Effects of the manufacturing process on the anti-A isoagglutinin titers in intravenous immunoglobulin products

Abstract

BACKGROUND

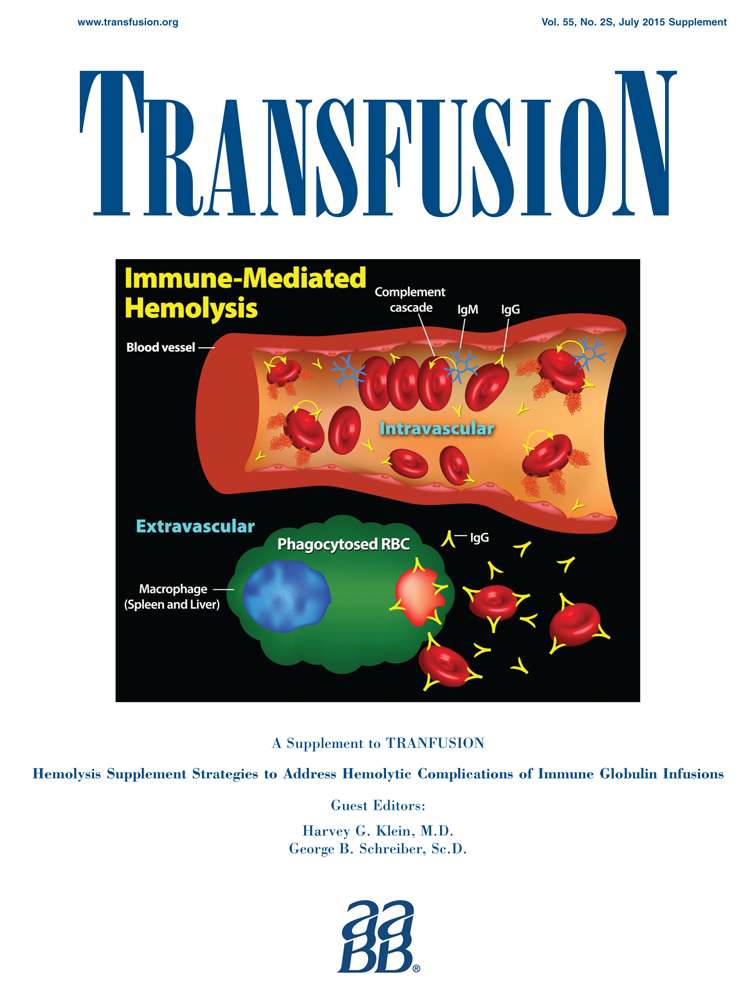

The first intravenous immunoglobulin G (IVIG) preparations for clinical use were produced from human plasma by Cohn-like fractionation processes. To achieve higher purity and yield, chromatography-based processes were developed. Using two products as examples, we compare the capacity of these two manufacturing processes to reduce the levels of anti-A and anti-B isoagglutinins in IVIG, which are believed to be responsible for rare hemolytic adverse events.

STUDY DESIGN AND METHODS

The isoagglutinin levels of Sandoglobulin (lyophilized, sucrose-stabilized IVIG produced by Cohn-like fractionation) and Privigen (10% l-proline–stabilized IVIG produced by a chromatography-based process) were measured by the indirect agglutination test (IAT). The intrinsic isoagglutinin reduction capacity of each fractionation step was assessed in laboratory- and industry-scale experiments using the IAT and a flow cytometry–based immunoglobulin-binding assay, respectively.

RESULTS

The median anti-A isoagglutinin titer recorded in 248 Sandoglobulin lots was three titer steps lower than the one measured in 651 Privigen lots (1:2 vs. 1:16). Over the entire process, we measured a five-titer-step isoagglutinin reduction in laboratory-scale Cohn-like fractionation; the largest reduction was observed between Fraction (F)II+III and FII. An overall four-titer-step reduction was recorded in the industry-scale process. In contrast, none of the steps of the chromatography-based manufacturing process caused any decrease in anti-A isoagglutinin content. Similar results were obtained for anti-B isoagglutinin reduction.

CONCLUSION

Unlike Cohn-like fractionation, chromatography-based IVIG manufacturing processes do not have an intrinsic capacity for isoagglutinin reduction. The addition of dedicated isoagglutinin reduction steps may help minimize the potential risk of hemolysis in IVIG-treated patients.