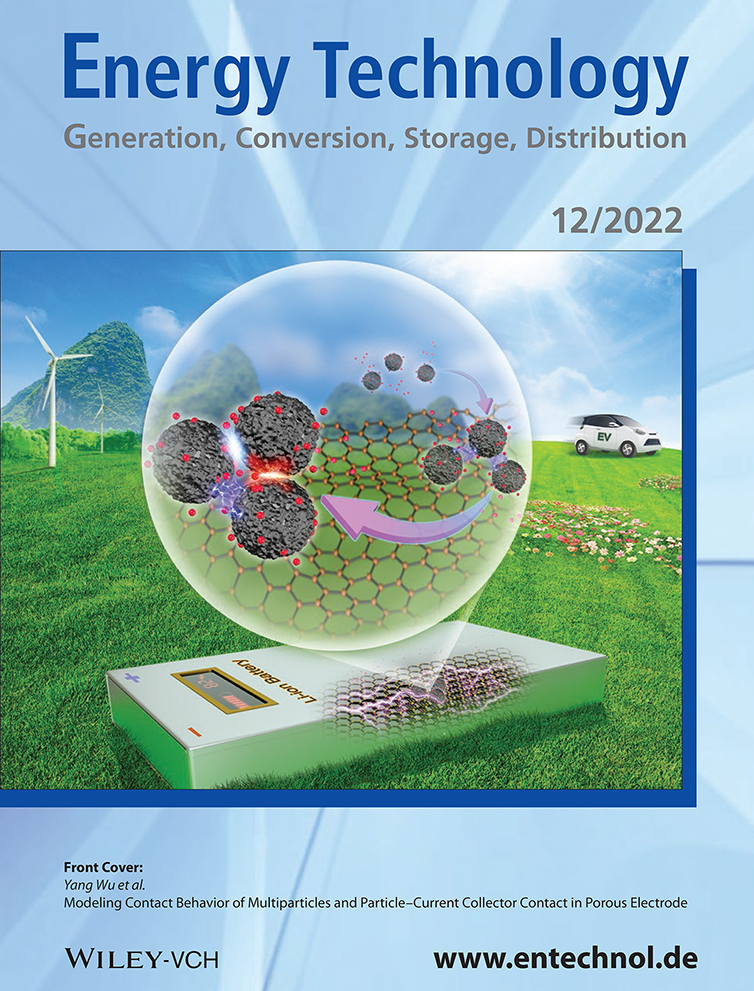

Modeling Contact Behavior of Multiparticles and Particle–Current Collector Contact in Porous Electrode

Abstract

There are various component contacts in porous electrodes, such as the direct contact between the active particles and the particle–current collector, during electrode manufacturing and lithium-ion battery electrochemical cycles. Herein, an electrochemical–mechanical representative volume element model is developed to study the contact behavior of porous electrodes. For the direct contact behavior of multiple particles, stronger battery constraints and larger size differences enhance the reduction in Li-ion concentration in the contact area of the active particles in the porous electrode and the contact stress in the porous electrode particles. For the contact between the active particles and current collector, the decrease in the elastic modulus of the current collector slightly increases the contact radius and significantly reduces the contact stress. By comparing the contact area and contact stress of the smooth and rough current collectors, the latter has a smaller contact area and larger contact stress when in contact with active particles. These findings provide insights into designing Li-ion batteries from the perspective of contact stress to minimize the mechanical failure of porous electrodes.

Conflict of Interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

Research data are not shared.