Surfactant-Free Emulsion Polymerization of Various Methacrylates: Towards Monodisperse Colloids for Polymer Opals

Abstract

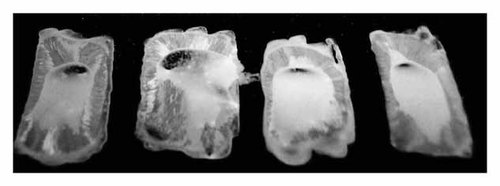

Summary: A systematic investigation of the surfactant-free emulsion polymerization (SFEP) on three different methacrylates (MMA, tert-butyl methacrylate and 2,2,2-trifluoro ethyl methacrylate) is described to obtain monodisperse colloids for the preparation of artificial “polymer opals”. The experimental results are in agreement with a model, in which seed particles are formed very early during the polymerization process. The particles grow afterwards into the colloids until all monomer is consumed. This gives rise to a linear relationship between the volume of the colloids and the ratio of monomer to water in the reaction batch. The concentration of the seed particles depends thereby on the hydrophobicity of the monomers and can be varied by the addition of salt. The relationship between the composition of the reaction batch and the size of the colloids differs from monomer to monomer. It can, however, be described for all systems by the introduction of an empirical system dependent parameter pM (master curve). It is thus possible to predict the colloidal size for new monomer (or salt) systems from a single measurement point. Colloids with a diameter of more than 500 nm can be prepared by a two stage seeded polymerization. The colloids prepared with this method are so monodispersed (well below 5%) that they can easily be crystallized into artificial polymer opals of a high optical quality.