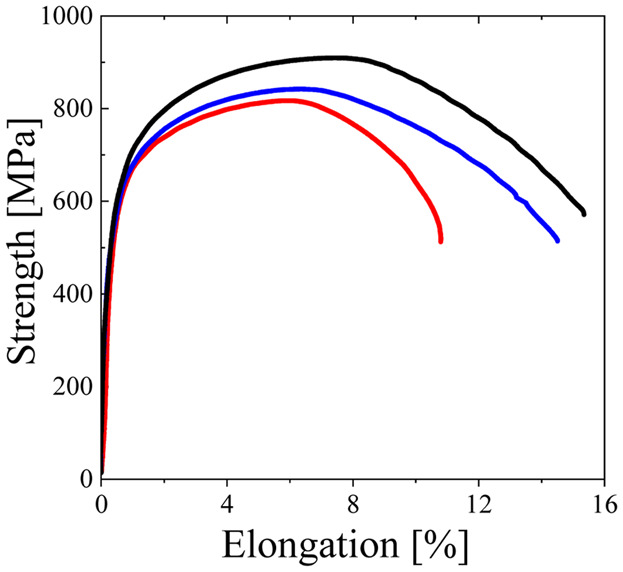

Influence of Austenite Conditioning on the Mechanical Properties of a Microalloyed Bainitic Steel

- First Published: 29 March 2019

The influence of the austenite conditioning on the mechanical properties of a microalloyed bainitic steel is investigated. The mechanical properties strength and toughness are influenced by different phenomes introduced due the deformation process. Especially, the microstructural characteristics, precipitations in the nm scale and the carbon partitioning result in various properties.

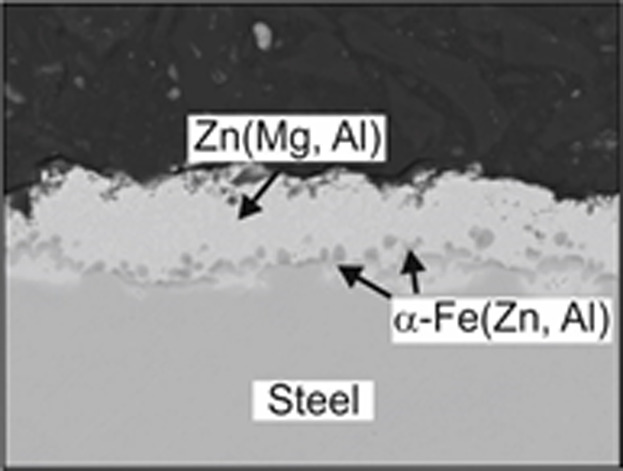

Phase Formation during Heat Treatment of Zn- and ZnAlMg-Coated Steels at 400 and 750 °C

- First Published: 25 March 2019

The paper presents the phase formation in Zn- and ZnAlMg-coated steel sheets after heat treatment at 400 and 750 °C for different dwell times. Phase formation is investigated by X-ray spectroscopy and galvanostatic stripping measurements. Depending on temperature and dwell time different intermetallic Zn–Fe phases are formed in the coating.

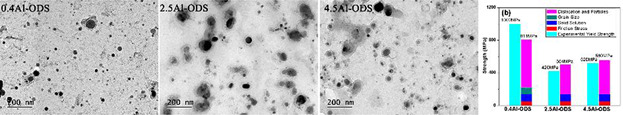

Microstructure Characterization and Mechanical Properties of Al Alloyed 9Cr ODS Steels with Different Al Contents

- First Published: 16 April 2019

The 0.4Al-ODS steel shows ferrite/martensitic duplex steel microstructure, and 2.5Al-ODS and 4.5Al-ODS steels are ferrite single-phase steels. The composition of dispersed particles in all ODS steels is mainly Y–Al–O and the Y/Al ratio of most particles is less than 1. The calculation of theoretical hardening models fit well with experimental data of yield strength for 2.5Al-ODS and 4.5Al-ODS steels if the gain boundary strengthening is not considered.

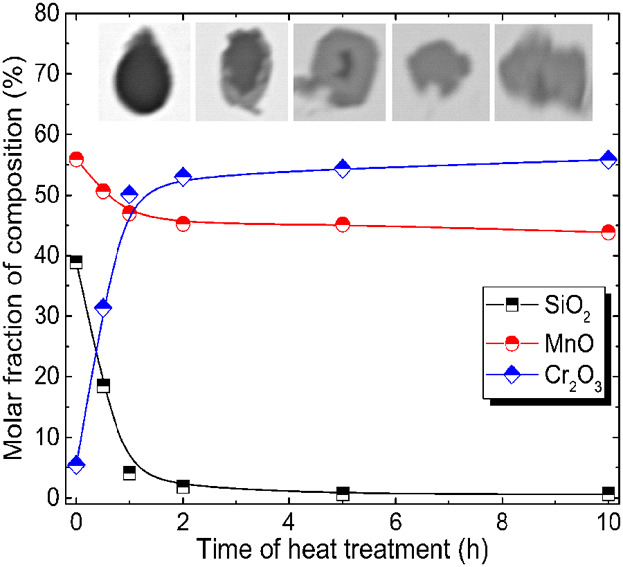

Thermodynamic and Kinetic Analysis for Transformation of Oxide Inclusions in Solid 304 Stainless Steels

- First Published: 27 February 2019

Inclusions in 304 stainless steels are transformed form manganese silicate to manganese chromite upon heat treatment at rolling insulation temperature (1235 °C). The transformation is a diffusion-control process, and shows strong effects of heating time. The mass transfer coefficients of oxides in inclusions are calculated through the change of concentration with time.

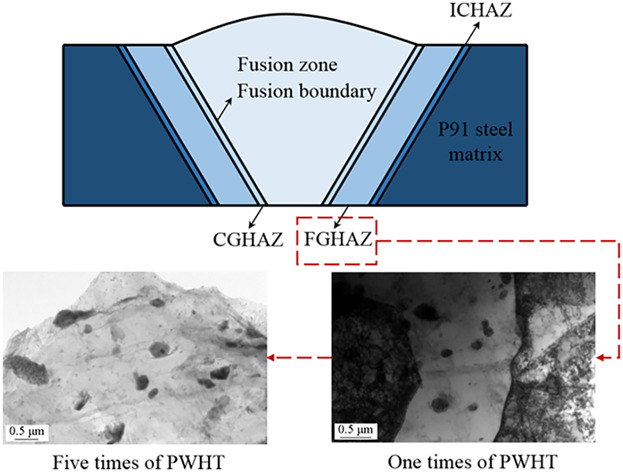

Effects of Multiple Post Weld Heat Treatments on Microstructure and Precipitate of Fine Grained Heat Affected Zone of P91 Weld

- First Published: 27 February 2019

The repair of weld defects in P91 weld usually needs multiple mending welding procedures, therefore, multiple post weld heat treatments (PWHTs) are required. This work reveals that the multiple PWHTs cause the recovery of martensite matrix and the coarsening of M23C6 carbide. These changes in fine grained heat affected zone (FGHAZ) are undesirable in terms of the creep resistance.

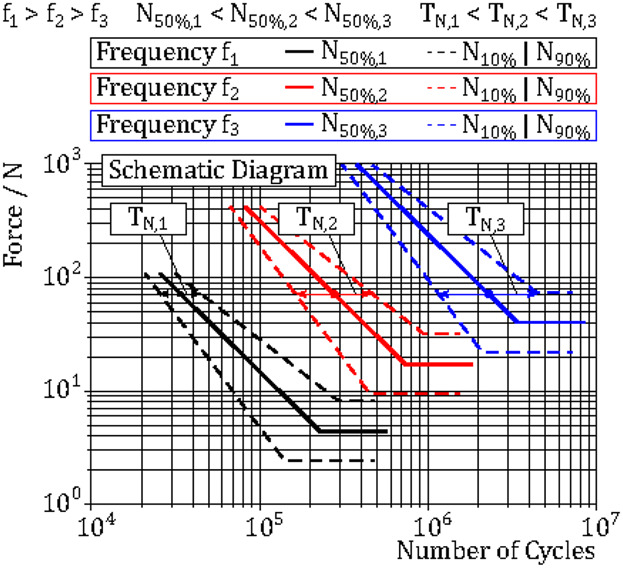

Frequency Dependent Fatigue Strength Investigations on Tempered Steel and Nodular Cast Iron

- First Published: 09 April 2019

The most important finding from the present investigations is the frequency-dependent material behavior of quenched and tempered steel and nodular cast iron. Two significant properties are identified. First, the higher the load frequency f, the lower the sustainable load cycles N50% and, secondly, the higher the frequency f the lower the scatter TN. These two facts lead to a shift of the Wöhler curve in the Wöhler diagram.

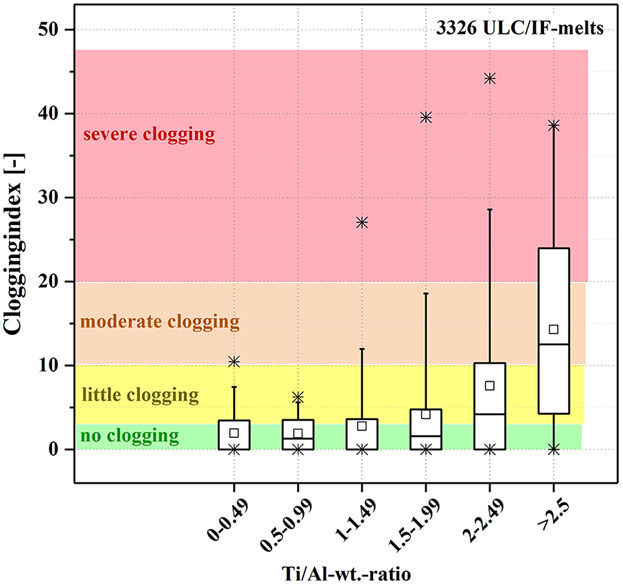

Study on the Influence of FeTi-Addition on the Inclusion Population in Ti-Stabilized ULC Steels and Its Consequences for SEN-Clogging

- First Published: 28 February 2019

Titanium is commonly used as a stabilizer for IF steel grades. The FeTi-addition is known to cause clogging problems in the continuous casting process, which is also shown in a statistical evaluation of the clogging tendency of 3326 melts. Examinations of samples from RH-processing and laboratory scale-experiments indicate that FeTi-addition leads to the formation of small inclusions which are prone to clogging.

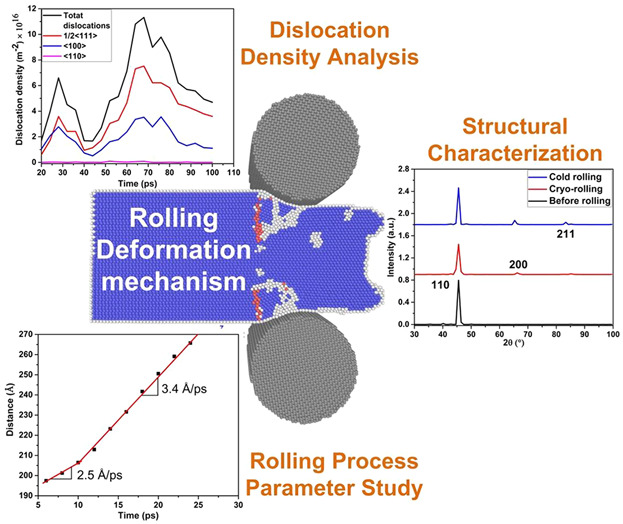

Dynamic Probing of Structural Evolution of Single Crystal Fe during Rolling Process Using Atomistic Simulation

- First Published: 20 March 2019

The authors perform molecular dynamics simulations of nanoscale cryo-rolling process for SC Fe and reported the atomistic mechanism of the deformation behavior. They also carried out virtual diffraction to characterize the structural transformations in the specimens. Results show the formation of new grains in {001}<100> and {011}<011> oriented specimens. Phase transformation from BCC-to-FCC phase is reported in {001}<100> oriented specimen.

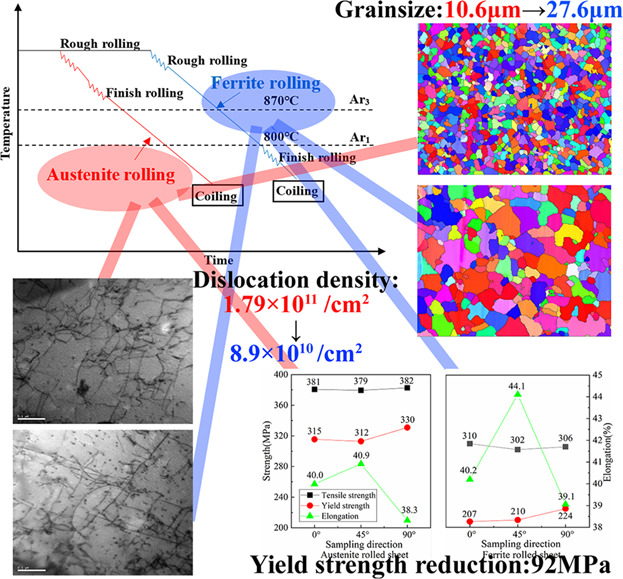

Microstructures and Mechanical Properties of Low Carbon Steel Hot Rolled in Ferrite Region Based on CSP Line

- First Published: 02 April 2019

Comparing ferrite rolled sheet with austenite rolled sheet, the average ferrite grain size of low carbon steel sheet rolled in ferrite region increases and the dislocation density is slightly reduced. The coarsening of grains contributes to the 70% reduction of yield strength of ferrite rolled sheet, and the reduction of dislocation density and other strengthening factors accounts for about 30%.

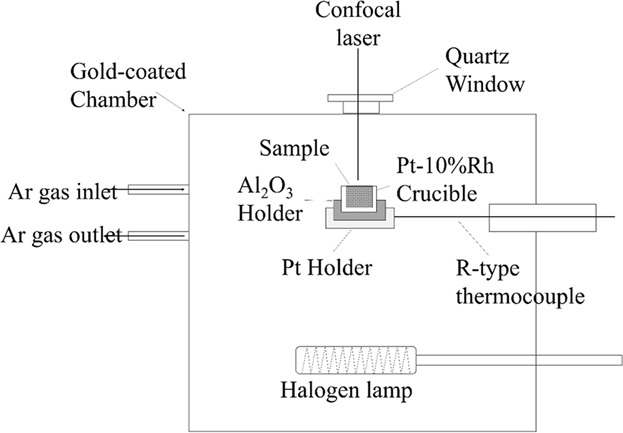

Investigation of the Effects of Al2O3 Content and Cooling Rate on Crystallization in Fe2O3–CaO–Al2O3 System Using In Situ Confocal Laser Scanning Microscopy

- First Published: 18 March 2019

The crystallization behavior of an FeO3–CaO–Al2O3 system with various Al2O3 contents is observed by using an in situ observation technique. The temperatures at which the primary phase forms for various Al2O3 contents and cooling rates differ from the equilibrium temperatures, and the phase-formation temperature ranges vary with the cooling rate.

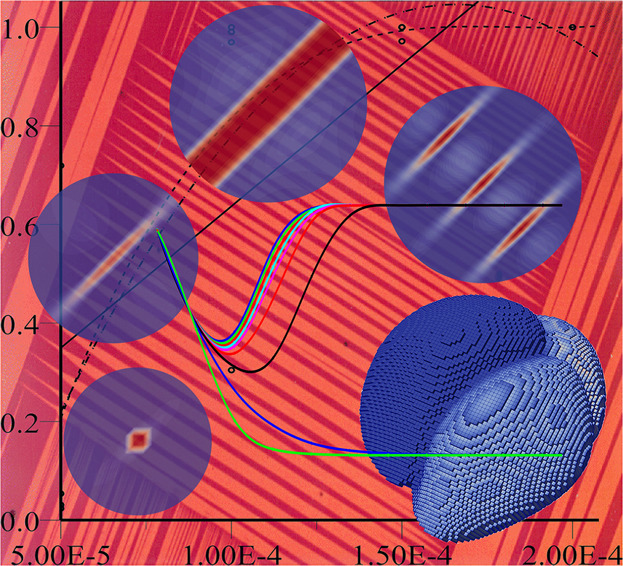

Influence of Material Parameters on Martensitic Transformation and Its Sensitivity Analysis

- First Published: 29 April 2019

Accurate acquisition of the microscopic of the martensite transformation process is the key to obtaining the best performance of the material. The paper shows the process of martensite transformation during quenching by modeling, and the influence of material parameters on this process is also analyzed, an orthogonal test is designed to find the optimal parameters to obtain ideal microstructure of material.

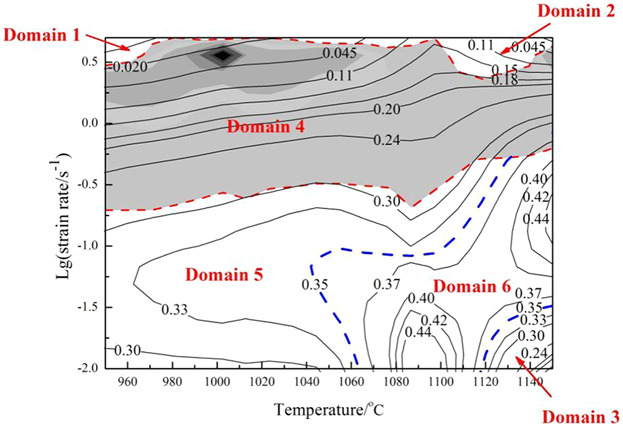

High Temperature Deformation Characteristics of an Alumina-Forming Stainless Steel

- First Published: 18 March 2019

This paper focuses on hot deformation behavior of an alumina-forming stainless steel. A modified constitutive model of this alloy is established based on the strain-compensated equation. In addition, processing maps of this alloy are also constructed. Form the microstructure characterization, the features of both adiabatic shear bands and flow localization are formed in this alloy of instability regions.

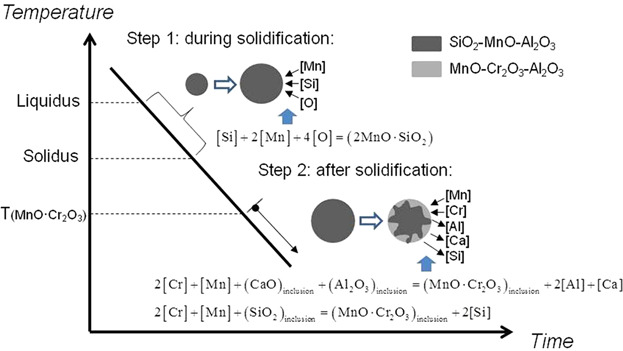

Effect of Cooling Rate on Oxide Inclusions During Solidification of 304 Stainless Steel

- First Published: 08 April 2019

The change of inclusions in 304 stainless steel during the cooling process is estimated to consist of two steps: 1) The precipitation and growth of SiO2-MnO-Al2O3 type inclusions during the solidification process and 2) the transformation of inclusions into the MnO-Cr2O3-Al2O3 system in solid steel by the interaction between inclusions and the steel matrix when the temperature decreased to the formation temperature of MnO-Cr2O3.

Thermal and Thermomechanical Responses Prediction of a Steel Ladle Using a Back-Propagation Artificial Neural Network Combining Multiple Orthogonal Arrays

- First Published: 29 April 2019

A method composed of the finite element modeling and back-propagation artificial neural network (BP-ANN) is developed to predict thermal and thermomechanical responses of a steel ladle. Multiple orthogonal arrays are applied to establish the representative dataset. Guidelines are proposed to define the minimum dataset size, the node number in the hidden layer, and select appropriate and efficient training algorithm.