Combinatorial Magnetron Sputtering

Advances with New Tools and New Predictive Techniques

Summary

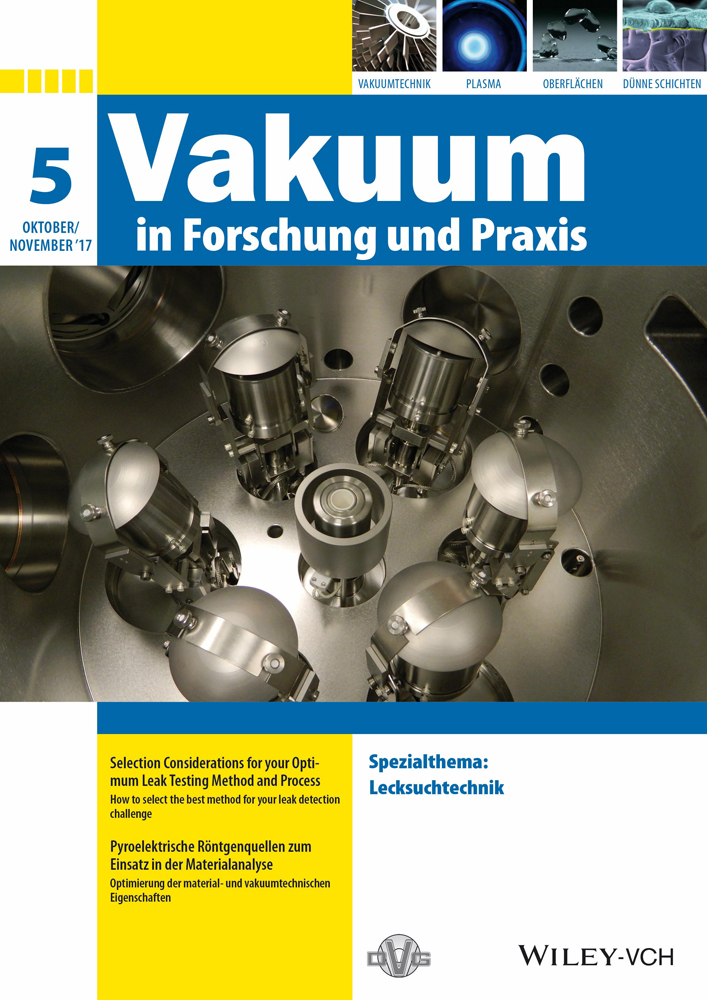

enCombinatorial Magnetron Sputtering is a process where large numbers of chemically distinct thin film samples can be made in a single deposition. Utilizing a multiple cathode sputter system manufactured by the Kurt J. Lesker Company, researchers at the California Institute of Technology have developed a process which enables them to make 5,000 unique compositions on one 4″ wafer in one deposition. Compositional control is achieved by varying the tilt angle of the cathodes and Z-distance relative to the substrate. In addition to this extraordinary fabrication capability, the group also developed a model which can predict the range of future compositions as well as a rapid characterization technique which can sort through thousands of compositions in a 24 hour period.

Zusammenfassung

deKombinatorische Magnetronsputtern – Fortschritte mittels neuer Geräte und prädiktiver Techniken

Das kombinatorische Magnetronsputtern gestattet die Abscheidung einer großen Anzahl von Schichten in einem einzigen Depositionsschritt. Mittels Anpassung eines Mehrkathoden-Sputtersystems der Kurt J. Lesker Company, gelang Wissenschaftlern vom California Institute of Technology die Abscheidung von 5000 einzelnen Verbindungen auf einem 4 Zoll Wafer in einem einzigen Prozessschritt. Ein Modell zur Voraussage der Variationsbreite zukünftiger Schichten und eine Technik zur schnellen Charakterisierung der Verbindungen wurden entwickelt.