Polypropylene Made with In-Situ Supported Me2Si(Ind)2ZrCl2 and Me2Si(2-Me-Ind)2ZrCl2 Catalysts: Properties Comparison

Abstract

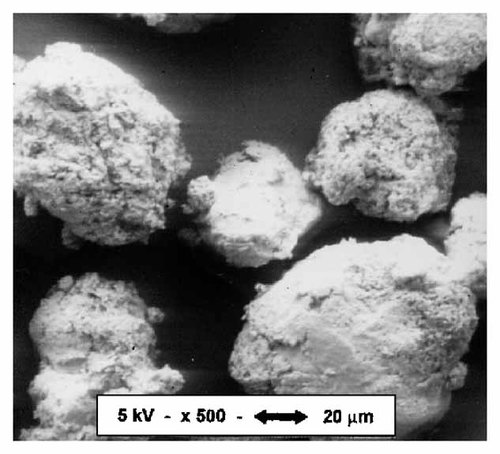

Summary: Propylene homopolymerizations were carried out using Me2Si(Ind)2ZrCl2 and Me2Si(2-Me-Ind)2ZrCl2, MAO-modified silica, and common alkylaluminum cocatalysts. Supported catalysts were prepared by the in-situ immobilization technique. The effect of the type and concentration of alkylaluminum on propylene polymerization was evaluated using TEA (triethylaluminum), IPRA (isoprenylaluminum), and TIBA (triisobutylaluminum) as cocatalysts. The polymers were analyzed by gel permeation chromatography (GPC), differential scanning calorimetry (DSC), and scanning electronic microscopy (SEM). The effect of the type and concentration of alkylaluminum on the melting temperature and the molar mass of the polypropylene was the same for both catalysts. The polymers made with in-situ supported catalyst had lower melting points and, in almost all polymerization conditions, higher molar masses than those produced by homogeneous polymerization. Polypropylene samples made with Me2Si(2-Me-Ind)2ZrCl2 had higher melting temperatures and molar masses than those made with Me2Si(Ind)2ZrCl2. SEM micrographs showed that the polymers obtained with in-situ supported systems had a well-defined morphology, confirming that the polymerization indeed took place onto the silica support.