Nitrite-reducing performance of two Lactobacillus strains isolated from traditional Sichuan fermented sausage in different production processes

Abstract

Two lactic acid bacteria (LAB) strains were screened in traditional Sichuan sausage, and their nitrite-reducing performance in different production processes was determined in this study. LAB were isolated from traditional Sichuan sausages and identified by 16S rDNA sequencing. The effects of the isolated bacteria on the bacterial community, physicochemical properties, and nitrite-decreasing capacity during sausage fermentation were investigated by comparing nonactivated treatment and activated treatment at 30°C. The results showed that the screened two LAB strains were identified as Pediococcus pentosaceus and Leuconostoc mesenteroides, which adapted well to the new habitat of fermented sausage, reaching a maximum of 7.00 and 7.32 lg CFU g−1 in the nonactivated treatment, 7.65 and 7.52 lg CFU g−1 in the activated treatment, and the two strains had strong acidizing potential, which could inhibit the growth of saprophytic bacteria. Otherwise, the activated treatment was better than the traditional process for nitrite degradation and fermentation time, except for color. Both strains contribute to nitrite consumption while reducing fermentation time and sausage production cycles. In conclusion, these two strains are expected to be the starting point for the improvement of biological safety and nitrite residue control in traditional Sichuan sausage production.

1 INTRODUCTION

Sausage products are among the favorite foods of people all over the world. In the long history of the development of Chinese sausages, spicy and salty Sichuan flavor sausages have become one of the most important types of sausages in China (X. Wang et al., 2019). However, traditional Sichuan sausage is naturally fermented, and it is difficult to maintain the consistency of the quality and flavor of different batches of sausages. In addition, the traditional production process of the sausage requires a long fermentation time, which is not favorable for mass production. Moreover, the growth of foodborne pathogenic microorganisms like Salmonella, Listeria monocytogenes, Staphylococcus aureus in the sausage often causes food safety problems and affects the development of the industry (Song et al., 2019).

The use of artificial pigments and fragrances is not allowed in meat fermentation processing processes. To date, nitrites and nitrates are an indispensable addition to conventional meat processing. Nitrites are usually used to improve the flavor and color; microbial safety color and flavor are quality parameters of fermented meats (Kim & Hur, 2018; Ku & Ho, 2016). This has an excellent effect on reducing pathogenic microorganisms in sausage fermentation and improving food biosafety. However, nitrites in combination with certain amines or amides could potentially form N-nitroso compounds (NOC), which can cause cancer in animals and had been classified as carcinogenic to humans by the International Agency for Research on Cancer (IARC) in 1978 (IARC, 1978; Karl-Otto, 2008; Natalia Campillo et al., 2011; Zhan et al., 2014). However, to reduce the harmful microbial organisms and increase the shelf life of the sausage, people usually add excess nitrite to sausage products. For example, in 23% of meat products, the nitrite levels were above the permitted standard during 2000–2011 in China, which pose safety risks to consumers (Zhan et al., 2014; H. Zhang et al., 2017). As consumers become more and more concerned about food safety, producers reduce their use of nitrite as far as possible, researchers are looking for a way to degrade it. Therefore, finding a beneficial microorganism that can reduce nitrite is of vital importance to ensure the safety of sausage.

Selected probiotic strains, some isolated from organic whey, can be used to make cured sausages by raw ripening, and the resulting products can be stored for 6 months under refrigerated conditions without reductions in their oxidative stability. The literature indicates that some strains of bacteria belonging to the genera Lactobacillus and Bifidobacterium have antioxidant activity and are antagonistic to pathogenic microflora; they can provide oxidative stabilization as well as fermented food, extending shelf life storage stability (Nicholas & Oliver, 2019). At the same time, they are characterized by good microbiological, chemical, and sensory qualities (Anna et al., 2019; Chlebowska-Smigiel et al., 2017). Many studies have shown that the starter culture can influence the nitrite concentration in Chinese pickled vegetables (Jung et al., 2019; Lee et al., 2019; J. Zhang et al., 2022) and meat products (Chen et al., 2016; Paik & Lee, 2014). Lactic acid bacteria (LAB) was recognized by the FAO and WHO as the only bacteriocin preservative used in food as early as 1969. Their presence effectively prevents harmful bacterial growth and controls the fermentation processes. During the fermentation, acids and alcohol are produced, leading to a decrease in pH (Ammor & Mayo, 2007), which makes LAB become advantageous microorganisms in fermented products. Among different LAB, Lactobacillus pentosus and Leuconostoc mesenteroides show nitrite depletion ability in fermented products (H. S. Kim & Hur, 2017; Xiao et al., 2018).

In Sichuan traditional sausage production, a large number of fermented condiments are added and dried at low temperatures, and the microorganisms in the condiments only proliferate a little, as if they are not activated. This is very different from the western sausage through the high temperature and humidity conditions to activate the microorganisms in the sausage and promote their proliferation. The condiments of Sichuan sausage provide LAB for the sausage. According to the preliminary study, it was found that even if nitrite was added, the content of nitrite in Sichuan sausage was low and even difficult to be detected after it was mature. Western fermented sausage can make LAB multiply, thereby reducing pH and degrading nitrite. Can the low-temperature air-drying conditions of Sichuan sausage production also have an effect on nitrite degradation? Therefore, this paper aims to study the ability of nitrite-reducing performance under different production and processing conditions of two LAB isolated from Sichuan traditional sausage.

2 MATERIALS AND METHODS

2.1 Sausage samples

The sausage samples used for LAB isolation were made in the traditional way in the Meat Processing Key Laboratory of Sichuan Province. Briefly, the sausage formulation contains lean pork 700 g, fat 300 g, thick broad-bean sauce 40 g, fermented bean curd 15 g, fermented soya beans 20 g, fermented glutinous rice 30 g, salt 8 g, monosodium glutamate (MSG) 1.5 g, and compound spices 3 g. All ingredients were mixed and placed in a vacuum tumbler for 30 min and soused for 24 h. The sausage mixture was then stuffed into a hog casing and hung in the air-dry house for 10 days. The temperature was controlled at 12°C in the day and 8°C at night; the air speed was 1.1–1.2m s−1, and the humidity was kept at 50 ± 5%. The ripened sausage was vacuum-packed and stored at 4°C and used for bacteria isolation within 2 days.

2.2 Isolation, screening, and identification of LAB strains

The 25 g samples were aseptically obtained from the ripened sausage and homogenized with 225 ml sterile saline in a flap homogenizer. Dilution samples were spread on de Man, Rogosa, and Sharpe agar (MRS, Luqiao) with 5% CaCO3 and incubated at 30°C for 48 h. The Gram-positive colonies with a transparent circle were streaked on MRS agar until purified. The isolates were incubated in MRS at 30°C for 24 h, and the colonies were stored in a magnetic bead preservation tube at −80°C until use. The ability of the isolates to reduce and tolerate nitrites was examined as described by Chen et al. (2016). The strains were first grown for 12 h in 20 ml MRS at 30°C and then inoculated at 30°C for 48 h with 106 CFU ml−1 and 100 mg L−1 NaNO2 in 150 ml MRS. The amounts of residual sodium nitrite were tested after 0, 4, 8, 12, 24, and 48 h of incubation.

The isolates with significant nitrite-reducing activity were first investigated by a microbial identification system (Biolog). The utilization of 95 carbon sources by the strains was tested against the GEN III board and BLAST data in Biolog microbial identification system. Then, the overnight cultured strains in MRS broth (1 ml) were centrifuged at 10,000 g for 1 min and at 4°C to precipitate the cell pellets, and genomic DNA was extracted using a DNA isolation kit for 16S ribosome sequencing (universal primers: 27 F: 5′-AGAGTTTGATCMTGGCTCAG-3′; 1492 R: 5′-TACGGYTACCTTGTTACGACTT-3′) (Tiangen). The amplified sequences were sent to Sangon Biotech (Shanghai) Co., Ltd. for determination and compared with the GenBank database (https://www.ncbi.nlm.nih.gov/) with a BLAST analysis.

2.3 Fermented sausage manufacture

Two strains with the strongest activity (MPKL03 and MPKL04) were selected to produce sausage. Briefly, the isolates were inoculated into 500 ml MRS broth and grown overnight at 30°C. The broth to be incubated was centrifuged at 10,000 g for 15 min and at 4°C; the cell pellets were washed twice with 0.85% (w/v) normal saline 200 ml and resuspended in 50 ml of 10% skim milk solution, and then freeze-dried. The lyophilized starter culture powders were stored at −20°C until use.

Activation of sausage refers to the process of placing sausage in an environment suitable for the growth of fermentation bacteria to promote bacterial colonization and proliferation. This study investigated the influence of activation on the fermentation of sausage by two strains of bacteria. The experiment was divided into activated and nonactivated sausage treatments, each including three groups, (A1) a control group (noninoculated group), (A2) the MPKL03 group, and (A3) the MPKL04 group, and each group was used in triplicate. The same formula was used for both the activated and nonactivated treatments, including lean pork 700 g, fat pork 300 g, salt 8 g, MSG 1.5 g, complex spices 3 g, and sodium nitrite (analytically pure, ≥99.0%) 0.1 g. For the LAB treatments, an appropriate amount of starter culture (approximately 1.0 × 107 CFU g−1) was added to each group (Cencigoga et al., 2016; Franciosa et al., 2018). The manufacture of the nonactivated treatment was placed in a vacuum tumbler for 30 min and soused for 24 h, while the ripening process of the activated treatment involved 2 days of fermentation at 30°C and then the same method used for the nonactivated treatment. Subsequently, the sausage mixture was stuffed into a hog casing and then hung in the air-dry house. The samples were collected on Days 0, 1, 2, 5, 10, 17, and 24 in the nonactivated treatment, and Days 0, 1, 2, 5, and 10 in the activated treatment. All of the analyses were conducted immediately after sampling.

2.4 Microbiological analysis

Samples (25 g each) for each treatment were aseptically obtained from the center of three sausage links and homogenized in 225 ml sterile saline (0.85% NaCl) in a flap homogenizer (SCIENTZ). Serial 10-fold dilutions were prepared and spread-plated in triplicate on appropriate growth media agar. The total bacteria were counted on Plate Count Agar (PCA) (Luqiao) after 24 h at 37°C. The LAB was enumerated on MRS agar in anaerobic conditions after 48 h at 30°C, and Micrococcaceae were counted on Mannitol Salt Agar (Luqiao) after 48 h at 37°C.

2.4.1 Water activity, moisture content, and pH detection

The water activity of the sausage samples was measured with an HD-3A Water Activity Meter (Shanghai Precision Scientific Instrument) at 25°C. The moisture content of the sausage samples was measured by the direct drying method, which dried 1.0 g of sausage to constant weight at 115°C. The pH was determined by inserting a PHS-3C-01 pH meter probe (Shanghai Sanxin) into the sausage samples, three replicates were set in different groups.

2.5 Nitrite residue analysis

Nitrite residues in the sausages were determined as described by Ito and colleagues (Grecco et al., 2016). Briefly, 10 g of the homogenized sausage was accurately weighed into a conical flask, and 5 ml of saturated borax solution (50 g L−1 Na2B4O7·10H2O) and 100 ml of boiled double-distilled water was added. The flask was heated in a boiling water bath for 15 min and then cooled to room temperature (22 ± 2°C). Reagent I (106 g L−1 K4 Fe (CN)6·3H2O) and reagent II (220 g L−1 Zn (CH3COO)2·2H2O, 30 ml L−1 glacial acetic acid), 2 ml each, were added. After mixing, the contents were transferred to a volumetric flask, and the final volume was brought to 200 ml with double-distilled water. It was then filtered through a layer of No. 42 filter paper (GE HealthCare Life Sciences). Twenty milliliters of the clear filtrate were mixed with 1 ml each of 2 g L−1 sulfanilamide, 1 g L−1 N-1-naphthyl-ethylene-diamine dihydrochloride, and HCl solution (445 ml of concentrated HCl diluted to 1000 ml with double-distilled water). After incubation at room temperature for 3 min, the contents were transferred to a volumetric flask, and the final volume was brought to 25 ml with double-distilled water. Configure nitrite standard to 10, 20, 30, 50, 100, 150, and 200 mg L−1. The pretreatment was carried out according to the nitrite detection method, and finally, the OD (optical density) value was determined at 540 nm, and the data obtained were plotted with the standard curve, and the standard curve in the range of 10–200 mg L−1 was y = 0.0042x + 0.1484, R2 = 0.9973. The nitrite content was determined according to the standard curve. The absorbance of the chromophore was measured at 540 nm using a UV-1800pc spectrophotometer (Mapada). Three replicates were set in different groups.

2.5.1 Color determination

Color measurements were taken with a CR-400 colorimeter (Konica-Minolta) using an 8 mm port size, illuminant D65, and a 10° standard observer. The colorimeter was calibrated using a white standard plate. The middle of the sausage from each treatment was cut into pieces and covered with polyethylene film to avoid bubbles. Only the lean color was measured. Three replicates were set in different groups. The values are expressed as L* (lightness), a* (redness), and b* (yellowness), and values were obtained from six different cross-section areas at ambient temperature.

2.6 Statistical analysis

All of the results in this article are expressed as the mean value (n = 3) and standard deviation (SD). After verification of a normal distribution and constant variance of the data, a one-way analysis of variance (ANOVA) with Duncan's test was applied to determine whether the differences between groups were significant (SPSS v.24, IBM Corp.). A value of p < 0.05 was considered significant, while a p < 0.01 was considered highly significant.

3 RESULTS AND DISCUSSION

3.1 Screening of LAB strains

In this study, a total of 25 strains of MRS containing a transparent ring and with Gram-positive staining were screened out from the Sichuan fermented sausage. According to Ammor and Mayo (2007), the acidogenic capacity of LAB allows pH <5.1 as a selection criterion, and five strains were eliminated; eight strains were excluded by gas production. The remaining 12 screened isolates were obtained and their degradation ability was then detected by their nitrite-reductive activity and nitrite-tolerating capability.

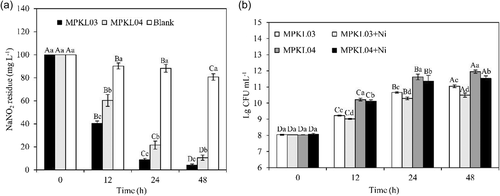

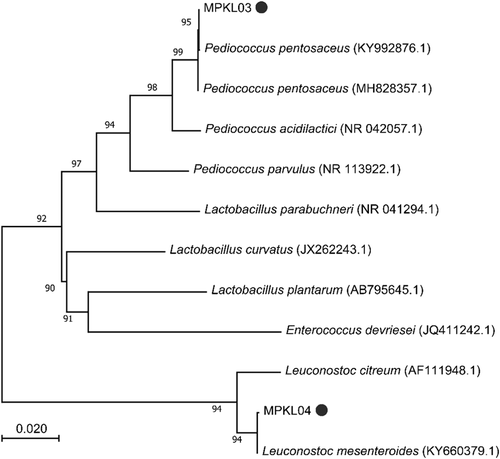

Through the above-screening procedures, two isolates (MPKL03 and MPKL04) showed significant nitrite-reducing and nitrite-tolerating capability. The depletion rate of nitrite in the MPKL03 treatment was 91.29% and that in the MPKL04 treatment was 89.49% for 24 h (Figure 1a). Meanwhile, two strains (1 × 108 CFU ml−1) grew well when cultured in 100 mg L−1 NaNO2 for 24 h, reaching 1.95 × 1010 and 2.29 × 1011 CFU ml−1 (Figure 1b). According to the carbon source utilization of GEN III and the genetic analysis based on the 16S rDNA sequences, MPKL03 and MPKL04 were identified as Pediococcus pentosaceus and Leuconostoc mesenteroides (Figure 2).

The nitrite added during production reacts with the lactic acid in the sausage to produce nitrate, which is unstable and forms nitrogen oxide. It combines with hemoglobin and myoglobin in the meat to produce bright red nitroso myoglobin and nitroso hemoglobin, which make the sausage appear bright red. It is also possible to reduce nitrite to N2 and release it into the atmosphere under the action of microorganisms. The degradation of nitrite has no potential hazards for the safety of the sausage.

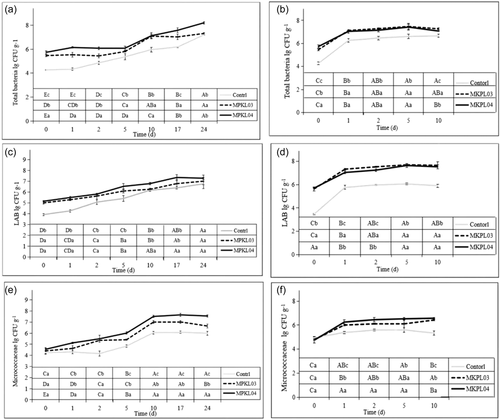

3.1.1 Microfloral profile of the fermented sausages

Moreover, the total bacterial count reflected the general trend of microorganisms in sausage. LAB is an important kind of bacteria for flavor formation in the production of traditional fermented sausage (Yuchen et al., 2016), and Micrococcaceae is another dominant bacterial type in fermented meats (Cencigoga et al., 2016; Eduardo et al., 2019; Xiao et al., 2017). The numbers of the total bacteria, LAB, and Micrococcaceae were counted in this experiment, and the results are shown in Figure 3. In general, activation affected the growth of microorganisms in the sausage, with bacteria growing faster in the activated group and slower in the inactive group during the first 2 days. In addition, the bacteria in the activated sausage gradually reached a saturation state after 2 d of fermentation, while it took nearly 10 d for the nonactivated sausage to reach a similar state. Further, the number of total bacteria and LAB did not change significantly after the two treatments. However, the number of Micrococcaceae in the nonactivated treatment was higher than that in the activated treatment. These results showed that the activation treatment could promote the rapid proliferation of total bacteria and LAB but inhibit the proliferation of Micrococcaceae. Micrococcaceae are sensitive to acid, while LAB are the dominant bacteria in fermented sausage (Papamanoli et al., 2002). Therefore, we speculate that with the increase in the number of LAB, the pH decreases, thus inhibiting the proliferation of Micrococcaceae bacteria.

This study also found that the introduction of MPKL03 or MPKL04 could promote the growth of bacteria in sausage, and the numbers of total bacteria, LAB, and Micrococcaceae in the MPKL03 and MPKL04 groups were significantly higher than those in the naturally fermented control group. In addition, the two groups showed differences in the nonactivated treatment, with higher bacteria in the MPKL04 group than in the MPKL03 group, but this difference was not observed in the activated treatment (Figure 4).

LAB can use sugar sources to produce a large amount of lactic acid and other organic acids through fermentation, which can reduce the pH to inhibit the growth of saprophytes in sausage (Ammor & Mayo, 2007; Z. et al., 2015). X. H. Wang et al. (2013) inoculated fermented sausages with Latilactobacillus sakei and this study showed that the production of lactic acid by L. sakei reduced the pH of the sausages to 4.52 and significantly reduced the nitrite content. In addition, some LAB contain nitrite reductase, which can also reduce nitrite levels (Huang et al., 2021). Thus, the rapid increase in the number of LAB under the activation treatment favors the accelerated consumption of nitrite. Micrococcaceae are involved in nitrite reduction, lipid and protein degradation, color development, and flavor production (Gøtterup et al., 2008). The Micrococcaceae came from the meat and environment in this study, and it seems that low-temperature processing was beneficial for the growth of Micrococcaceae. This study found that MPKL03 and MPKL04 stimulated the growth of LAB and Micrococcaceae, with LAB growing well in the activated treatment and Micrococcaceae growing well in the nonactivated treatment. Acidification is considered the main cause of Micrococcaceae inhibition in fermented sausages (Eda et al., 2018). Therefore, LAB may competitively inhibit the growth of Micrococcaceae, and the effect of this on sausage fermentation needs to be studied further.

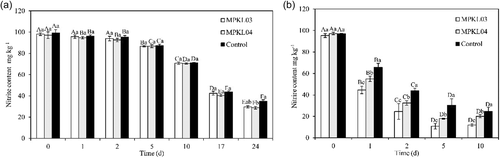

3.1.2 Nitrite depletion in sausages

Nitrite is allowed in meat at less than 150 mg kg−1, and its residue needs to be less than 30 mg kg−1 in China (Authority, 2010). It is used to prohibit the growth of harmful bacteria, such as Clostridium botulinum, and to protect the color. However, excessive nitrite leads to the production of nitrosamines, which are carcinogenic substances (Yyh et al., 2021). In this study, the nitrite content of the sausage in each group was adjusted to 100 mg kg−1 to study the effects of different treatments and MPKL addition on its degradation ability. The content of nitrite in each group showed a decreasing trend in which the rate of nitrite decline in the activated treatment was significantly faster than that in the nonactivated treatment. The nitrite decreased nearly fivefold in the activated treatment after 10 days, while it decreased only threefold in the nonactivated treatment by 24 days. In addition, MPKL03 and MPKL04 showed a greater ability to reduce nitrite in activated treatment. Under the nonactivated treatment, there was a slight decrease of nitrite in the LAB supplement groups (MPKL03 and MPKL04) compared to the control group, only showing a significant difference between these groups on the 24th day (the control group was 35.02 mg kg−1, the MPKL03 group was 29.64 and the MPKL04 was 28.79 mg kg−1) (p < 0.05). However, after activation treatment, the ability to decrease nitrite in the LAB supplement groups was significantly stronger than that in the control group (p < 0.05). Yan et al. (2008) showed that among the many LAB isolated from Chinese paocai, P. pentosaceus and L. mesenteroides had a high nitrite degradation capacity. In addition, the ability to decrease nitrite in the MPKL03 group was significantly stronger than that in the MPKL04 group (p < 0.05). The activated treatment group dropped to the national limit on the 10th day, but the other group on the 24th day. Based on this, the physical and chemical, and microbiological indicators of each group were tested. Therefore, two different experimental observation times were set. The hedging period of the activated treatment group is 5–6 months. The preservation period of Sichuan Traditional sausage is over 6 months.

The level of nitrite residues is important for sausage safety. Nitrite residues in sausage sometimes exceed the national standards, as has been reported in individual workshops, which may be caused by a poor production environment and contaminated materials and equipment. In this study, by controlling the natural environmental factors, such as wind speed, wind direction, temperature, and humidity changes during the processing of Sichuan traditional sausage, the optimal technological conditions suitable for sausage processing were designed (Zhu et al., 2019). Among them, the sausage curing method of the control group with nonactivated treatment was the same as that of Sichuan traditional sausage. This study found that the traditional production process of Sichuan sausage also had a certain effect on the reduction of nitrite, but it took a long time, and the activation treatment was conducive to accelerating the removal of nitrite. In addition, MPKL03 and MPKL04 also showed strong nitrite reduction abilities, which were significantly stronger in the activated treatment. Therefore, the activation treatment and the supplementation with LAB may contribute to the technical structure optimization of the traditional sausage production process (Roselino et al., 2017).

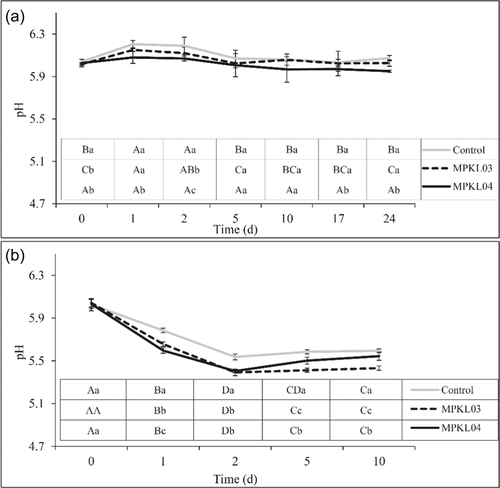

3.1.3 PH, moisture content, and water activity

After the initial treatment of the sausage, the pH of each group was approximately 6.0, and the pH value volatility of each group is shown in Figure 5. The results showed that the pH of the sausage in the nonactivated treatment group fluctuated at approximately 6 during the fermentation process, while in the activated treatment group, it decreased significantly (Pei et al., 2017; Qing et al., 2020; Yefang et al., 2018). It has been shown that lower pH can accelerate nitrite consumption (Izumi et al., 1989; X. H. Wang et al., 2013). Additionally, MPKL03 and MPKL04 could further reduce the pH. In the nonactivated treatment, the pH was high in the control group, medium in the MPKL03 group, and low in the MPKL04 group, but there was no significant difference between the three groups. The changes in pH largely corresponded to the growth of LAB, and the activation treatment showed that the LAB approached saturation when pH dropped to a minimum on the 2nd day. Notably, the activated treatment showed a significant decrease on the 2nd day, followed by a small rebound. This is probably due to the fact that protease in microorganisms promotes proteolysis, producing basic peptides, amino acids, and amines that provide buffering (Lorenzo et al., 2014). The control group was again at a high level, with the middle in the MPKL04 group and a low level in the MPKL03 group. The results showed that the change in pH was related to the bacteria and the activated treatment of the sausage, which may help to reduce the proliferation of saprophytes in sausage fermentation (de Barros et al., 2010). Cheng An et al. found that there was a significant decrease in L. monocytogenes and Salmonella Typhimurium in sausages at pH values of 5.2 to 4.6 (Hwang et al., 2009).

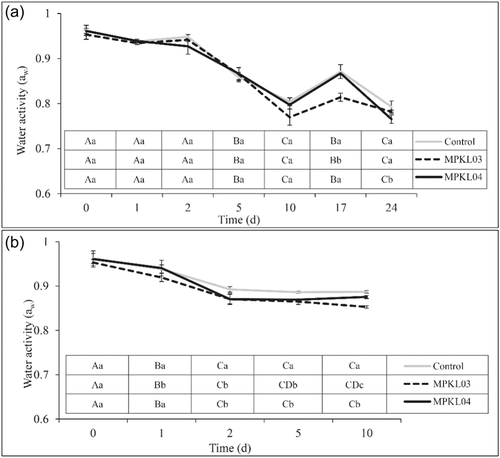

The water activity of the sausage can distinguish the fermentation state of the product, in which 0.9 indicates that the sausage is in semidry fermentation (Arslan & Soyer, 2018). In this study, the effects of different treatments on the water activity of the sausages are shown in Figure 6. The water activity began to decrease below 0.9 on the 4th day under nonactivated treatment, while it decreased to the same level on the 2nd day under the activated treatment. The water activity of the nonactivated treatment decreased to 0.8 and fluctuated around there by the 10th day, while that of the activated treatment fluctuated approximately 0.86. Semidry fermentation with different water activities may affect the enzyme activity of microorganisms (Jia et al., 2022). Additionally, the number of microorganisms under the noactivated treatment was lower than that in the activated treatment (Figure 7), which may be related to the different water activity levels. In addition, water activity decreased below 0.9 faster in the MPKL03 group and the MPKL04 group than in the control group under the activated treatment, which may help the sausages enter the dry fermentation state more quickly.

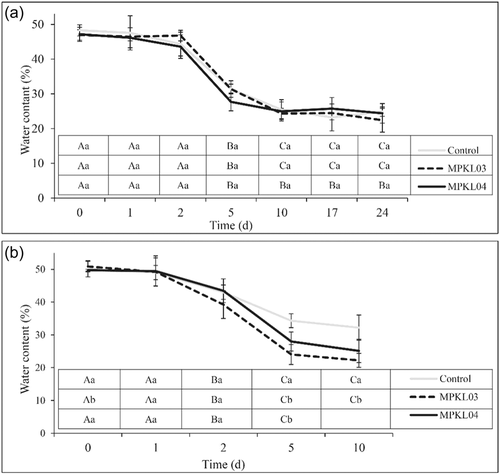

A sausage with less than 30%–50% moisture content is considered the mark of complete fermentation (Q. Zhang et al., 2017). The results showed that there was no significant difference in the effects of the activated treatment and nonactivated treatment on sausage moisture content, and both reached the minimum state of approximately 10 d (Figure 7). In addition, each group under the nonactivated treatment showed the same change trend of moisture content during fermentation. However, the moisture content in the MPKL04 group and the MPKL03 group decreased significantly faster than that in the control group (p < 0.05), and the capacity of MPKL03 was stronger than that of MPKL04. The study showed that activated treatment had no significant effect on sausage moisture, while LAB supplementation could accelerate the consumption of moisture in the sausage, which would shorten the fermentation time of the sausage, and this result was consistent with that of Lorenzo et al. (2011).

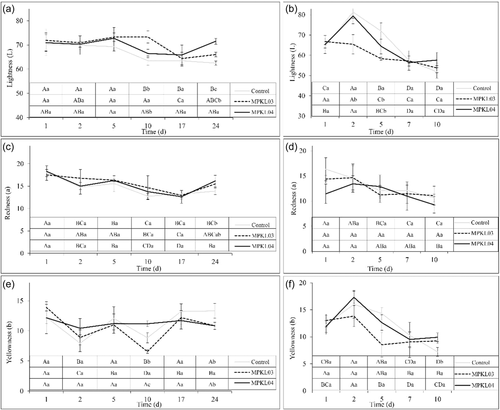

3.2 Color of sausages

The sausage color changes are shown in Figure 8. The brightness (L) and red (a) of the nonactivated treatment decreased gradually, while yellow (b) fluctuated slightly. The brightness (L) and red (a) under the activated treatment increased slightly with the temperature increase in the first 2 days and then gradually decreased with the temperature decrease in the next 2 days; yellow (b) decreased gradually. On the 10th day, the nonactivated treatment was brighter and redder than the activated treatment. In addition, the changes in the LAB supplement group were the same as in the control group. The results showed that the LAB had little effect, but the different treatments had greater effects on the color of the sausage (Blanco-Lizarazo et al., 2018). In addition, the activated treatment had a weaker effect on color generation, which may be related to the fewer Micrococcaceae after activation treatment (Gøtterup et al., 2008).

4 CONCLUSIONS

Traditional Sichuan sausages have a long history in China. However, the traditional fermentation method is greatly affected by the environment and has the disadvantages of unstable flora, a long production cycle, and difficult quality control. Therefore, safety cannot be guaranteed, which is an important factor restricting the traditional Sichuan fermented meat products. Therefore, it is very important to develop a good fermenting technique, which not only helps to shorten the fermentation time but also can realize the large-scale production of fermented meat products, and also effectively control the quality and ensure food safety.

In this study, strains of bacteria that degraded nitrite were isolated from traditional Sichuan sausage, and they were used as the starter cultures to study their role in the production of fermented Sichuan sausage. The improved technology was also studied through the traditional process (nonactivated treatment) and activated treatment at 30°C, and the effects of the isolated bacteria on the bacterial community, pH, nitrite decreasing capacity, water activity, moisture content, and color during sausage fermentation were investigated. The results showed that the activated treatment was better than the traditional process for nitrite degradation and fermentation time, but the color was not as good as the traditional process. Therefore, it is necessary to make further improvements to achieve the synchronization of nitrite degradation and color enhancement. The improvement of the activated treatment has great advantages for expanding the workshop production of traditional Sichuan sausage. In addition, the screened LAB strains were well adapted to the new habitat of fermented sausage, reaching a maximum of 7.00 and 7.32 lg CFU g−1 in the nonactivated treatment, and 7.65 and 7.52 lg CFU g−1 in the activated treatment. The results showed that the two strains had strong acidizing potential, which could inhibit the growth of saprophytic bacteria and improve microbial safety. These two strains of bacteria are highly adaptable in the fermentation process and can reproduce rapidly, contributing to the consumption of nitrite, improving food safety, and both strains shortened the fermentation time of the sausage and shortened the production cycle of sausage. In conclusion, MPKL03 and MPKL04 are expected to be the starting point for improvements in biological safety and nitrite residue control in traditional Sichuan sausage production.

Based on the research progress at domestic and foreign, the screening methods of sausage ferment and the characteristics of microbial ferment have achieved good results. Lactobacillus and Staphylococcus were mainly screened to be used in the fermentation of sausage. China has rich resources of natural fermentation strains, so it is necessary to utilize good strains resources to develop functional fermented sausages with Chinese characteristics, and more importantly, to make further research on excellent microbial strains. At present, the development of a functional sausage ferment needs further research. In future research, by studying the molecular mechanism of the degradation of nitrite by the two strains of bacteria in this study, and the relevant substances can be found for factory production and then applied to sausage fermentation and cooked meat processing. This provides new ideas for shortening the fermentation time and improving the quality of meat products and meat safety.

AUTHOR CONTRIBUTIONS

Lili Ji: Conceptualization; Writing–original draft; Writing–review and editing. Chunyan Zhou: Data curation; Validation. Jia-wen Ning: Investigation; Visualization. Shu Wang: Formal analysis; Project administration. Qing Nie: Project administration; Validation. Wei Wang: Resources. Jiamin Zhang: Investigation. Zhiping Zhao: Supervision. Lili Ji and Chunyan Zhou contributed the work equally. All authors read and approved the final manuscript.

ACKNOWLEDGMENTS

This study was supported by the Sichuan Provincial Department of Science and Technology Key R&D Project (2020YFN0147); Research and Integration Demonstration of Key Technologies for Quality and Efficiency Improvement of Sichuan Pig Industry Chain; Sichuan University-Suining School-City Cooperation Project (2020CDSN-19); Sichuan Live Pig Innovation Team of National Modern Agricultural Industry System (scsztd-2022-08-07); Natural Science Foundation of Sichuan Province (2022NSFSC1687).

CONFLICT OF INTEREST

The authors declare no conflict of interest.

ETHICS STATEMENT

None declared.

Open Research

DATA AVAILABILITY STATEMENT

The data used to support the findings of this study are available from the corresponding author upon request.