Comprehensive review of innovative construction technology of high-core rockfill dam: Nuozhadu project

Abstract

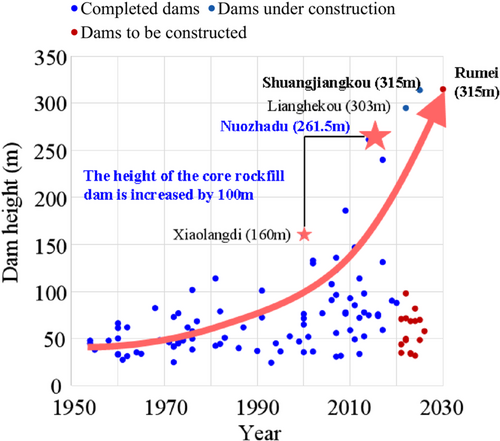

Underpinned by the ultrahigh-core rockfill dam at the Nuozhadu Hydropower Station, comprehensive studies and engineering practices have been conducted to address several critical challenges: coordination of seepage deformation in dam materials, prevention and control of high-water-pressure seepage failure, static and dynamic deformation control, and construction quality monitoring. Advanced technologies have been developed for modifying impermeable soil materials and utilizing soft rocks. Constitutive models and high-performance fine computational methods for dam materials have been improved, along with innovative seismic safety measures. Additionally, a “Digital Dam” and an information system for monitoring the construction quality were implemented. These efforts ensured the successful construction of the Nuozhadu Dam, making it the tallest dam in China and the third tallest dam in the world upon completion. This achievement increased the height of core dams in China by 100 m and established a design and safety evaluation framework for ultrahigh-core rockfill dams exceeding 300 m in height. Furthermore, the current safety monitoring results indicate that the Nuozhadu Dam is safe and controllable.

1 INTRODUCTION

Since the founding of China, extraordinary achievements have been achieved in dam construction. Rockfill dams comprise 95% of the nearly 100,000 constructed dams. As the 21st century dawned, the construction technology of earth-rockfill dams in China underwent unprecedented development in terms of quantity, height, and construction scale. By 2023, 120 rockfill dams exceeding 100 m in height had been constructed in China. As one of the main types of earth-rockfill dams, core rockfill dams have undergone rapid advancements in construction technology. China has transitioned from the introduction and adaptation of foreign technologies during the Lubuge project to achieving parity with international standards in projects such as Xiaolangdi and Pubugou and ultimately to establishing a leading position in the construction of ultrahigh-core-wall rockfill dams such as Nuozhadu and Lianghekou. This reflects a leapfrog in development by following and keeping pace with global advancements in this field (Yang et al., 2019). As crucial pillars of national energy security and water safety, the operational safety of these projects is linked to major national security issues concerning flood control, economics, ecology, and public welfare and thus occupies a prominent strategic position.

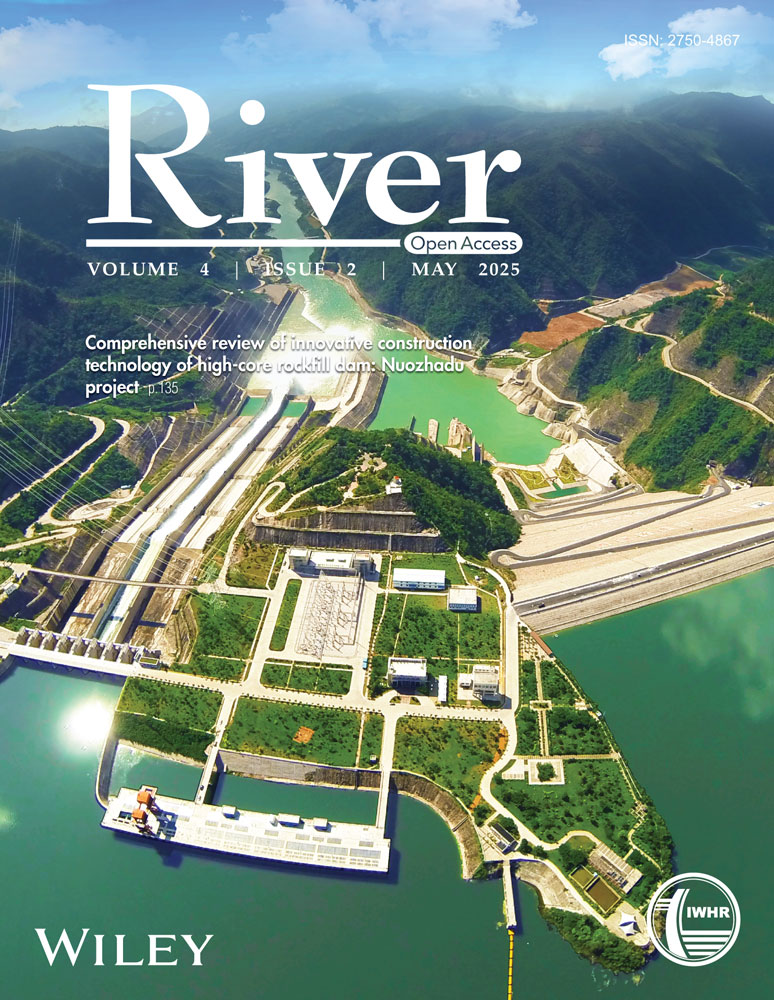

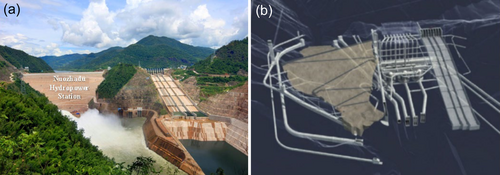

The Nuozhadu project on the Lancang River stands as a testament to China's ambitious commitment to infrastructure development and is a pivotal project to the Western Development strategy, “12th 5-Year Plan,” “West-to-East Power Transmission,” and “Yunnan Electricity Export Strategy.” With a total investment of 61.1 billion yuan, a filling volume of 34.32 million cubic meters, an installed capacity of 5,850 MW, and a total reservoir capacity of 23.7 billion cubic meters, the dam body is a gravel–sand core wall structure, reaching a maximum height of 261.5 m. The left bank features an open spillway with a discharge capacity of 66,940 MW and maximum flow rate of 31318 cubic meters per second, as illustrated in Figure 1. The project faces complex geological conditions and high technical design specifications, with several technical indicators for dams, spillways, and underground powerhouses ranked globally. As shown in Figure 2, upon completion in 2014, its dam height ranked first in China and third in the world for the same dam type and increased the height of China's core wall dam by 100 m (Zhang et al., 2006a, 2006b).

Numerous significant technical challenges were successfully addressed during the construction of the Nuozhadu project. Through an innovative study on a comprehensive set of technologies for modifying anti-seepage soil materials, the complex issue of achieving both seepage control and deformation coordination was effectively resolved. Groundbreaking constitutive models, computational analysis methods, and seismic safety measures have been introduced to overcome the formidable challenges posed by static and dynamic deformations in ultrahigh dams, as well as to prevent high-water pressure seepage failure. Furthermore, the establishment of a commercial “Digital Dam” and sophisticated construction quality monitoring information system provides effective solutions for ensuring comprehensive quality control in ultrahigh rockfill dam construction. This study systematically encapsulates the invaluable experience gained from the Nuozhadu ultrahigh-core dam, emphasizing the pivotal innovative achievements that serve as vital technical support for the future construction of ultrahigh-core dams exceeding 300 m.

2 DAM MATERIAL DESIGN AND ZONING UTILIZATION

2.1 Artificial modification technology for anti-seepage soil

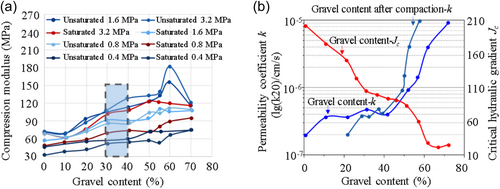

To address the challenges posed by the high clay content and compressibility in natural soil, which hinder the simultaneous achievement of permeability safety and deformation stability requirements for ultrahigh dams, a novel method for artificially modifying natural soil with graded gravel has been proposed. This modification involves the incorporation of gravel into natural soil, which enhances both its permeability and mechanical properties, improving its resistance to seepage. Importantly, this approach eliminates the need for chemical additives and offers a sustainable and cost-effective solution. As shown in Figure 3, after conducting over 3,000 laboratory tests and six large-scale field trials, an optimal gravel content of 30%–40% was identified (Zhang et al., 2016). This modification strategy doubled the compressive modulus and increased the shear strength by 20% (Xu et al., 2016), effectively resolving the conflict between permeability stability and deformation control in the impermeable core wall.

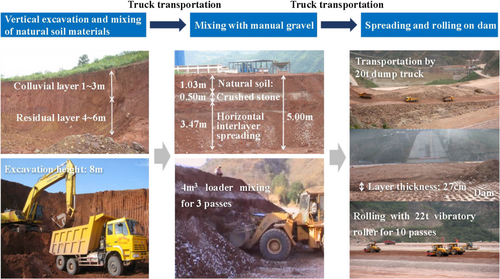

In response to the modification requirements of the Nuozhadu Dam, a comprehensive set of techniques for artificial gravel mixing construction was developed. This includes a method for alternating the soil and gravel layers to ensure uniformity and quality. Figure 4 illustrates the construction process: vertical extraction of natural soil (approximately 8 m high) and transportation by dump trucks to the mixing site. Natural soil (thickness of 1.03 m) and crushed gravel (thickness of 0.5 m) were layered horizontally in an alternating pattern and spread evenly using bulldozers, ensuring that the total height remained below 5 m. The soil and gravel were mixed in three cycles using excavators, after which 20-ton dump trucks transported the mixture to the dam surface. At the dam, the material was unloaded using a retreating method, leveled with a road grader, and compacted in layers of 27-cm thickness, with a 22-ton vibrating roller applying 10 passes of compaction (Zhang et al., 2013).

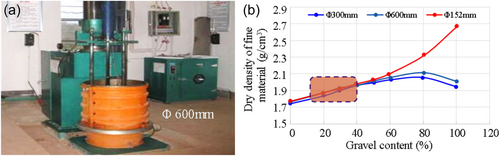

To achieve rapid quality testing for gravel-mixed soil fill, a three-point rapid compaction quality testing method was developed for coarse and fine materials, significantly increasing the testing accuracy and efficiency. Given that the maximum particle size of the soil in the Nuozhadu project is 120 mm, a specially designed φ600-mm large-scale compaction apparatus was created to investigate the compaction characteristics of gravel-mixed soil (Figure 5a). As shown in Figure 5b, when the gravel content was below 50%, it was feasible to adopt the results from the alternative method for large-scale compaction instead of the original grading of the superlarge compaction to control the quality of the gravel-mixed soil. To evaluate the testing efficiency of the gravel-mixed soil fill quality, a comparative analysis was conducted on methods for controlling the overall material compaction, pre-control line methods for the overall compaction, and fine material compaction control techniques. The onsite detection method for fine material compaction demonstrated reduced compaction functionality and a significantly reduced workload, aligning with the construction schedule requirements. Ultimately, a three-point rapid compaction method with a fine material compaction functionality of 595 kJ·m³ was adopted for onsite quality control (Ma, 2012), supplemented by laboratory verification of overall compaction using the proportionate large-scale compaction apparatus.

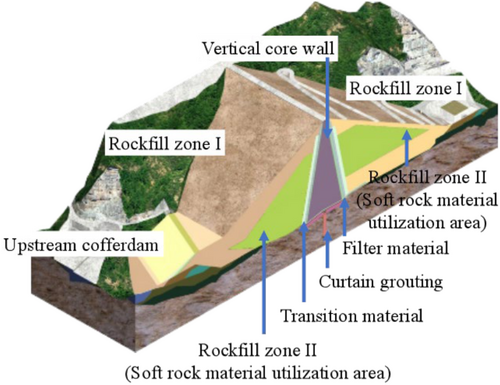

2.2 Soft rock material utilization

The materials excavated from the Nuozhadu hydropower station contain soft rock (mudstone), which can degrade the mechanical properties of the rockfill owing to disintegration and weathering (Kanji, 2014; Xing et al., 2006). Utilizing excavated materials containing soft rock in the secondary rockfill area of a dam can yield substantial economic benefits. Finite-element calculations simulating the complete weathering of soft and moderately hard rocks in the secondary rockfill area indicated that the maximum stress level in the dam was only 0.84, which did not reach the plastic limit. Additionally, the principal stress on the upstream face of the core wall did not exhibit negative values, indicating that tensile cracks did not occur. Therefore, a rockfill containing soft rock can be used in a secondary rockfill area (Figure 6), resulting in an actual filling of 4.78 million cubic meter and savings of approximately 330 million yuan.

2.3 Permeability stability and deformation coordination control

Permeability stability and deformation control are fundamental issues in ensuring the safe construction and operation of high earth-rockfill dams. For core rockfill dams, effective seepage control should be grounded in thorough geological and hydrological engineering investigations, adhering to the principles of an integrated approach that combines impermeability, filtration, and drainage in an optimized manner. The core wall serves as an impermeability core, the filter layer maintains seepage stability, the transition zone facilitates deformation coordination and rapid drainage, and the rockfill zone ensures the structural stability of the dam.

In recent years, the observed settlement of 200-m-high earth-rockfill dams has commonly exceeded 1% of the maximum dam height, both domestically and internationally. Deformation control for ultrahigh-core rockfill dams should follow the principles of total deformation management and coordinated deformation between the core wall and shell materials. This can be achieved by increasing the core wall deformation modulus to reduce the modulus disparity with the rockfill and thereby minimizing the arching effect of the shell rockfill on the core wall. Practical experience from the Nuozhadu project indicates that the average median value of the Duncan–Chang E-B model parameter K for the core wall materials should exceed 350.

The Nuozhadu hydropower station implemented multiple measures for seepage and deformation control to ensure dam safety. Foundation excavation involved the removal of completely and severely weathered rock masses. The core wall foundation underwent consolidation grouting treatment, and the core wall materials were artificially modified. Experimental results and computational analyses indicated that the strength and deformation characteristics of the foundation satisfied the relevant standards. The gravel–soil core had good impermeability, with the permeability coefficient of the core material ranging from 2.02 × 10-7 to 8.47 × 10-6 cm/s. At the Nuozhadu Hydropower Station, two filter layers with a thickness of 4 m each were installed on the upstream side of the dam's core wall, whereas two additional layers, each 6 m thick, were positioned on the downstream side. Furthermore, to coordinate the deformation between the core wall and the dam shell material, a 10-m-wide transition zone of fine rockfill was established between the upstream and downstream filter layers and the rockfill. Three-dimensional finite-element analyses revealed that the core wall exhibited a certain degree of arching. Notably, all three principal stresses on the upstream face were positive, indicating substantial safety margins against tensile stress for both the major and intermediate principal stresses. Additionally, with the protection of the downstream filter layer, the gravel-soil core wall exhibited significant safety against hydraulic fracturing.

3 NUMERICAL CALCULATION METHOD FOR ULTRAHIGH-CORE DAM

Safety analysis of ultrahigh-core rockfill dams requires precise calculation methods that necessitate in-depth studies of the constitutive model of rockfill materials, failure mechanisms in the seepage control system, and seepage evolution law. Concurrently, with advancements in computational capabilities, a large-scale fine numerical simulation platform has been developed to facilitate coupled analyses under various complex conditions.

3.1 Constitutive model of dam materials for core rockfill dams

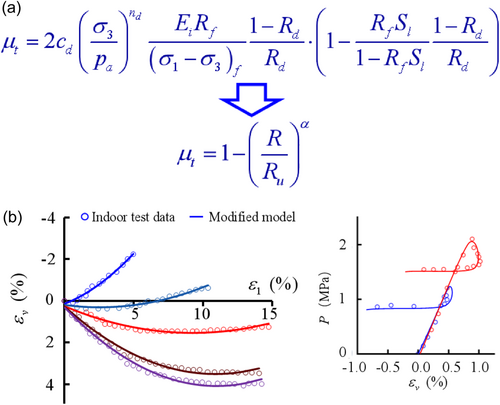

In the numerical calculations related to rockfill dams, static constitutive models for rockfill materials typically employ nonlinear elastic and elastoplastic models to accurately represent their mechanical properties, including elasticity, dilatancy, rheological wetting, and anisotropy. Our research team conducted a comparative analysis of commonly used static constitutive models, such as the Duncan–Chang E-B model, Tsinghua KG model, and Shen Zhujiang dual-yield surface elastoplastic model (Zhang et al., 2008). The results indicated that the Duncan–Chang model often failed to account for soil shear dilation, leading to the issue of “underestimating high dams and overestimating low dams.” Although the stress and deformation results from the Shen Zhujiang double-yield surface model aligned well with the actual data, they occasionally exaggerated the shear dilation characteristics of the rockfill. A modified Rowe shear dilation equation for rockfills was proposed to enhance the increase of the mechanical-behavior description (Figure 7). This improvement refined the representation of volumetric deformation in the Shen Zhujiang double-yield surface model, effectively addressing the deformation analysis issue of “overestimating low dams and underestimating high dams” and thereby increasing the accuracy of deformation calculations for ultrahigh-core rockfill dams (Zhang et al., 2007, 2010).

In the study of dynamic constitutive models, significant advancements have been made in the establishment of a Quantified Memory (SM) model, including the formulation methods, relationships with other models, parameter determination, and implementation of multidimensional Quantified Memory models and their associated algorithms. Numerical simulations have been employed to replicate the hysteresis loops observed in dynamic triaxial tests under various dynamic stress conditions, yielding innovative results in the field of dynamic constitutive modeling. The Quantified Memory model effectively links various empirical and elastoplastic models with the actual characteristics of soils observed in the tests, providing a clear theoretical expression and application. Based on the Masing similarity criterion and traditional plastic incremental theory, this model can be readily applied to anisotropic materials and irregular dynamic stress–strain responses. The SM concept offers a geometric representation of stress–strain responses, transforming the nonlinear variation in the shear modulus under monotonic loading into a piecewise linear distribution and thus facilitating the description of the hysteretic behavior in materials subjected to cyclic loading.

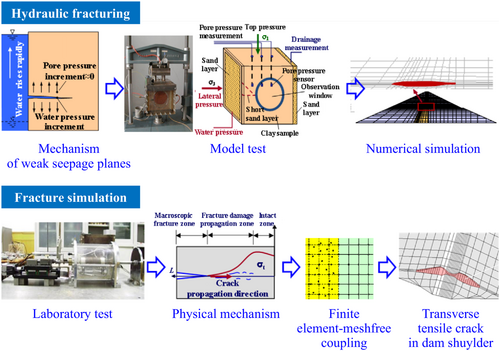

3.2 Hydraulic fracturing mechanisms and crack analysis methods

This study, in conjunction with the Nuozhadu project, revealed that weak seepage planes within the core wall are critical conditions for the occurrence of hydraulic fracturing, clarifying the arching effect in the core wall and the mechanisms of hydraulic fracturing. A model was developed that elaborates on the hydraulic wedge fracturing effect induced by the water pressure in these weak seepage planes (Figure 8) (Zhang et al., 2005). As the reservoir water level rapidly increases, the water pressure within the seepage planes rises quickly, while the pore water pressure within the core wall increases at a lower rate. This disparity creates a wedging action that propagates from the weak zones toward both sides of the core wall. A novel experimental apparatus developed to investigate hydraulic fracturing phenomena was employed to conduct hydraulic fracturing tests on the mixed soil material of the Nuozhadu core wall, validating the proposed hydraulic wedge fracturing effect model.

By integrating the theory of diffuse fractures with Biot's consolidation theory, a finite-element numerical simulation model and an algorithm were derived and established to describe the occurrence and expansion of hydraulic fracturing. This approach effectively addresses the challenges associated with the simulation of the development of hydraulic and tensile fractures. Using Biot's consolidation theory, a coupled finite-element model was constructed with the pore water pressure and displacement as primary variables. Diffuse fracture theory was employed to characterize the evolution of cracks during the hydraulic fracturing process, overcoming the limitations of mesh handling encountered in traditional linear elastic fracture mechanics. Crack expansion was simulated according to variations in the local stress field. When the minimum principal stress decreased below the tensile strength of the soil, the cracks lost their stiffness in the normal direction and began to propagate, resulting in an increased permeability coefficient along the direction of the cracks. The model accurately reproduced the phenomenon of water pressure seepage following crack formation.

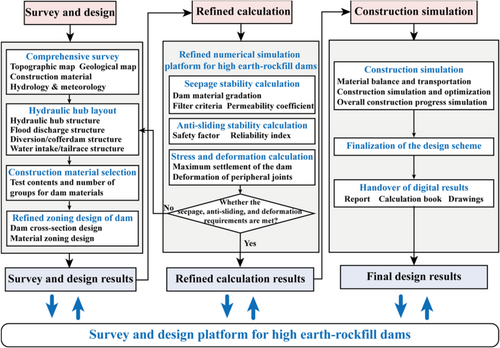

3.3 Refined numerical simulation platform for different calculation scales of earth-rock dams

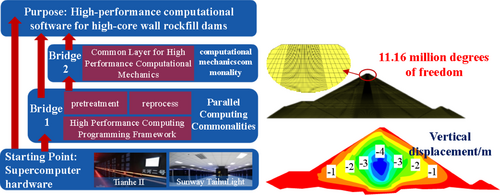

To analyze and calculate the rockfill dams in China, a combination of widely used foreign commercial software and custom-developed programs was employed. However, for major national projects, reliance on commercial software poses risks of “bottleneck” issues and data leakage. To address these issues, our team has engaged in continuous programming development, adhering to the principles of “accuracy, stability, and speed.” By employing suitable hardware and software optimization configurations, parallel computing techniques, and multi-software collaboration interfaces, we developed a numerical simulation platform capable of small-, medium-, and large-scale computations that plays a significant role in the analysis and safety evaluation of earth-rockfill dams in China.

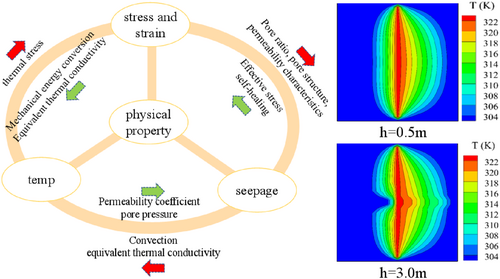

For medium- and small-scale computational challenges, the team developed a multifunctional Mage program for stress–seepage–state–temperature coupling analyses (Figure 9) (Wu et al., 2016). This program employs an iterative algorithm that combines the secant method and linear search techniques along with various efficient direct and iterative solving methods. It enables small-scale computations with millions of degrees of freedom on standard PCs as well as medium-scale computations with tens of millions of degrees of freedom on small workstations, offering high accuracy and computation speed.

To meet the demands of refined calculations for ultralarge-scale structures, our team designed a large-scale refined computation framework for complex large-deformation conditions on high-performance computing platforms (Figure 10). In collaboration with partner institutions, we have developed calculation methods and programs suitable for ultrahigh-core-wall rockfill dams on supercomputing platforms. This allows detailed simulations with tens of millions of degrees of freedom, effectively addressing dam calculations and analyses under complex stress conditions and providing precise and reliable computational tools for major engineering projects.

3.4 Inversion of dam material parameters

To assess the permeability stability of ultrahigh-core rockfill dams, an inversion analysis program system that integrates artificial neural networks and evolutionary algorithms was employed to invert the permeability coefficients of the core materials and the underlying bedrock of Nuozhadu (Ni & Chi, 2017). The inverted parameters were then utilized to perform finite-element simulations of the seepage behavior of the dam (see Figure 11a). The results indicated that the inverted permeability coefficient at the base of the core wall was lower than that at the upper sections, suggesting a significant reduction in permeability due to compaction during the construction of the gravelly soil. The calculated seepage rates aligned well with measurements obtained from the flow measurement weir, confirming the reliability of the inverted permeability coefficients of the foundation (Lv & Chi, 2018).

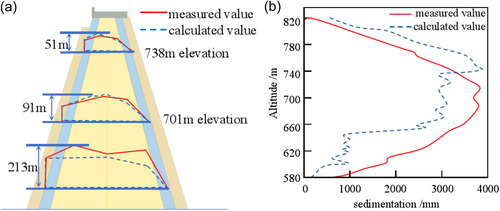

To address the deformation control issues of ultrahigh-core-wall rockfill dams, an inversion analysis system was used to invert the EB model parameters, rheological parameters, and wetting parameters for both the rockfill and core wall materials, followed by finite-element simulations (Wu et al., 2014; Zhao et al., 2012). The simulation results aligned well with the measurements from various monitoring instruments, indicating that the maximum settlement of the dam at completion was 3.91 m, which closely matched the measured maximum settlement (Figure 11b). From the perspective of deformation control, the average filling quality of the core wall satisfied the design expectations.

4 SEISMIC SAFETY OF DAMS

4.1 Dynamical calculation

The key to slope stability of dams is their dynamic anti-sliding stability under seismic conditions. For high rockfill dams, a comprehensive analysis employing multiple methods is advisable (Du et al., 2015; Zhou et al., 2015). The stability design of the Nuozhadu high-core rockfill dam utilizes various approaches, including pseudostatic methods, pseudostatic methods with different acceleration distribution coefficients, reliability methods, strength-reduction finite-element methods, finite-element analysis, the Newmark sliding block deformation method, and stability analysis based on the variational principle (Hu & Xu, 2011; Pan et al., 2015). The dynamic response analysis indicated that the overall acceleration response within the dam body was relatively weak, with the amplification factors for both the downstream and vertical accelerations in most regions of the dam section being less than 2.0. Notably, the acceleration response at the crest was more pronounced. The results of the seismic safety assessment suggest that the probability of significant deformation occurring in the dam over a 100-year design reference period is low. However, the likelihood of minor settlement and lateral displacements at the dam crest exceeds 70%. Consequently, the dam crest was identified as a critical area for seismic design, corroborating the findings of dynamic model tests conducted on a shake table (Dong et al., 2013; Yuan et al., 2014; Zhang et al., 2022).

4.2 Seismic measures

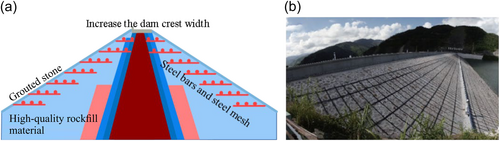

Earth-rockfill dams typically employ measures such as geogrids, concrete slab beams, precast concrete frame beams, and seismic reinforcement bars to enhance their seismic resistance. The simulation results indicate that the Nuozhadu core rockfill dam is stable and safe under the designed earthquake conditions, and a series of additional seismic reinforcement measures have been implemented to enhance the integrity of the dam crest and reduce the risk of shallow sliding failures on the dam slope during seismic events (Zhang et al., 2011).

The Nuozhadu project developed and applied seismic measures for ultrahigh-core rockfill dams designed for a seismic intensity of 9° (Figure 12). These measures include placing a layer of contact clay between the impermeable body and the foundation layer; installing two layers of filter material and a fine rockfill transition layer on both the upstream and downstream faces of the impermeable body; widening the dam crest to prevent rockfill from rolling off and causing local instability; reinforcing critical areas of the dam crest up to one-fifth of the dam height with high-quality rockfill materials; embedding stainless steel anchor bars and placing reinforcement meshes on both sides of the dam body to ensure overall seismic resistance; using stone masonry revetments in the crest areas upstream and downstream to further enhance stability; and installing through-steel reinforcement bars on the crest to maintain the integrity of the dam top.

In contrast to traditional methods, such as geogrid reinforcement or diaphragm walls, Nuozhadu measures improve both flexibility and stability. The integration of stainless-steel anchor bars and reinforcement meshes distributes the seismic forces more evenly, whereas through-steel reinforcement bars prevent crest displacement. The widened crest and high-quality rockfill reduced the rockfill displacement and ensured stability. These combined measures provide a more adaptable and resilient solution for seismic forces.

5 DIGITAL DAM AND CONSTRUCTION QUALITY MONITORING

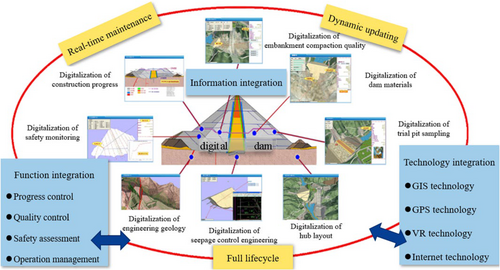

The construction of high-core rockfill dams involves substantial project volumes, complex phased and zoned operations, and stringent requirements for compaction and filling (Zhong et al., 2009, 2018). Conventional quality control methods often struggle to achieve precise control of construction quality. The Nuozhadu Project pioneered the development of a “Digital Dam” system that allows real-time monitoring and information feedback on dam material transport, construction parameters, test results, and monitoring data. This system facilitates fine real-time online monitoring throughout the process of dam filling and compaction, ensuring high construction quality and establishing a precedent for digital construction in China's hydraulic and hydropower projects.

The “Digital Dam System” integrates 3S technologies (GIS, GPS, and RS), virtual reality (VR), and other information technologies to dynamically collect and digitize engineering information and safety monitoring data related to the planning, design, construction, and operation of the Nuozhadu hydropower station. This provides comprehensive informational support and analytical platforms for engineering decision-making and management as well as for safe operation and health diagnostics of the dam (Figure 13). Although the system primarily focuses on engineering information management and construction quality monitoring, it is not designed to directly monitor the long-term safety of a dam after its completion.

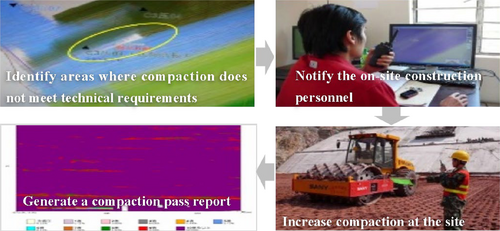

The Nuozhadu core rockfill dam has introduced a construction quality monitoring system centered around the “Digital Dam” for the first time during its filling process (Figure 14). This system leverages onboard GPS and high-precision GPS mobile terminals to monitor the entire dam-construction process. Its capabilities include real-time monitoring of material source matching, on-dam strength, and vehicle density during material transportation, which provides a foundation for optimizing vehicle scheduling and ensuring the absence of mixing issues in fill quality. During the compaction phase, the system tracks the compaction vibration force, trajectory, speed, number of passes, and compaction thickness. If anomalies are detected, the system automatically triggers an alarm and facilitates timely corrections to ensure the compaction quality of each unit (Ma, 2014). The “Digital Dam” system has significantly enhanced the level and efficiency of construction quality monitoring for the Nuozhadu Dam, ensuring that construction quality is consistently under control. It has created a new avenue for achieving high-quality control standards in high-rockfill dam construction. From 2009 to 2011, the Nuozhadu Dam achieved an average annual fill volume of 9.4 million cubic meters and completed construction a year ahead of schedule. This highlights the significant supportive role of the system in high rockfill dam construction, which has been adopted in subsequent high dam projects.

6 ENGINEERING SAFETY

6.1 Security monitoring

The safety monitoring system for the Nuozhadu core rockfill dam integrates various advanced technologies (Tan et al., 2012). Through the Nuozhadu project, a series of high-precision monitoring instruments were developed, including new layered settlement gauges, pressure-type water pipe settlement gauges, four-tube water pipe settlement gauges, electric measuring crossbeam settlement gauges, and chord settlement gauges. In addition, equipment such as shear deformation gauges, a 500-mm ultralarge range potentiometric displacement gauge, electromagnetic settlement gauges, fixed inclinometer gauges, and six-directional soil pressure gauges was employed to comprehensively monitor the internal settlement of the upstream rockfill, internal settlement of the core wall, and the relative deformation and spatial stress state between the core wall, filter layer, and concrete cushion. The system also incorporates measurement robots and a GNSS deformation-monitoring system to achieve high-precision automated monitoring of both the surface and internal deformations of the dam. With an internal and external automated system and online monitoring data compensation technology, the accuracy of the real-time monitoring data was ensured, providing robust support for the long-term safe operation of the dam.

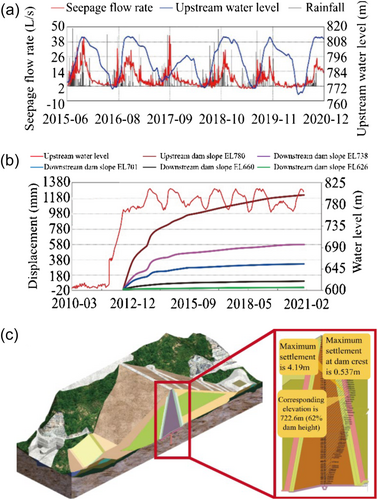

As of January 2021, the monitoring results indicated that the central region in the Nuozhadu core wall was a zone of concentrated displacement, with the settlement decreasing outward from this area. The measured settlements at various points stabilized, with the maximum displacement occurring in the upper middle section of the core wall, exhibiting a distribution pattern in which the middle had the greatest displacement, whereas the top and bottom had lower values. The maximum measured settlement of the core wall was 4779 mm, representing 1.84% of the fill height, which occurred at an elevation of 740.4 m in the upper middle section. The maximum settlement at the dam crest was 1437 mm, which was significantly less than 1% of the dam height. The differential movement between the core wall and the filter layer ranged from –34 to –37.1 mm, indicating that the filter layer effectively mitigated the deformation differences between the core wall and the rockfill, contributing to the good overall deformation coordination of the dam.

The water-level distribution of the core–wall rockfill dam indicated that the upstream reservoir level was the highest. The pore water pressure within the core wall was generally positively correlated with the reservoir water-level, with a stronger correlation observed closer upstream and at higher elevations. In contrast, the downstream water levels were lower and relatively stable, indicating effective impermeability of the core wall, cushion layer, and impervious curtain. The measured water levels in the pressure pipes within the foundation gallery ranged from 638.3 to 794.7 m, while the surrounding seepage water level measurements varied between 606.7 and 807.8 m. The water levels in the first drainage hole behind the curtain ranged from 717.4 to 785.7 m, with stable measurements on both banks indicating good water-level reduction effects. Overall, the total seepage flow of the dam is currently measured at 14.06 L/s, which is the lowest among similar projects, both domestically and internationally. These monitoring data demonstrate that the deformation, seepage, and other monitored parameters of the Nuozhadu core rockfill dam are reliable and consistent with the distribution characteristics and developmental trends of the monitored physical quantities aligned with general laws (Figure 15).

6.2 Safety evaluation and early warning

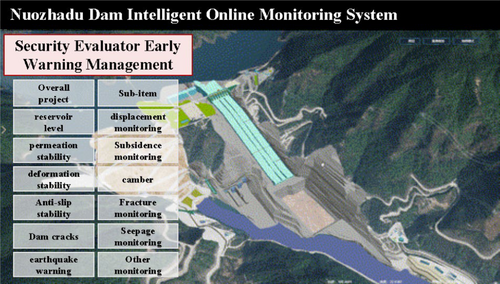

On the basis of onsite monitoring data and advanced information technology, a safety evaluation and early warning information system for earth-rockfill dams was established, which is crucial for the safe construction, reservoir acceptance, and lifetime safety operation of the dam. The Nuozhadu project developed a remote monitoring safety evaluation and early warning management information system for ultrahigh-core rockfill dams by leveraging Internet technologies (Figure 16). This system integrates functions such as monitoring data collection and analysis, numerical calculations, inversion analysis, a comprehensive safety evaluation index system, and an early warning system. It enables real-time monitoring of the dam status, automated data analysis, and comprehensive safety assessments, effectively supporting safety management throughout the entire lifecycle of the dam. Thus, it serves as a significant demonstration in the field of high-earth-rockfill dam construction.

The Nuozhadu project established a two-tier safety monitoring indicator system for its ultrahigh-core rockfill dam, addressing critical issues such as reservoir water level, seepage stability, structural stability, slope stability, and dam cracks. This system provides robust technical support for dam safety assessments and early warning systems. The overall safety indicators included parameters such as the seepage flow, maximum settlement of the dam body, maximum settlement at the crest, deformation of the upstream and downstream slopes, and cracking at the dam crest. Specific safety indicators include the longitudinal horizontal displacement, dam body settlement, seepage flow, pore water pressure, earth pressure, and crack development, allowing precise monitoring of safety conditions in specific areas or functional units to ensure comprehensive and refined safety assessments.

The core of the system lies in the real-time collection and intelligent analysis of monitoring data combined with numerical simulation and inverse analysis modules to predict, assess, and issue early warnings regarding the behavior of the dam under various conditions. The numerical simulation module can model seepage, stability, and stress–strain characteristics, whereas the inverse analysis utilizes historical data to make accurate predictions about the future behavior of the dam. According to the analysis results, the system can promptly issue tiered warnings (red, orange, and yellow) and generate corresponding emergency plans. These plans address various issues, such as deformation, seepage, cracks, and slope stability, ensuring that operators can take appropriate measures before a crisis arises and maintain dam safety within controllable limits. Furthermore, the system can dynamically adjust warning thresholds and alert levels based on real-time monitoring data, ensuring the effectiveness and flexibility of the early warning mechanisms in a changing environment.

7 CONCLUDING REMARKS

- (1)

A modification technique for natural soil mixed with graded crushed stone was proposed, maximizing the utilization of excavation materials containing soft rock, which significantly enhances the impermeability and deformation control capabilities and addresses critical challenges in seepage and deformation for ultrahigh earth-rockfill dams.

- (2)

Significant breakthroughs have been achieved in improving the constitutive model of core rockfill dams, proposing mechanisms for hydraulic fracturing and fracture calculation methods, and developing a refined numerical simulation platform suitable for various calculation scales. An accurate inversion of dam material parameters was realized, significantly increasing the accuracy of dam calculation and analysis, which provides strong technical support for the design and construction of ultrahigh-core-wall rockfill dams.

- (3)

Seismic reinforcement measures suitable for ultrahigh-core rockfill dams were developed, ensuring the safety of the dam under extreme conditions and reducing the risk of shallow slope failures.

- (4)

The “Digital Dam” system allows real-time monitoring and high-quality management throughout the dam construction process. A comprehensive safety evaluation and early warning management information system was established for the entire lifecycle of the dam. Advanced monitoring equipment allows precise tracking of the internal stress, deformation, and seepage within the dam, ensuring its long-term operational safety.

The Nuozhadu project is a landmark initiative that illustrates China's transition from a follower to a global leader in high dam engineering technology. The exceptional contributions of this project have garnered significant recognition, both domestically and internationally. The project received the International Commission on Large Dams' Milestone Project Award for Rockfill Dams, the FIDIC Project Excellence Award, and the Zhan Tianyou Award for Civil Engineering in China. Additionally, two key research outcomes—“Key Technologies and Applications for Ultrahigh Core Rockfill Dams” and “Critical Technologies for Real-Time Control in Major Water Conservancy and Hydropower Projects”—were awarded the Second Prize of National Science and Technology Progress. The innovative achievements and successful experiences derived from the Nuozhadu project not only provide vital technical references and support for the construction of 300-m ultrahigh-core rockfill dams in China but also make significant contributions to the advancement of hydropower engineering technologies worldwide.

ACKNOWLEDGEMENTS

Financial support for this project from the National Natural Science Foundation of China (No. 52309153) and the Key Science and Technology Projects of China Power Construction Group (No. DJ-ZDXM-2022-01 and DJ-ZDXM-12025-45) is acknowledged.

ETHICS STATEMENT

None declared.

Open Research

DATA AVAILABILITY STATEMENT

Data sharing not applicable to this article as no datasets were generated or analysed during the current study.