Enhancing flame retardancy of polyphenylene sulfide nanocomposite fibers by the synergistic effect of catalytic crosslinking and physical barrier

Yan Yu

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorLiping Zhu

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorLu Dai

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorCorresponding Author

Zexu Hu

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

College of Mechanical and Engineering, Donghua University, Shanghai, China

Correspondence

Zexu Hu and Zhe Zhou, State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai 201620, China.

Email: [email protected] and [email protected]

Search for more papers by this authorLili Li

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorHengxue Xiang

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorCorresponding Author

Zhe Zhou

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Correspondence

Zexu Hu and Zhe Zhou, State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai 201620, China.

Email: [email protected] and [email protected]

Search for more papers by this authorMeifang Zhu

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorYan Yu

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorLiping Zhu

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorLu Dai

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorCorresponding Author

Zexu Hu

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

College of Mechanical and Engineering, Donghua University, Shanghai, China

Correspondence

Zexu Hu and Zhe Zhou, State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai 201620, China.

Email: [email protected] and [email protected]

Search for more papers by this authorLili Li

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorHengxue Xiang

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorCorresponding Author

Zhe Zhou

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Correspondence

Zexu Hu and Zhe Zhou, State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai 201620, China.

Email: [email protected] and [email protected]

Search for more papers by this authorMeifang Zhu

State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Search for more papers by this authorAbstract

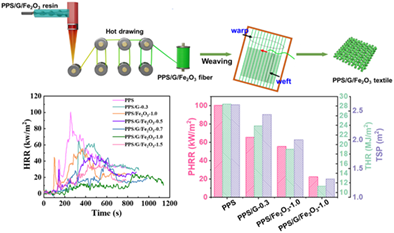

Protective clothing with fascinating flame-retardant features is urgently needed to reduce the large amount of smoke and heat released from combustion during fire protection. In this study, polyphenylene sulfide (PPS) nanocomposite resin with efficient flame retardancy is obtained by mixing a low content of graphene and Fe2O3 via a twin screw extruder. Followed by, the PPS/G/Fe2O3 fibers are fabricated via melting spinning. The PPS/G/Fe2O3 nanocomposite resin with 0.3 wt% of graphene and 1.0 wt% of Fe2O3 performs the best during the flame retardant tests, giving a shorter self-extinguishing time, lower peak heat release rate (22.3 kW/m2), total heat release (11.3 MJ/m2) and total smoke production (1.32 m2) than others. The pyrolysis analysis indicates that a large number of products with fused rings are formed in the residual char layer, which effectively inhibit the release of heat and smoke and thus improve the flame retardancy of PPS nanocomposite resin. In addition, the flame retardant textile weaved with PPS/G/Fe2O3 fibers gives a high-limiting oxygen index (40.1%), zero after-flame time, no droppings and small damaged length (114 mm in warp and 98 mm in weft direction) during the standard flame retardancy tests provided by a third-party independent inspection organization. The fabrication of PPS fibers with effective and enhanced synergistic flame retardancy through melting spinning is facile and scalable, providing a promising strategy for advanced protective clothing.

Graphical Abstract

Supporting Information

| Filename | Description |

|---|---|

| pol20230032-sup-0001-supinfo.docxWord 2007 document , 1.1 MB | Data S1. Supporting Information. |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

REFERENCES

- 1R. Singh, R. Kumar, L. Feo, F. Fraternali, Compos. Part B: Eng. 2016, 101(15), 77.

- 2Z. Zhao, W. Liu, Y. Jiang, Y. Wan, R. Du, H. Li, J.Clean. Prod. 2022, 359(20), 132134.

- 3K. K. S. Custodio, T. R. Walsh, J. Polym. Sci. 2021, 60(4), 726.

- 4S. Chang, X. Zhou, Z. Xing, T. Tu, J. Colloid Interface Sci. 2017, 498(15), 343.

- 5Z. Yu, J. Liu, A. Suryawanshi, H. He, Y. Wang, Y. Zhao, Cellulose 2021, 28(15), 2581.

- 6Y. Zhang, T.-T. Li, B.-C. Shiu, J.-H. Lin, C.-W. Lou, Appl. Surf. Sci. 2022, 584, 152573.

- 7R. Jeencham, N. Suppakarn, K. Jarukumjorn, Compos. Part B: Eng. 2014, 56, 249.

- 8Y. Liu, W. Zhao, X. Yu, J. Zhang, Y. Ren, X. Liu, H. Qu, J. Wang, Compos. Part B: Eng. 2022, 245, 110194.

- 9Y. Hua, B. Ding, S. Jiang, H. Li, X. Gu, S. Zhang, Compos. Commun. 2022, 35, 101308.

- 10A. B. Morgan, P. Mukhopadhyay, J. Mater. Sci. 2022, 57(14), 7155.

- 11X. Su, C. Cheng, Y. Zheng, X. Liu, Y. Ren, J. He, S. Lin, B. Cheng, Cellulose 2021, 28(5), 3201.

- 12T. P. Molaba, S. Chapple, M. J. John, J. Appl. Polym. Sci. 2016, 133(46), 44175.

- 13Y. Liu, L. Ye, Y. Shu, X. Zhao, Compos. Part A: Appl. Sci. Manuf. 2018, 115, 274.

- 14X. Chen, Z. Wei, W. Wang, C. Jiao, Polym. Adv. Technol. 2019, 30(1), 170.

- 15Y. Yu, G. Jia, L. Zhao, H. Xiang, Z. Hu, G. Xu, M. Zhu, Chem. Eng. J. 2023, 452(15), 139112.

- 16Y. Yu, L. Ren, M. Liu, S. Huang, X. Xiao, R. Liu, L. Wang, W. Xu, ACS Appl. Mater. Interfaces 2019, 11(34), 31291.

- 17Y. Yu, D. Pan, L. Zhao, S. Huang, P. Lin, Z. Wang, Y. Jia, H. Wang, L. Wang, Adv. Fiber Mater. 2022, 4(5), 1246.

- 18Y. Yu, W. Xiong, H. Huang, L. Zhao, K. Nie, S. Chen, J. Xu, Z. Yin, H. Wang, L. Wang, React. Funct. Polym. 2022, 150, 104539.

- 19L. Dai, Z. Hu, Z. Zhou, M. Zhu, Synth Fiber China 2022, 51(8), 27.

- 20B. Yuan, Y. Hu, X. Chen, Y. Shi, Y. Niu, Y. Zhang, S. He, H. Dai, Compos. Part A: Appl. Sci. Manuf. 2017, 100, 106.

- 21B. Yuan, Y. Sun, X. Chen, Y. Shi, H. Dai, S. He, Compos. Part A: Appl. Sci. Manuf. 2018, 109, 345.

- 22S. Liu, Z. Fang, H. Yan, V. S. Chevali, H. Wang, Compos. Part A: Appl. Sci. Manuf. 2016, 89, 26.

- 23C.-Y. Chang, S.-P. Ju, J.-W. Chang, S.-C. Huang, H.-W. Yang, RSC Adv. 2014, 4(50), 20674.

- 24M. Hojamberdiev, Z. C. Kadirova, S. S. Daminova, K. Yubuta, H. Razavi-Khosroshahi, K. T. Sharipov, M. Miyauchi, K. Teshima, M. Hasegawa, Appl.Surf. Sci. 2019, 466(1), 837.

- 25M. Wang, K. Deng, W. Lu, X. Deng, K. Li, Y. Shi, B. Ding, Z. Cheng, B. Xing, G. Han, Z. Hou, J. Lin, Adv. Mater. 2018, 30(13), e1706747.

- 26J. C. Wang, J. Ren, H. C. Yao, L. Zhang, J. S. Wang, S. Q. Zang, L. F. Han, Z. J. Li, J. Hazard. Mater. 2016, 311(5), 11.

- 27E. M. Sullivan, P. Karimineghlani, M. Naraghi, R. A. Gerhardt, K. Kalaitzidou, Eur. Polym. J. 2016, 77, 31.

- 28J. Teno, G. González-Gaitano, J. González-Benito, J. Polym. Sci. B Polym. Phys. 2017, 55(21), 1575.

- 29Y. Gao, K. Su, X. Wang, Z. Li, J. Membr. Sci. 2019, 574(15), 55.

- 30Z. Hu, K. Hou, J. Gao, G. Zhu, Z. Zhou, H. Xiang, T. Qiu, M. Zhu, Compos. Part A: Appl. Sci. Manuf. 2020, 129, 105716.

- 31X.-Y. Ma, T.-T. Fan, G. Wang, Z.-H. Li, J.-H. Lin, Y.-Z. Long, Compos. Commun. 2022, 29, 101017.

- 32H. Uematsu, K. Yoshida, A. Yamaguchi, A. Fukushima, S. Sugihara, M. Yamane, Y. Ozaki, S. Tanoue, Compos. Part A: Appl. Sci. Manuf. 2023, 165, 107355.

- 33H. Wang, Z. Zhu, J. Yuan, H. Wang, Z. Wang, F. Yang, J. Zhan, L. Wang, Compos. Commun. 2021, 27, 100852.

- 34B. Yuan, A. Fan, M. Yang, X. Chen, Y. Hu, C. Bao, S. Jiang, Y. Niu, Y. Zhang, S. He, H. Dai, Polym. Degrad. Stab. 2017, 143, 42.

- 35X. Peng, Q. Liu, D. Wang, C. Liu, Y. Zhao, R. Wang, P. Zheng, Compos. Part B: Eng. 2021, 224(1), 109162.

- 36D. Wang, H. Peng, Y. Wu, L. Zhang, M. Li, M. Liu, Y. Zhu, A. Tian, S. Fu, ACS Sustain. Chem. Eng. 2020, 8(11), 4331.

- 37Q. Chen, L. Liu, A. L. Zhang, W. D. Wang, Z. Z. Wang, J. Z. Zhang, J. B. Feng, S. Q. Huo, X. S. Zeng, P. G. Song, Chem. Eng. J. 2023, 448, 137661.

- 38W. Cai, X. M. Feng, B. Wang, W. Z. Hu, B. H. Yuan, N. G. Hong, Y. Hu, Chem. Eng. J. 2017, 316(15), 514.

- 39Y. Guo, C. Zuo, W. Tan, Y. Liu, L. Jiang, D. Yu, Y. Ren, X. Liu, Polym. Degrad. Stab. 2022, 206, 110176.

- 40S. Li, Y. Liu, Y. Liu, Q. Wang, Compos. Part B: Eng. 2021, 223(15), 109115.

- 41H. Ou, J. Xu, B. Liu, H. Xue, Y. Weng, J. Jiang, G. Xu, Polymer 2021, 221(14), 123586.