Development of Tough Thermoplastic Elastomers by Leveraging Rigid–Flexible Supramolecular Segment Interplays

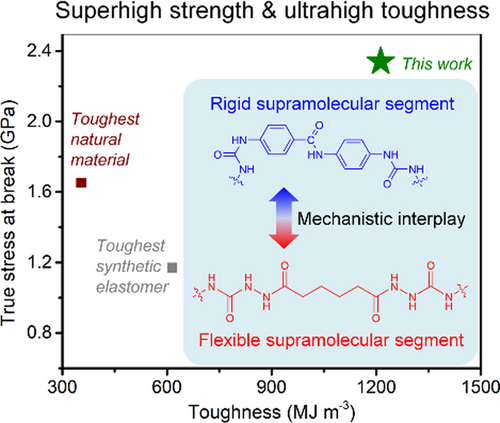

Graphical Abstract

A cooperative strategy for toughening thermoplastic elastomers without toughness–strength trade-off limitations is developed by leveraging the interplays between rigid and flexible supramolecular segments, resulting in the toughest (toughness 1.2 GJ m−3) thermoplastic elastomer thus far. This work presents a general design principle for toughening polymer materials by mismatched supramolecular interactions.

Abstract

Supramolecular interactions facilitate the development of tough multifunctional thermoplastic elastomers. However, the fundamental principles that govern supramolecular toughening are barely understood, and the rational design to achieve the desired high toughness remains daunting. Herein, we report a simple and robust method for toughening thermoplastic elastomers by rationally tailoring hard–soft phase separation structures containing rigid and flexible supramolecular segments. The introduced functional segments with distinct structural rigidities provide mismatched supramolecular interactions to efficiently tune the energy dissipation and bear an external load. The optimal supramolecular elastomer containing aromatic amide and acylsemicarbazide moieties demonstrates a record toughness (1.2 GJ m−3), extraordinary crack tolerance (fracture energy 282.5 kJ m−2), an ultrahigh true stress at break (2.3 GPa), good elasticity, healing ability, recyclability, and impact resistance. The toughening mechanism is validated by testing various elastomers, confirming the potential for designing and developing super-tough supramolecular materials with promising applications in aerospace and electronics.

Conflict of interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.