Characterization of Volatile Release and Sensory Properties of Model Margarines by Changing Fat and Emulsifier Content

Abstract

Fat ratio and emulsifier content of water in oil margarine emulsions changes the sensory properties of the margarines by affecting the volatile release. The effect of fat and emulsifier content on volatile release using headspace/solid phase microextraction/gas chromatography/mass spectrometry (HS/SPME/GC/MS), and sensory properties of model margarine emulsions is investigated. 2-Heptanone, 2-nonanone, 2-undecanone, hexanoic acid, and δ-decalactone releases are found to be lower, while 2,3-butanedion and butanoic acid releases are higher in model margarine with high fat content. Also the releases of 2-nonanone, 2-undecanone, hexanoic acid, and δ-decalactone decreases due to the increase of the emulsifier ratio used in the model margarine. It is found that the hardness and G′ values of the margarines increased together with the increase of fat and emulsifier ratio. In model margarines, butter aroma and taste, cheese aroma and taste are intensely perceived characters by descriptive sensory analysis and they perceived more intensely in products with higher fat content. On the other hand, creamy character is perceived more intensely in model margarines with less fat content. The release of volatile compounds depended on fat and emulsifier content used in the model margarines. Taste and aroma of model margarines are especially affected by the change in fat content while textural properties are affected by both fat and emulsifier content.

Practical Applications: The flavor of the food plays an important role in the consumer's choice of food, and it is influenced by the matrix and composition of the food. Fat is an important part of food, and on the other hand, overconsumption of fat could cause health problems. There is an increasing interest in foods with low fat content for healthier human diets. However, reducing the fat in the product leads to a change in the flavor and texture of the product. Designing the product with the desired properties without affecting the flavor of the food generates problems for the researchers. This study aimed to investigate the effect of fat and emulsifier content on volatiles of model margarine. Knowledge obtained from this study could provide a guide for margarine and spread producers to formulate low-fat margarine by using the data obtained on volatile release and flavor depending on fat content and emulsifier mixture of margarines.

The volatile release and sensory properties of model margarines are affected by fat and emulsifier content. Model margarine emulsions with high fat content has higher 2,3-butanedion and butanoic acid release. Also 2-nonanone, 2-undecanone, hexanoic acid, and δ-decalactone releases decreases with increasing emulsifier content. Butter aroma, butter taste, cheese aroma, and cheese taste are intensely perceived volatiles in high-fat-content model margarines.

1 Introduction

The acceptability of a food product by the consumer depends on its sensory characteristics, especially its flavor.1-3 Flavor perception before and during food consumption is important factors that directs consumer preferences and repurchase behavior.4-6 Volatile flavor compounds are sensed when they come into contact with the receptors in the olfactory epithelium in the nose either they are directly sniffed or transmitted retronasally. Prior to the taste sensation, the volatile flavor components move out from the food and progress in the oral/nasal cavity.7 The headspace concentration of volatiles and speed of volatile release affect the flavor perception.8 The composition and structure of the food product plays an important role on the volatile release and also influence the sensory perception of flavor.9

Oil phase is an important part of food products and also emulsions and oil phase affects both volatile perception and volatile release in addition to food structure and mouthfeel.10 Margarine emulsions consist of two immiscible phases, one of them is dispersed in the other as small droplets; these are known as dispersed phase and continuous phase, respectively.11 Margarine emulsions are water-in-oil (W/O) emulsions containing semisolid fats, water, emulsifiers and other ingredients.3, 12 Margarine emulsions are generally produced with addition of butter aroma compounds. Diacetyl is the main compound of butter aroma, also lactones, butanoic acid, hexanoic acid, aldehydes, and ketones are included in butter aroma mixture used in margarine production. Volatile release from emulsions depends on the physicochemical properties of the volatile compounds and the ingredients in the emulsions and their concentrations.13, 14 Among the factors affecting the release of volatiles in emulsions, oil has a more significant role than any other emulsion ingredient.15 Oils could act as solvents for volatiles and volatile release modulators.16 Volatile release from food matrix could be modified by changing oil content.17, 18

Emulsifiers have critical roles in the formation of emulsions, and they have a strong impact on most of the emulsion properties.19 Emulsion stability increases by using emulsifiers such as monoglycerides, diglycerides, lecithin, sucrose, and sorbitan fatty acid esters. Generally lecithin and mono, and diglycerides were used in margarine emulsions to produce stable W/O emulsions. Emulsifier content and type used in food emulsions influence the volatile release and also flavor and texture of food products. Although there are a many studies conducted on volatile release in O/W emulsions7, 20-23 there are limited studies of W/O emulsions that investigate the effect of fat emulsifier content on the volatile release and flavor. Therefore, the aim of this study was to investigate the effects of fat and emulsifier mixture (lecithin, mono, and diglycerides) content on the volatile release behavior of butter volatile compounds from model margarine emulsion and their effect on flavor.

2 Experimental Section

2.1 Materials

In the production of model margarine palm, cotton seed, canola, and sunflower oil (Küçükbay Inc., Turkey), lipophilic butter aroma (Aromsa Inc., Turkey) lecithin (Aromsa Inc.), mono and diglycerides (Selim, Ltd Co., Turkey), NaCl (Carlo Erba Reagents, France), lactic acid (Smart Chemicals, Ltd Co., Turkey), potassium sorbate (Smart Chemicals, Ltd Co.), skimmed milk powder (Pınar Dairy Products In., Turkey), whey protein (Hard Line Nutrition, Kavi Food Ltd Co.) were used. Divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) fiber (Supelco Inc., Bellefonte, PA, USA) was used for the extraction of the volatile components, 2,3-pentandione (Supelco Inc.) was used as internal standard and C7-C30 alkane mixture (Supelco Inc.) was used to calculate the kovats index.

2.2 Methods

2.2.1 Model Margarine Production

Model margarine production was implemented by modifying the methods suggested by Shiota3 and Lefébure et al.24 The water-soluble components were dissolved in the water phase and the oil-soluble components were dissolved in the fat phase. Whey protein isolate (WPI), skimmed milk powder, potassium sorbate, sodium chloride, and lactic acid were dissolved in the water phase by mixing at 120 rpm in a magnetic stirrer (Daihan Scientific, MSH-20D, South Korea). The fat used in the emulsion was completely melted and emulsifiers (lecithin, mono, and diglycerides), butter aroma were dissolved by stirring in the magnetic stirrer at 120 rpm. The temperature of the prepared fat phase was maintained at 55 °C in a water bath (Büchi, B 465, Swithzerland) and emulsification was achieved by dropwise addition of the water phase at 55 °C with mixing at 3000 rpm (IKA, Ultra Turrax T25, Germany). The prepared emulsion was cooled to 10 °C with stirring at 200 rpm (Daihan Scientific, HT-120DX) in the jacketed vessel. The fat content and emulsifier mixture content of the model margarines are given in Table 1. WPI, skimmed milk powder, potassium sorbate, sodium chloride, and lactic acid ratios were kept constant in the margarine formulations (Table 2).

| Sample code | Fat content [%] | Emulsifier mixture content [%] |

|---|---|---|

| 80F1 | 80 | 1.00 |

| 80F0.5 | 80 | 0.50 |

| 80F0.1 | 80 | 0.10 |

| 70F1 | 70 | 1.00 |

| 70F0.5 | 70 | 0.50 |

| 70F0.1 | 70 | 0.10 |

| 60F1 | 60 | 1.00 |

| 60F0.5 | 60 | 0.50 |

| 60F0.1 | 60 | 0.10 |

| Content [%] | |

|---|---|

| WPI | 1.00 |

| Skimmed milk powder | 1.00 |

| Potassium sorbate | 0.10 |

| Sodium chloride | 0.20 |

| Lactic acid | 0.08 |

| Butter aroma | 0.82 |

2.2.2 Headspace Solid-Phase Microextraction

SPME procedure was performed by a manual SPME device (Supelco) at predetermined optimum extraction conditions.25 Volatiles of model margarines were extracted using 50/30 μm DVB/CAR/PDMS SPME fiber. For headspace sampling 10 g of margarine sample was transferred in a 40 mL vial and 1 μL 2,3-pentandione was added as internal standard. The vial was closed with a Teflon coated silicone septum and placed on a block heater at 47.57 °C. The SPME fiber was placed in the vial for 33.63 min to adsorb the volatile components on the fiber and at the end of the time fiber was injected into the GC-MS and thermally desorbed.

2.2.3 GC-MS Analysis

GC-MS analysis was implemented by Hewlett-Packard (HP) 6890 GC/HP 5973 MS (Agilent Technologies, USA). The separation of volatiles was performed on a fused silica capillary column DB-WAX (60 m × 0.25 mm, 0.50 μm film thickness, Agilent Technologies). Thermal desorption of the volatiles from the fiber was carried out in the GC injector at 250 °C. The inlet was operated in the splitless mode. Helium was used as carrier gas at flow rate of 1.0 mL min−1. The oven temperature gradient began at 50 °C for 5 min, and then it was raised to 240 °C at 8 °C min−1 and held at this temperature for 10 min. The electron impact mass spectra were generated at 70 eV. The mass spectrometer was scanned from 50 to 550 m/z. Identification of the volatile compounds was achieved by comparing their mass spectra in the MS library (NIST and WILEY). Also the Kovats indexes were calculated for each volatile compound by using the retention times of homologous series of C7–C30 to confirm the identity of volatile compounds. Kovats indexes were compared with compounds analyzed in similar conditions in the literature.

2.2.4 Texture Analysis

The hardness of model margarines was determined using TA-XT Plus Texture Analyzer (Stable Micro Systems Ltd., Godalming, UK). The margarine texture measurements were performed immediately after they were removed from the refrigerator at 4 °C in 200 g plastic cups using a 45° conical cone (P/45) and 5 kg load cell. Force in compression mode was used. The cone probe was lowered into the margarine at 1 mm s−1 speed, and then the probe penetrate the sample at a constant speed of 2.0 mm s−1 to a distance of 10 mm. Hardness was reported as the maximum penetration force (N) based on measurements.26

2.2.5 Solid Fat Content

Solid Fat Content (SFC) of the model margarines were analyzed with Bruker Minispec PC 100 Pulsed NMR (Germany) spectrometer at 20, 30, and 35 °C and determined as %SFC.27

2.2.6 Rheological Measurements

The rheological measurements were implemented on an advanced rheometer (TA Instruments, Discovery HR-3 Hybrid Rheometer, UK) equipped with a Peltier system for temperature control. Parallel plate (40 mm diameter) geometry was used with 2000 μm geometry gap. Storage moduli (G′) of model margarines were determined in the range of linear viscoelastic regime. Frequency sweep test was applied to samples at 4 °C frequency from 0.1 to 100 Hz at constant shear stress of 2 Pa.28

2.2.7 Color Measurement

Color of model margarines were determined using hand type colorimeter (Konica Minolta Sensing, CR-300, Japan). The color values were expressed as L* (lightness or brightness), a* [redness (+a), greenness (-a)], and b* [yellowness (+b), blueness (-b)].

2.2.8 Descriptive sensory analysis

Descriptive sensory analysis was performed with a trained panel of four females and two males aged between 23 and 54, from Food Engineering Department, Ege University. Assessors developed descriptive terms in nine-1-h training panels. Descriptive terms related to odor, taste and oral texture developed by the assessors and references used are given in Table 3. Sensory analyses were carried out at controlled room temperature and artificial day light illumination was used. Model margarine samples were presented to assessors in covered plastic containers at refrigerator temperature (4 °C). Water and unsalted crackers were available as palate cleansers for the assessors and two samples were evaluated per session.

| Descriptive terms | Definition | Reference |

|---|---|---|

| Aroma | ||

| Butter | Aromatics associated with butter | Butter |

| Creamy | Creamy aromatics associated with milk fat | Milk cream |

| Cheesy | Aromatics associated with cheese | Tulum cheese |

| Animal-like | Aromatics associated with animal | No reference used |

| Margarine | Aromatics associated with margarine | Margarine |

| Oxidized | Aromatics associated with oxidized oil | Stored oil |

| Taste | ||

| Butter | Taste elicited by butter | Butter |

| Cream | Taste elicited by milk cream | Milk cream |

| Cheesy | Taste elicited by cheese | Tulum cheese |

| Oxidized | Taste elicited by oxidized oil | Stored oil |

| Salty | Taste sensation elicited by salts | 0.43 g L−1 NaCl solution |

| Texture (Oral) | ||

| Melting rate | The rate of complete melting of margarine in the mouth | Slowest: Tallow fastest: Olive oil |

| Hardness | Force required to bite margarine | Min: Yoghurt max: Tallow |

| Residue fat | Residual fat in the mouth after swallowing margarine | Min: Olive oilmmax: Tallow |

2.2.9 Statistical Analysis

Statistical evaluation of the analysis results was conducted with SPSS 16.0 Windows package program (SPSS 16.0 for Windows). The significant difference between the averages was assessed using Analyzes of Variance (ANOVA) and Duncan multiple range test at the level of 0.05. Cluster Analysis and Principle Component Analysis (PCA) were performed by trial version of XLSTAT 2018 for determining the relationship among model margarines by considering volatiles and sensory terms.

3 Results and Discussion

3.1 Effect of Fat and Emulsifier Content on Volatile Release

The volatile compounds identified in model margarines and the chemical group they belong, retention time, Kovats index and their sensory descriptors are given in Table 4. In model margarines seven different volatile compounds were identified namely; 2,3-butanedione, 2-heptanone, 2-nonanone, 2-undecanone, butanoic acid, hexanoic acid, and δ-decalactone. The volatile compounds determined in the model margarines; 2,3 butanedione, 2-heptanone, 2-nonanone, and 2-undecanone were included in ketone class; butanoic acid and hexanoic acid were included in acid class; δ-decalactone were included in lactone class.

| Chemical group | Volatile compound | Retention time [min] | Kovats index | Sensory descriptora) |

|---|---|---|---|---|

| Ketone | 2,3-butanedione | 9.71 | 989 | Buttery |

| Ketone | 2-heptanone | 14.56 | 1188 | Milky, cheesy |

| Ketone | 2-nonanone | 18.69 | 1396 | Hot milky, cheesy |

| Ketone | 2-undecanone | 22.20 | 1607 | Floral, milky |

| Acid | Butanoic acid | 22.71 | 1643 | Cheesy, sweaty, fecal, putrid |

| Acid | Hexanoic acid | 25.88 | 1865 | Doughy, sweaty, blue cheese, pungent |

| Lactone | δ-decalactone | 31.45 | 2201 | Waxy, sweet |

The area of volatile compounds detected in the model margarines are shown in Table 5. According to the GC-MS results the release of 2,3-butanedione and butanoic acid was higher in model margarines with 70 and 80% fat content . However, the release of 2-heptanone, 2-nonanone, 2-undecanone, hexanoic acid, and delta-decalactone was higher in the products with lower fat ratio (p < 0.05). The fact that the release of volatile compounds behave differently according to the change of the fat ratio could be explained by the hydrophilic or lipophilic character of the volatile compounds. The volatile compounds detected in the model margarines 2,3-butanedione and butanoic acid are hydrophilic; 2-heptanone, 2-nonanone, 2-undecanone, hexanoic acid, and delta-decalactone are lipophilic compounds. In agreement with our study it was determined that the reduction in fat content accelerates the release of lipophilic volatile compounds, thereby increasing headspace concentration of lipophilic volatile compounds in emulsions with reduced fat ratio.3, 7, 18

| Sample | 2,3-butanedione | 2-heptanone | 2-nonanone | 2-undekanone | Butanoic acid | Hegzanoic acid | δ-decalactone |

|---|---|---|---|---|---|---|---|

| 80F1 | 1.17 ± 0.08c | 1.22 ± 0.11a | 0.81 ± 0.18a | 0.14 ± 0.05a | 1.46 ± 0.19b | 0.39 ± 0.04a | 0.06 ± 0.01a |

| 80F0.5 | 1.13 ± 0.09c | 1.16 ± 0.18a | 0.85 ± 0.04a | 0.16 ± 0.05a | 1.67 ± 0.22b | 0.39 ± 0.04a | 0.07 ± 0.02a |

| 80F0.1 | 1.13 ± 0.03c | 1.19 ± 0.06a | 0.87 ± 0.04a | 0.19 ± 0.04a | 1.59 ± 0.20b | 0.41 ± 0.05a | 0.07 ± 0.01a |

| 70F1 | 0.76 ± 0.07ab | 1.22 ± 0.08a | 1.03 ± 0.12b | 0.25 ± 0.03ab | 1.79 ± 0.18b | 0.45 ± 0.04a | 0.12 ± 0.02ab |

| 70F0.5 | 0.68 ± 0.07a | 1.15 ± 0.17a | 1.13 ± 0.05bc | 0.26 ± 0.02ab | 1.83 ± 0.12b | 0.48 ± 0.04ab | 0.12 ± 0.03ab |

| 70F0.1 | 0.88 ± 0.05b | 1.26 ± 0.21a | 1.20 ± 0.07cd | 0.33 ± 0.04b | 1.71 ± 0.14b | 0.48 ± 0.05ab | 0.16 ± 0.03b |

| 60F1 | 0.63 ± 0.08a | 1.81 ± 0.18b | 1.34 ± 0.01de | 0.55 ± 0.07c | 0.89 ± 0.04a | 0.56 ± 0.05c | 0.36 ± 0.05c |

| 60F0.5 | 0.63 ± 0.15a | 1.96 ± 0.10b | 1.40 ± 0.05e | 0.57 ± 0.18c | 0.94 ± 0.09a | 0.58 ± 0.09bc | 0.38 ± 0.05c |

| 60F0.1 | 0.64 ± 0.08a | 1.92 ± 0.16b | 1.49 ± 0.06e | 0.59 ± 0.06c | 0.91 ± 0.06a | 0.59 ± 0.08bc | 0.40 ± 0.06c |

- a)Volatile component areas are calculated by dividing the area of internal standard; b)Each value expressed as mean ± standard deviation (n = 3). Means with different letters along a column significantly different (p < 0.05).

The emulsifier content used in model margarines affected the release of 2-nonanone, hexanoic acid, and δ-decalactone. Model margarine emulsions with higher emulsifier content showed lower 2-nonanone, hexanoic acid, and δ-decalactone release (p < 0.05). Calligaris37 disclosed the reduction of the release of volatile compounds by emulsifier that the emulsifier adsorbs at the interface and strengthens the barrier property of the interface, making it difficult to release into the headspace. According to another opinion, the increase of the emulsifier ratio is associated with the increase of the emulsion consistency and the decrease of the volatile component diffusion.38

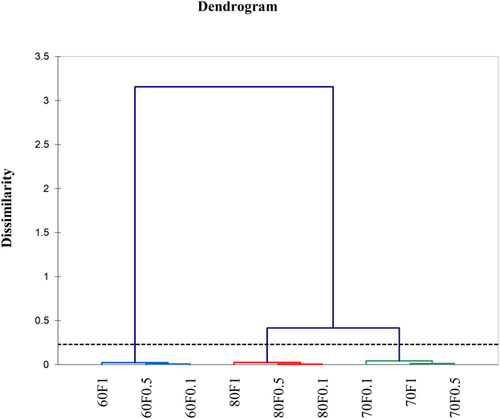

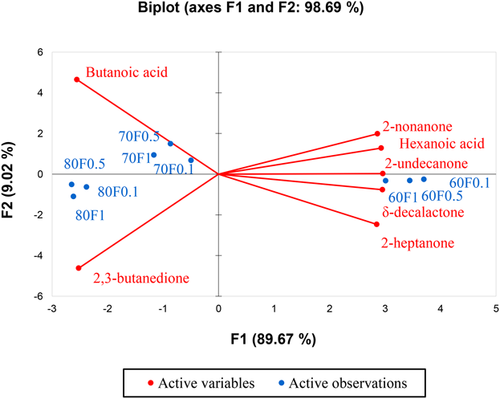

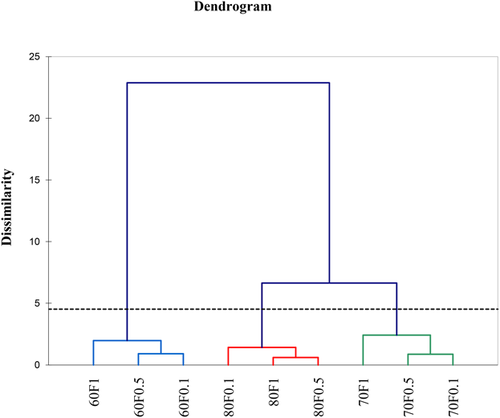

In order to evaluate the difference between model margarines with different fat and emulsifier content cluster analysis and PCA were applied to volatile compounds (Table 5) that were identified in all samples. The cluster analysis showed that while model margarine with 70 and 80% fat content formed one cluster, model margarine with 60% fat content formed a separate cluster. Also subclusters were formed and shown in Figure 1. PCA was applied and two principle components (F1 89.67%; F2 9.02%) were found to explain the variations to determine the compounds contributing to the cluster (Figure 2). Butanoic acid and 2,3-butanedione were effective in differentiating 70 and 80% fat model margarines with respect to biplot diagram drawn using F1 and F2 components. On the other hand 2-nonanone, hexanoic acid, 2-undecanone, δ-decalactone, and 2-heptanone were effective in differentiating 60% fat model margarines.

3.2 Texture Analysis

According to the results of the texture analysis, the hardness values of the model margarines ranged from 29.72 to 6.95 N. Statistically significant difference was determined between the hardness values of the samples (p < 0.05). 80F1 was the hardest, 60F0.1 was the softest samples among the samples analyzed (p < 0.05) (Table 6).

| SFC% | ||||||||

|---|---|---|---|---|---|---|---|---|

| Sample | Hardness (N) | G′ (Pa) | L* | a* | b* | 20 °C | 30 °C | 35 °C |

| 80F1 | 29.72 ± 0.77jk | 16.72 ± 0.44h | 85.05 ± 1.29a | −1.21 ± 0.08bc | 13.58 ± 0.54g | 29.16 ± 0.37c | 11.35 ± 0.64c | 7.23 ± 0.31d |

| 80F0.5 | 28.15 ± 2.69ijk | 15.59 ± 0.48g | 84.69 ± 2.01a | −1.47 ± 0.06bc | 12.83 ± 0.42f | 28.23 ± 0.27c | 11.98 ± 0.33c | 7.78 ± 0.65d |

| 80F0.1 | 25.80 ± 1.62hi | 14.50 ± 0.45f | 85.60 ± 0.88a | −2.13 ± 0.13ab | 11.38 ± 0.84c | 28.95 ± 0.92c | 11.88 ± 0.95c | 7.07 ± 0.11d |

| 70F1 | 21.35 ± 1.71fg | 13.70 ± 0.21f | 86.54 ± 1.2 a | −1.57 ± 0.12abc | 11.65 ± 0.47cd | 24.47 ± 0.64b | 9.40 ± 0.45b | 4.75 ± 0.28c |

| 70F0.5 | 20.13 ± 0.73ef | 11.62 ± 0.64e | 85.15 ± 1.61a | −1.71 ± 0.10abc | 11.77 ± 0.08cd | 24.81 ± 0.72b | 9.05 ± 0.57ab | 4.60 ± 0.42c |

| 70F0.1 | 16.80 ± 0.95d | 10.58 ± 0.73d | 84.84 ± 1.45a | −2.02 ± 0.07ab | 10.58 ± 0.16b | 24.18 ± 0.22b | 8.97 ± 0.74ab | 4.77 ± 0.19c |

| 60F1 | 11.96 ± 0.56c | 8.94 ± 0.31c | 86.42 ± 0.61a | −0.56 ± 0.20d | 10.69 ± 0.43b | 20.48 ± 0.40a | 8.10 ± 0.28a | 3.62 ± 0.28ab |

| 60F0.5 | 10.75 ± 0.54bc | 8.21 ± 0.19bc | 86.41 ± 1.47 | −1.59 ± 0.07abc | 10.34 ± 0.24b | 20.80 ± 0.49a | 7.87 ± 0.52a | 3.32 ± 0.29a |

| 60F0.1 | 6.95 ± 0.31a | 7.19 ± 0.32a | 84.47 ± 1.63 | −1.95 ± 0.17abc | 9.66 ± 0.41a | 20.95 ± 0.23a | 8.10 ± 0.28a | 3.43 ± 0.30a |

- a)Each value expressed as mean ± standard deviation (n = 3). Means with different letters along a column significantly different (p < 0.05); b)L*, lightness; a*(+), redness; a*(−), greenness; b*(+), yellowness; b*(−), blueness.

It was determined that the hardness of model margarines was affected by fat content of the product. The hardness of the samples increased with higher fat content. In accordance with the obtained data, Glibowski39 found that as the fat content of margarines increases, the hardness increases, and the spreadability decreases. Similarly, Tiwari40 found that 80% fat margarine (0.9 N) was harder than 60% fat margarine (too soft to measure). Margarine with higher fat content had more extensive crystalline fat network so the greater amount of crystal bonds broken and/or displaced during texture measurement resulted in a higher hardness value. Also, the product hardness was increased by increasing the emulsifier ratio used in the model margarines. As the emulsifier ratio increased, the diameter of the droplets formed in the emulsion decreased and the distance between the droplets decreased. This results in increased hardness by increasing interactions between droplets.41

3.3 Rheological Properties

The frequency sweep test results of the model margarines are given in Table 6. The storage modulus (G′) values of the samples at 1 Hz were found to be between 7.19 × 105–16.72 × 105 Pa. It was determined that 80F1 had the highest G′ value and 60F0.1 had the lowest G′ value. There was a statistically significant difference between the G′ values of the samples (p < 0.05). The increase in the ratio of fat used in the model margarines caused increase in G′ of the model margarine samples (p < 0.05). Similarly Rukke et al.42 found that G′ value of margarine and butter samples with high fat content was higher than samples with lower fat content. In our study it was observed that the G′ value of the samples increased with the increase of the emulsifier ratio (p < 0.05). This result was supported by Shakerardekani et al.43 it was seen that the G′ increased with the increase of the monoglyceride ratio used as emulsifier in peanut butter.

3.4 Color

There were no statistically significant difference between L* values of the samples as shown in Table 6 (p < 0.05). Model margarines had high L* values indicating white and shiny properties. All the samples were determined to have negative a* values. This suggested that margarines had no redness but low greenness. Statistically significant differences were found between a* values of the samples (p < 0.05). The positive b* values of the model margarines showed that there were yellowness in the products but not blueness. As result of ANOVA test, statistically significant difference found between b* values of margarines (p- < 0.05). It was determined that 80F1 showed maximum, 60F0.1 minimum yellowness property.

3.5 Solid Fat Content

The SFC of the model margarines measured at 20, 30, and 35 °C is given in Table 6. According to the results, the SFC of the model margarines at 20, 30, and 35 °C were found to be between 20.95–29.16, 7.87–11.98, and 3.32–7.78%, respectively.

The SFC was used as an indicator for products with high fat content such as margarines to predict mechanical properties. The SFC at 20 and 22 °C provided information about product stability and resistance to oil exudation at room temperature. When SFC value was higher than 10% at these temperatures, oiling off was prevented. The SFC between 35 and 37 °C determines stickiness and volatile component release in the mouth. Margarines with the SFC less than 3.5% were completely melted at body temperature without waxy mouthfeel.44

According to our SFC results, model margarine emulsions was resistant to oil exudation, on the other hand only emulsions with 60% fat content completely melted at body temperature. It was revealed that fat content affect SFC and SFC increased by increasing fat ratio (p < 0.05). In agreement with our study Shiota et al.3 found that the SFC of emulsion with 70% fat content was lower than the fat blend. As a result of our study, it was determined that the emulsifier ratio did not affect the SFC. Also Estevez et al.41 determined no statistically significant difference (p > 0.05) in the SFC of emulsions with emulsifier ratio change.

3.6 Descriptive Sensory Analysis

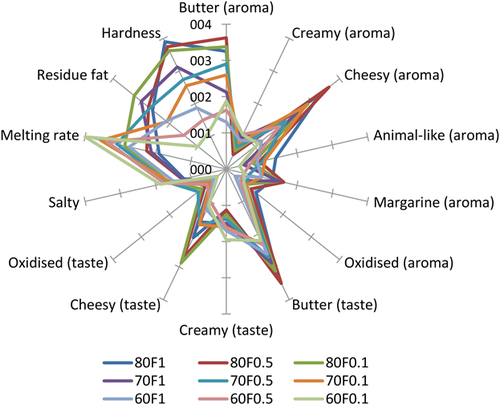

Descriptive sensory characteristics of model margarines (Figure 3) demonstrate that butter, creamy, cheesy, animal-like, margarine, and oxidized aroma characteristics were perceived in the samples. Butter and cheese aroma had been found to be the most intense aroma characteristics of the products. Model margarines with higher fat content had more intense butter and cheese aroma. On the other hand, creamy aroma was more intense in the model margarines with low fat ratio (p < 0.05).

In the model margarine samples the most perceived taste characteristic was butter among cream, cheese, oxidized, and salty taste. Butter taste varied at a statistically significant level depending on the samples. Butter taste perceived more intensively in model margarine with 80% fat content than model margarine with 70 and 60% fat content. On the other hand cream taste was more intense in margarines with lower fat (p < 0.05). Whereas there was an increase in cheese taste due to the increase in fat ratio. The melting rate of the products was statistically different (p < 0.05). The rate of melting was slower by the increase of the fat and the emulsifier ratio. It was determined that products with higher oil content and higher emulsifier content had more residual fat left in the mouth. The perceived hardness of the model margarines was found to increase with increasing fat ratio (p < 0.05).

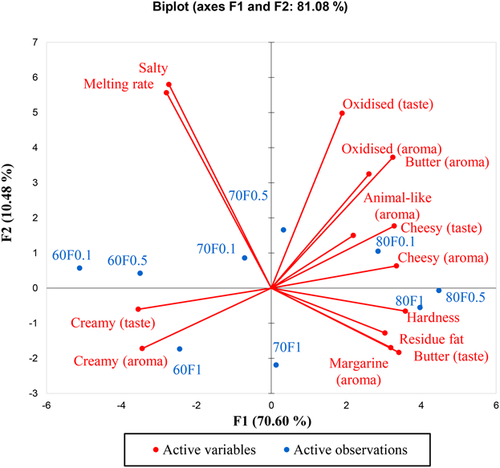

Cluster analysis and PCA were applied to evaluate the difference between the model margarine samples and the relationship between variables to the intensity ratings of the aroma, taste, and texture descriptors. The cluster analysis resulted in two main clusters; margarine emulsions with 80 and 70% fat content formed one cluster while emulsion with 60% fat content formed a separate cluster (Figure 4). Under the main group formed by 70 and 80% fat model margarine emulsions, 80F0.1 formed a subgroup, 80F1 and 80F0.5 formed a second subgroup. In emulsions containing 70% fat, a subgroup was composed by 70F1 and the other subgroup was composed by 70F0.5 and 70F0.1. Emulsion with 60% fat constituted a subgroup with 60F1 and second subgroup with 60F0.5 and 60F0.1. To determine the sensory descriptors contributing to the clusters, PCA was applied and two principle components (F1 70.60%; F2 10.48%) were found to explain the variation (Figure 5). According to the PCA results aroma characters of cheesy, butter, and animal-like; taste characters of cheesy and butter; texture characters of hardness and residue fat determined to have close correlation with the sensory characteristics of 80% fat content model margarine. Creamy aroma and taste characters determine to have close correlation with the sensory characteristics of model margarine with 60% fat content.

4 Conclusions

Depending on the consumer demands, margarines are produced in different fat ratio and different emulsifier ratios to produce stable emulsion and to change physical properties. Our study suggested that in addition to the physical properties of the margarine, the fat and emulsifier ratio used in margarine production also changes the release of the volatile components and therefore the sensory properties of the product. The results obtained from the study are thought to guide margarine producers in modulating the release of volatile compounds and the effect of flavor depending on the margarine formulation they use in their processes.

Acknowledgement

This study was supported by Ege University Scientific Research Projects Coordination Unit (Project No:16/MUH/028). The authors would also like to thank Aromsa Food Aroma and Food Additives Inc for supplying the aroma used in this research.

Conflict of Interest

The authors have declared no conflict of interest.